Patents

Literature

41results about How to "Avoid the extraction process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

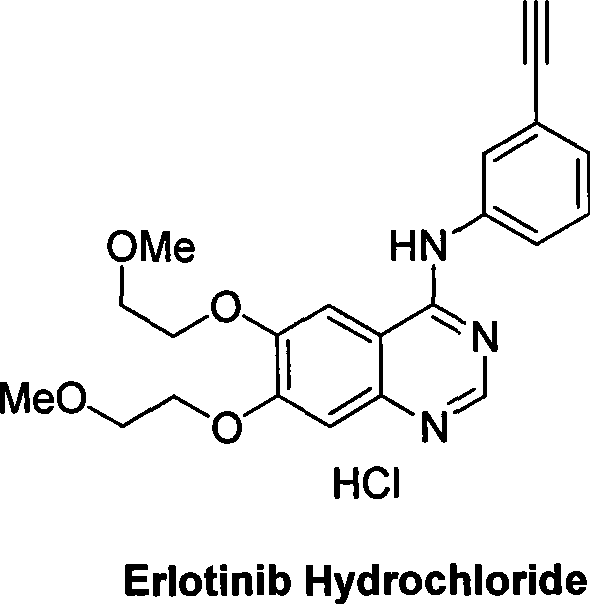

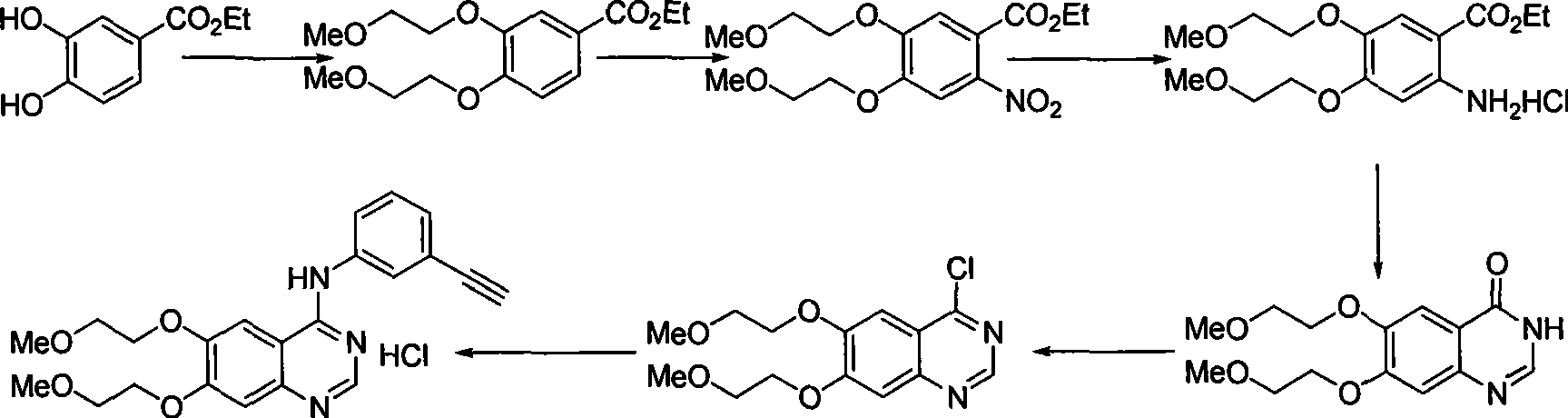

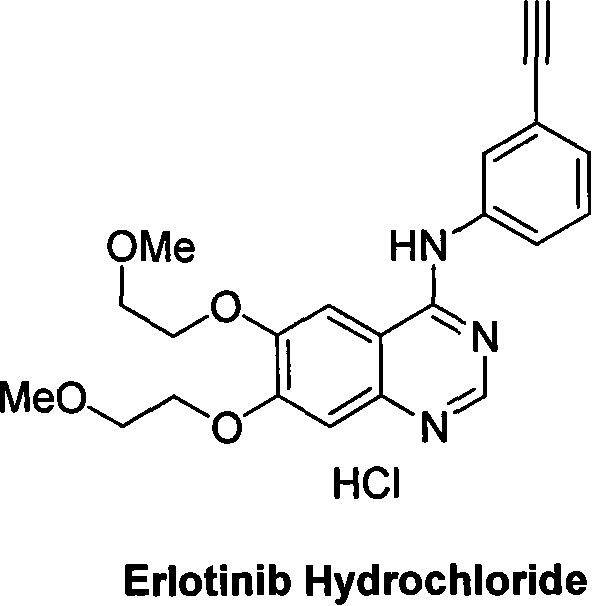

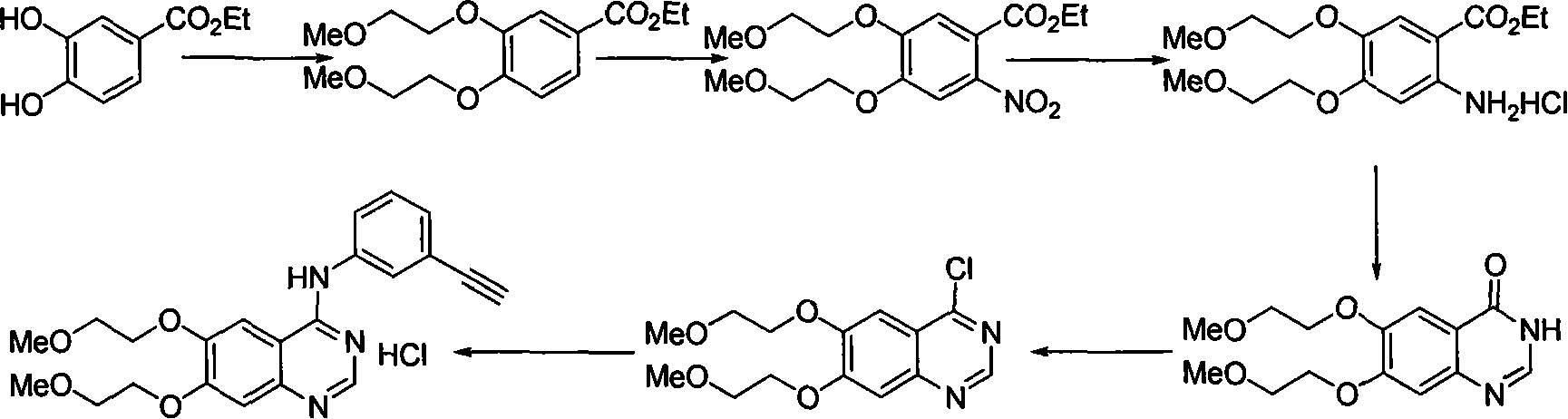

Preparation of erlotinid hydrochloride

ActiveCN101463013AShort synthetic routeAvoid excessive hydrolysisOrganic chemistryDimethylquinazoloneMedicinal chemistry

The invention discloses a preparation method of erlotinib hydrochloride. The method is characterized by taking 3,4-dihydroxybenzaldehyde as a raw material, synthesizing to obtain 6,7-dimethoxyquinazoline-4-one, directly chloridizing to obtain a product, allowing the product to react with meta-ethynylaniline to obtain the erlotinib hydrochloride. The method has mild reaction condition and is applicable to industrialized production.

Owner:FUJIAN SOUTH PHARMA CO LTD

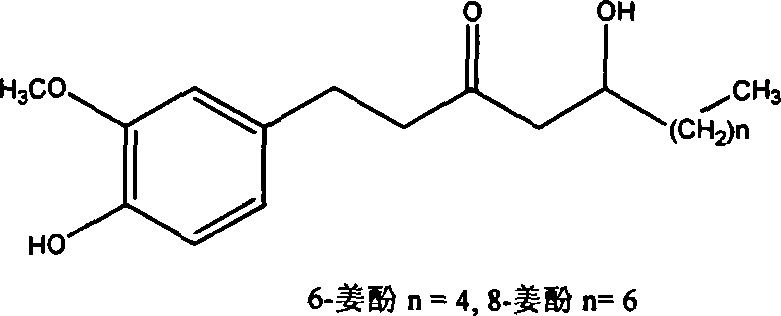

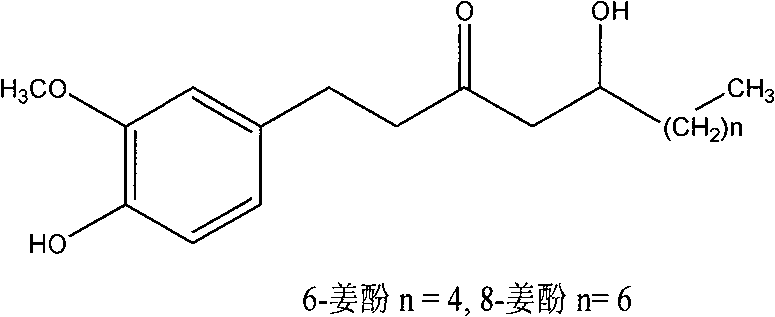

Method for preparing 6-gingerol and 8-gingerol from ginger

InactiveCN101085727AEasy to operateInstrument and equipment requirements are lowCarbonyl compound separation/purificationSolventChemistry

The invention relates to a method for preparing 6- gingerol and 8- gingerol with fresh ginger. It is characterized in that it compries following steps: cutting fresh ginger into sheets, drying at low temperature, disintegrating, sifting with screen of 100 order, heating and refluxing and extracting with acetic ester or acetone, or extracting through immersion, extracting for three times, combining extract liquid, decompressing and recovering solvent, getting extract concretem dissloving it with acetic ester, treating it with chromatographic silica gel and washing it with benzinum purificatum acetic ester with gradient solvent, checking washing process by using TLC, decompressing to recover solvent and getting coarse 6- gingerol and 8- gingerol; washing coarse product with chloroform- carbinol solvent in Sephadex LH20 gel column, checking washing process with TLC, and getting washung liquid containing 6- gingerol and 8- gingerol with higher purity, decompressing to recover solvent and getting pure 6- gingerol and 8- gingerol, checking content with HPLC. The invention is characterized by simple operation, high productivity and production of two kinds of product at the same time.

