Patents

Literature

70results about How to "Easy to phase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Transportation system for sheet delivery between sheet or sheet stack processing equipment

InactiveUS20050042072A1Eliminate needEasy to phasePile receiversStacking articlesDocument handlingModularity

A sheet or sheet stack handling system for performing at least one operation on successive sheets or stacks of sheets, and interface for the same, wherein the document handling system includes at least two modules selected from a group consisting of an elevator transfer station, a modular transfer station, a storage station, a transportation cart, and a modular processing station. When more than one modular processing station are coupled to form the document handling system, the system may be utilized to perform a series of operations on successive sheets or stacks of sheets. Alternately, the individual processing stations or a group of the processing stations may be utilized to perform only certain functions on the sheets. The modules each contain a plurality of parallel, spaced, elongated support surfaces that form a sheet support surface. The parallel, spaced, elongated support surfaces of the two modules are sized and disposed that they may intermesh to allow a transfer of sheet stacks between the modules when one set of parallel support surfaces is moved upward or downward relative to the other.

Owner:AMDAHL SAMUEL +4

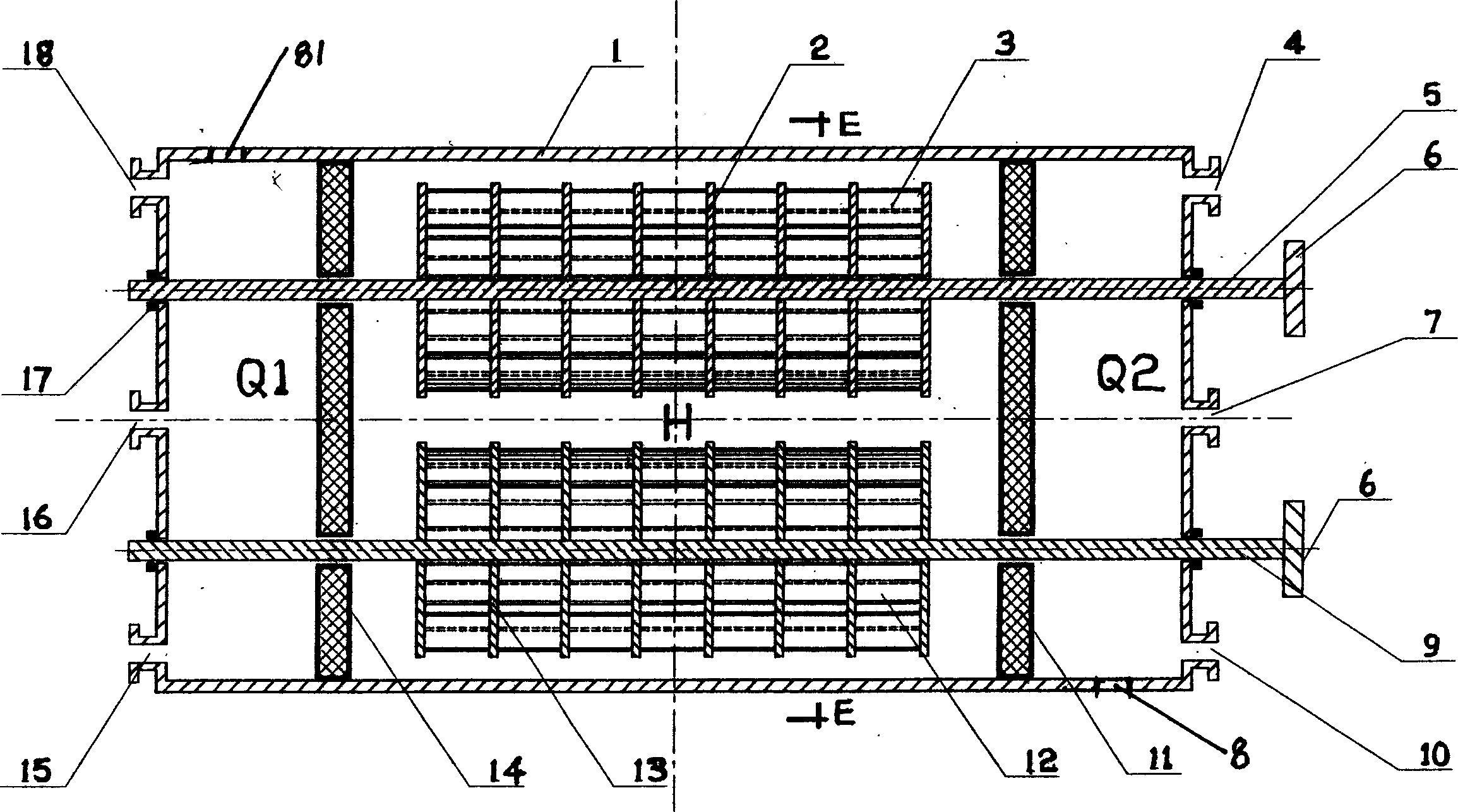

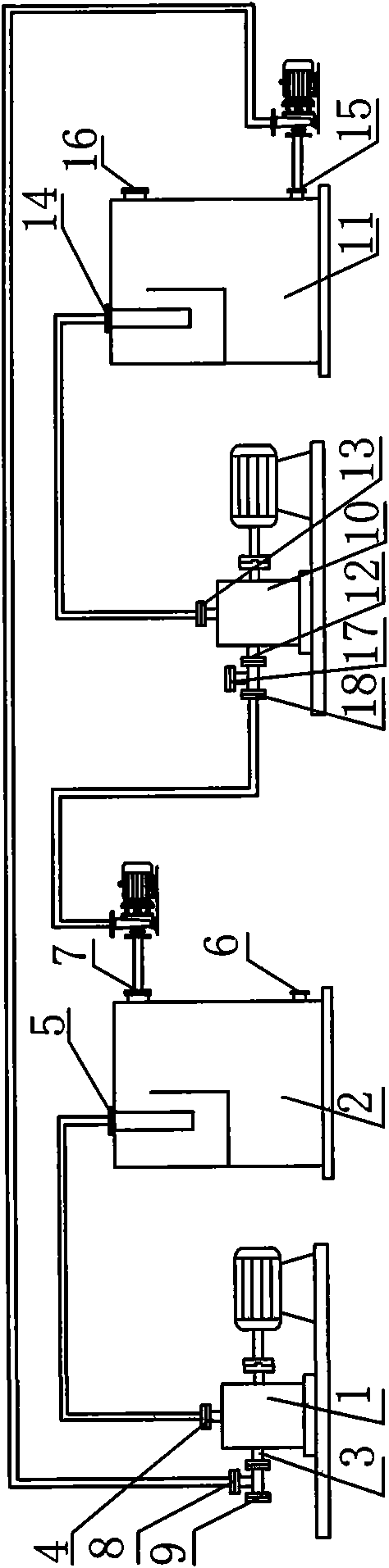

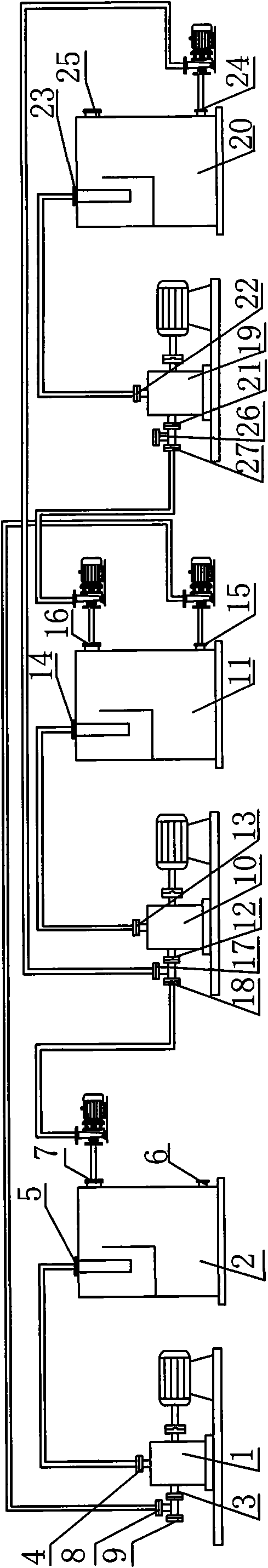

Liquid-liquid-liquid triphase horizontal continuous lifting stirring extraction device

InactiveCN1463782AReduce interfacial tensionReduce backmixingLiquid solutions solvent extractionEngineeringMotor drive

The liquid-liquid-liquid three-phase continuous lifting and stirring extractor includes one horizontal reactor with two stuffing-holding isolating board cases in its two ends; one upper shaft and onelower shaft penetrating the reactor side walls and installed parallelly to the isolating board cases; upper baffle and lower baffle with horizontal arc lift tank in between; light phase outlet, middle phase inlet and heavy phase outlet successively arranged on one side wall of the reactor; light phase inlet, middle phase outlet and heavy phase inlet successively arranged on the opposite side wallof the reactor; and motor driven wheels installed in the ends of the two shafts. With simple structure, low power consumption, flexible operation, no emulsification and less back mixing, the presentinvention is suitable for separating and purifying high-value biochemical product from relevant fermented liquid.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for fractionating, extracting and separating zirconium and hafnium

The invention relates to a method for fractionating, extracting and separating zirconium and hafnium, in particular to a method for fractionating, extracting and separating zirconium and hafnium by using di(2-ethylhexyl)phosphorous acid as an extracting agent. The method comprises the following steps of: (1) extraction, using 50-300 parts by weight of di(2-ethylhexyl)phosphorous acid, 25-150 parts by weight of mixing alcohol with the carbon number of 7-9, and 550-925 parts by weight of sulfonated kerosene to prepare a di(2-ethylhexyl)phosphorous acid organic phase to extract; (2) washing, adding oxalic acid into a sulphuric acid solution to prepare a washing solution to wash; and (3) stripping, using a mixing solution of ammonia and carbonate as a strip liquor, stripping to obtain a strip liquor containing hafnium, slowly adding concentrated hydrochloric acid to adjust the solution into acidity, adding concentrated ammonia to obtain hafnium hydroxide precipitate, washing, filtering, calcining, and then obtaining hafnium oxide. The used chemical agents are difficult to volatilize, the toxicity is low, the corrosion is weak, the disposition is easy, and the discharged waste water can not cause the environments to be polluted. The technology has the advantages of quick phase separation, convenient operation, and high and stable product quality.

Owner:有研资源环境技术研究院(北京)有限公司

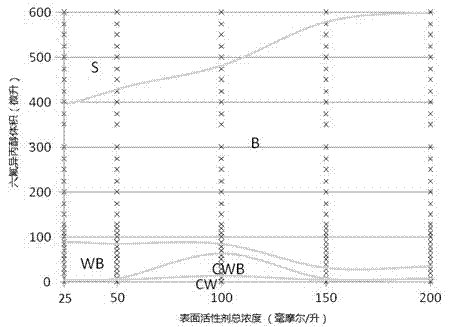

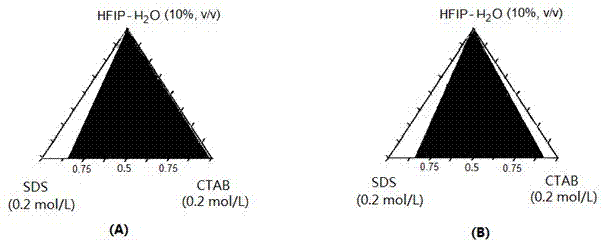

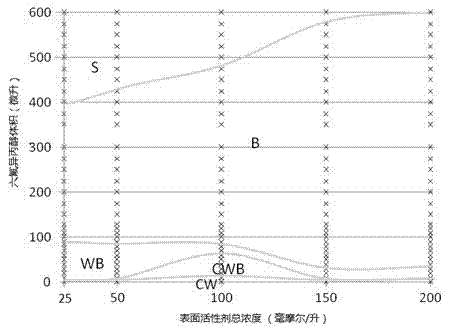

Aqueous two-phase extraction system of mixed surfactant

InactiveCN102430265AModerate conditions for phase formationPhase formation conditions are simpleLiquid solutions solvent extractionActive agentPhysical chemistry

The invention provides an aqueous two-phase extraction system formed by anion / cation mixed surfactant which is induced by fluoroalcohol, a preparation method and an application thereof. The aqueous two-phase extraction system comprises anion surfactant sodium dodecyl sulfate, cation surfactant hexadecyl trimethyl ammonium bromide, hexafluoroisopropanol and water. The extraction system has short phase forming time, wide phase forming range, gentle and simple phase forming condition, low consumption and high efficiency, so the extraction system is a novel extraction system. The invention can extract and separate different types of compounds through the phase forming conditions of the system, so the application prospect is good.

Owner:WUHAN UNIV

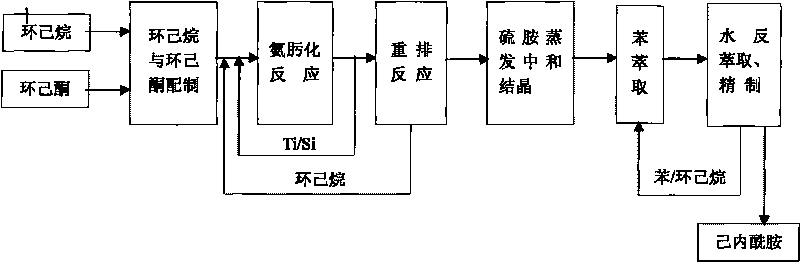

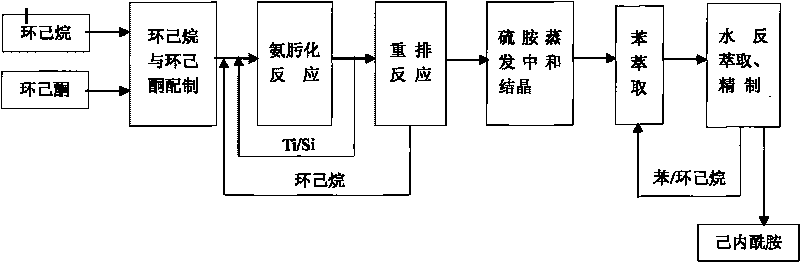

Process for preparing caprolactam

The invention discloses a process for preparing caprolactam, which comprises the following steps: after mixing cyclohexanone and cyclohexane evenly, carrying out an oxamidine reaction to obtain a cyclohexane solution of cyclohexanone oxime; enabling the cyclohexane solution of the cyclohexanone oxime and oleum to react to generate a caprolactam sulfate solution, curing the caprolactam sulfate solution, then carrying out a neutralization reaction on the cured caprolactam sulfate solution and ammonia, afterwards separating the two materials to obtain a crude product of caprolactam and then carrying out extraction and water back extraction respectively to prepare a finished product. Because of the existence of a cyclohexane inert solvent, rectification and separation do not need to be carried out after the oxamidine reaction, and only a rearrangement reaction needs to be carried out after the water phase of a catalyst is separated, thereby saving a rectification device and the steam consumption; as a result, a caprolactam enterprise with an annual yield of a hundred thousand tons can save energy worth approximately 60000000 yuan every year and can also save the one-off equipment investment totaling 60000000 yuan, the technological process of caprolactam is simplified, the procedures of water washing, extraction, distillation and the like are reduced, the production period is shortened, and the annual yield is enhanced.

