A method for separating ferromolybdenum from vanadium extractant by organic phase regeneration

A technology of organic phase and extractant, applied in the field of separation of uranium, molybdenum and ferromolybdenum in leaching solution

Active Publication Date: 2014-07-23

BEIJING RES INST OF CHEM ENG & METALLURGY

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Metals such as uranium and molybdenum are not further separated and recovered

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

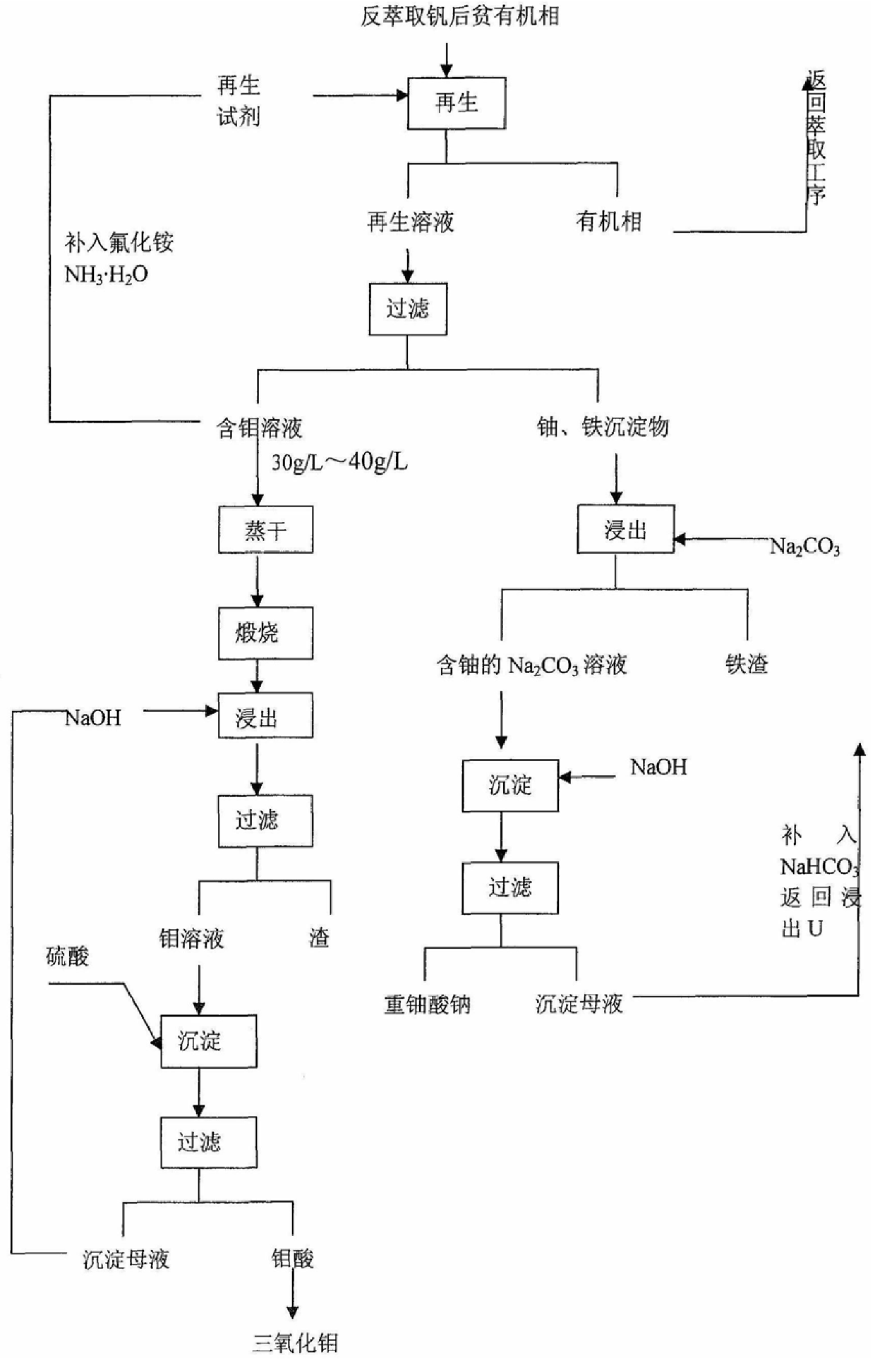

The invention provides a method for separating uranium, molybdenum and iron from a vanadium extraction agent by utilizing organic phase regeneration. (2) filter the regeneration solution to obtain uranium-containing, iron-containing precipitates and molybdenum-containing solutions; (3) adopt Na CO to the gained uranium-containing and iron-containing precipitates for leaching of solution, filter to obtain uranium-containing Na CO leaching solution and iron slag, and transfer the leaching solution and iron slag to the uranium-containing and iron-containing precipitates. NaOH was added to the Na2CO3 leaching solution of uranium, and Na2U2O7 was prepared by NaOH alkaline uranium precipitation process; for the obtained molybdenum-containing solution, when the molybdenum concentration was greater than 30g / L~40g / L, it was evaporated to dryness and then calcined; the calcined product was leached with NaOH Take, add sulfuric acid to the obtained molybdenum solution, and pyrolyze molybdic acid to prepare molybdenum trioxide. The method effectively regenerates the organic phase, avoids the reduction of the capacity of the extractant due to the accumulation of uranium, molybdenum and iron in the organic phase, recovers the uranium and molybdenum and obtains qualified products, and comprehensively recycles the resources. .

Description

A method for separating uranium-molybdenum ferromolybdenum from vanadium extractant by using organic phase regeneration Technical field The present invention relates to the separation method of ferrouranium molybdenum in the leaching solution, be specifically related to a kind of mode that adopts organic phase regeneration from A method for separating uranium, molybdenum and ferromolybdenum from a vanadium-poor organic phase. Background technique The abundance of vanadium in the earth's crust is 0.0135%, but the distribution is very scattered, there is no independent deposit, usually with iron, titanium, Uranium, molybdenum, lead, zinc, aluminum symbiosis. The acidic leaching solution of vanadium often contains impurity elements such as iron, uranium, molybdenum, zinc, aluminum, calcium, etc. P204 (di(2-ethyl)hexylphosphoric acid) extracts tetravalent vanadium, back extraction with sulfuric acid, oxidation of qualified vanadium solution, more acidic ammonium salt precip...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22B3/26C22B3/14C22B34/34C22B60/02

Inventor 李培佑贾秀敏黄永陈天宝刘忠臣刘会武李广

Owner BEIJING RES INST OF CHEM ENG & METALLURGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com