Owner:NO 411 HOSPITAL OF PLA

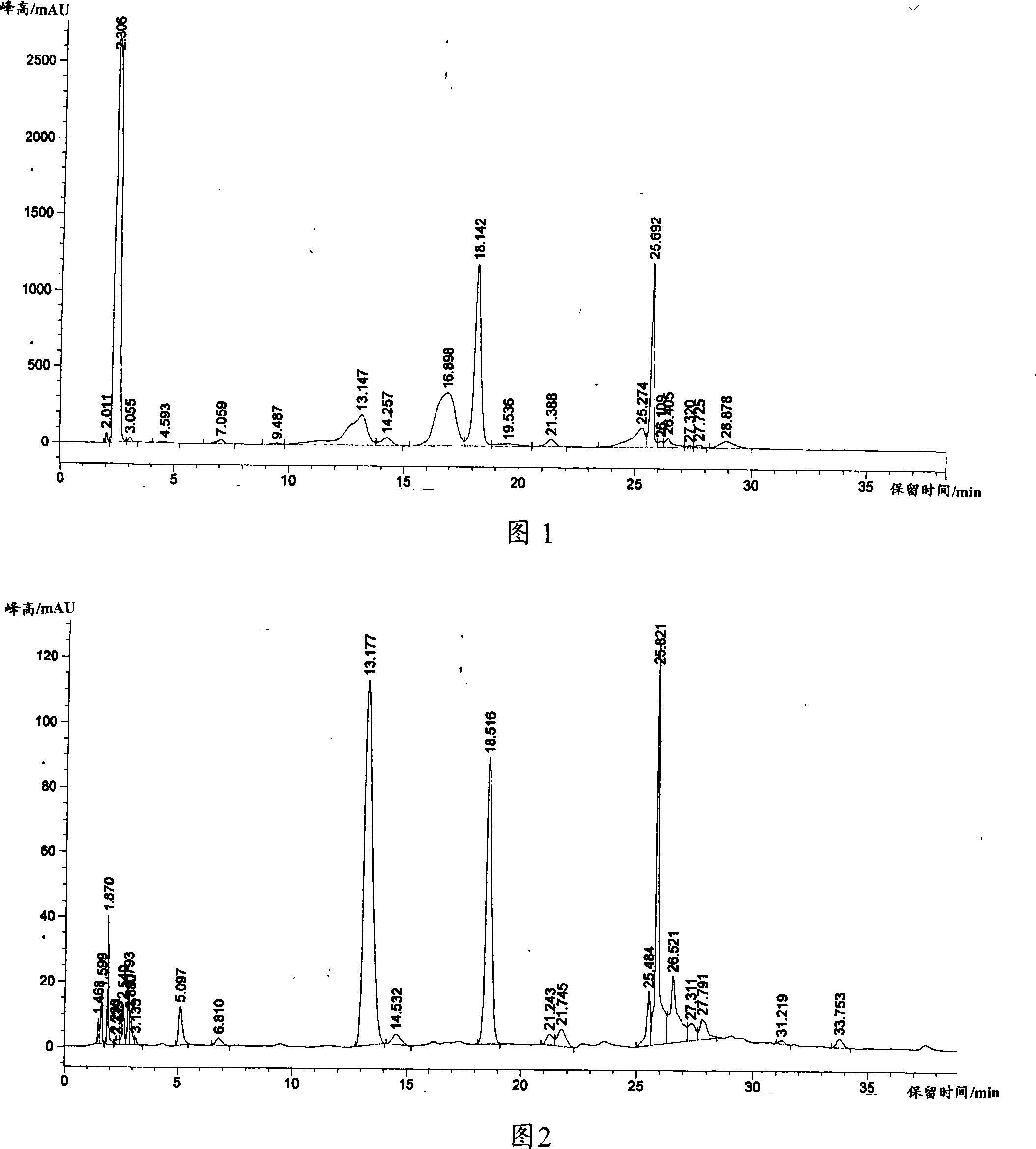

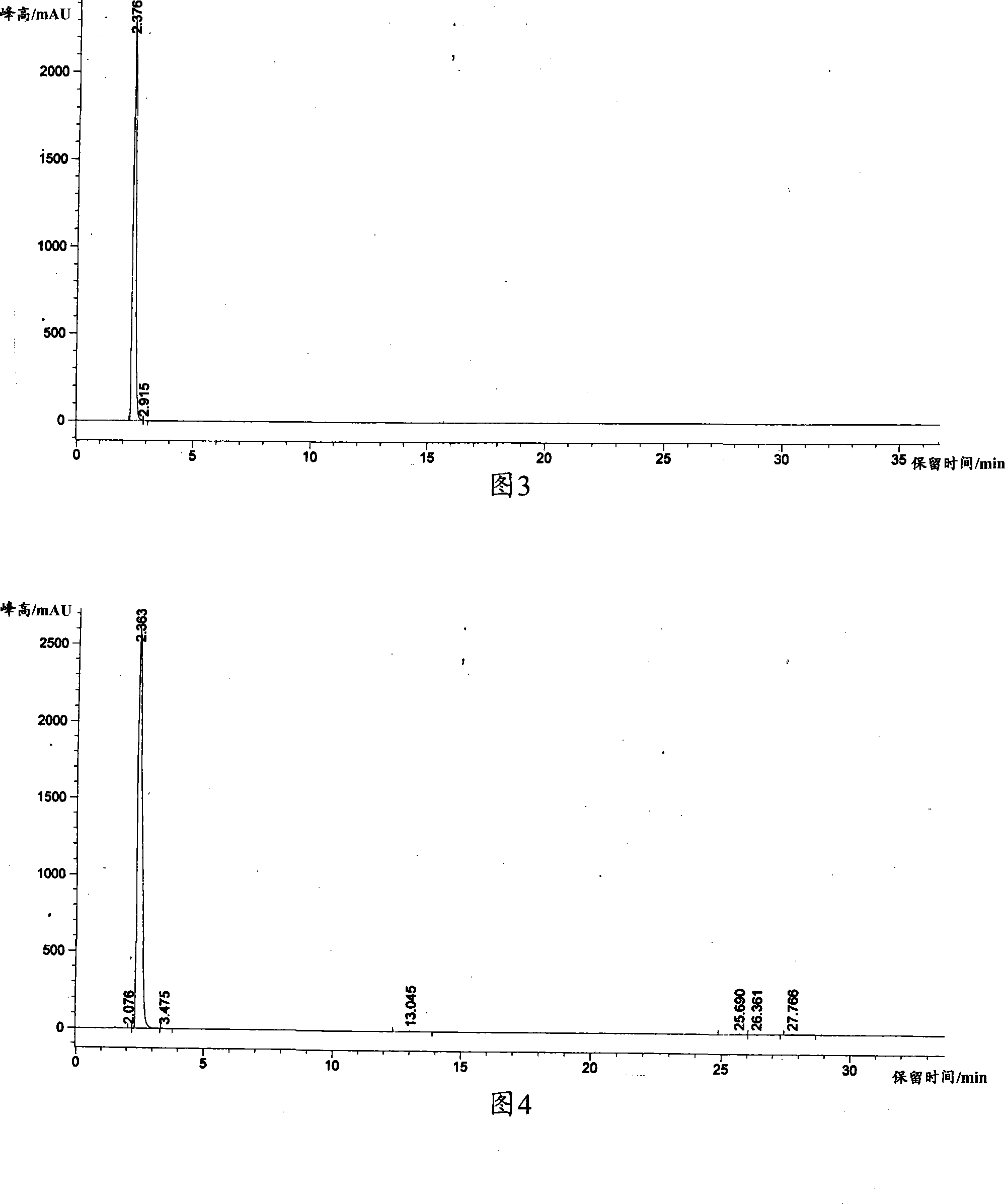

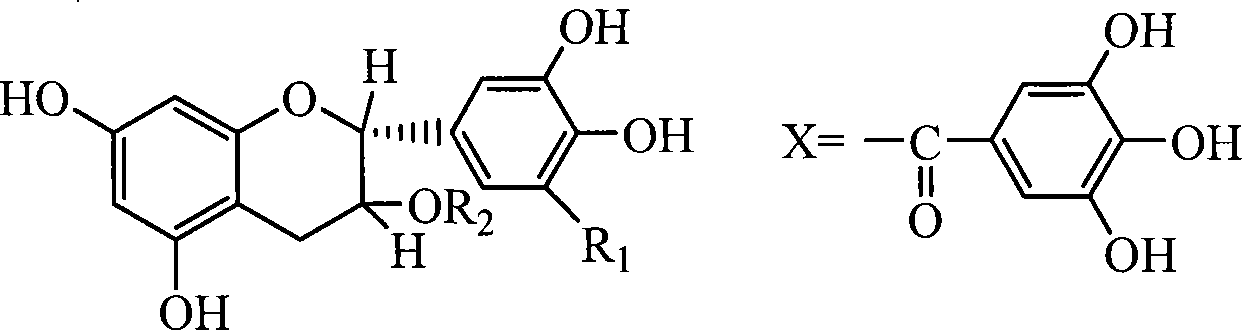

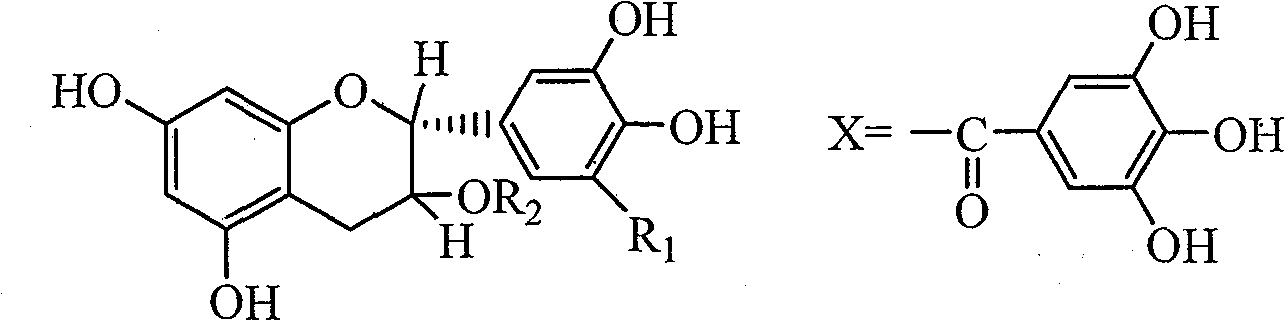

Method for extracting tea-polyphenol and separating monomer EGCG from tea

The invention discloses a method of extracting tea polyphenol and separating monomer EGCG from tea, which is characterized in that: tea and solid phase alkali are mixed according to mass ratio of 1:0.1 to 2 and grinded jointly and mixed evenly before solved using water, stirred and centrifuged; inorganic acid is added into the supernatant to regulate pH value into 1.0 to 8.0, thereby getting sedimentation and filtering; filter residue is monomer EGCG; the filtrate is tea polyphenol solution which is then dried to get crude product of tea polyphenol. The extraction and separation method adopts the mechanical and chemical technique to extract tea polyphenol and separate monomer EGCG. The method of extracting tea polyphenol and separating monomer EGCG from tea has the advantages of new extraction and separation technique without solvent, simple technique, low cost, high yield, high product purity, short production period, no pollution basically and wide industrial prospect for extracting and separating.

Owner:ZHEJIANG UNIV OF TECH

Novel method for extracting tea polyphenol from tea

The invention discloses a novel method for extracting tea polyphenol from tea, and the extraction method is as follows: mixing the tea raw materials and solid phase reagent (containing solid phase reaction reagent and protective agent) in the mass ratio of 1:0.01-2; grinding fully the mixture in a ball mill; taking out the grinded powder; adding water to dissolve; filtering; taking the supernatant; adjusting the pH value to 2.0-6.0; and separating and purifying to obtain the tea polyphenol. The invention has the advantages of environmental friendliness, high purity of products, little residueof solvent, convenient operation, short production cycle, low production cost and the like, thus being a method for extracting tea polyphenol from tea with better promotion and application prospect.

Owner:李奇峰 +1

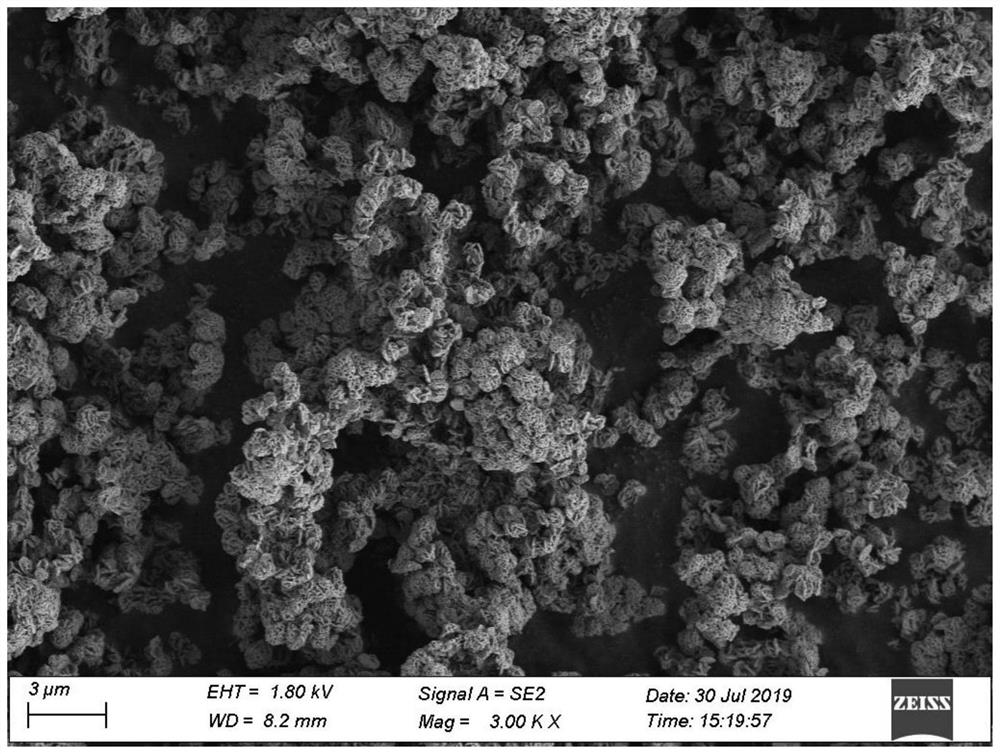

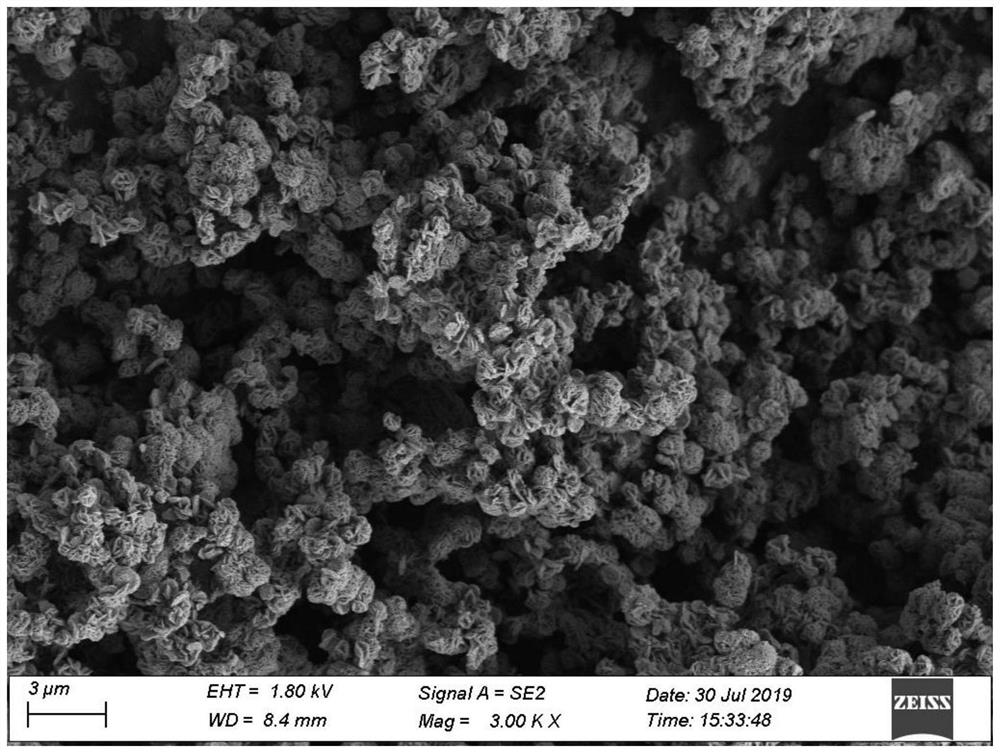

Method for synthesizing iron phosphate by utilizing titanium dioxide byproduct ferrous sulfate

InactiveCN112479174AIncrease concentrationIncrease profitPhosphorus compoundsO-Phosphoric AcidFerrous sulfate iron

The invention discloses a method for synthesizing iron phosphate by utilizing a titanium dioxide byproduct ferrous sulfate. According to the method, the titanium dioxide byproduct ferrous sulfate is used as a raw material, through pretreatment, oxidation of ferrous sulfate in advance, partial substitution of phosphoric acid with sulfuric acid or hydrogen chloride and other inorganic acids to serveas acidizing fluid, generation of Mn3(PO4)2 and Mg3(PO4)2 precipitates in the iron phosphate preparation process is effectively inhibited, therefore the iron phosphate finished product with the low impurity Mn, Mg and S element content is prepared. Meanwhile, the utilization rate of iron ions is increased, and the iron-phosphorus ratio of the prepared iron phosphate is obviously higher than thatof the related technology. According to the method, complex and tedious operations such as extraction, recrystallization and sulfide precipitation are avoided, the titanium dioxide byproduct ferrous sulfate is successfully utilized to prepare the iron phosphate with low impurity content and high iron-phosphorus ratio, the process is simple, and the effect is remarkable.