Owner:河北美邦工程科技股份有限公司

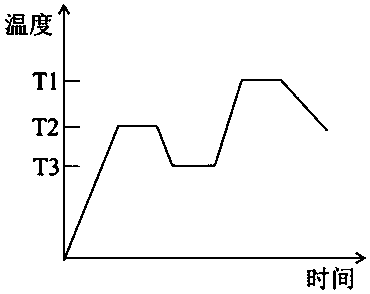

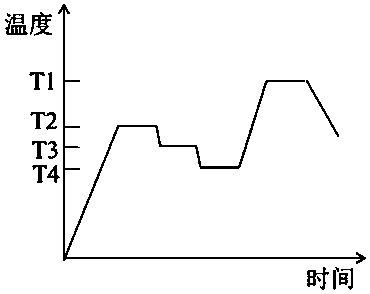

Colorless transparent cordierite microcrystalline glass and preparation method thereof

The invention relates to colorless transparent cordierite microcrystalline glass and a preparation method thereof, and the microcrystalline glass comprises the following components in percentage by mole: 15%-25% of MgO, 10%-20% of Al2O3, 62%-73% of SiO2 and 2%-6% of B2O3. The preparation method comprises the following steps: carrying out phase-splitting heat treatment on the base glass for many times, and then carrying out crystallization heat treatment. A large number of nucleation sites are formed in the base glass through multiple times of split-phase heat treatment, and crystal nucleuses grow into nanocrystals with small sizes in a controlled manner; therefore, high light transmittance and good mechanical strength of the microcrystalline glass are guaranteed, and the problems that a nucleating agent needs to be added in an existing cordierite transparent microcrystalline glass preparation process, and microcrystalline glass coloring, principal crystalline phase change, comprehensive performance reduction and the like are caused are solved. The microcrystalline glass obtained by the method belongs to a magnesium-aluminum-silicon system, alpha-cordierite is the only crystalline phase, and is colorless, transparent, high in bending strength, high in surface hardness and low in expansion coefficient.

Owner:JINGDEZHEN CERAMIC INSTITUTE

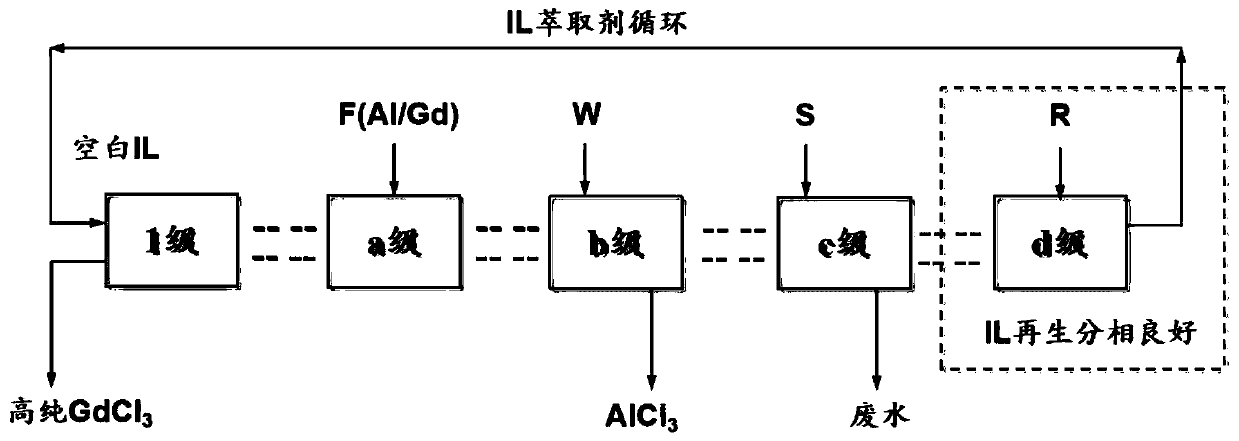

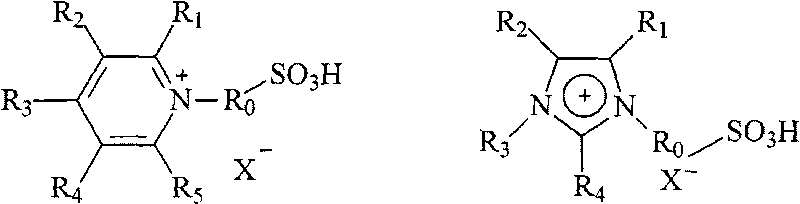

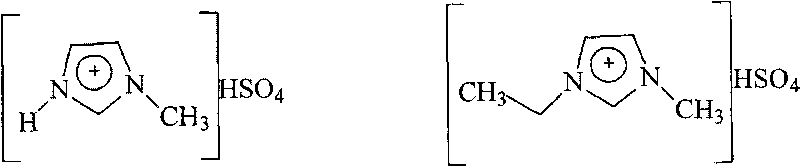

Method for preparing high-purity gadolinium through refining and removing aluminum in rare earth gadolinium solution by ionic liquid method

ActiveCN111440945ASimple extraction and recoveryWill not polluteProcess efficiency improvementOrganic solventPhysical chemistry

The invention relates to a method for preparing high-purity gadolinium through refining and removing aluminum in a rare earth gadolinium solution by an ionic liquid method, and belongs to the field ofextraction separation. The method is characterized in that functional ionic liquid with a specific structure is used as an extraction agent, an organic solvent is a diluent, an organic phase with selective extraction of the aluminum is formed, and efficient aluminum removal of the rare earth gadolinium solution is realized through cascade extraction. The aluminum content of impurity aluminum ina GdCl3 solution after aluminum removal is less than 10 ppm, the rare earth yield is greater than 99.5%, and the impurity content requirement of the high-purity gadolinium (greater than 4N5) is met. Compared with an existing rare earth solution aluminum removal method, the method has the advantages that saponification is not needed, the process is simple, the cost is low, the aluminum removal efficiency is high, and the rare earth loss is low.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

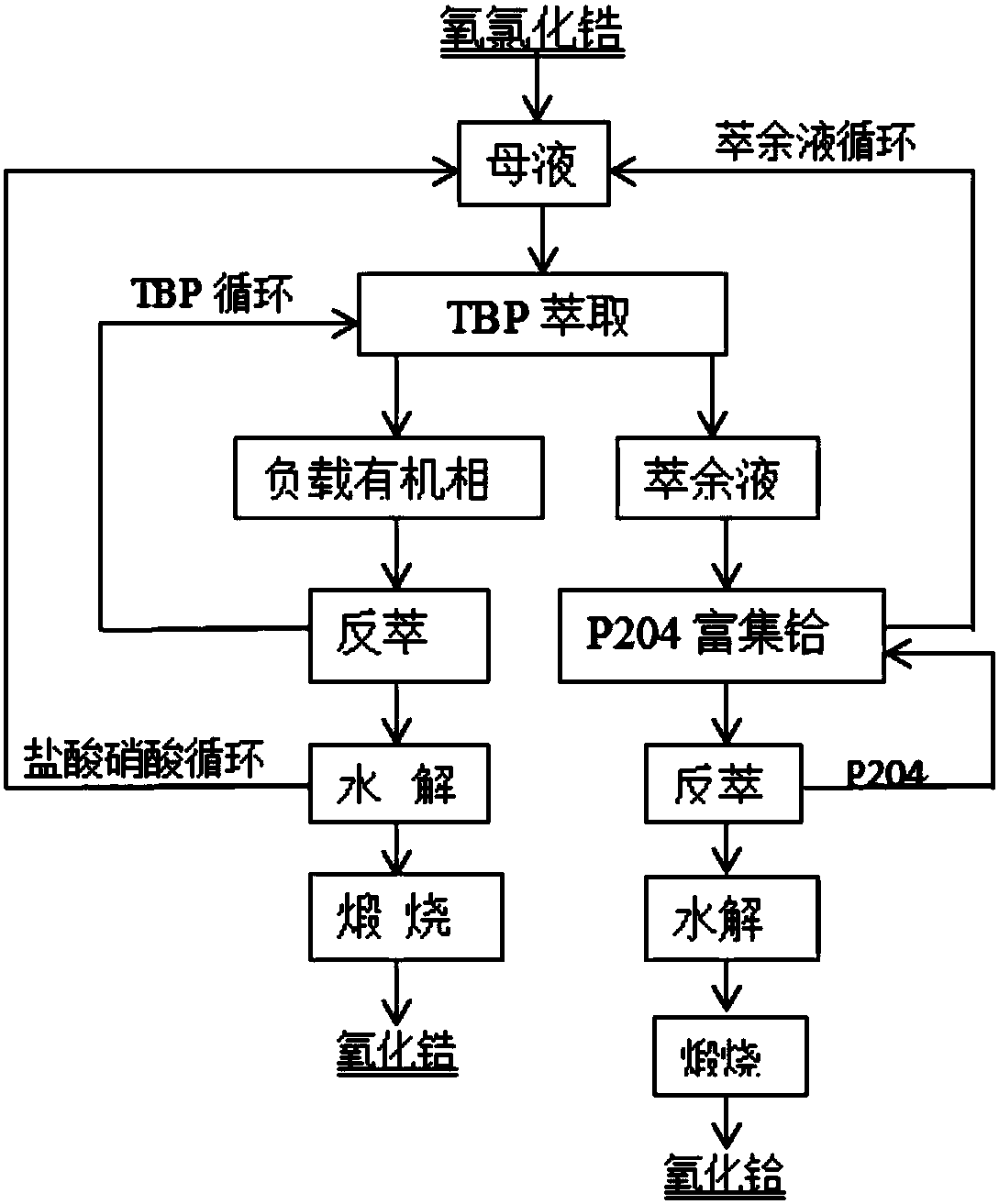

Process for preparing nuclear-grade hafnium oxide and zirconium oxide through solvent extractive separation of zirconium and hafnium

InactiveCN107720820ASimple processReduce waste dischargeSolid solvent extractionZirconium oxidesIonKerosene

The invention discloses a process for preparing nuclear-grade hafnium oxide and zirconium oxide through solvent extractive separation of zirconium and hafnium. The process comprises the following steps: (1) mixing tributyl phosphate or tributyl phosphate and ionic liquid, which serve as extractants, and kerosene, which serves as a diluent, so as to prepare an organic phase; and then, mixing the organic phase with nitric acid, and carrying out countercurrent acidification in a centrifugal extractor; (2) adding zirconium oxychloride, which serves as a raw material, into deionized water, carryingout dissolving, and then, adding hydrochloric acid and nitric acid into the solution, so as to prepare a feed solution containing zirconium and hafnium; (3) carrying out countercurrent extraction onthe acidified organic phase and the feed solution containing zirconium and hafnium, prepared in the step (2), in a centrifugal extractor; (4) carrying out back-extraction on a zirconium-containing organic phase with water, then, carrying out hydrolysis, and carrying out calcination, so as to obtain nuclear-grade zirconium oxide; and (5) enriching hafnium-containing raffinate with P204, then, carrying out back-extraction, carrying out hydrolysis, and carrying out calcination, so as to obtain nuclear-grade hafnium oxide. According to the process, the problems, i.e., complicated process, much waste liquid and environmental pollution in the prior art are solved, and the production efficiency is increased.

Owner:NANJING YOUTIAN METAL TECH

Method for preparing high-purity geniposide

InactiveCN102399251AReduce the amount of polysaccharidesEase of handling in subsequent stepsSugar derivativesSugar derivatives preparationPolyethylene glycolSolvent

The invention discloses a method for preparing high-purity geniposide. The method comprises the following steps of: extracting active ingredients from gardenia fruits by using a 75 mass percent ethanol aqueous solution or water under the ultrasonic wave condition; extracting extractum obtained after concentration by using ethyl acetate; adding polymers such as sodium carboxymethylcellulose, polyacrylamide, polyethylene glycol and the like into a retained bottom phase aqueous solution and dissolving completely; extracting by using a mixed solvent of normal butanol and ethyl acetate; merging an upper phase organic solution; decoloring by using active carbon; concentrating under reduced pressure and performing vacuum drying to obtain a geniposide crude product; and recrystallizing the geniposide crude product to obtain the high-purity geniposide. The method is easy to operate; the production cycle is short; yield and purity of the products are high; and the method is suitable for industrialized mass production.

Owner:GUANGXI UNIV

Method for treating chemical nickel plating concentrated waste liquid by solvent extraction method and ion exchange method

ActiveCN104962888AFast extractionImprove extraction efficiencyLiquid/solution decomposition chemical coatingLiquid solutions solvent extractionLiquid wasteIon exchange

The invention discloses a method for treating a chemical nickel plating concentrated waste liquid by a solvent extraction method and an ion exchange method. The method comprises adjusting a chemical nickel plating concentrated waste liquid concentration to 6-7 by NaOH, fully mixing the waste liquid subjected to pH adjustment and an extractant, carrying out standing for two phase layering, separating the two phases to obtain organic and water phases, wherein the water phase is a nickel-free solution and the organic phase is a loading organic phase, fully mixing sulfuric acid and the above organic phase, carrying out standing for two phase layering, separating the two phases to obtain a water phase and an organic phase, wherein the water phase is a nickel sulfate solution and the organic phase is an extractant, treating the nickel-free solution by an alkalescent anion exchange resin column to remove hypophosphite, carrying out cooling to precipitate sodium sulfate crystals, and adding nickel sulfate and hypophosphite into the sodium sulfate crystals to obtain a regenerated chemical nickel plating liquid for direct chemical nickel plating. The method has the advantages of high extraction efficiency, environmental friendliness, simple operation, low cost and high economic value.