Owner:HUNAN YACHENG NEW MATERIAL CO LTD

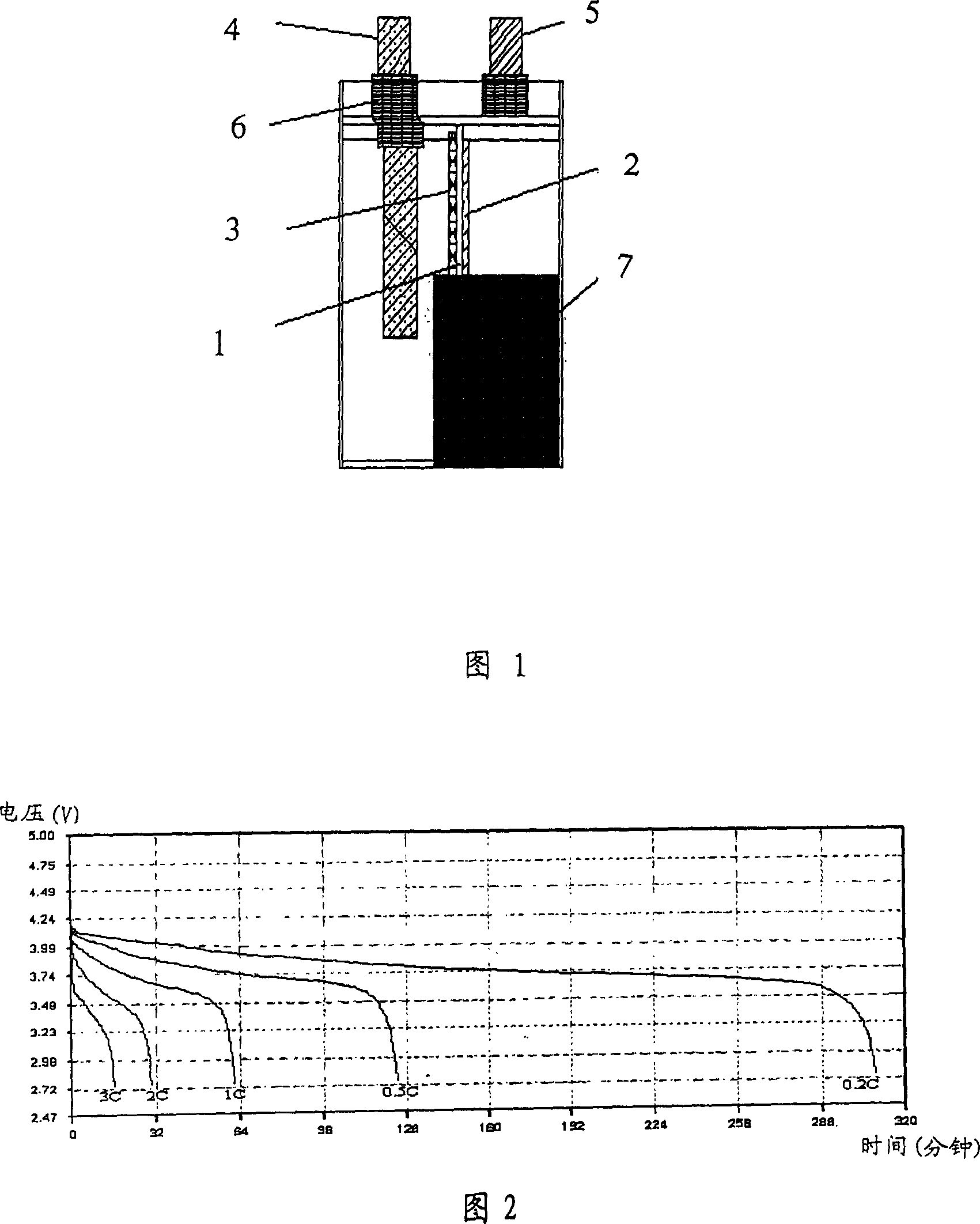

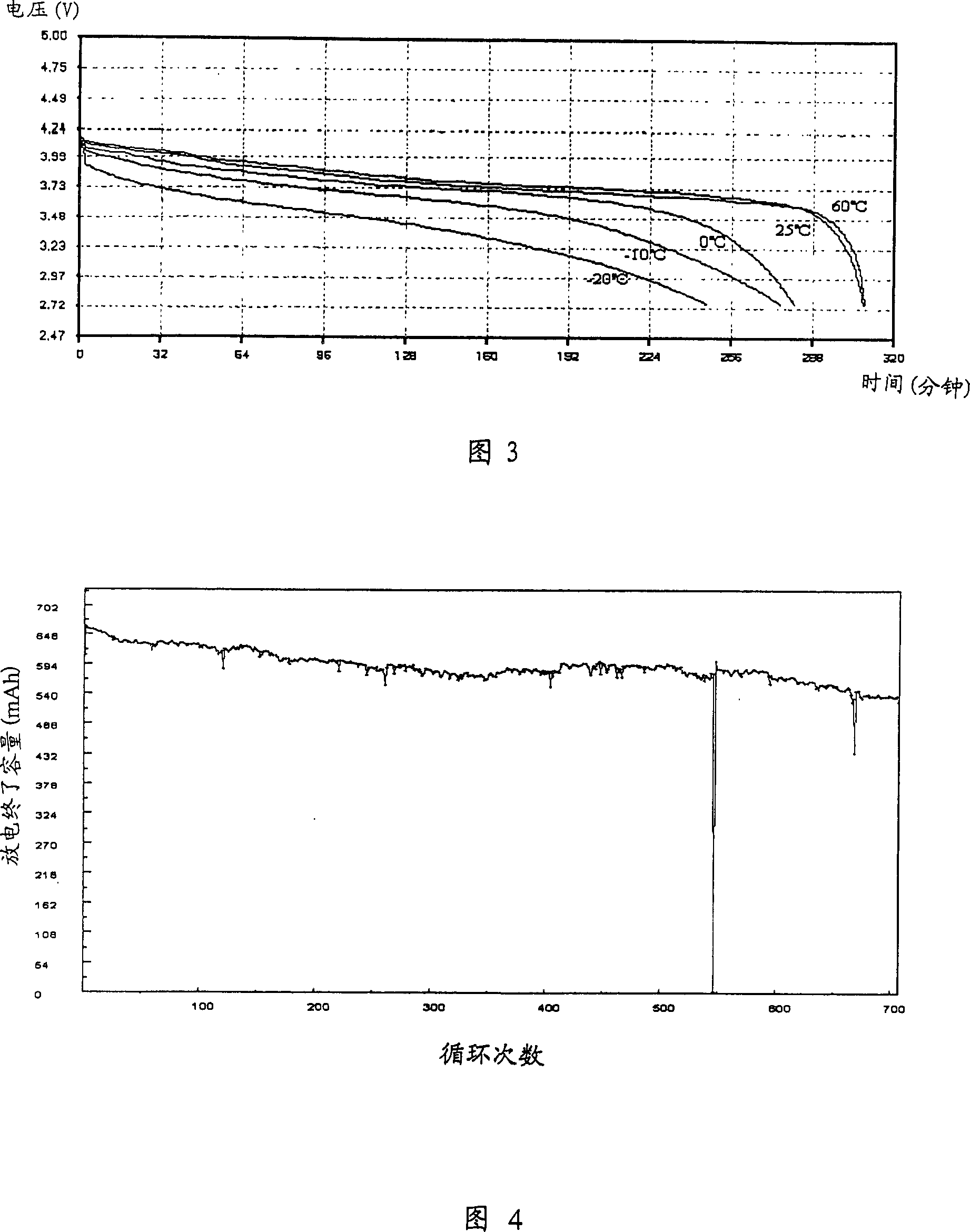

Polymer lithium ion battery preparation technique and products

ActiveCN101098025AReduce manufacturing costRealize large-scale productionFinal product manufactureSecondary cellsBoiling pointSlurry

The invention discloses a novel polymer lithium battery and a relative preparation method. The invention modifies the baffle membrane of general liquid lithium battery, adds chemical crosslink agent monomer with high boiling point into anode slurry and cathode slurry used for preparing liquid lithium battery, fills liquid lithium battery electrolyte with thermal initiator, to process thermal solidification, to obtain a novel polymer lithium battery. The invention can use general production process and device of prior liquid lithium battery, with the support for batch production of polymer battery, while the novel battery has same electric property of liquid battery.

Owner:广东风华新能源股份有限公司

Method for extracting Gingko extract from ginkgo leaves

ActiveCN101449805AEradicate pollutionReduce the impactFood preparationGinkgo bilobaGinkgo leaf extract

The invention discloses a method for extracting ginkgo leaf extract from ginkgo leaves, which includes steps of: mixing ginkgo leaves and solid-phase reagent according to quality ratio of 1 to 0.1-2, fully grinding the mixture in a ball mill, fetching out the grinded powder, adding water to dissolve, filtering, adjusting pH value of supernatant to 2.0-6.0, separating and purifying. The invention has advantages of no pollution, high product purity, less solvent residue, convenient operation, short production period, low production cost, and better popularization and application prospect.

Owner:ZHEJIANG UNIV OF TECH

Method for preparing 6-gingerol and 8-gingerol from ginger

InactiveCN100595183CAvoid the extraction processHigh purityCarbonyl compound separation/purificationSilica gelEthyl acetate

The invention relates to a method for preparing 6- gingerol and 8- gingerol with fresh ginger. It is characterized in that it compries following steps: cutting fresh ginger into sheets, drying at lowtemperature, disintegrating, sifting with screen of 100 order, heating and refluxing and extracting with acetic ester or acetone, or extracting through immersion, extracting for three times, combiningextract liquid, decompressing and recovering solvent, getting extract concretem dissloving it with acetic ester, treating it with chromatographic silica gel and washing it with benzinum purificatum acetic ester with gradient solvent, checking washing process by using TLC, decompressing to recover solvent and getting coarse 6- gingerol and 8- gingerol; washing coarse product with chloroform- carbinol solvent in Sephadex LH20 gel column, checking washing process with TLC, and getting washung liquid containing 6- gingerol and 8- gingerol with higher purity, decompressing to recover solvent and getting pure 6- gingerol and 8- gingerol, checking content with HPLC. The invention is characterized by simple operation, high productivity and production of two kinds of product at the same time.

Owner:NO 411 HOSPITAL OF PLA

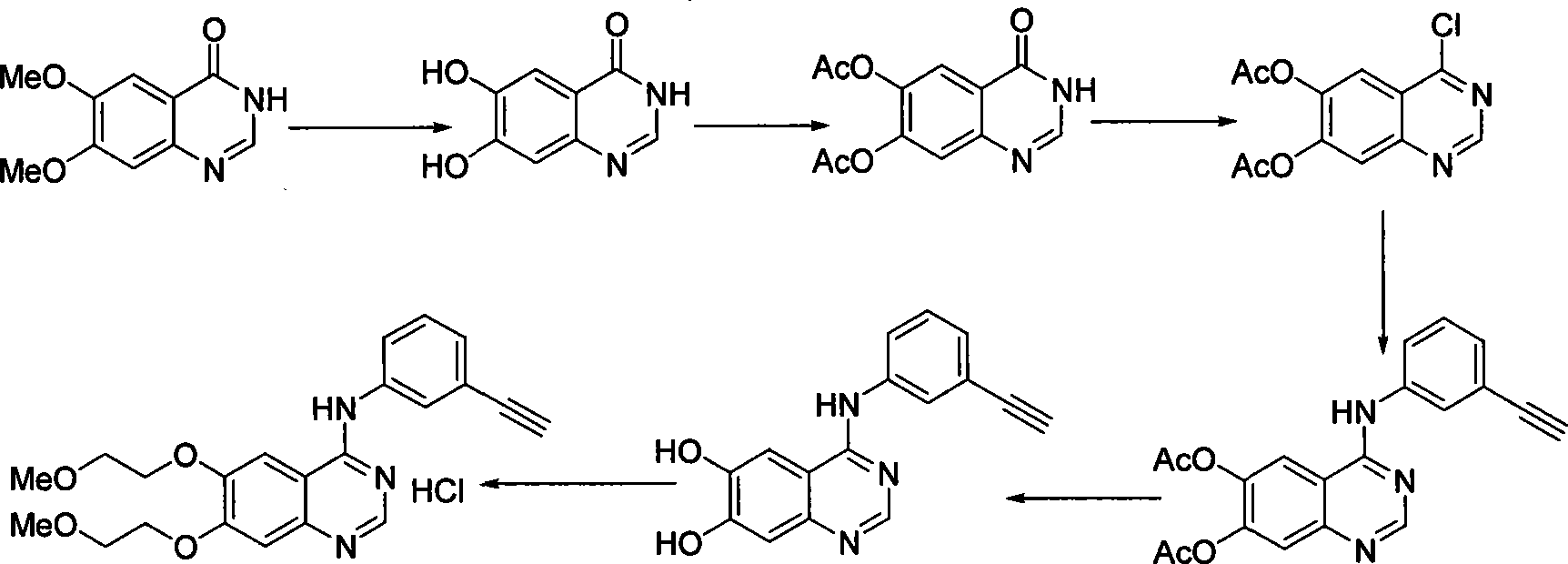

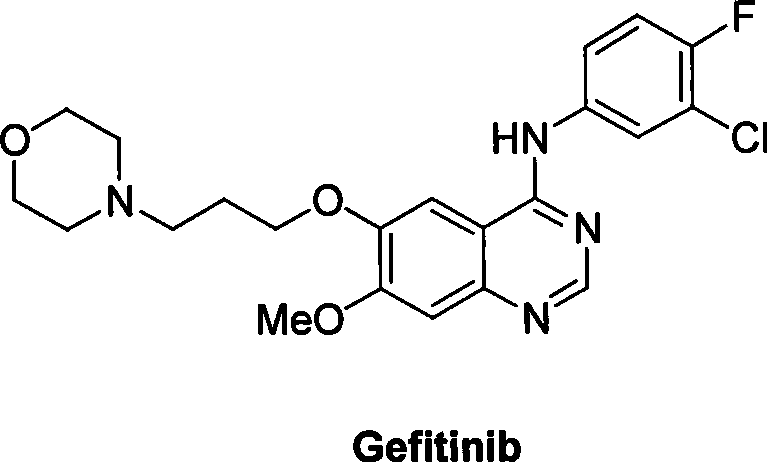

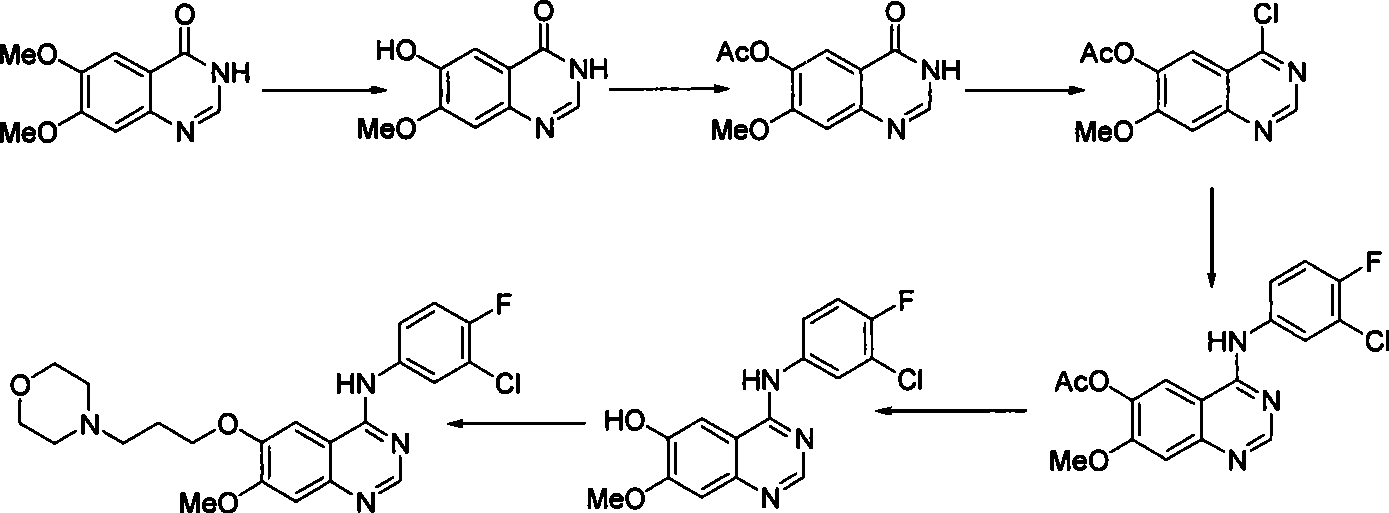

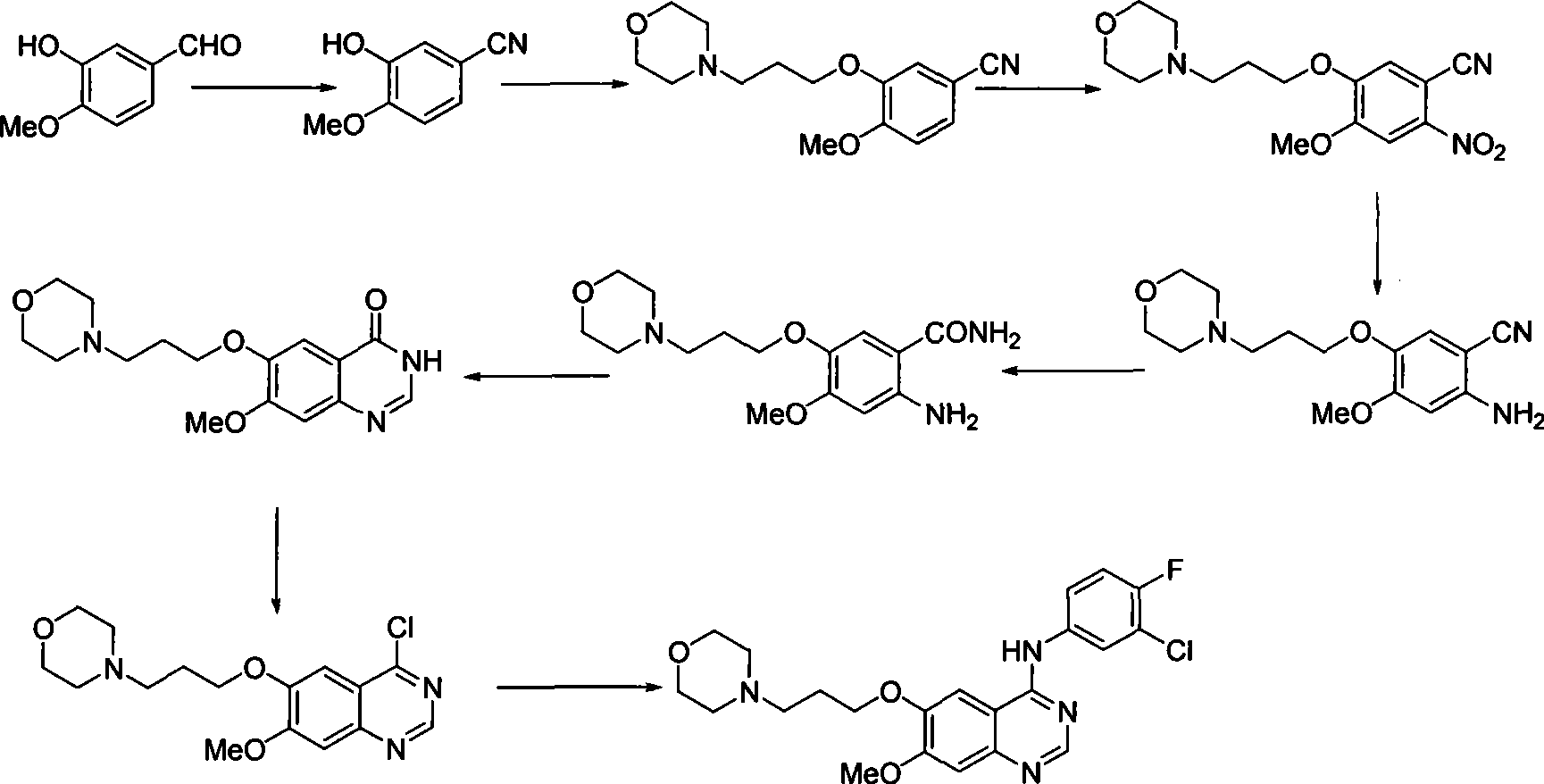

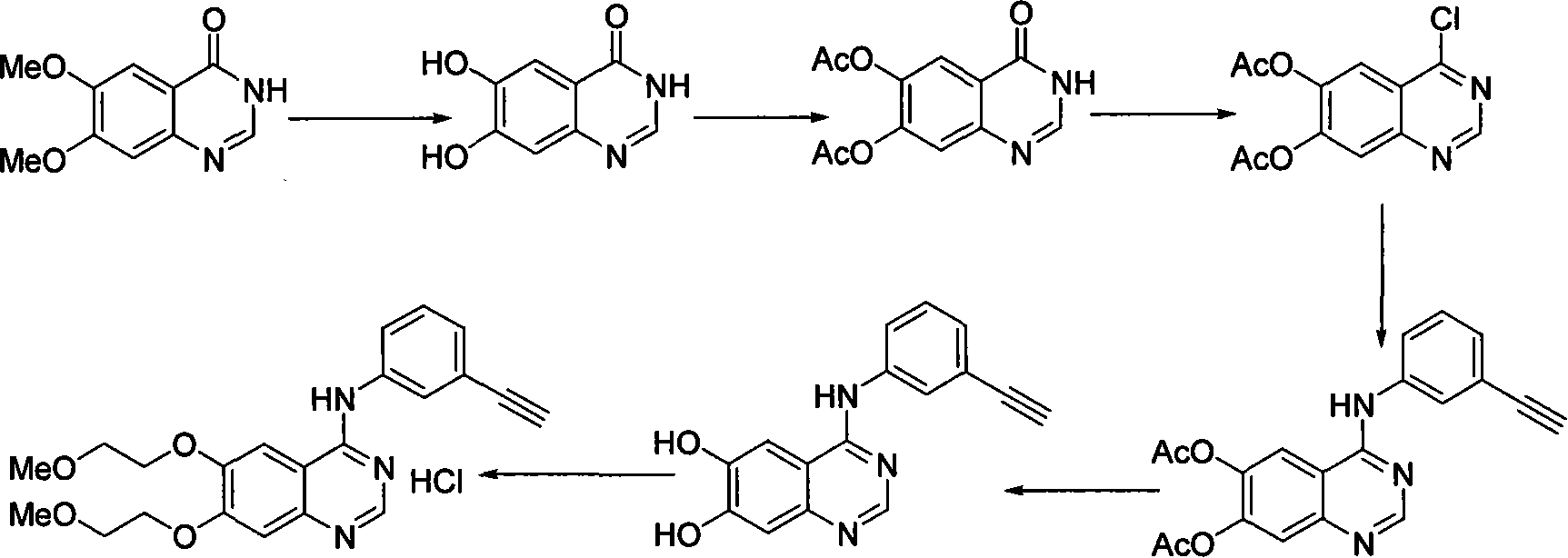

Preparation of gefitinib

ActiveCN101463012AAvoid the risk of overhydrolysisMild reaction conditionsOrganic chemistryMorpholineQuinazoline

The invention discloses a preparation method of gefitinib. In the method, isovanillin is taken as a raw material and synthesized to obtain 7-methoxy-6-(3-morpholine-propoxy)quinazoline-4-one which is directly chloridized to obtain a product, the product is allowed to react with 3-chlorine-4-fluoroaniline to obtain gefitinib hydrochloride which neutralized off hydrochloric acid to obtain the gefitinib. The method has mild reaction condition and is applicable to industrialized production.

Owner:FUJIAN SOUTH PHARMA CO LTD

Method for extracting Gingko extract from ginkgo leaves

The invention discloses a method for extracting ginkgo leaf extract from ginkgo leaves, which includes steps of: mixing ginkgo leaves and solid-phase reagent according to quality ratio of 1 to 0.1-2, fully grinding the mixture in a ball mill, fetching out the grinded powder, adding water to dissolve, filtering, adjusting pH value of supernatant to 2.0-6.0, separating and purifying. The invention has advantages of no pollution, high product purity, less solvent residue, convenient operation, short production period, low production cost, and better popularization and application prospect.

Owner:ZHEJIANG UNIV OF TECH

Method for separating and extracting 1,3-propylene glycol from fermentation broth

ActiveCN105712841ASolve problems that hinder evaporationHigh purityHydroxy compound separation/purification1,3-PropanediolSolvent

The invention discloses a method for separating and extracting 1,3-propylene glycol from fermentation broth. The method comprises the following steps: (1) removing solids in fermentation broth; (2) heating fermentation broth to concentrate and evaporate fermentation broth, and removing precipitated solids to obtain 1,3-propylene glycol concentrated liquid; (3) adding an aromatic aldehyde solvent into the concentrated liquid, and keeping on heating the concentrated liquid until all water is removed to obtain an organic solution containing 1,3-propylene glycol; (4) adding a catalyst into the organic solution to carry out acetalation reactions; (5) distilling the reaction liquid obtained in the step (4) to evaporate unreacted aromatic aldehyde solvent; (6) adding pure water and catalyst into the product obtained in the step (5) to carry out hydrolysis, wherein the aromatic aldehyde solvent forms an organic phase layer, 1,3-propylene glycol is dissolved in the lower-layer water phase, and the water phase layer is filtered to remove catalyst; (7) subjecting the water phase layer obtained in the step (6) to rectification dehydration, and collecting the 1,3-propylene glycol fraction. The method has the advantages that the technology is simple, toxic extracting agent is not used, and the product purity and yield are high.

Owner:CHINA PETROLEUM & CHEM CORP +1

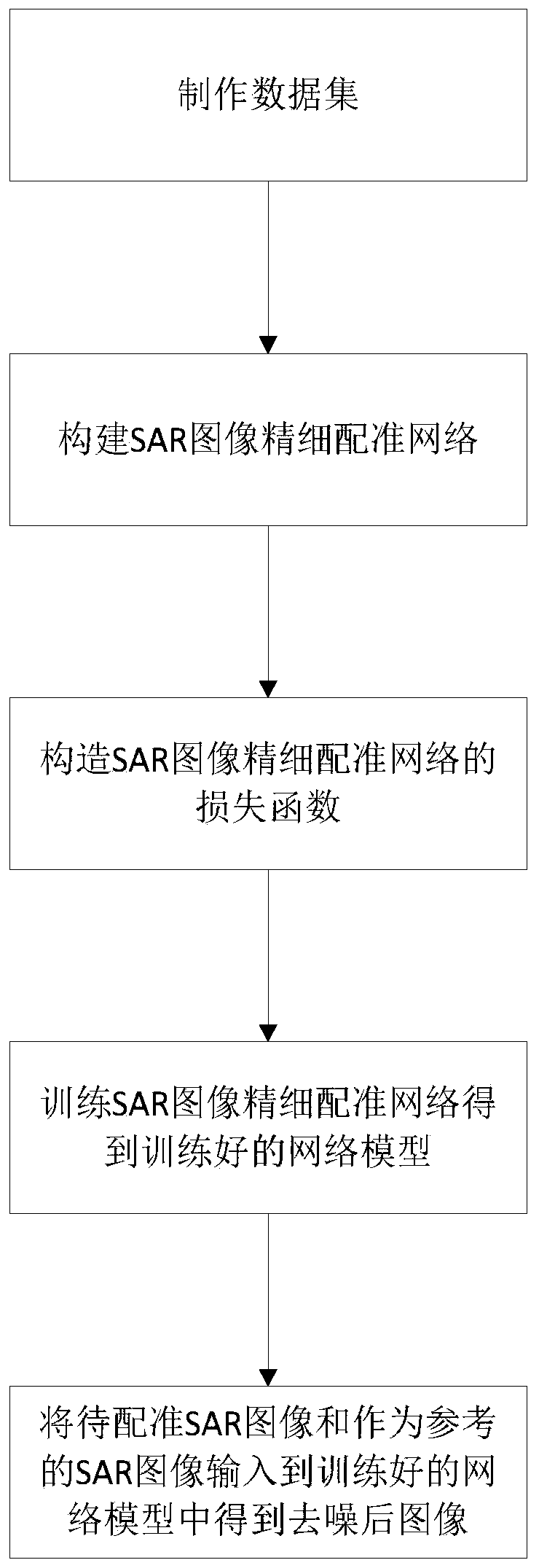

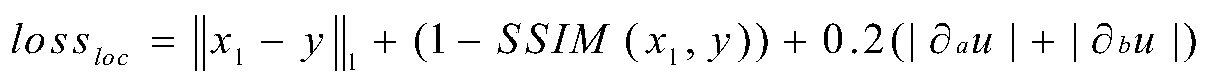

SAR image fine registration method based on deep learning

ActiveCN110728706AImprove registration performanceAvoid the extraction processImage enhancementImage analysisTraining data setsSynthetic aperture radar

The invention discloses an SAR (Synthetic Aperture Radar) image precise registration method based on deep learning, and mainly solves the problems that local distortion cannot be corrected and time isconsumed in a traditional method. According to the implementation scheme, the method comprises the steps of 1) obtaining a training data set; 2) constructing a neural network for SAR image fine registration; 3) constructing a loss function of a neural network model for SAR image fine registration; 4) training a neural network for SAR image fine registration by using the training data set to obtain a trained network model; and 5) inputting the SAR image to be registered and the SAR image as a reference into the trained network model to obtain a registered SAR image. The SAR image registrationmethod can correct the overall deformation and local distortion between the SAR images, improves the registration performance, accelerates the registration speed, and can be used for SAR image fusionand change detection.