Owner:SOUTHEAST UNIV

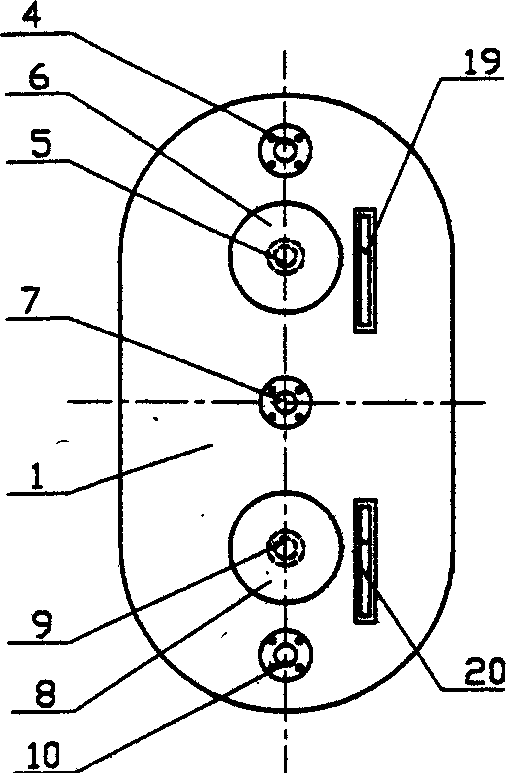

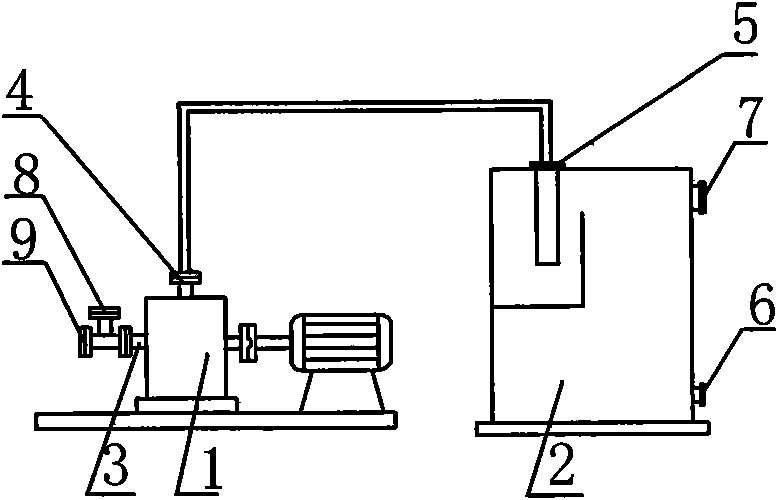

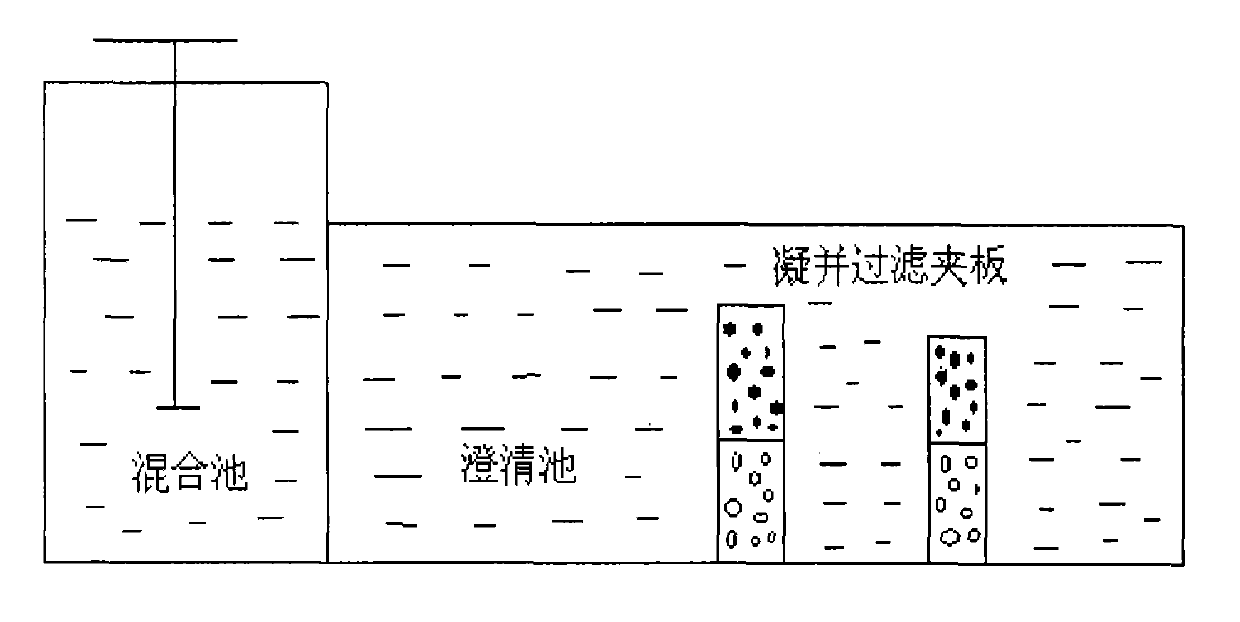

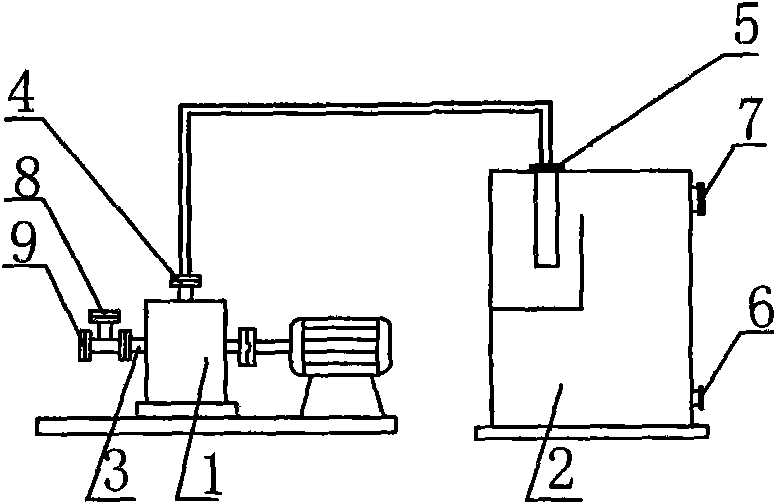

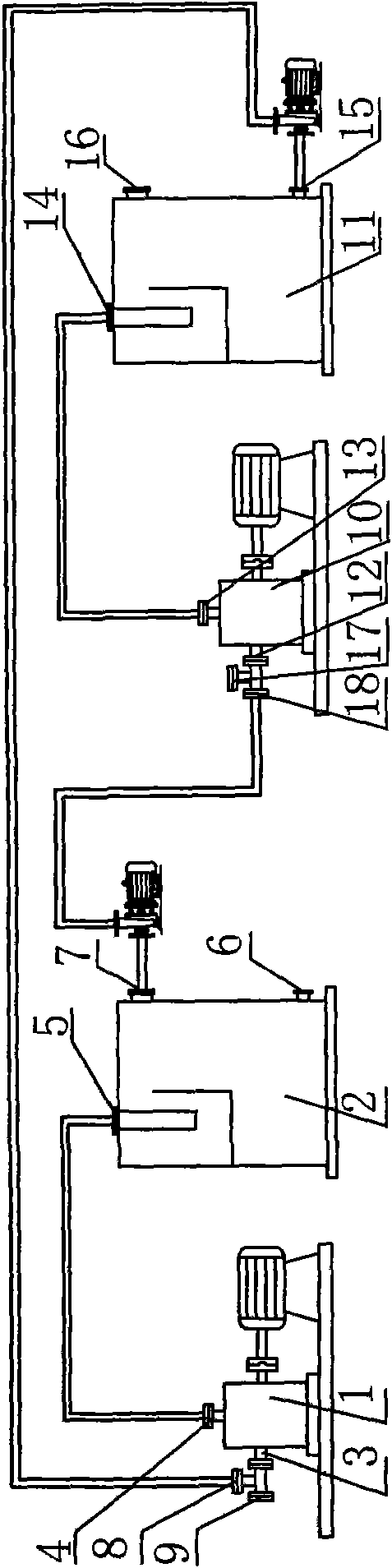

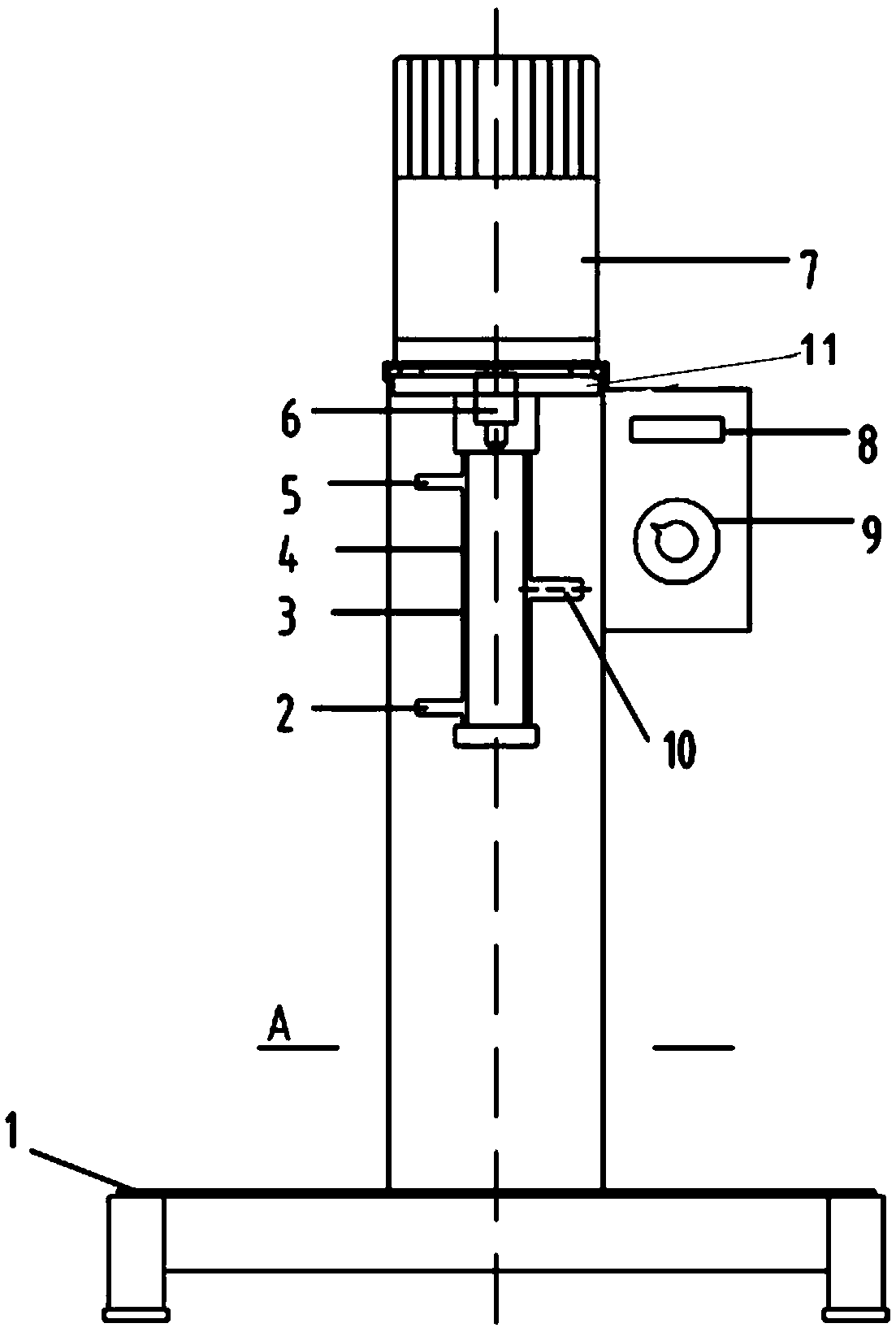

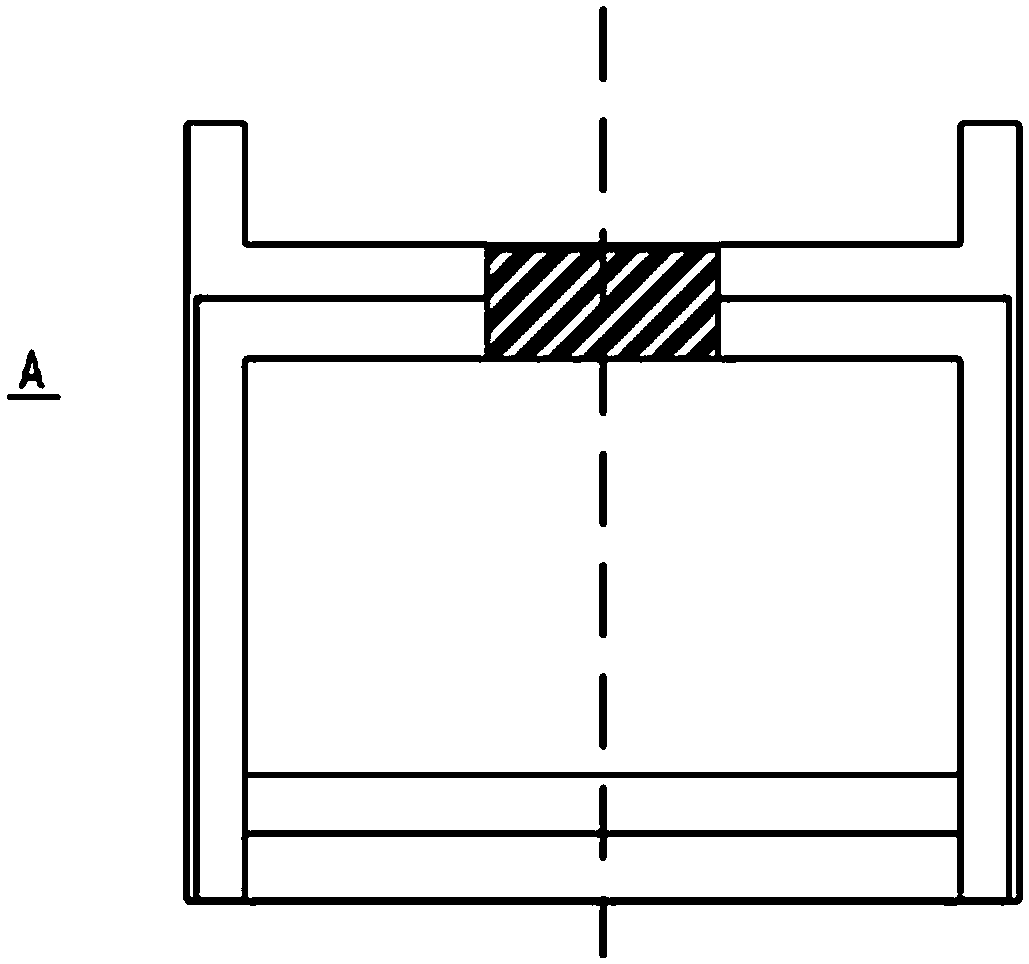

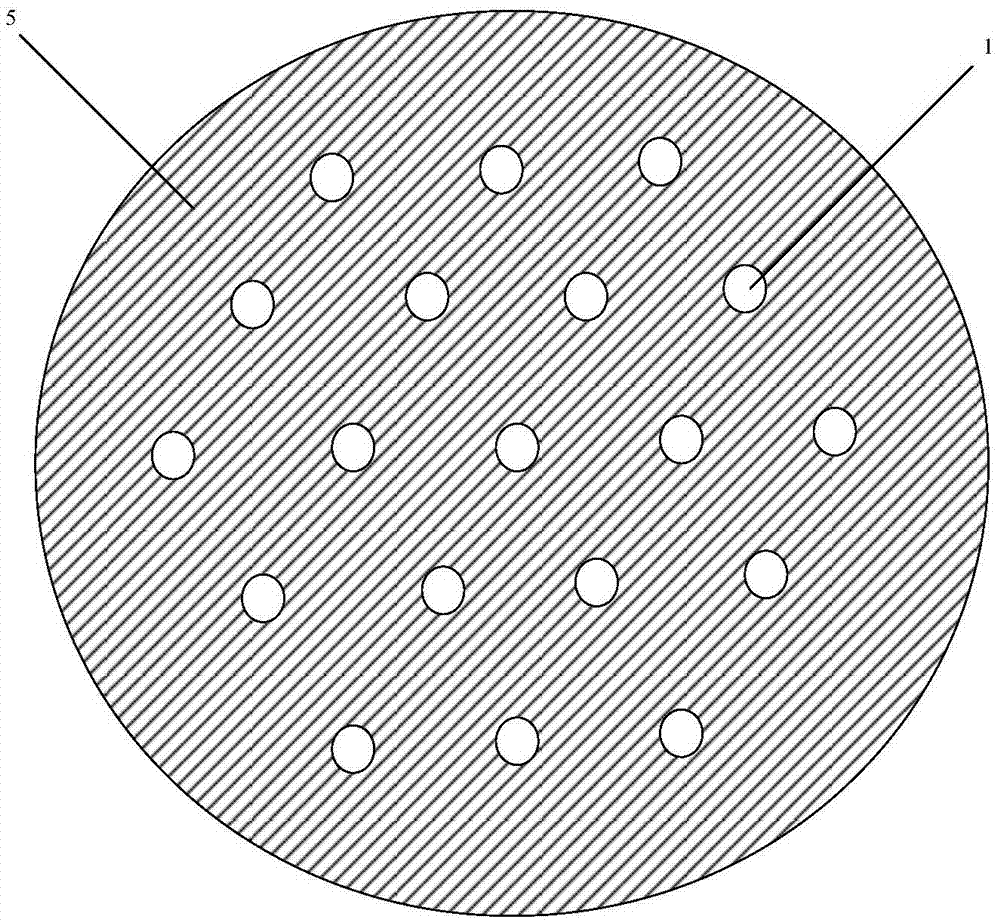

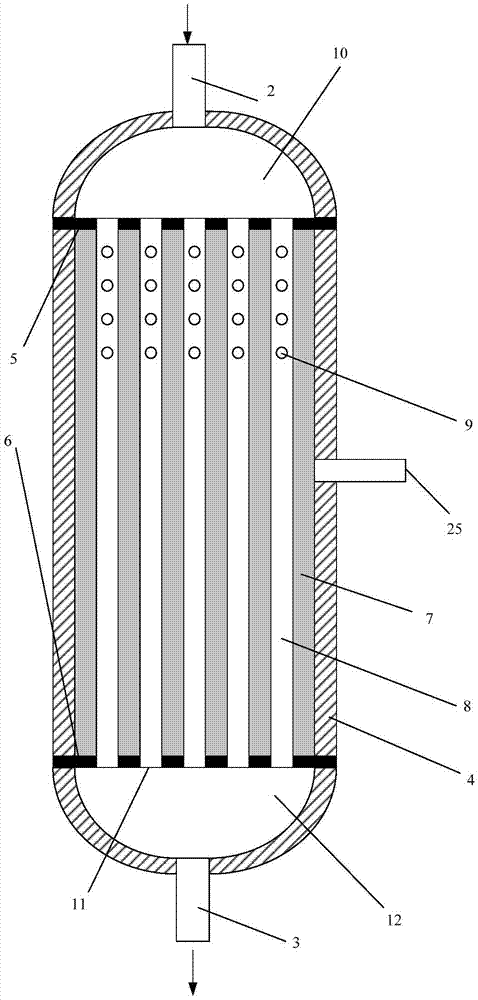

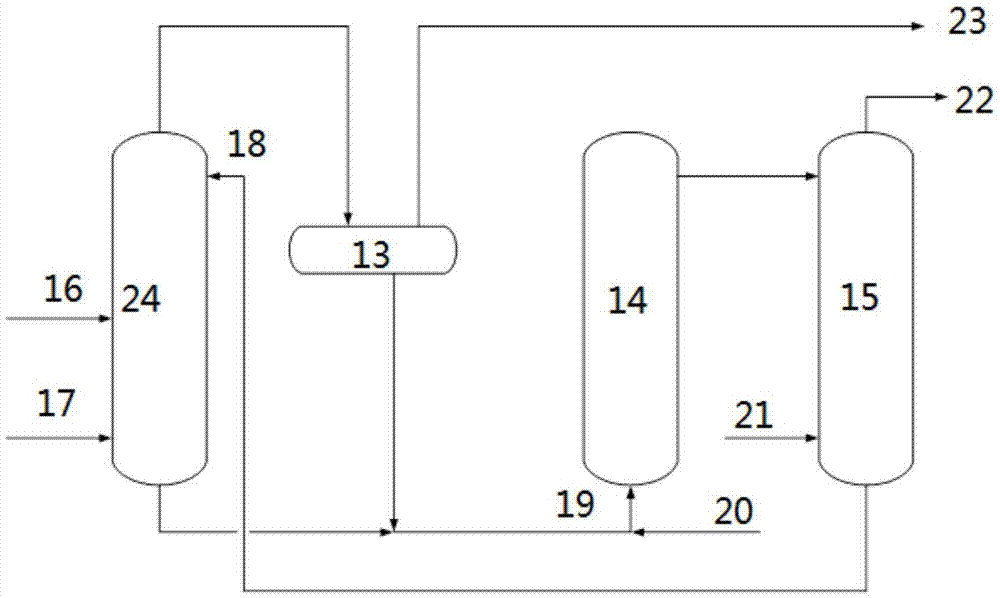

Extraction device

InactiveCN101898048ALarge mass transfer areaEasy to phaseLiquid solutions solvent extractionPhase splittingEngineering

The invention discloses an extraction device comprising an emulsifying machine (1) and a phase-splitting apparatus (2). The emulsifying machine (1) is provided with an emulsifying machine inlet (3) and an emulsifying machine outlet (4), the phase-splitting apparatus (2) is provided with a mixed phase inlet (5), a heavy phase outlet (6) and a light phase outlet (7), the emulsifying machine inlet (3) is connected with an extracted object inlet (8) and a solvent inlet (9), and the emulsifying machine outlet (4) is connected with the mixed phase inlet (5) of the phase-splitting apparatus. When multistage extraction devices are combined, the light phase outlet of the phase-splitting apparatus in the extraction device at the current level is connected with the solvent inlet of the extraction device at the next level through a pipeline provided with a pump, and the heavy phase outlet of the phase-splitting apparatus in the extraction device at the next level is connected with the extracted object inlet of the extraction device at the current level through the pipeline provided with the pump. The invention has high extraction efficiency, small size, less occupied area, simple operation and capability of saving apparatus investment and running cost.

Owner:WENGFU (GRP) CO LTD

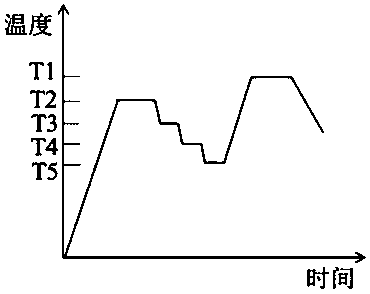

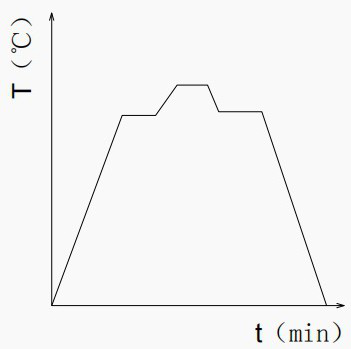

Roller kiln low-temperature sintered colorful halo crystal glaze and preparation method thereof

The invention relates to the technical field of new ceramic materials, and particularly discloses a roller kiln low-temperature sintered colorful halo crystal glaze which comprises a ground glaze anda cover glaze, and the ground glaze comprises the following components in parts by weight: 80 to 90 parts of lead-zinc frit and 10 to 20 parts of pigment; the cover glaze is prepared from the following components in parts by weight: 50 to 70 parts of high-boron frit, 5 to 10 parts of titanium dioxide, 10 to 20 parts of zinc oxide, 5 to 15 parts of talc, 0 to 10 parts of calcite and 17 to 30 partsof seeding colorant, wherein the seeding colorant is prepared from manganese dioxide, vanadium pentoxide and copper oxide. The preparation method of the roller kiln low-temperature sintered colorful halo crystal glaze comprises the steps of preparing the ground glaze and cover glaze, glazing and sintering, wherein the highest sintering temperature is 1125 to 1135 DEG C, and the sintering period is190 to 210 min. The crystal glaze suitable for roller kiln low-temperature sintering is prepared, the glaze surface can show a circle of colorful halo under the sun, and the process effect of metal and crystal glaze is achieved.

Owner:佛山市玉矶材料科技有限公司

Method for preparing dimer acid and dimer acid methyl ester

InactiveCN101735035ANot corrosiveImprove stabilityFatty acid chemical modificationOrganic compound preparationCentrifugationDimer acid

The invention relates to an improvement of a method for preparing dimer acid and dimer acid methyl ester by using unsaturated fatty acid and corresponding fatty acid methyl ester thereof, which is characterized in that a catalyst for reaction is sulfonate ionic liquid which contains SO3H functional groups and accounts for not less than 0.5% in parts by weight, the reaction is carried out at the temperature of 150-300 DEG C, the iodine value of products are controlled to be 65-80%, and the products and the catalyst are stratified by standing after the reaction is complete. The method has the advantages of high polymerization reaction activity, fast reaction speed and relatively mild reaction conditions, and the reaction can be carried out at atmospheric pressure and relatively low temperature, thereby not only reducing the reaction energy consumption and having low requirements on equipment, but also greatly reducing the preparation cost. The catalyst has good stability and small usingquantity, only 0.5% by weight of the catalyst can carry out full reaction, the catalyst is difficult to hydrolyze and easy to realize the phase separation with the products, the catalyst can be separated from the products only through ordinary standing or centrifugation without entrainment of the products, the catalyst can be repeatedly recycled, and the production process is environment-friendly.