Owner:XIDIAN UNIV

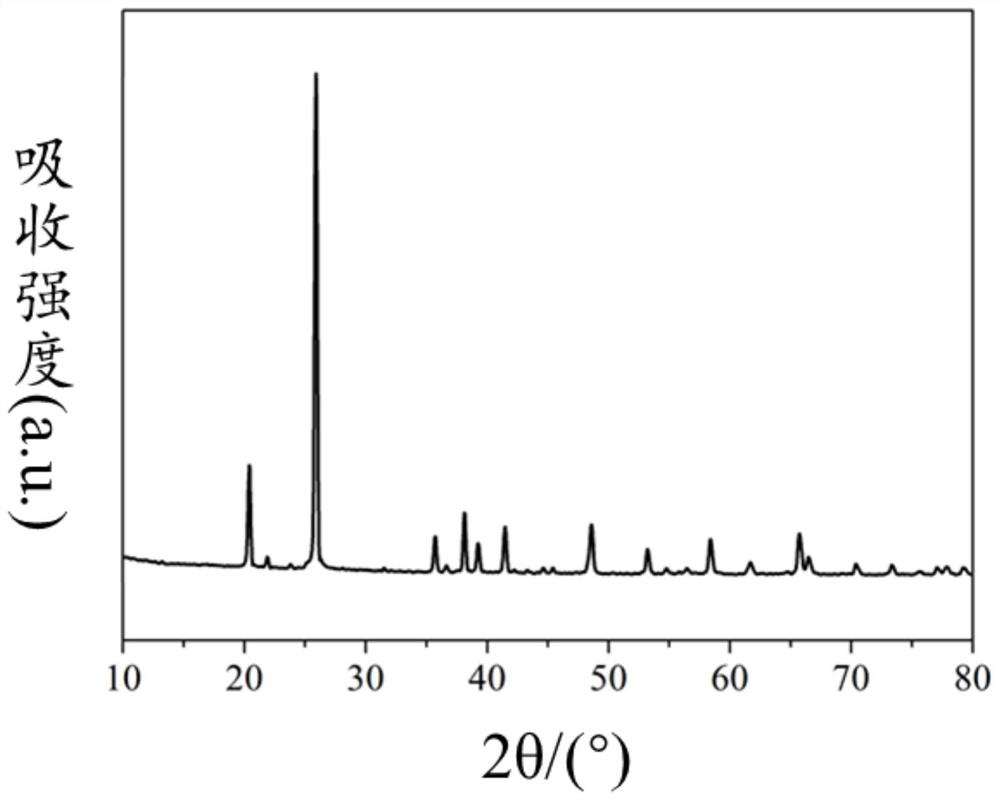

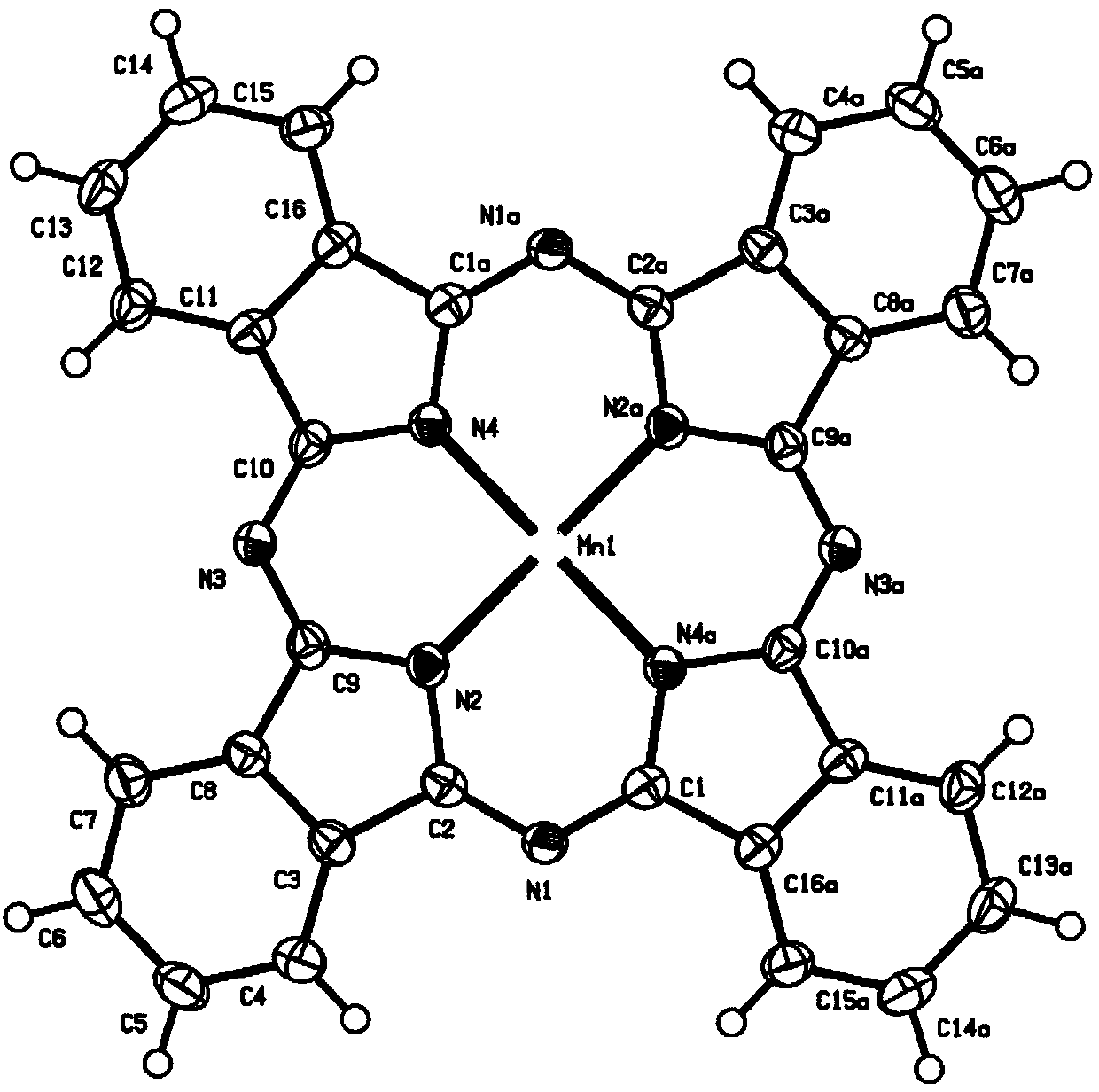

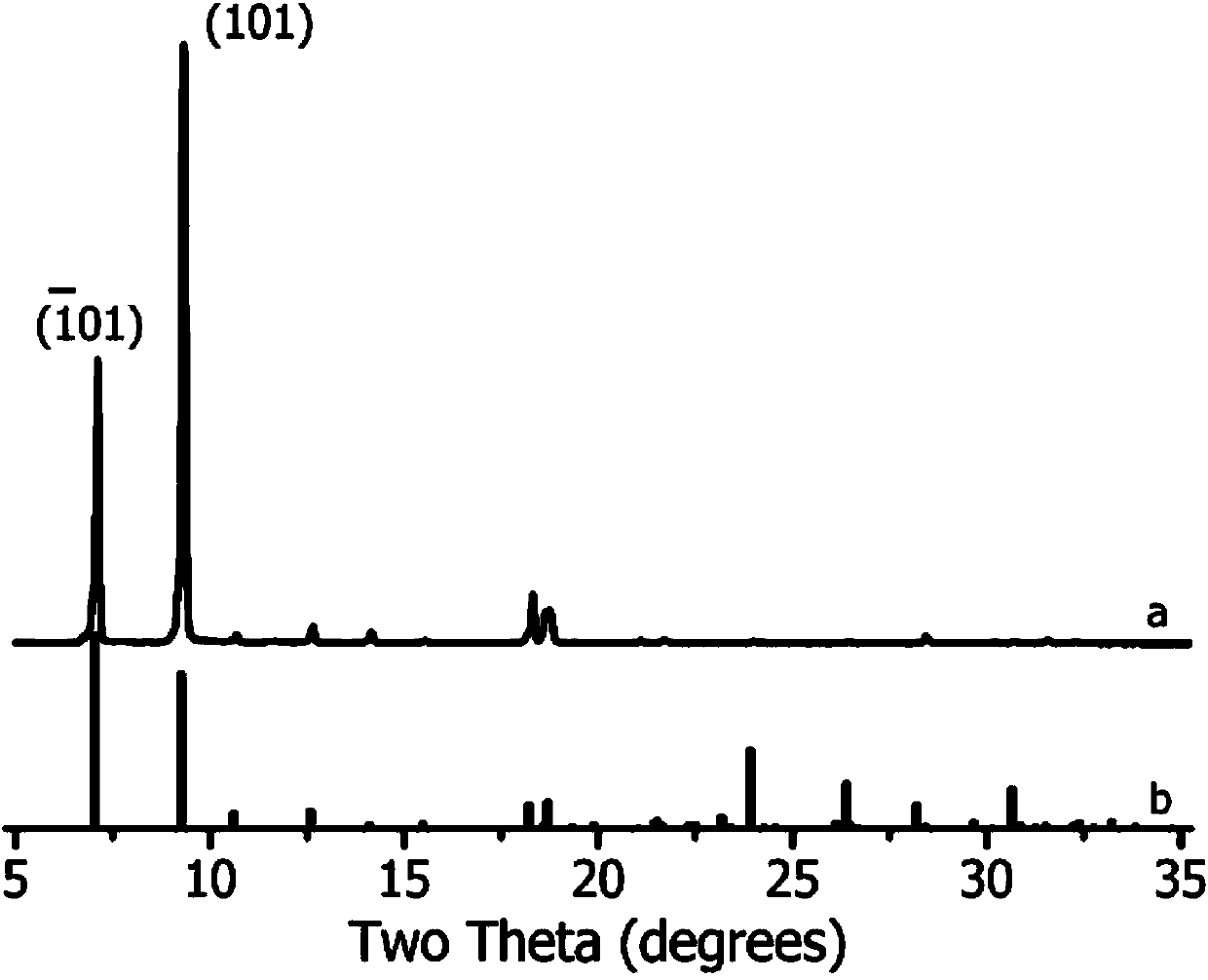

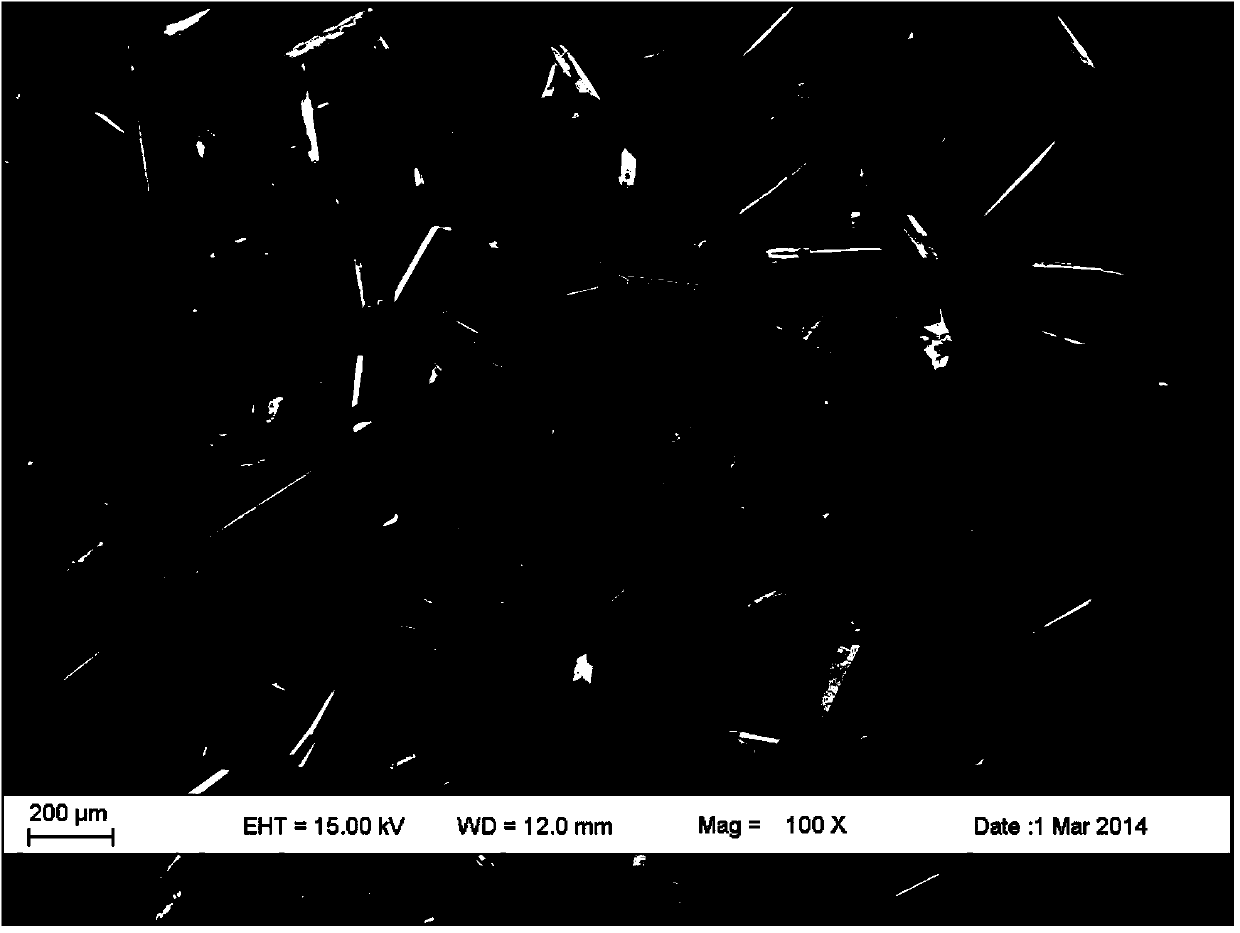

Method for one-step preparation of manganese phthalocyanine crystal through solvothermal reaction

The present invention relates to a method for one-step preparation of a manganese phthalocyanine crystal through a solvothermal reaction. The method comprises: adding phthalonitrile and manganese acetate tetrahydrate to a reaction kettle according to a molar ratio of 4:1, adding an anhydrous ethanol solution, uniformly stirring, sealing the reaction kettle, carrying out a solvothermal reaction for not less than 1 h at a temperature of 180-200 DEG C, stopping heating after completing the reaction, naturally cooling to a room temperature, taking out the prepared sample, adopting hot water and hot ethanol to repeatedly wash the remaining reactant adsorbed on the manganese phthalocyanine crystal surface, and drying to obtain the manganese phthalocyanine crystal. According to the present invention, the manganese phthalocyanine crystal prepared by using the method has the regular crystal appearance, and the whole preparation process has characteristics of simple operation, low cost, no harmful pollutant generation and easily controllable reaction process, and meets actual production requirements.

Owner:XUCHANG UNIV

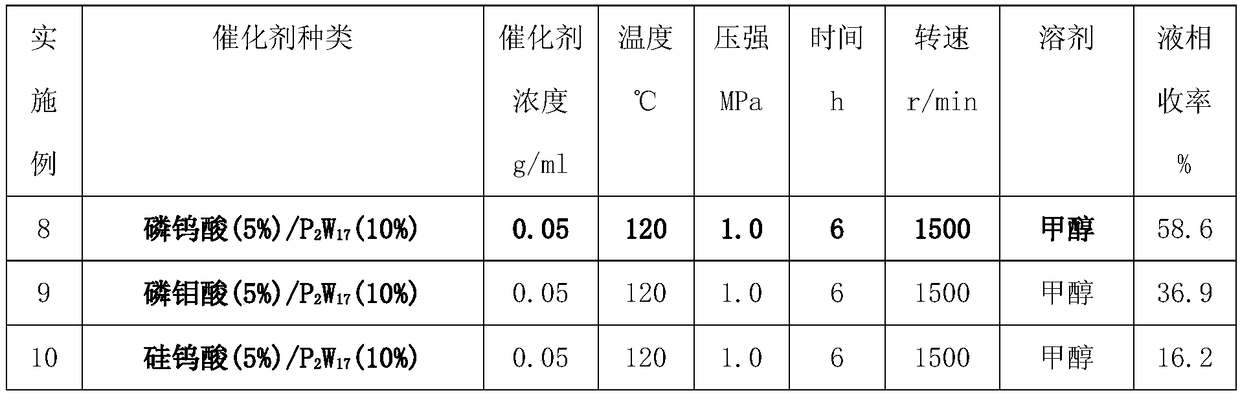

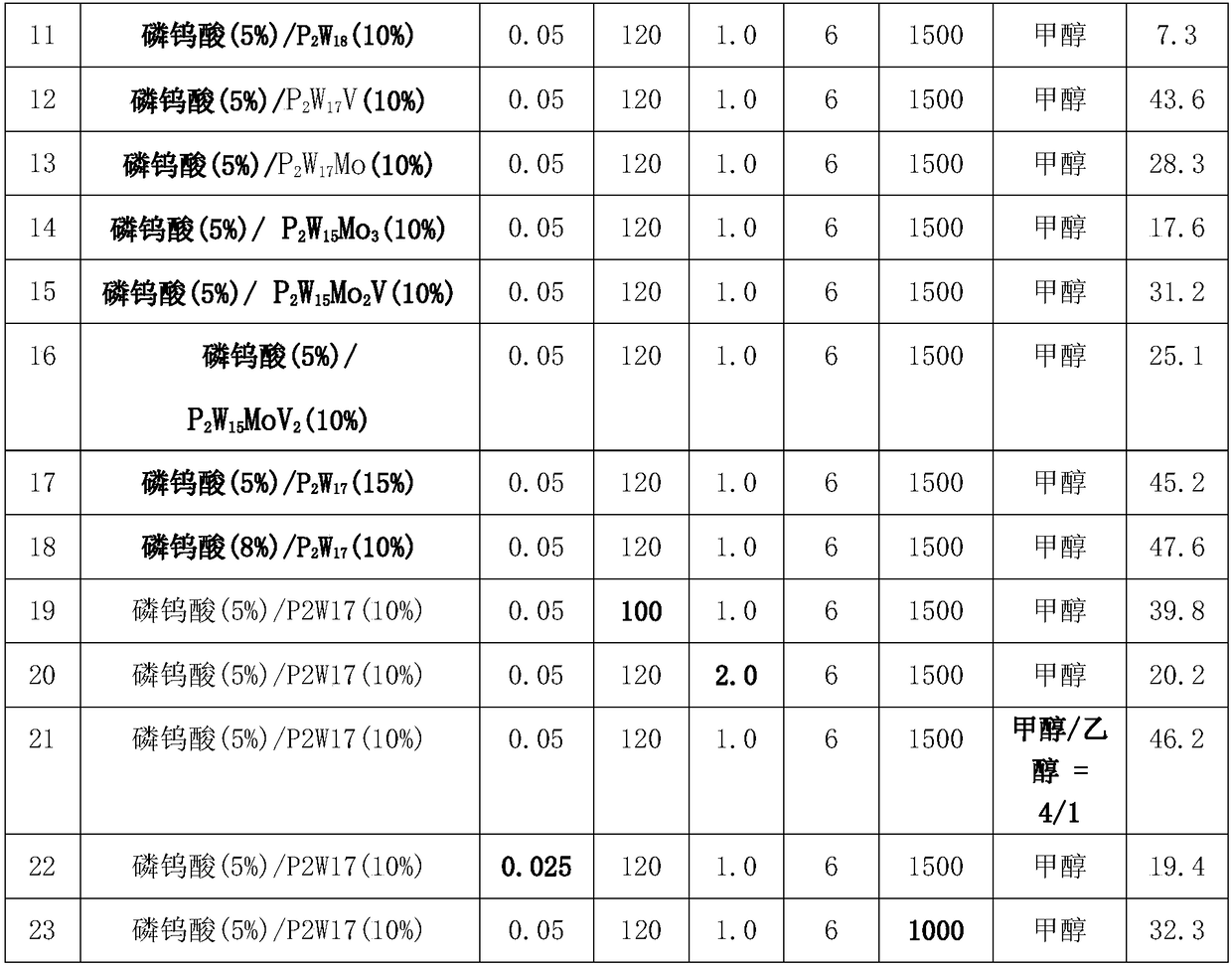

Method for catalytic oxidation degradation of wood chips by novel polyoxometallate