Owner:JIANGSU ZHONGSHENG GAOKE ENVIRONMENTAL CO LTD +1

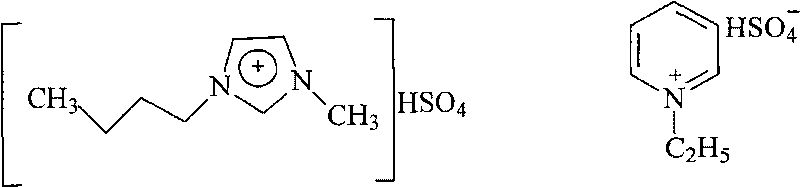

Extraction and boron removal method for lithium-containing brine

InactiveCN107459163AImprove solubilityEasy to separateWater contaminantsHydrocarbon distillation2-OctanolLithium chloride

The invention discloses an extraction and boron removal method for lithium-containing brine. The extraction and boron removal method comprises the following steps that 1, acidification is performed, wherein the pH value of a lithium chloride water solution containing boron is acidized to 1-3 by using hydrochloric acid; 2, mixing and extraction are performed, wherein isooctyl alcohol and 2-octanol are mixed according to the ratio of 10-18 to 1 to obtain an octanol mixed solution; the octanol mixed solution is mixed with kerosene to prepare a mixed extracting agent, the kerosene accounts for 30-70% of the total volume of the mixed extracting agent, and standing is performed for 1-3 hours after the acidized lithium chloride water solution containing boron and the mixed extracting agent are fully mixed; 3, phase splitting is performed, wherein a mixed liquid phase of the lithium chloride water solution containing boron and the mixed extracting agent is divided into an oil phase and a first water phase after standing; 4, recovery is performed, wherein the first water phase is guided out, the boron content is detected, the first water phase is re-guided back to the step 2 under the situation that the boron content exceeds the standard and serves as lithium chloride water containing boron to perform extraction, the operation is repeated till the boron content of the water phase is up to the standard. The lithium-containing brine can be extracted in a low-cost and efficient mode, treated waste water can be secondarily utilized, and environmental pollution can be reduced.

Owner:JIANGSU CHANGJILI NEW ENERGY TECH CO LTD

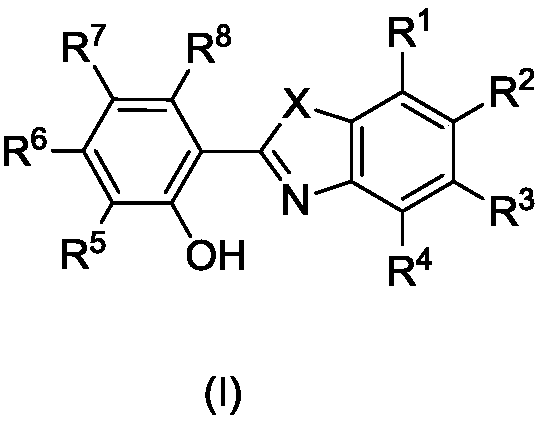

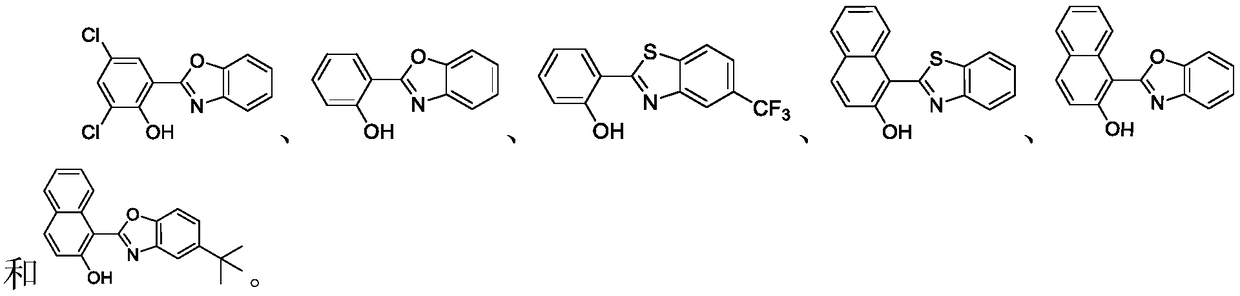

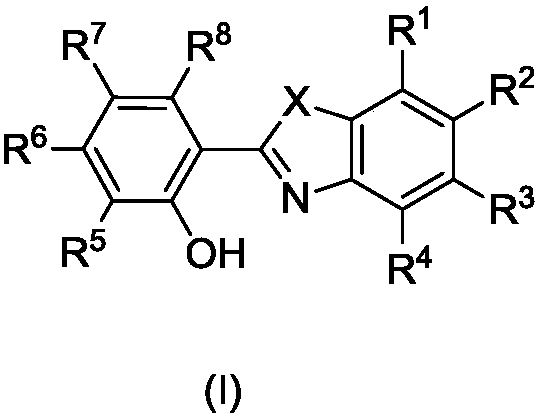

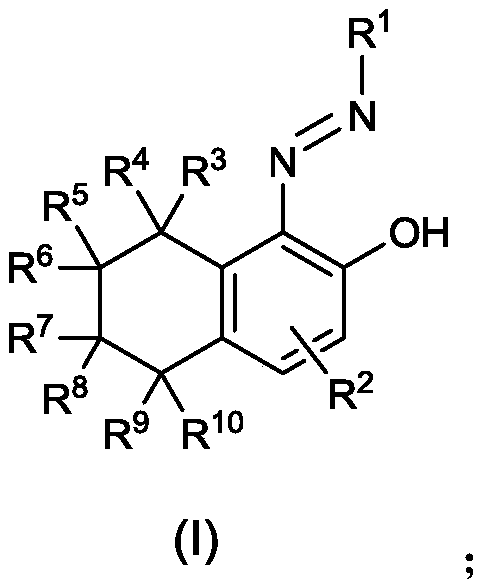

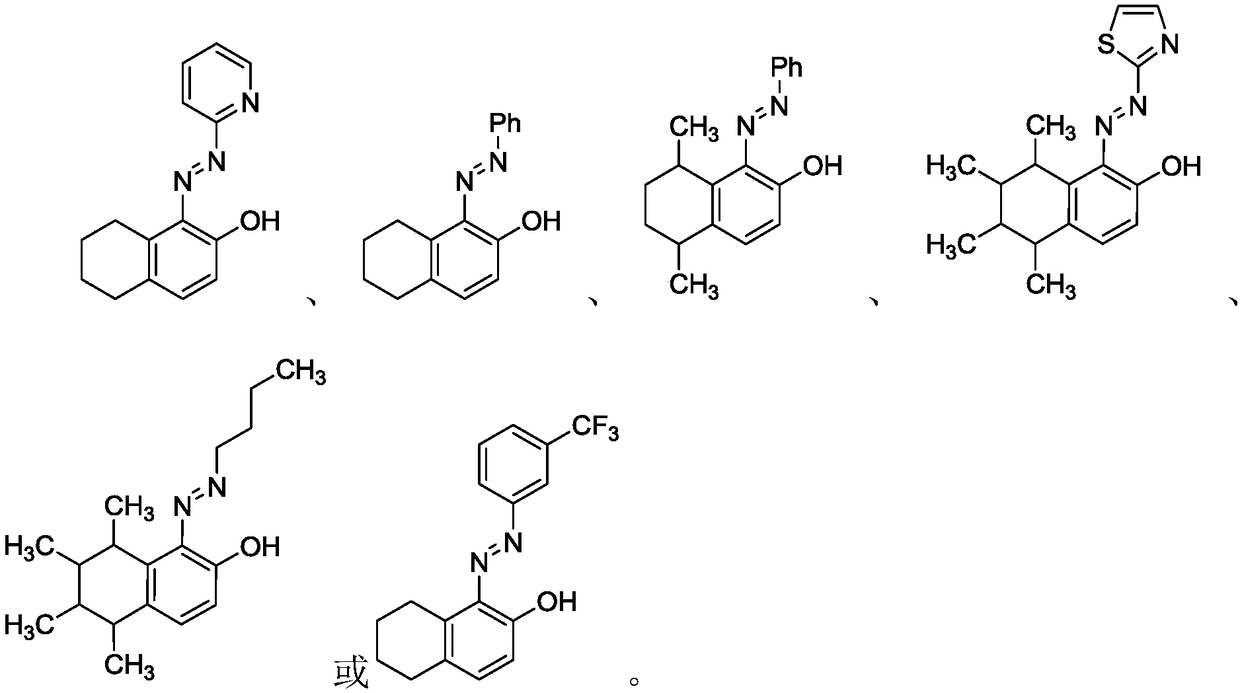

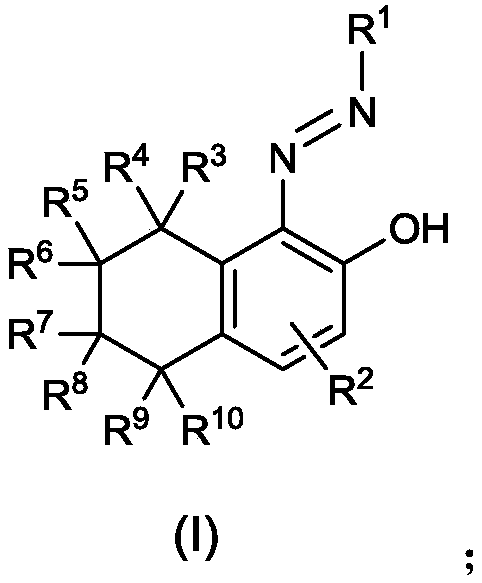

Extractive organic phase and application thereof

ActiveCN108754141AConvenient sourceLow costProcess efficiency improvementLithiumSeparation coefficient

The invention discloses an extractive organic phase and application thereof. The extractive organic phase comprises a diluting agent, a modifying agent and a compound expressed as a formula (I); the concentration of the compound expressed as the formula (I) (as described in the description) in the extractive organic phase is 0.05-2 mol / L; and the concentration of the modifying agent in the extractive organic phase is 0.05-2 mol / L. The application can comprise the following steps: the extractive organic phase is used for extracting water phase extractives containing lithium ions; and the layering is performed to collect organic phases. The extractive organic phase and the extracting method for extracting lithium have the advantages of high extracting efficiency of the lithium ions, easy phase separation and convenient operation method, meanwhile, achieve excellent lithium-sodium and lithium-potassium separation coefficients, and can realize high-selectivity separation of lithium from other alkali metal.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

Dark green transmutation glaze ceramic product and preparation method thereof

The invention relates to the technical field of ceramic preparation, and concretely relates to a dark green transmutation glaze ceramic product and a preparation method thereof. The dark green transmutation glaze ceramic product is prepared from, by weight, 64-72 parts of kaolin, 40-45 parts of glass powder, 6-10 parts of talc, 10-12 parts of quartz, 4-9 parts of calcium carbonate, 3-5 parts of ferric oxide, 3-8 parts of copper oxide, 1-3 parts of chrome green and 1-2 parts of phosphorus pentoxide. The preparation method comprises the following steps: S1, glaze preparation; S2, slurry preparation; S3, glazing; and S4, sintering. The ceramic product has the characteristics of bright color, uniform and clear texture, wear resistance and scratch resistance.