ActiveCN108689819AHigh selectivityFlexible adjustment of activityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPhosphomolybdic acidCatalytic oxidation

The invention provides a method for catalytic oxidation degradation of wood chips by a novel polyoxometallate composite catalyst. The method comprises the following steps: blending wood chips, the catalyst and a solvent, and catalytically oxidatively degrading wood chips in an oxygen atmosphere, at a certain pressure and at a certain temperature to obtain oxidation products. The catalyst is a polyoxometallate / hydrotalcite composite catalyst containing two active centers: one catalytic active center is one or more acids selected from the group consisting of Keggin-type polyoxometallate phosphotungstic acid, silicotungstic acid, phosphomolybdic acid and silicon molybdenum; and the other catalytic active center is selected from one or more of the Dawson type, the notched Dawson type and the heteroatom-substituted Dawson type polyoxometallates. The reaction products include aromatic aldehyde and ketone compounds. Compared with the prior art, the invention relates to a novel polyoxometallate / hydrotalcite composite catalyst for high-efficiency catalytic oxidation degradation of wood chips to generate aromatic aldehyde and ketone compounds. According to the invention, an organic solvent such as alcohol is selected as a reaction medium; wood chips, a catalyst and a small molecule compound are directly separated by centrifugation; and the extraction process is avoided. The conditions are mild, the operation is simple, and the catalyst is cheap and easily available.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

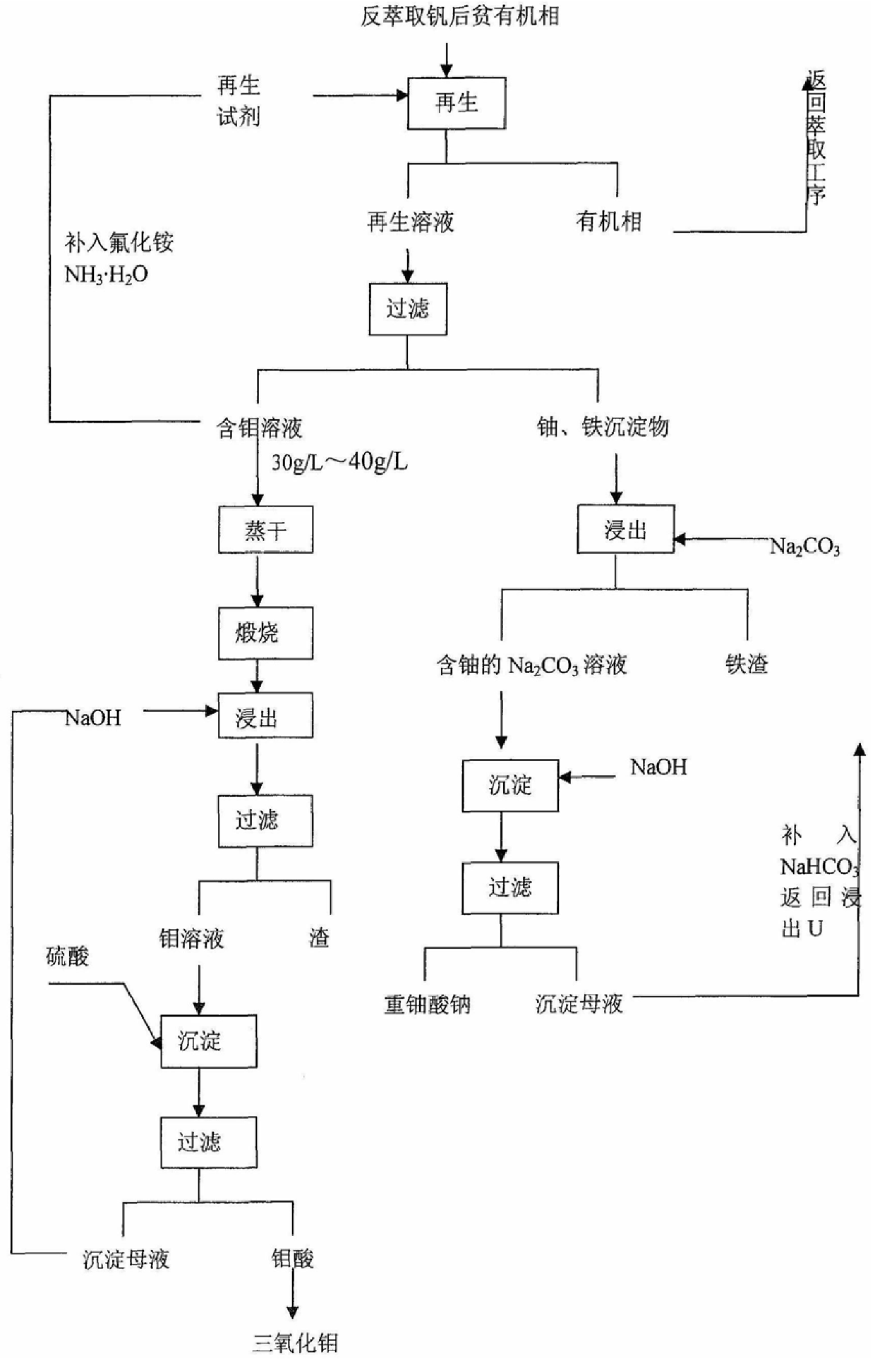

A method for separating ferromolybdenum from vanadium extractant by organic phase regeneration

The invention provides a method for separating uranium, molybdenum and iron from a vanadium extraction agent by utilizing organic phase regeneration. (2) filter the regeneration solution to obtain uranium-containing, iron-containing precipitates and molybdenum-containing solutions; (3) adopt Na CO to the gained uranium-containing and iron-containing precipitates for leaching of solution, filter to obtain uranium-containing Na CO leaching solution and iron slag, and transfer the leaching solution and iron slag to the uranium-containing and iron-containing precipitates. NaOH was added to the Na2CO3 leaching solution of uranium, and Na2U2O7 was prepared by NaOH alkaline uranium precipitation process; for the obtained molybdenum-containing solution, when the molybdenum concentration was greater than 30g / L~40g / L, it was evaporated to dryness and then calcined; the calcined product was leached with NaOH Take, add sulfuric acid to the obtained molybdenum solution, and pyrolyze molybdic acid to prepare molybdenum trioxide. The method effectively regenerates the organic phase, avoids the reduction of the capacity of the extractant due to the accumulation of uranium, molybdenum and iron in the organic phase, recovers the uranium and molybdenum and obtains qualified products, and comprehensively recycles the resources. .

Owner:BEIJING RES INST OF CHEM ENG & METALLURGY

Method for preparing methyl hesperidin

InactiveCN108129531AReduce processingReduce dosageSugar derivativesSulfonic acids salts preparationOrganic solventFiltration

The invention provides a method for preparing methyl hesperidin. The method comprises the following steps: enabling hesperidin as a main raw material to react with trifluoro-methyl methanesulfonate inthe presence of an alkali, performing acidification, filtration and desolvation, further washing with an organic solvent, and filtering, thereby obtaining the methyl hesperidin, wherein the purity ofthe methyl hesperidin is 95% or greater, and the yield of the methyl hesperidin is greater than 90%. The byproduct trifluoro-mesylate is a raw material for synthesizing trifluoromethanesulfonic acid.Compared with the prior art, the method for preparing the methyl hesperidin is safe in reaction process, simple and convenient to operate, efficient and environmental-friendly and applicable to industrial production.

Owner:HANDAN ZHAODU FINE CHEM CO LTD

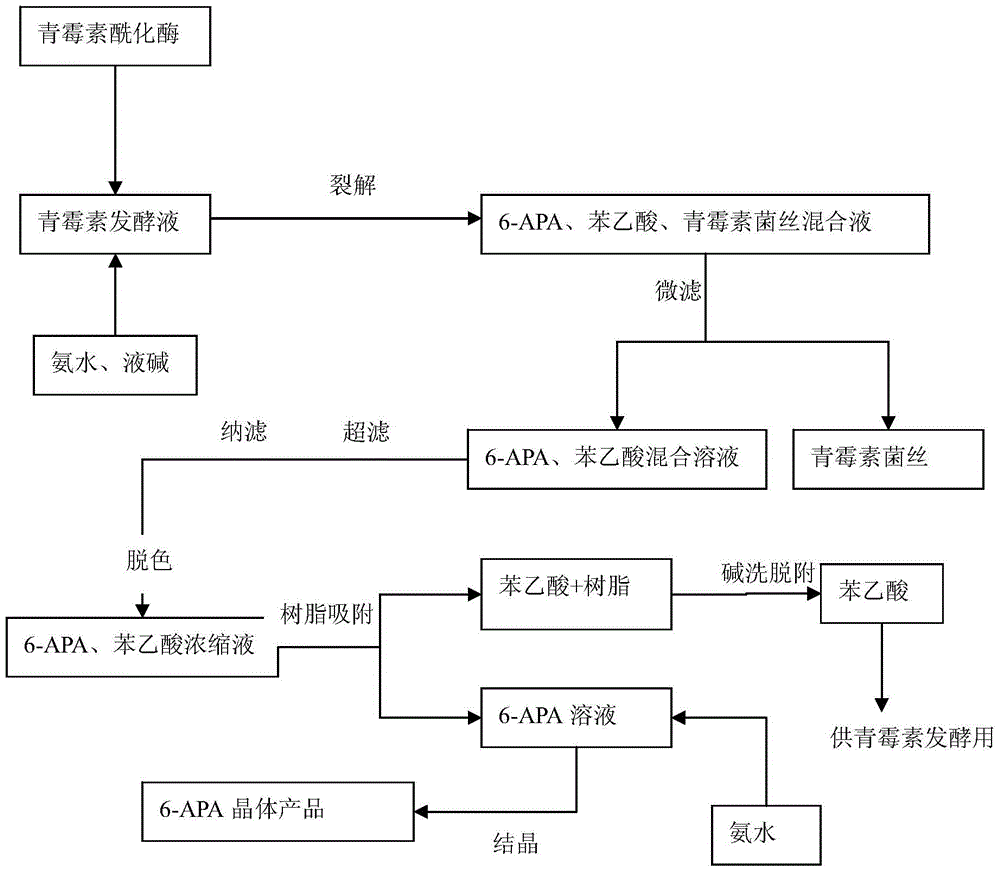

A method for directly preparing 6-aminopenicillanic acid from penicillin fermentation broth

The invention belongs to the biological medicine field, and relates to a method using penicillin fermentation liquor for direct preparation of 6-aminopenicillanicacid. Preparation methods of the 6-aminopenicillanicacid in the prior art have the technical problems of large environmental pollution, high energy consumption, low product yield and the like; in order to overcome the technical problems, the invention provides the method using the penicillin fermentation liquor for direct preparation of the 6-aminopenicillanicacid, the method avoids use of butyl acetate, n-butyl alcohol and other organic solvents, improves the product yield, reduces the energy consumption in the process of preparation, is a green energy-saving 6-aminopenicillanicacid production method, and is very suitable for popularization and application in industry.