Owner:福建省春秋陶瓷实业有限公司

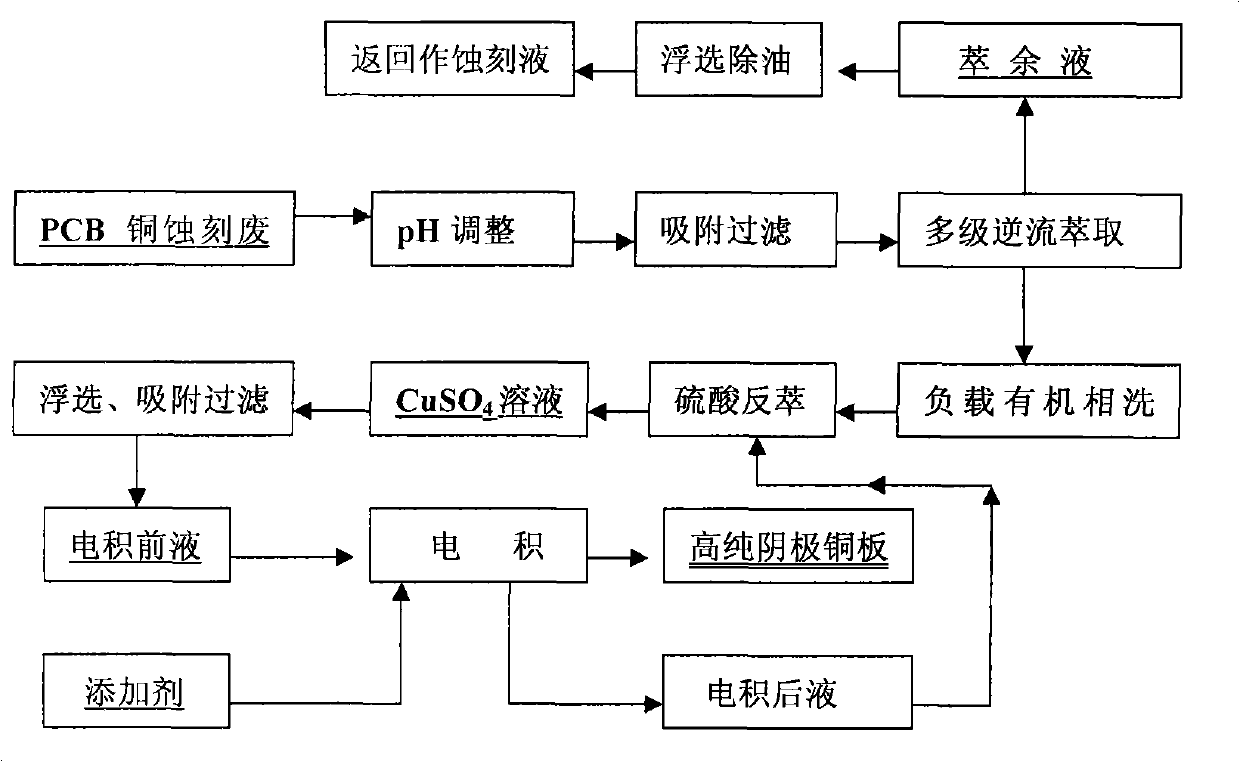

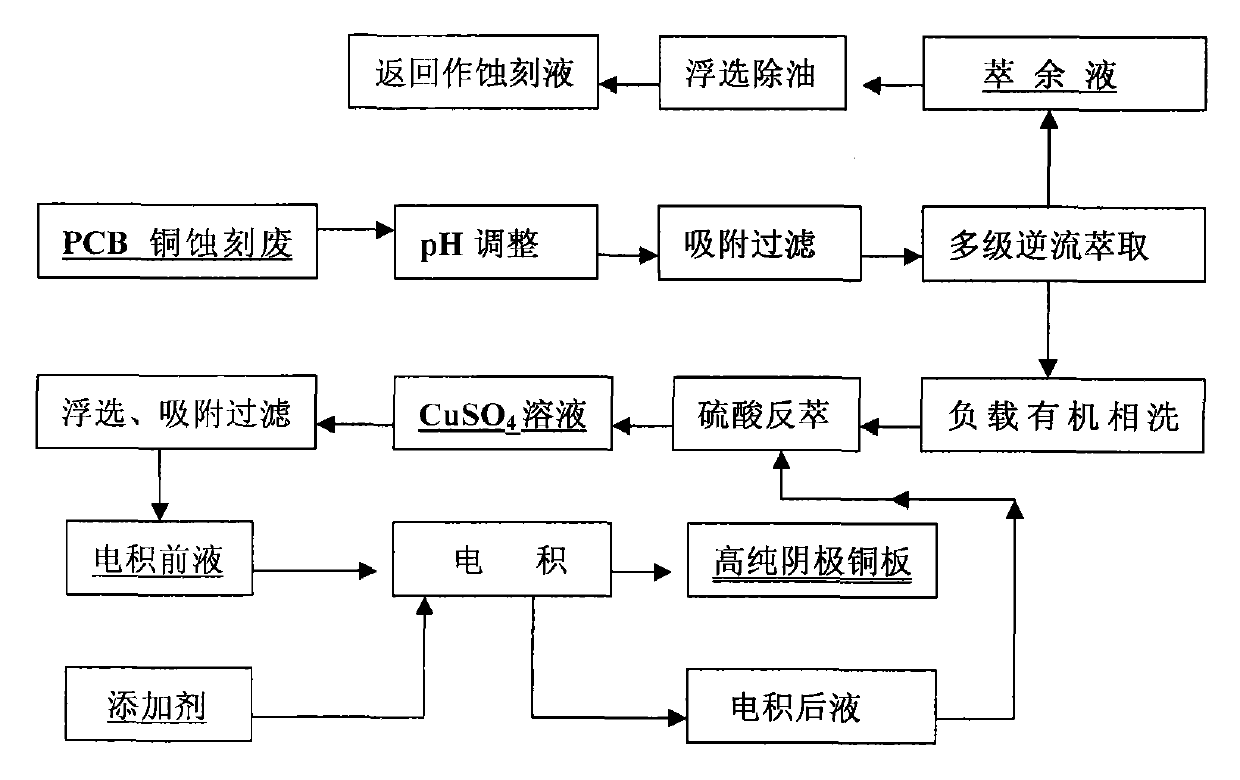

Method of preparing high pure cathode copper by using PCB acid chlorine copper etching solution sewage

InactiveCN101550488BHigh extraction recoveryHigh crystallinityPhotography auxillary processesProcess efficiency improvementSimultaneityCrystallinity

The present invention disclose a method of preparing high pure cathode copper by using PCB acid chlorine copper etching solution sewage, the main technical characteristics include applying sewage preprocess procedure to satisfy extraction need better, programming multi-extraction to improve extraction recovery rate of cooper, applying extractant with high selectivity avoid extraction entrainment design, washing procedure etc. to reduce carried impurity and dispel affect of chloride ion to electrodeposition. The electrodeposition applies additive to improve copper crystallinity, simultaneity, utilize residual useful ingredient in raffinate to prepare copper etching solution, arriving the objective of both prepare high pure cathode copper effectively and regenerative cycle use of the etchingsolution. The purity of the prepared cathode copper reaches 99.99%.

Owner:CENT SOUTH UNIV +1

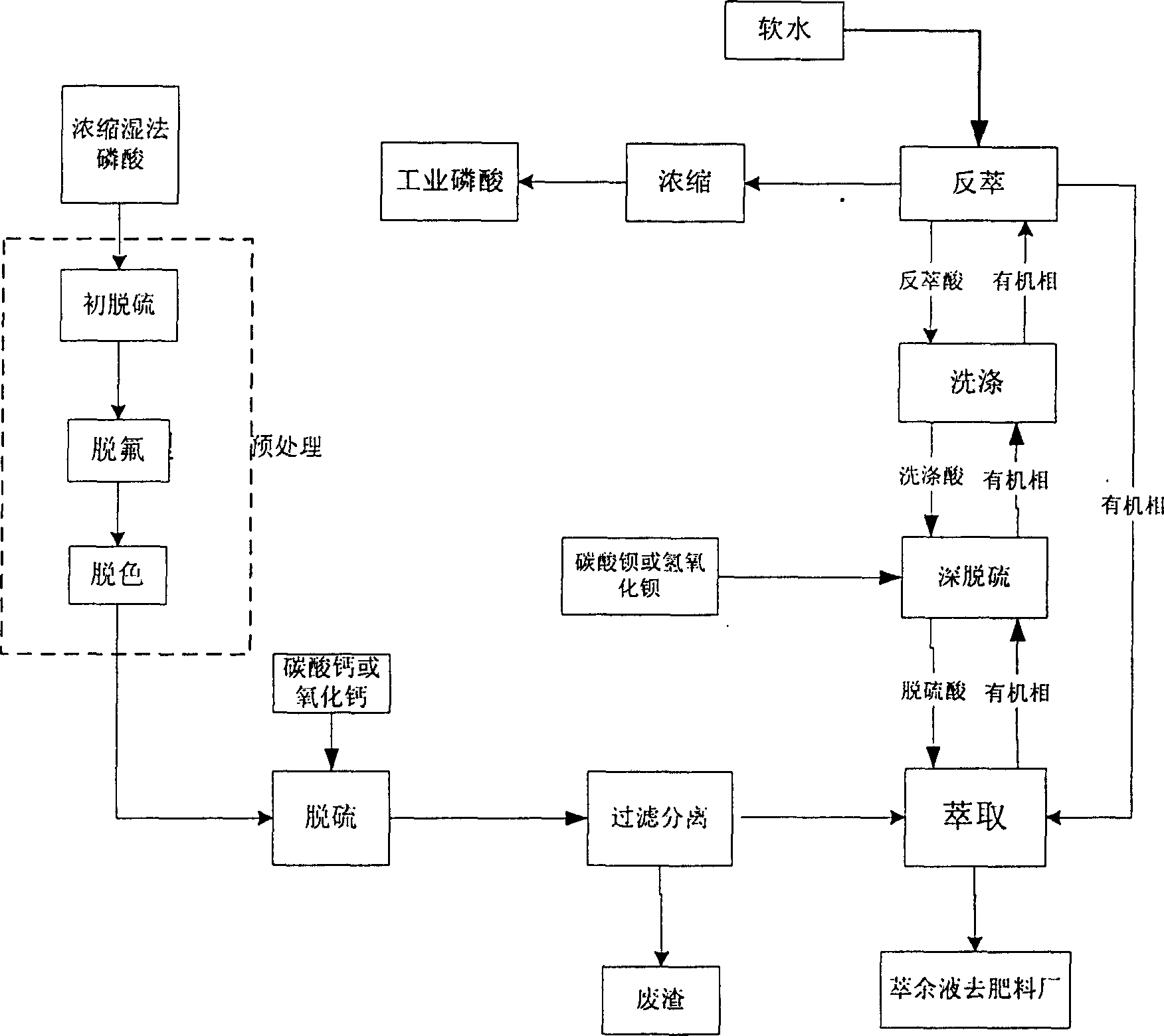

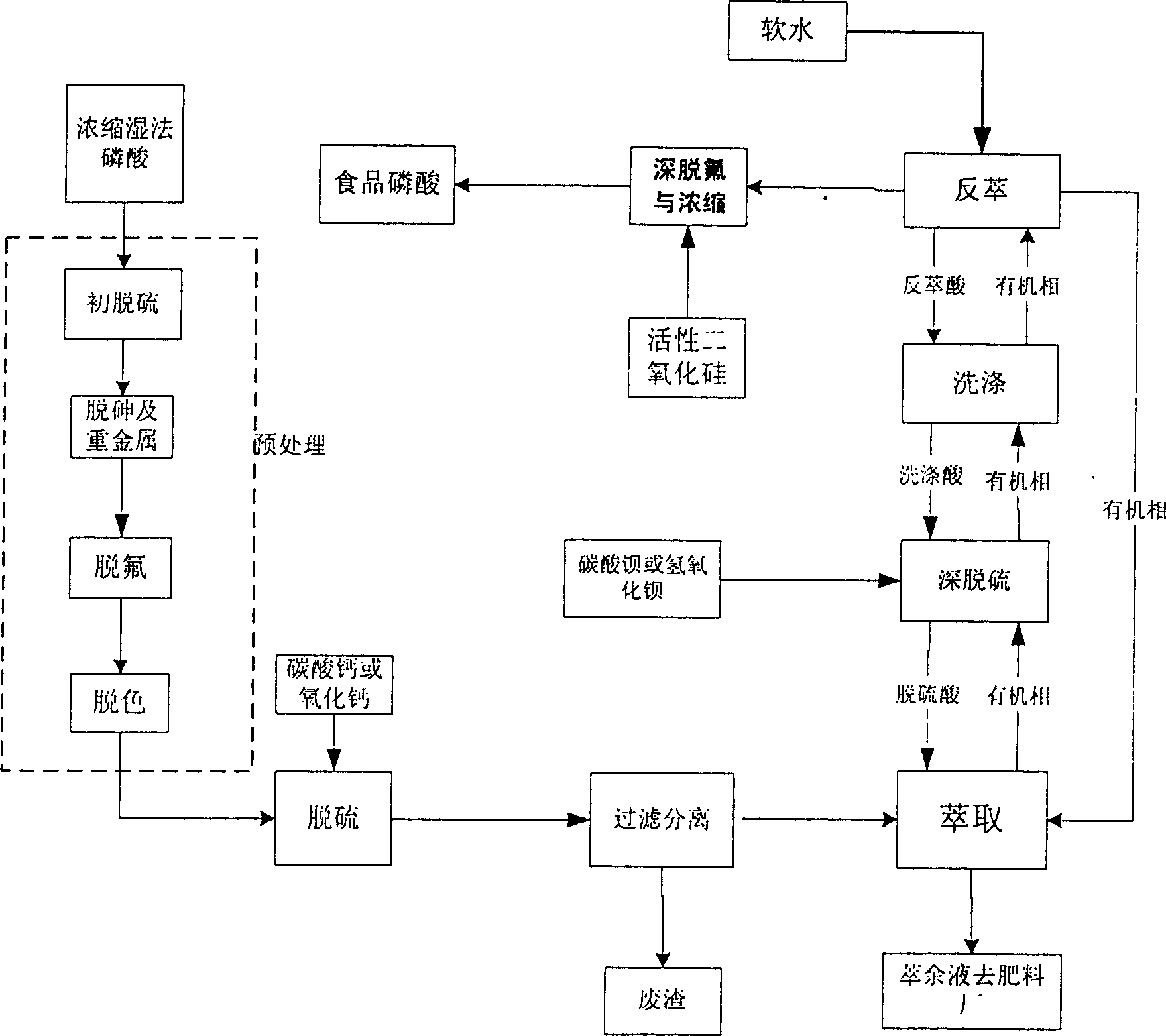

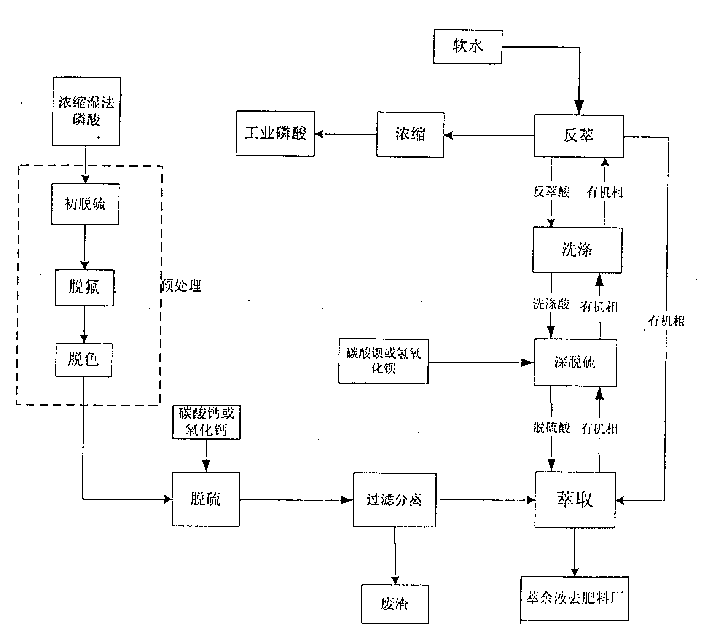

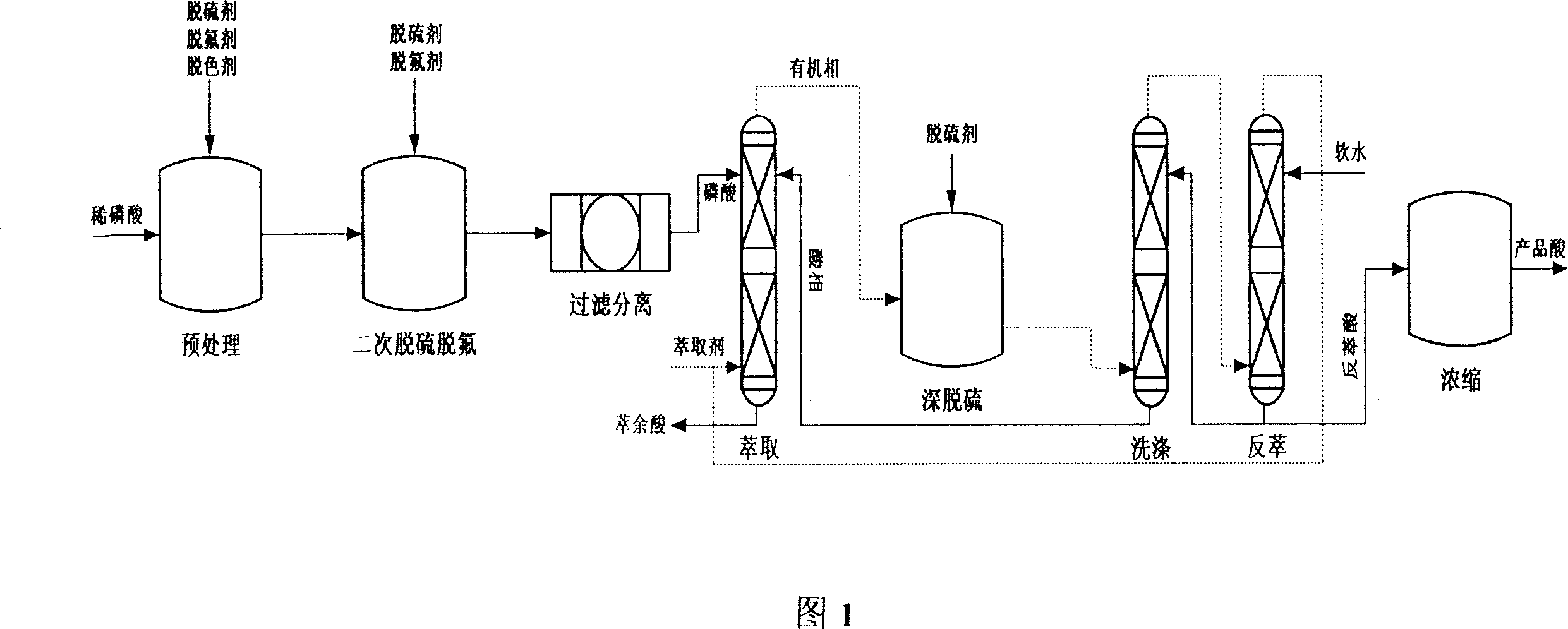

Method for preparing industrial grade and food grade phosphoric acid by wet method phosphoric acid

InactiveCN1204044CGood effectSimple processLiquid solutions solvent extractionPhosphorus compoundsO-Phosphoric AcidFiltration

Owner:SICHUAN UNIV +1

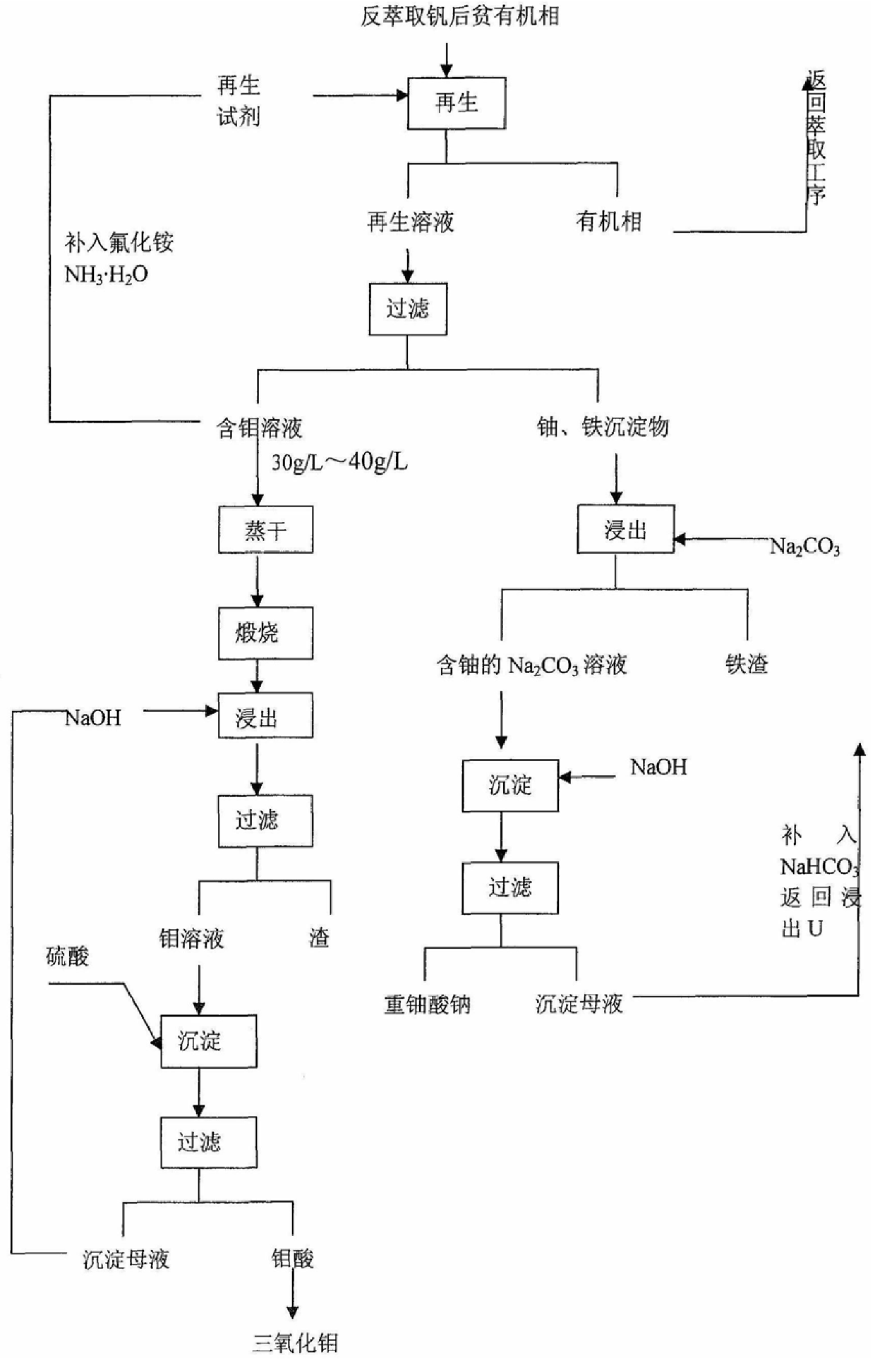

A method for separating ferromolybdenum from vanadium extractant by organic phase regeneration

The invention provides a method for separating uranium, molybdenum and iron from a vanadium extraction agent by utilizing organic phase regeneration. (2) filter the regeneration solution to obtain uranium-containing, iron-containing precipitates and molybdenum-containing solutions; (3) adopt Na CO to the gained uranium-containing and iron-containing precipitates for leaching of solution, filter to obtain uranium-containing Na CO leaching solution and iron slag, and transfer the leaching solution and iron slag to the uranium-containing and iron-containing precipitates. NaOH was added to the Na2CO3 leaching solution of uranium, and Na2U2O7 was prepared by NaOH alkaline uranium precipitation process; for the obtained molybdenum-containing solution, when the molybdenum concentration was greater than 30g / L~40g / L, it was evaporated to dryness and then calcined; the calcined product was leached with NaOH Take, add sulfuric acid to the obtained molybdenum solution, and pyrolyze molybdic acid to prepare molybdenum trioxide. The method effectively regenerates the organic phase, avoids the reduction of the capacity of the extractant due to the accumulation of uranium, molybdenum and iron in the organic phase, recovers the uranium and molybdenum and obtains qualified products, and comprehensively recycles the resources. .

Owner:BEIJING RES INST OF CHEM ENG & METALLURGY

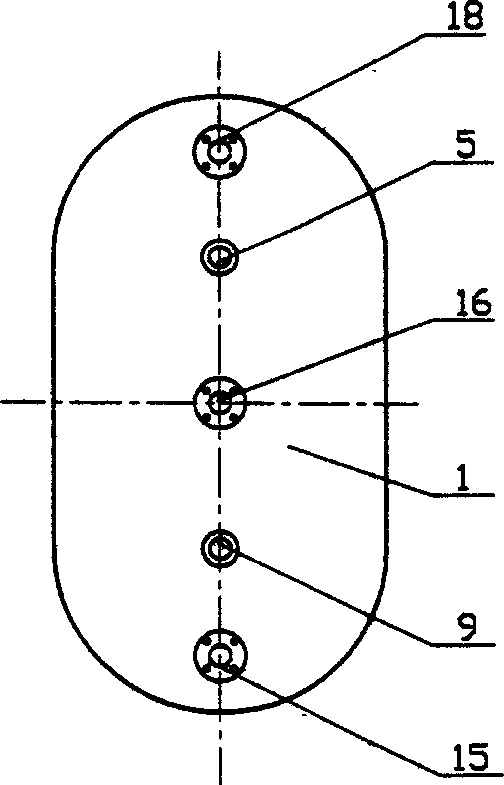

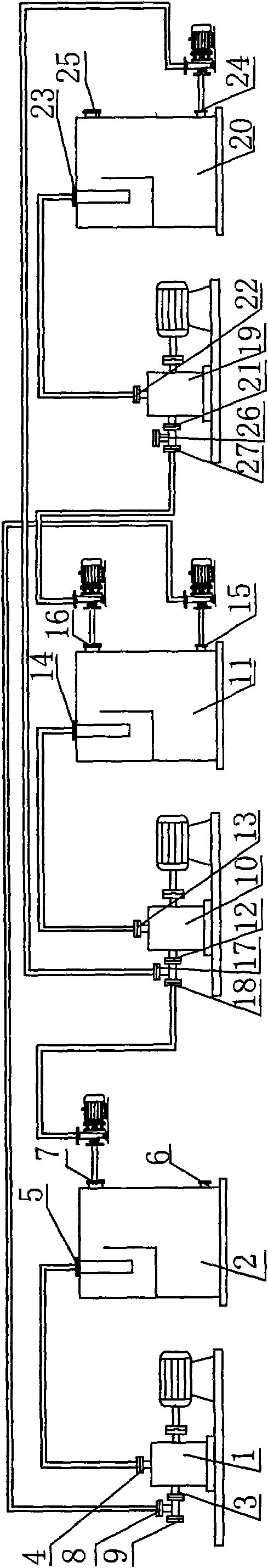

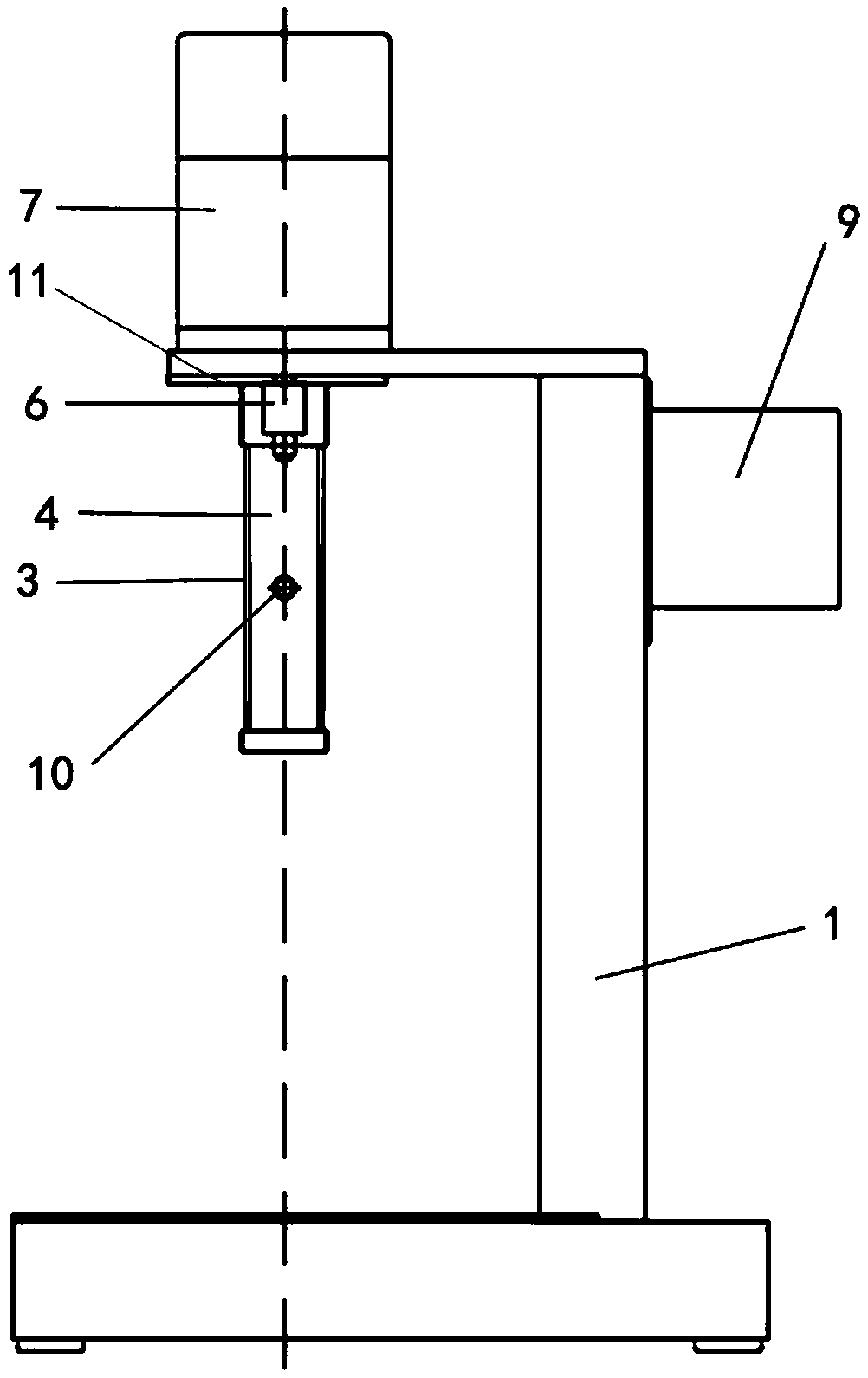

Stripping device

ActiveCN101898049ALarge mass transfer areaImprove stripping efficiencyLiquid solutions solvent extractionPhase splittingSolvent

The invention discloses a stripping device which comprises an emulsifying machine (1) and phase splitting equipment (2), wherein an emulsifying machine inlet (3) and an emulsifying machine outlet (4) are arranged on the emulsifying machine (1), a mixed-phase inlet (5), a heavy-phase outlet (6) and a light-phase outlet (7) are arranged on the phase splitting equipment (2), the emulsifying machine inlet (3) is connected with a stripping agent inlet (8) and a solvent inlet (9), and the emulsifying machine outlet (4) is connected with the mixed-phase inlet (5) of the phase splitting equipment. When multiple stages of stripping devices are combined, the light-phase outlet of the phase splitting equipment in the stage of stripping device is connected with the solvent inlet in the next stage of stripping device through a pipeline provided with a pump; and the heavy-phase outlet of the phase splitting equipment in the next stage of stripping device is connected with the stripping agent inlet in the stage of stripping device through the pipeline provided with the pump. The invention can strengthen the mass transfer performance, improve the stripping efficiency and lower the stripping equipment investment and the operating cost.