Owner:TIANJUSHI ENG TECH GROUP +1

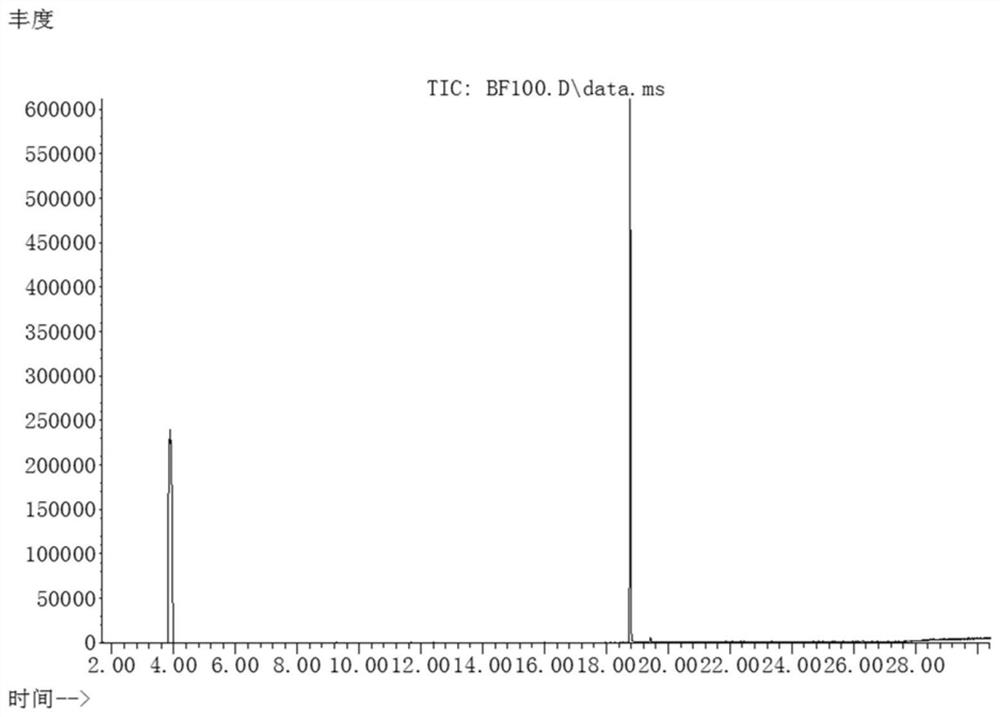

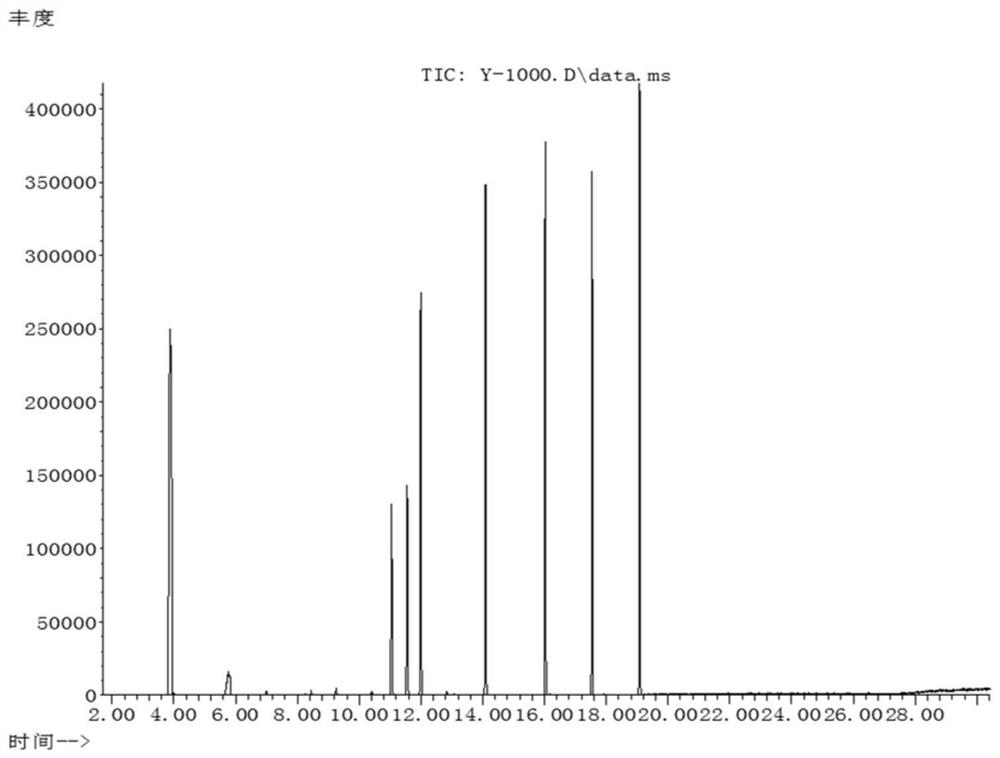

Method for rapidly determining content of phenol in wastewater through purge and trap-gas chromatography-mass spectrometry

PendingCN114216973APrevent purityAvoid askingComponent separationO-Phosphoric AcidIndustrial waste water

The invention relates to a method for rapidly determining the content of phenol in wastewater by purge and trap-gas chromatography-mass spectrometry, which comprises the following steps: 1) collecting a wastewater sample, adding phosphoric acid, and adjusting the pH value of the wastewater sample to weak acidity; (2) purging phenol in the wastewater sample by using a purging and trapping sample injector, trapping the phenol by using a trapping trap, and then analyzing the phenol to enter a gas chromatograph-mass spectrometer; and (3) carrying out qualitative and quantitative analysis on the phenol trapped by the trapping trap by using a gas chromatograph-mass spectrometer. Compared with the prior art, the method for measuring the phenol content in the industrial wastewater is simple, rapid, efficient and accurate, the wastewater with complex components and high organic matter concentration can be directly purged, the pretreatment processes such as separation and purification are omitted, an organic solvent is not needed for extraction, the detection cost is reduced, and the method is suitable for large-scale popularization and application. The time for detecting a group of water samples is shortened from two hours to about 30 minutes, and the detection limit is 0.01-1 mg / L.

Owner:SHANGHAI INST OF TECH +1

Preparation of erlotinid hydrochloride

ActiveCN101463013BShort synthetic routeAvoid the risk of overhydrolysisOrganic chemistryHydroxy groupPharmacology

The invention discloses a preparation method of erlotinib hydrochloride. The method is characterized by taking 3,4-dihydroxybenzaldehyde as a raw material, synthesizing to obtain 6,7-dimethoxyquinazoline-4-one, directly chloridizing to obtain a product, allowing the product to react with meta-ethynylaniline to obtain the erlotinib hydrochloride. The method has mild reaction condition and is applicable to industrialized production.

Owner:FUJIAN SOUTH PHARMA CO LTD

Preparation method of ceftiofur hydrochloride

The invention provides a preparation method of ceftiofur hydrochloride, which comprises the following steps: step 1, preparation of a ceftiofur hydrochloride crude product: adding 7-ACF into an organic solvent, dropwise adding organic alkali for dissolving, then adding AE active ester, carrying out heat preservation reaction, after the reaction is finished, adding hydrochloric acid to adjust the pH, and filtering to obtain the ceftiofur hydrochloride crude product; and 2, refining the ceftiofur hydrochloride, adding the crude ceftiofur hydrochloride product obtained in the step 1 into water, adding alkali to adjust the pH value, dissolving, filtering by adding activated carbon, adding hydrochloric acid to adjust the pH value, dropwise adding an organic solvent into the filtrate, crystallizing, filtering and drying to obtain a white product, namely the ceftiofur hydrochloride. In the preparation process, the solvent amount is small, the solvent can be recycled and reused, waste water is little, the method is more environmentally friendly, the purity of the product ceftiofur hydrochloride reaches 99.0% or above, the reaction yield is high, and the appearance color is good; the method is simple in preparation process, short in production period, high in product purity, high in yield, economical and environment-friendly.

Owner:河南立诺制药有限公司

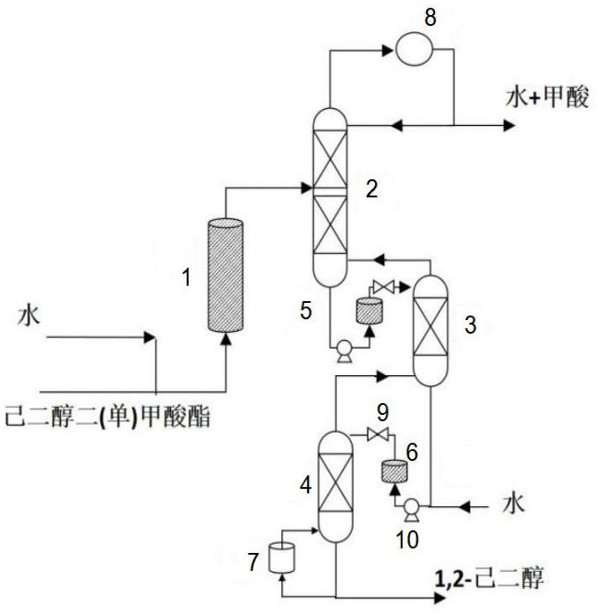

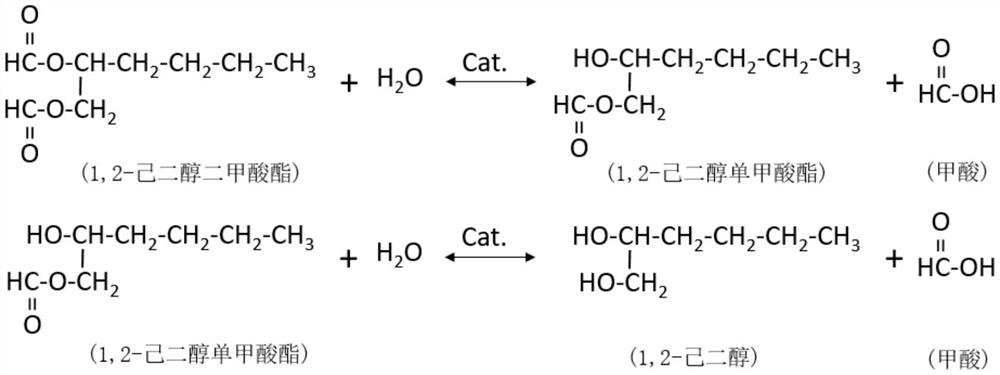

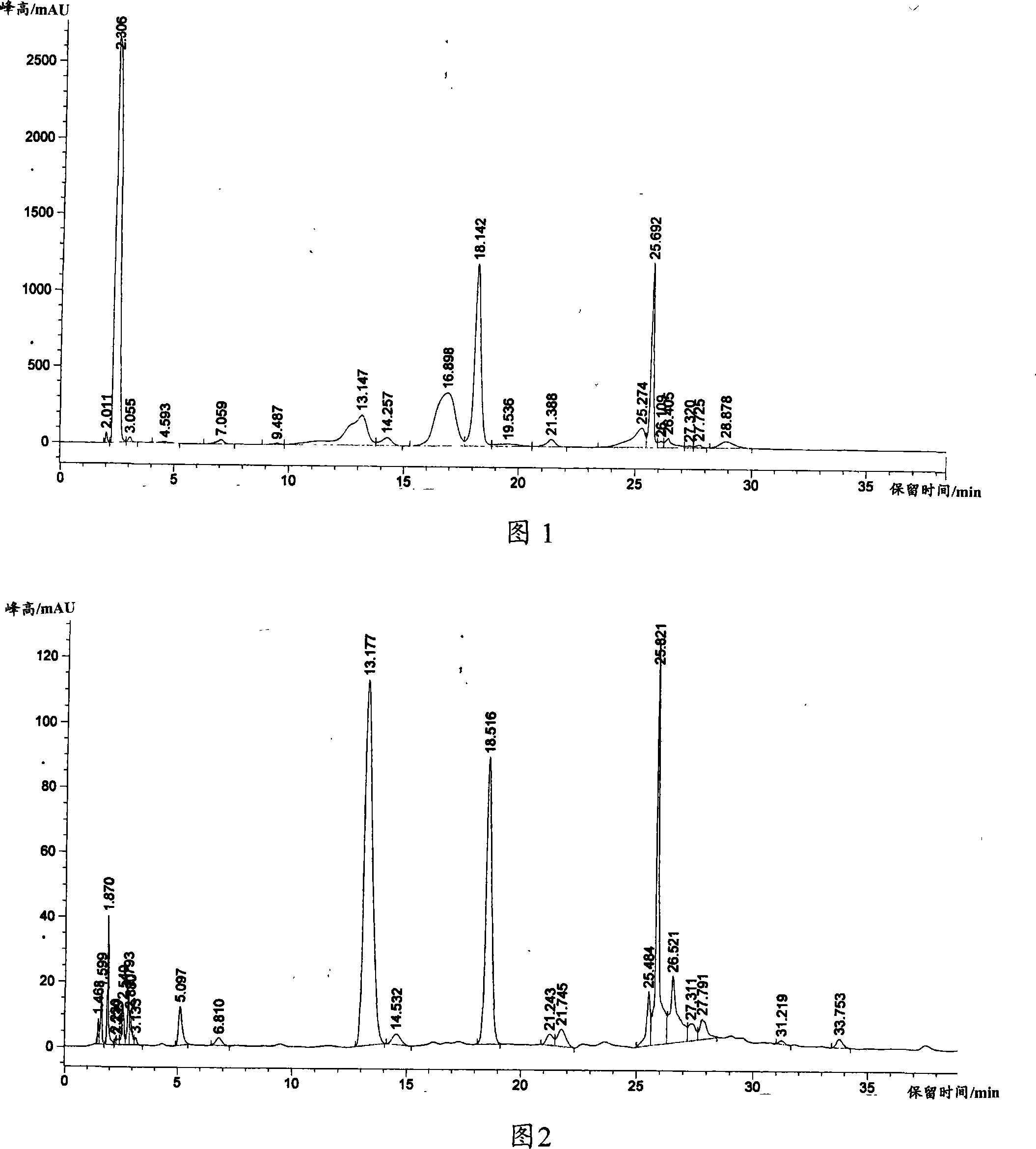

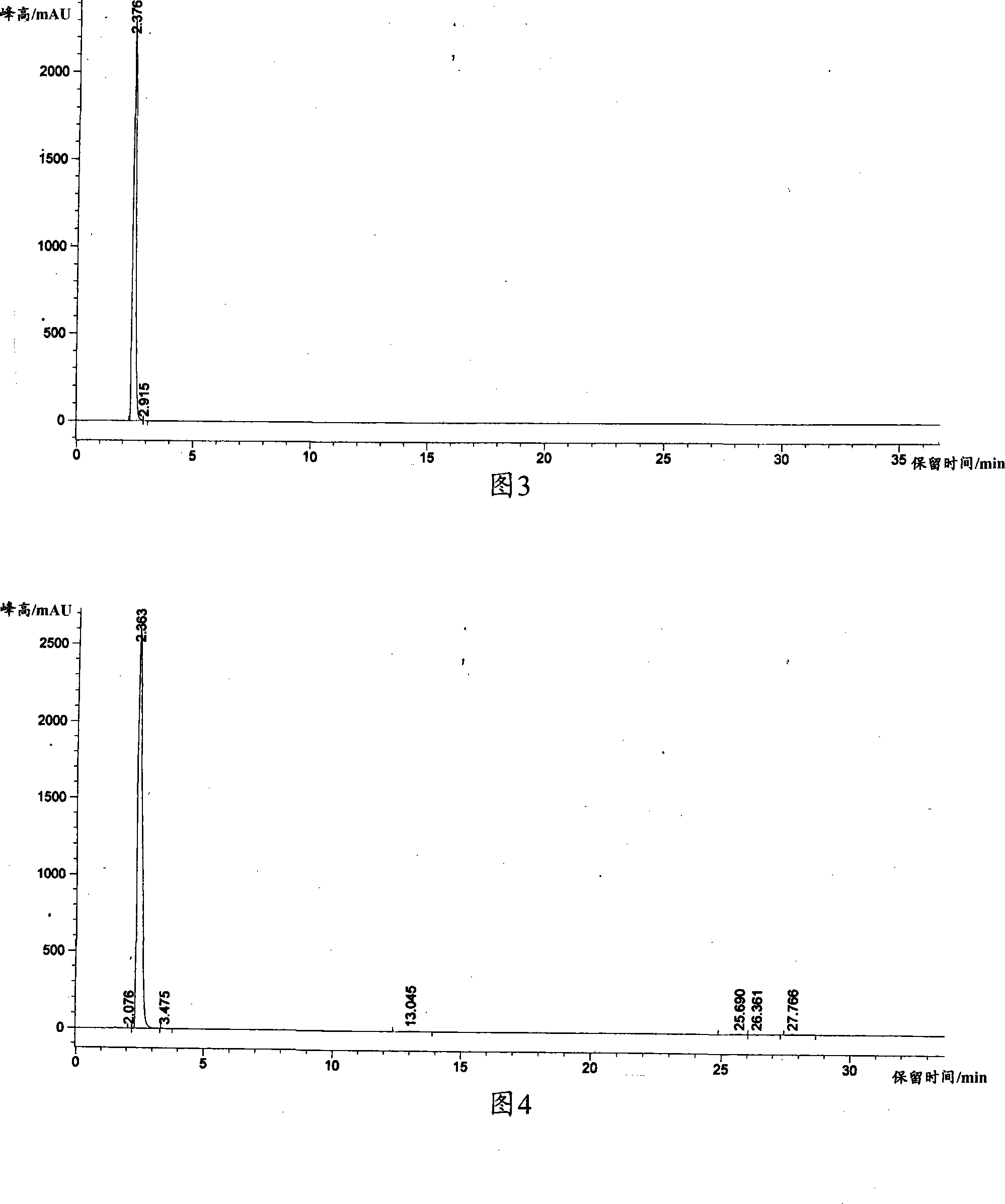

Method for producing 1, 2-hexanediol and device system thereof

ActiveCN111704527ASimple processEasy for industrialized continuous productionOrganic compound preparationCatalystsPtru catalystPartial hydrolysis

The invention belongs to the technical field of organic synthesis application, and particularly relates to a method for producing 1, 2-hexanediol and a device thereof. According to the method, 1, 2-hexanediol diformate or 1, 2-hexanediol monoformate is taken as a raw material, water and 1, 2-hexanediol diformate (or 2-hexanediol monoformate) are mixed in proportion and then fed into a pre-reactorfilled with an acidic resin catalyst for partial hydrolysis, and a pre-reaction solution is fed into a reaction and rectification coupled tower device to realize complete hydrolysis. An aqueous solution containing formic acid is extracted from the top of the tower device, and a 1, 2-hexanediol crude product is obtained from a tower kettle at the bottom. The method is mild in reaction condition, simple in process and easy for industrial continuous production, the one-way hydrolysis rate of the 1, 2-hexanediol di (mono) formate is higher than 99%, and the 1, 2-hexanediol product with the purityhigher than 99.5% can be obtained after simple refining.