Owner:WENGFU (GRP) CO LTD

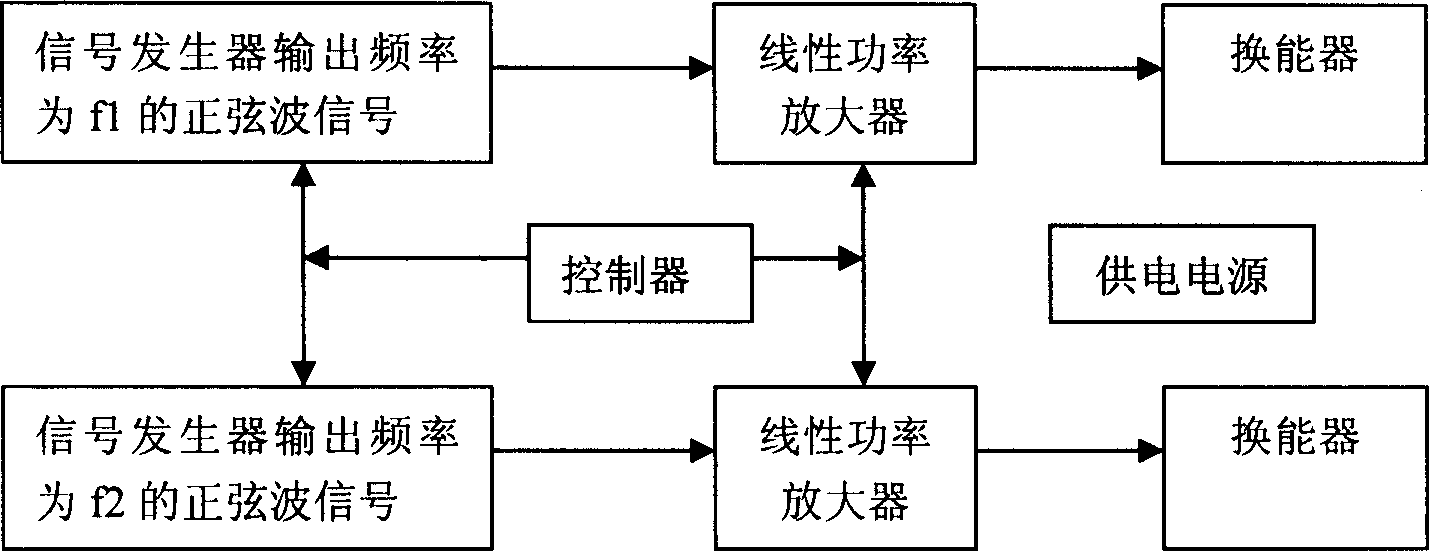

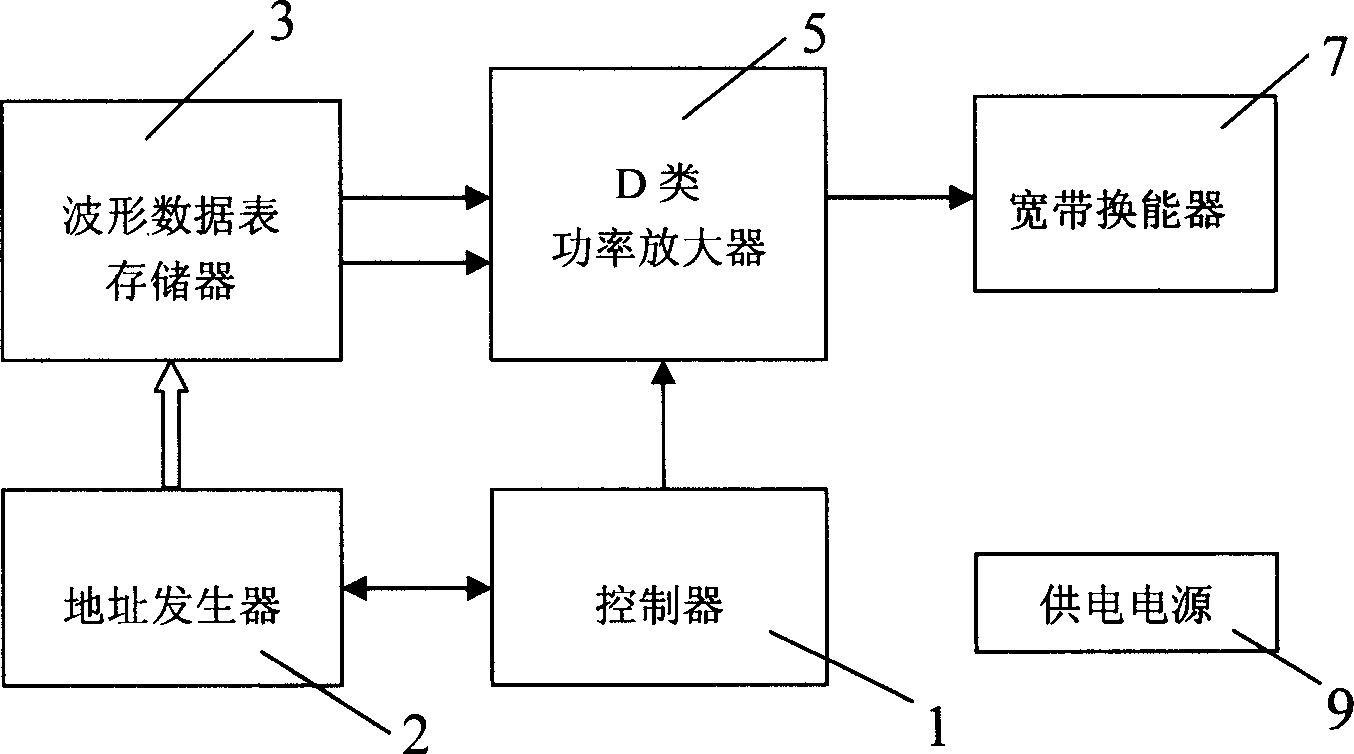

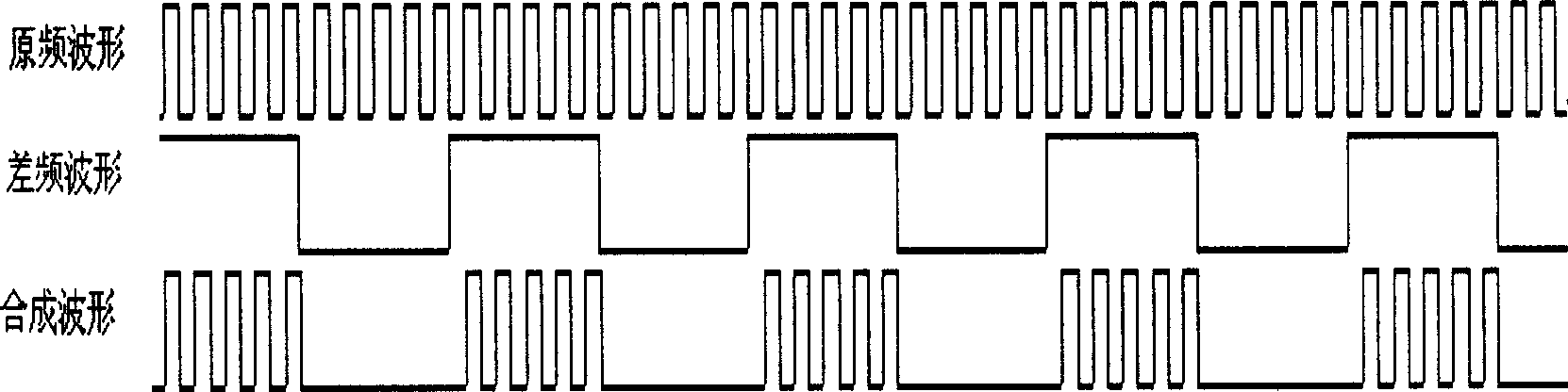

System and method for sending sound with two different frequencies at the same time using one energy converter

InactiveCN1790480AReduce manufacturing costReduce volumeElectrophonic musical instrumentsWave based measurement systemsElectricitySound sources

The invention discloses an energy converter to launch two different frequency sound sources, which comprises the following parts: broad-band energy converter, controller, feeding power, D-type power amplifier, waveshape data list storage and address generator, wherein the controller coordinates each part to work simultaneously, which controls the pulse breadth and repeating times per second of sound signal and outputs the order to the address generator and D-type power amplifier; the address generator outputs the data address to the waveshape data list storage, which outputs the data to the D-type power amplifier; the D-type power amplifier connects the broad-band energy converter, which supplies enough power to drive the electric power; the broad-band energy converter transmits the electric power into sound power to launch out.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

Preparation method and application of ionic liquid-sodium (mono-/di-)hydrogen phosphate buffer aqueous two-phase system

The invention discloses a method for extracting a tobacco alkaloid by a novel nicotine modified ionic liquid-sodium (mono- / di-)hydrogen phosphate buffer aqueous two-phase system. The method comprises(1) preparing a nicotine modified ionic liquid; (2) preparing the aqueous two-phase system; and (3) in the aqueous two-phase solution, adding a solution of a tobacco crude extract to be extracted, performing shaking for 3-7 min, placing the mixture in a water bath pot of 30-50 DEG C, allowing the mixture to be stand, after layering is stable, and separating out the upper phase, so as to obtain 85%or more of the tobacco alkaloid in an initial tobacco extract through once extraction. According to the technical scheme, the aqueous two-phase system of the ionic liquid and the sodium (mono- / di-)hydrogen phosphate buffer is adopted to separate the nicotine, the technological conditions of the aqueous two-phase extraction are selected and optimized, and the method has the advantages of pH-control phase separation, low price, high efficiency and mild extraction, no toxicity, small loss of activity of the extract and the like, and is a green process. At the same time, the aqueous two-phase system of the method has high selectivity and high enrichment degree on the nicotine, and has high practical value.

Owner:李辉

Organic recovery method in extraction and separation line

ActiveCN102517463AImprove living conditionsGood for healthProcess efficiency improvementRecovery methodProduction line

An organic recovery method in an extraction and separation line comprises the following steps of: placing organic substances into a first stage of an extraction box; placing alkaline for saponification during a second stage; carrying out cascade clarification during third and fourth stages; and carrying out countercurrent extraction on rare earth soap wastewater obtained during fifth and sixth stages and saponified wastewater obtained during the second stage in the first stage of the extraction box by the use of blank organic substances. By the application of the organic recovery technology, continuity and high efficiency of rare earth industrial production are realized, material consumption of the product is reduced, and production cost is decreased. In addition, the production process is continuous, is simple to operate, and is easy to connect with other rare earth production line. In comparison with traditional technologies, the method can be used to reduce organic consumption by more than 30% and has substantial economic benefits.

Owner:甘肃稀土新材料股份有限公司

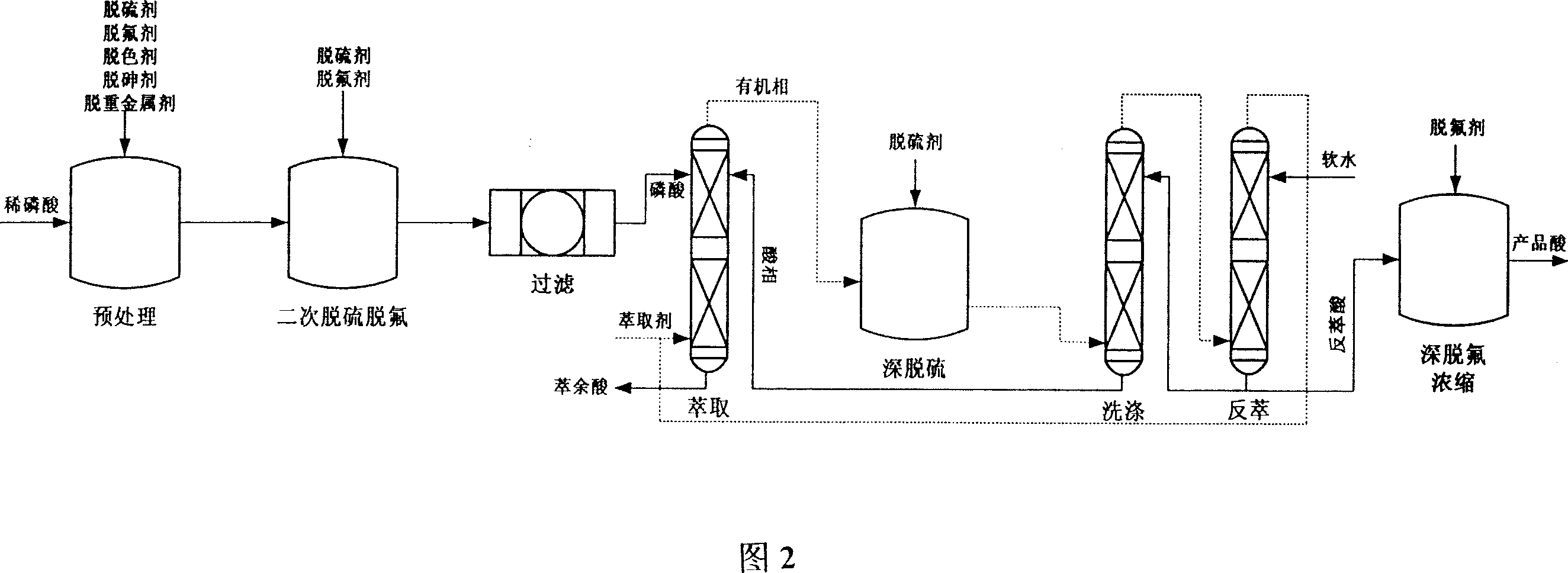

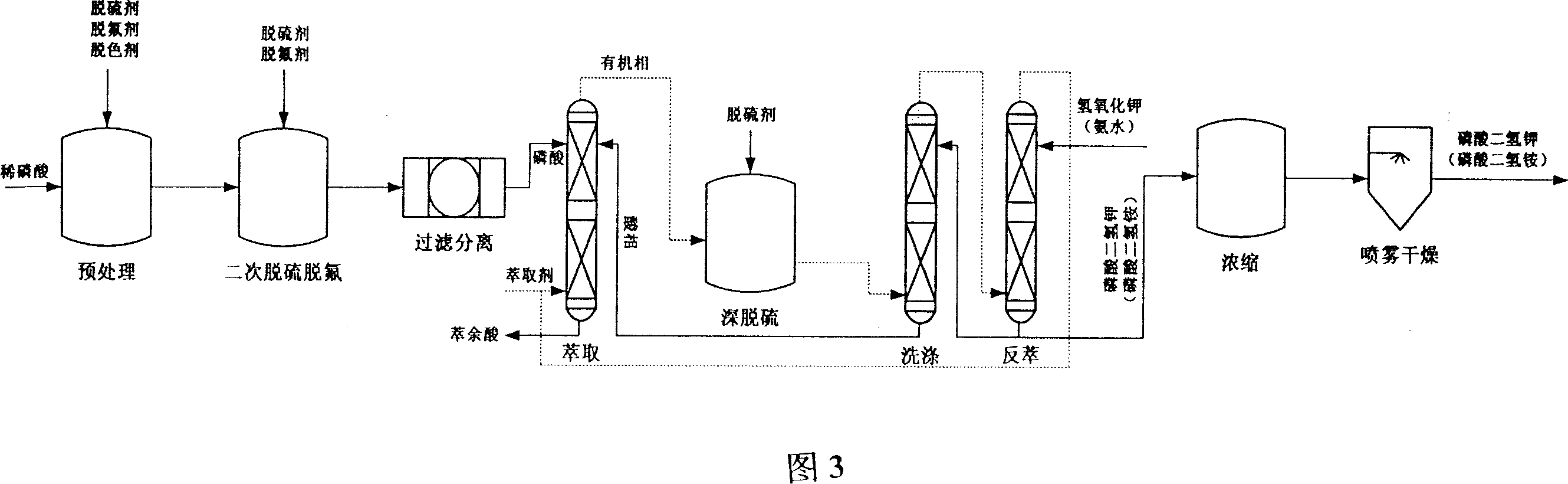

Method for preparing technical grade phosphoric acid, foodstuff grade phosphoric acid and phosphate using wet method and thin phosphoric acid

The invention discloses a method for preparation of technical grade phosphoric acid with wet- process diluted phosphoric acid, which sequentially contains pretreation, secondary desulfurizion and defluorination, filteration and separation, extraction, deeply desulfurization, washing, retrograde extraction and concentration. Different from method for preparation of food-grade phosphoric acid with wet-process diluted phosphoric acid, the pretreating contains not only desulfurization, defluorination, decoloring, but also de-arsenic, de-heavy metal, and defluorination and deep concentration proceeds parallelly after retrograde extraction. The process of preparation of technical grade phosphoric acid with wet- process diluted phosphoric acid sequentially contains pretreation, secondary desulfurization and defluorination, filteration and separation, extraction, deeply desulfurization, washing, retrograde extraction, concentration, spray drying or shotcrete granulation, the extractant using in the process of retrograde extraction being KOH saturated solution or NH4OH saturated solution. With said process, it can decrease the energy consumption and the production cost; and it can produce and purify phosphoric acid, and also directly produce plural of phosphonate with the same device.

Owner:SICHUAN JINGCUI CHEM TECH

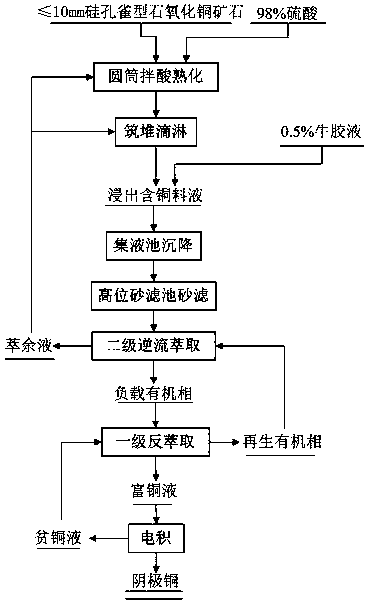

Method for extracting copper from chrysocolla type copper oxide ores through wet process

InactiveCN108118160AShorten the leaching timeReduce volumeProcess efficiency improvementDiluentCopper oxide

The invention relates to a method for extracting copper from chrysocolla type copper oxide ores through a wet process, and belongs to the field of non-ferrous metal hydrometallurgy. The method comprises the following technological steps: 1) curing ores by adding sulfuric acid and performing desiliconization; 2) performing heaping and dipping to leach copper; 3) precipitating silicon in leaching feed liquid by utilizing ox glue; and 4) continuously inhibiting the volume of interphase dirt by selecting an organic phase component and a controlled phase. According to the method disclosed by the invention, after the chrysocolla type copper oxide ores are subjected to acid mixing, curing and desiliconization and the silicon of the leaching copper-containing feed liquid is precipitated by using the ox glue, the situation that the copper-containing feed liquid SiO2 is less than 500mg / L can be maintained, an extraction requirement is met, and the leaching time of the ores can be shortened; an extracting agent adopts M5640 and a diluent adopts SX-80, and extraction and back extraction are continuously carried out by adopting an organic phase, so that the emulsification volume and the compression volume of the interphase dirt can be reduced, and therefore, the chrysocolla type copper oxide ores can realize industrial application.

Owner:YUNNAN CHIHONG RESOURCE COMPREHENSIVE UTILIZATION CO LTD

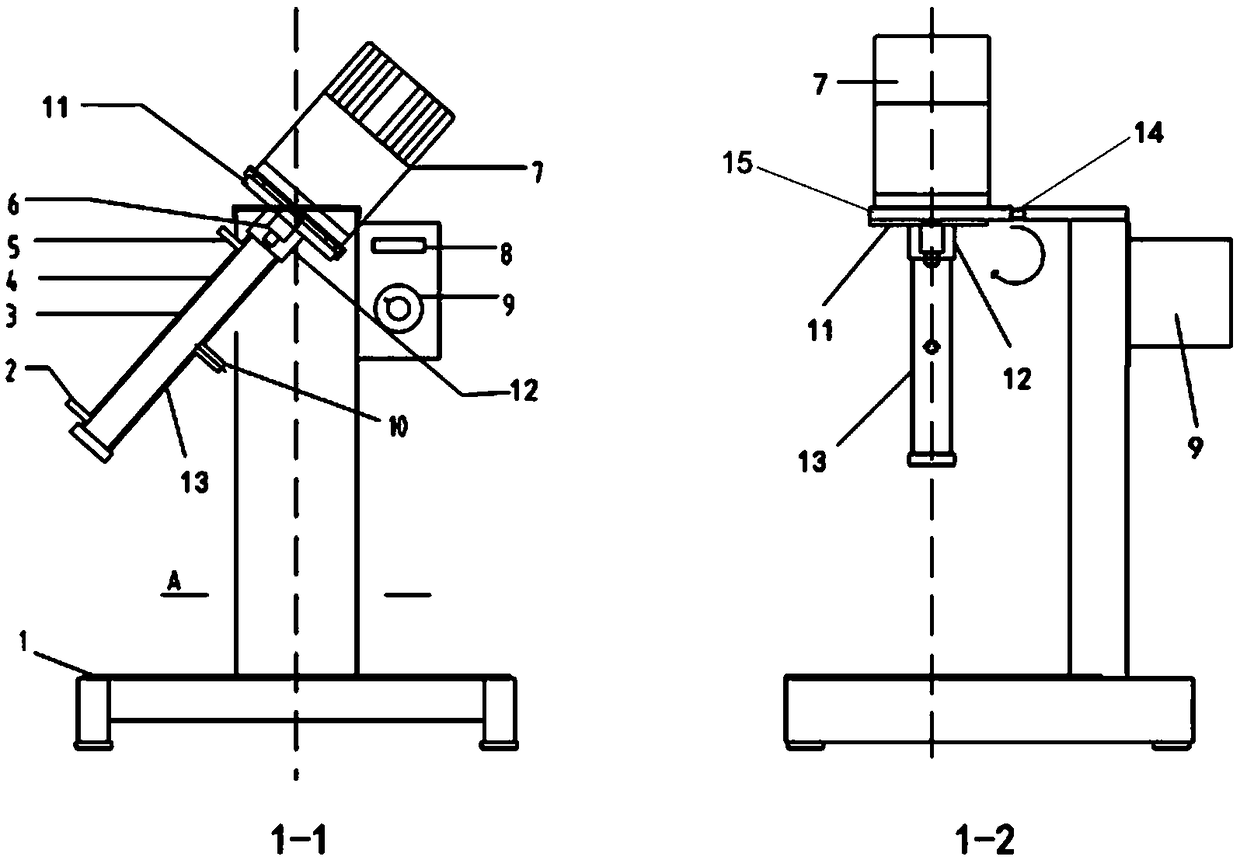

Lengthened scraping film type rotary channel enhanced-extraction device and application thereof

ActiveCN109395431AEasy to phaseShort reaction timeLiquid solutions solvent extractionProcess efficiency improvementEngineeringLiquid–liquid extraction

The invention provides a lengthened scraping film type rotary channel enhanced-extraction device and application thereof. The lengthened scraping film type rotary channel enhanced-extraction device comprises a supporting frame, an internal cylinder and an external cylinder sleeving the outside of the internal cylinder. The top of the supporting frame is provided with a rotary part, the bottom of the rotary part is connected with the external cylinder, the external cylinder and the internal cylinder can rotate in the range of 0-90 degrees along a vertical line under the effect of the rotary part. The gap between the external cylinder and the internal cylinder is 0.15-0.35 mm. the top of the internal cylinder is connected with a rotary shaft, the rotary shaft is arranged at the bottom of therotary part and is connected with a motor, and the rotary shaft, the internal cylinder and the external cylinder have the same central line. The outer wall of the internal cylinder is marked with a plurality of strips. The external cylinder is provided with an upper feeding port, a lower feeding port and a discharging port. The lengthened scraping film type rotary channel enhanced-extraction device is applied to a liquid-liquid extraction enhancing method, and the time for shortening extraction to achieve balance can be remarkably shortened.

Owner:SICHUAN UNIV

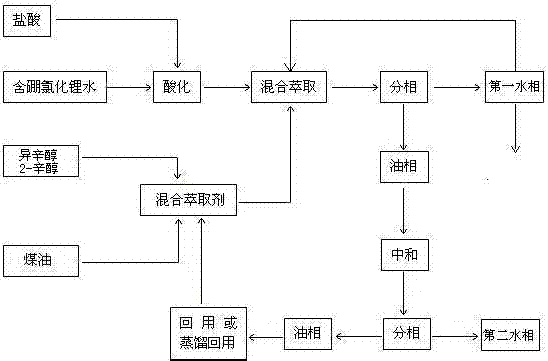

Extraction composition and application thereof

ActiveCN109055743AThe synthesis method is simpleLow costProcess efficiency improvementSolubilityLithium

The invention discloses an extraction composition and an application thereof. The composition comprises a compound and a modifier as shown in the formula (I), and the molar ratio of the compound to the modifier is 1:0.2-1:6. When the composition contains a diluent, the application preferably comprises the following steps that the composition and a water phase whose pH value is larger than 10 and which contain lithium ions are subjected to extraction to obtain an organic phase loaded with the lithium ions. The synthesis method of the compound shown in the formula (i) is simple and convenient, and low in costs, and has the characteristics of excellent oil solubility and low water solubility. The lithium-extracted composition and the diluent have the advantages of being good in oil solubility, low in water solubility, easy in phase separation, and large in loading quantity of the lithium ions in the organic phase, possessing excellent lithium-sodium and lithium-potassium separation effect, and being capable of extracting and separating with high selectivity the lithium ions from a complex alkali metal mixed solution. (Please see the formula (I) in the specification).

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

Method for extracting and purifying nicotine by using polyethylene glycol (PEG)-disodium hydrogen phosphate aqueous two-phase system

InactiveCN103951650AHigh selectivityLittle loss of activityOrganic chemistryPhysical chemistryPolythylene glycol

The invention discloses a method for extracting and purifying nicotine by using a polyethylene glycol (PEG)-disodium hydrogen phosphate aqueous two-phase system. The method comprises the steps of putting 2.8-3.2g of PEG2000 and 1.8-2.2g of disodium hydrogen phosphate into a container, adding 2-4ml of deionized water, shaking out, adding a nicotine solution to be extracted and purified, then adding deionized water again until the total weight reaches 8-12g, shaking out for 3-7 minutes, putting into a water bath kettle at 35-45 DEG C, standing, and separating nicotine in an upper phase after stably layering. The method disclosed by the invention is used for separating and purifying nicotine by adopting the PEG-disodium hydrogen phosphate aqueous two-phase system, and screening and optimizing the process conditions of aqueous two-phase extraction, has the advantages of easy phase splitting, cheap price, efficient and mild extraction, no toxicity, small activity loss of extracts and the like, and is a green process; meanwhile, an aqueous two phase disclosed by the invention has relatively strong selectivity to nicotine, is high in degree of enrichment, and has relatively strong practical values.

Owner:JISHOU UNIVERSITY

Film scratching type rotary micro-channel enhanced extraction equipment and application thereof

PendingCN109589643AEasy to phaseShort reaction timeLiquid solutions solvent extractionEngineeringScratching

The invention provides film scratching type rotary micro-channel enhanced extraction equipment and application thereof. The extraction equipment comprises an inner barrel and an outer barrel which sleeves the outer part of the inner barrel, wherein a gap between the inner barrel and the outer barrel is 0.15 to 0.35mm; a plurality of vertical strips are engraved on an inner wall of the inner barrel; the top of the inner barrel is connected with a rotary shaft; the rotary shaft is connected with a motor; and the outer barrel is provided with an upper feeding opening, a lower feeding opening anda discharging opening. The equipment is applied to an enhancement method of solvent extraction; the enhancement method comprises the following steps: conveying a solution to be extracted and an extracting agent into the gap between the inner barrel and the outer barrel through the upper feeding opening and the lower feeding opening respectively under the pushing of an injection pump at the same time; and after the gap between the inner barrel and the outer barrel is fully filled with liquid, a motor is started and the inner barrel is rotated, so that a two-phase flow is formed in the gap and the two-phase flow is discharged from the discharging opening through movement. By adopting the film scratching type rotary micro-channel enhanced extraction equipment, the time that extraction is balanced can be greatly shortened and the extraction energy consumption is reduced.

Owner:SICHUAN UNIV

Light hydrocarbon desulfurization method

ActiveCN106978208ARealize deep desulfurizationLess prone to cloggingGaseous fuelsRefining with aqueous alkaline solutionsPhase mixingMass transfer resistance

The present invention relates to the field of oil refining, and discloses light hydrocarbon desulfurization method, which is performed in a system containing an alkali washing unit, and comprises that an alkali liquid is introduced into a reactor shell side from the dispersed phase inlet of a two-phase mixing reactor, enters a mixing flow channel through distribution holes, and contacts a light hydrocarbon, wherein the light hydrocarbon is introduced into the mixing flow channel sequentially through a reactor inlet and a mixing flow channel inlet, and the flowing direction of the alkali liquid in the reactor shell side is opposite to the flowing direction of the alkali liquid in the mixing flow channel; and the mixture obtained after the contact of the alkali liquid and the light hydrocarbon is led out of the two-phase mixing reactor sequentially through a mixing flow channel outlet and a reactor outlet. According to the present invention, by using the two-phase mixing reactor, the sulfur-containing light hydrocarbon and the alkali liquid flow in the mixing flow channel at the high speed and are mixed vigorously, the mass transfer resistance is low, the acidic sulfur-containing substance in the sulfur-containing light hydrocarbon completely reacts with the alkali liquid, the deep desulfurization of the sulfur-containing light hydrocarbon is achieved, and the acidic sulfur-containing substance removal rate is more than 90%.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com