Owner:FUZHOU UNIV

Method for extracting tea-polyphenol and separating monomer EGCG from tea

The invention discloses a method of extracting tea polyphenol and separating monomer EGCG from tea, which is characterized in that: tea and solid phase alkali are mixed according to mass ratio of 1:0.1 to 2 and grinded jointly and mixed evenly before solved using water, stirred and centrifuged; inorganic acid is added into the supernatant to regulate pH value into 1.0 to 8.0, thereby getting sedimentation and filtering; filter residue is monomer EGCG; the filtrate is tea polyphenol solution which is then dried to get crude product of tea polyphenol. The extraction and separation method adoptsthe mechanical and chemical technique to extract tea polyphenol and separate monomer EGCG. The method of extracting tea polyphenol and separating monomer EGCG from tea has the advantages of new extraction and separation technique without solvent, simple technique, low cost, high yield, high product purity, short production period, no pollution basically and wide industrial prospect for extractingand separating.

Owner:ZHEJIANG UNIV OF TECH

Method for recycling spent vanadium catalyst through phosphoric acid solution

ActiveCN111304451AAvoid the extraction processAvoid strippingAlkali metal silicatesProcess efficiency improvementPotassium silicateO-Phosphoric Acid

The invention discloses a method for recycling a spent vanadium catalyst through a phosphoric acid solution. The method comprises the steps: after the spent vanadium catalyst reacts with the phosphoric acid solution, filtering and separation are conducted to obtain filtrate I and filter residue I; the filtrate I is subjected to still standing and filtered to obtain filtrate III and primary precipitate I, and the filtrate III is subjected to still standing, filtered and separated to obtain secondary precipitate II and filtrate IV; a potassium oxalate solution is added into the filter residue Ifor sufficient reacting, still standing and filtering are conducted, a solid is washed with water for 2-3 times, and filtrate II and filter residue II are obtained; the filtrate II is returned to replace the potassium oxalate solution, and when the content of vanadium in a solution exceeds 40 g / L, leaching is stopped to obtain a mixed solution; after the mixed solution is treated, potassium sulfate and filtrate V are obtained; after the filtrate V is treated, vanadium pentoxide is obtained; after the primary precipitate I is treated, potassium vanadium phosphate is obtained; and the filter residue II is treated to obtain potassium silicate. According to the method, at the normal temperature, the recovery rate is high, the process is simple, and energy consumption is low.

Owner:贵州威顿催化技术有限公司

A kind of separation and extraction method of 1,3-propanediol in fermented liquid

ActiveCN105712842BSolve problems that hinder evaporationHigh purityOrganic compound preparationHydroxy compound preparationDistillation1,3-Propanediol

The invention discloses a method for separating and extracting 1,3-propylene glycol from fermentation broth. The method comprises the following steps: (1) separating 1,3-propylene glycol fermentation broth to remove insoluble solids; (2) adding an aromatic aldehyde solvent, an acetalation catalyst, and a phase transfer catalyst into the fermentation broth, and carrying out acetalation reactions of 1,3-propylene glycol under stirring; (3) allowing the reaction liquid to stand still for a while to carry out layering, wherein the aromatic aldehyde solvent and acetalation products are in the upper layer (organic phase layer), and the lower layer (water phase layer) is removed through phase separation; (4) subjecting the obtained organic phase layer to distillation to obtain acetalation products; (5) adding pure water and a hydrolysis catalyst to carry out hydrolysis of the acetalation products, allowing the system to stand still for a while to carry out layering, wherein the aromatic aldehyde solvent is the organic phase layer, and 1,3-propylene glycol enters the water phase layer, and filtering the water phase layer or subjecting the water phase layer to centrifugation to remove the catalyst; (6) subjecting the obtained water phase layer to rectification and dehydration, and carrying out rectification to collect the 1,3-propylene glycol fraction. The extraction method has the advantages that the technology is simple, no toxic extracting agent is used, and the purity and yield of product are high.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrolysis-resistant glass fiber reinforced polypropylene composite material for automobile kettle and its preparation process

ActiveCN103044774BOvercoming the disadvantage of insufficient heat resistanceImprove heat resistancePolypropylene compositesElastomer

The invention discloses a hydrolysis-resistant glass fiber reinforced polypropylene composite material for a car water kettle and a preparation process thereof. The composite material comprises the following components in percentage by weight: 48-86% of polypropylene, 2-6% of metallocene polypropylene elastomer, 0-2% of a thermal stabilizer, 0-2% of an additive, 0-2% of a nucleating agent, 2-10% of a compatilizer and 10-30% of chopped glass fiber. The metallocene polypropylene elastomer is adopted to modify polypropylene, so that the shortcoming of poor heat resistance of polypropylene can be overcome and the welding performance of polypropylene at a welding interface is enhanced; and in addition, the adopted thermal stabilizer can be used for inhibiting degradation in the processing process and preventing hot water from extracting an antioxidant system so as to effectively improve the ageing resistance of the water kettle material. The prepared composite material is excellent in heat resistance, high in rigidity, excellent in hydrolysis resistance and good in bonding performance, and satisfactorily meets the production demand of the car water kettle.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD

A method for separating and extracting 1,3-propanediol from fermentation broth

ActiveCN105712841BSolve problems that hinder evaporationHigh purityHydroxy compound separation/purificationDistillationEvaporation

Owner:CHINA PETROLEUM & CHEM CORP +1

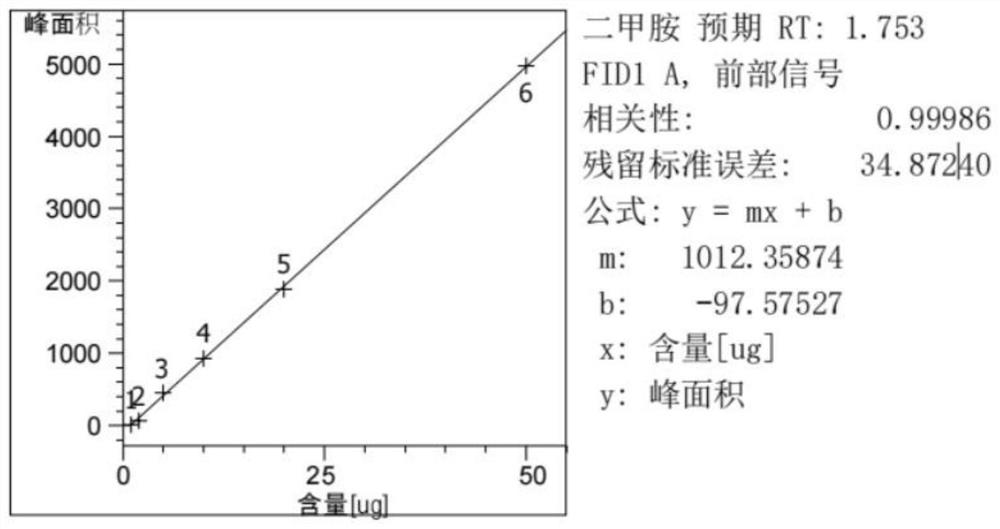

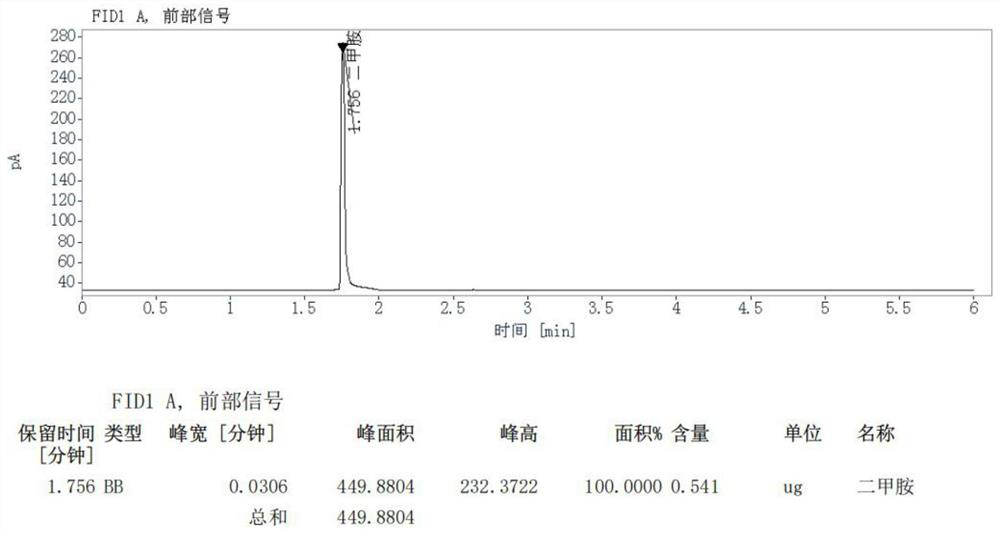

Method for detecting content of N, N-dimethylformamide in solid waste

PendingCN113777193AReduce consumptionStrong chemical polarityComponent separationAlkaline waterAqueous solution

The invention discloses a method for detecting the content of N, N-dimethylformamide in solid waste. The method comprises the following steps: dispersing the solid waste in an alkaline solution to obtain a mixed solution, heating the mixed solution to obtain a dimethylamine solution, detecting the content of dimethylamine in the dimethylamine solution, and calculating the content of N, N-dimethylformamide in the solid waste according to the content of dimethylamine. By adopting the technical scheme, the N, N-dimethylformamide is heated in the alkaline aqueous solution to derive and decompose the dimethylamine, and the content of the N, N-dimethylformamide in the solid waste is obtained by indirectly measuring the content of the dimethylamine, so that the process of extracting by using a large amount of solvent is avoided, the test flow is simplified, the consumption of an organic reagent is reduced, and the cost is reduced.

Owner:SHANDONG ACAD OF ENVIRONMENTAL SCI CO LTD +1

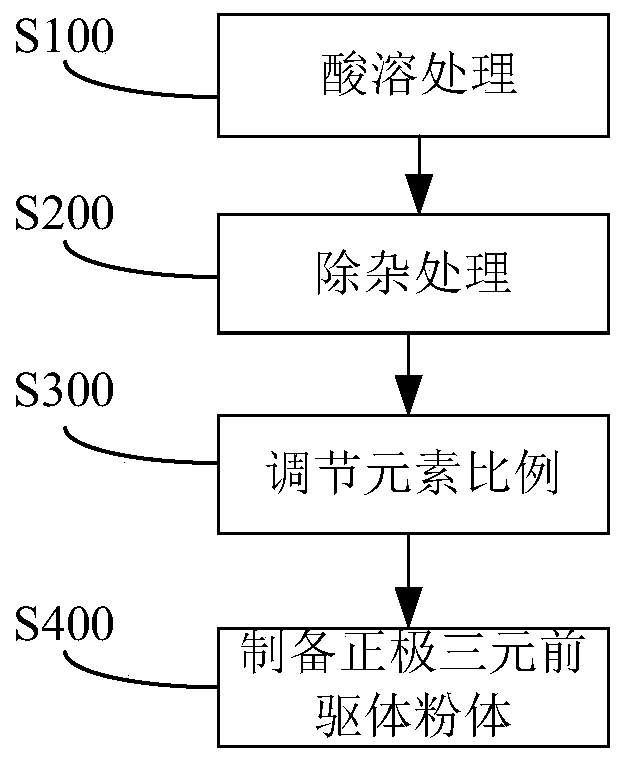

Method for preparing positive electrode ternary precursor powder

A method for preparing positive electrode ternary precursor powder. The positive electrode ternary precursor powder contains three elements, i.e., nickel, cobalt and manganese. The method comprises: carrying out acid dissolution on nickel cobalt hydroxide so as to obtain a solution after acid solving; carrying out impurity removal treatment on the solution after acid solving so as to obtain a solution after impurity removal; adjusting the proportions of nickel, cobalt, and manganese in the solution after impurity removal so as to obtain a former solution; and using the former solution to prepare the positive electrode ternary precursor powder.

Owner:CHINA ENFI ENGINEERING CORPORATION

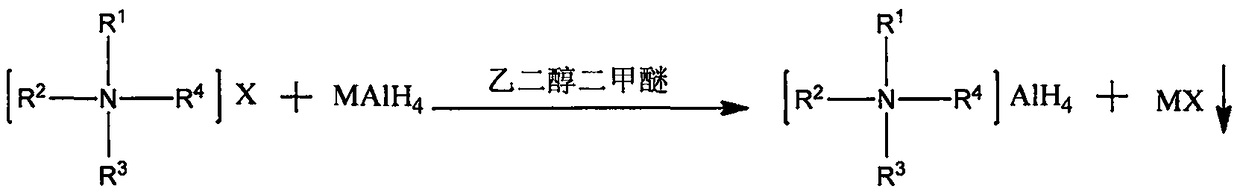

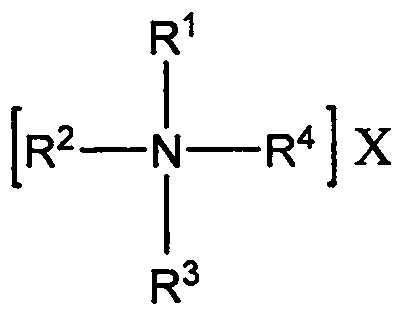

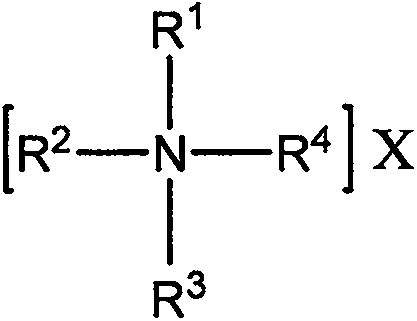

Method for preparing quaternary ammonium aluminum hydride

InactiveCN109280009AReduce usageProcess safety and environmental protectionOrganic compound preparationAmino compound preparationAlkaneQuaternary ammonium cation

The invention discloses a method for preparing a quaternary ammonium aluminum hydride. The method comprises the following steps: (1) adding an alkali metal aluminum hydride into a reactor with a reflux condensation tube and a constant-pressure dropping funnel under the protection of nitrogen, adding an organic solvent, then weighing a quaternary ammonium salt in a flask with a branch opening, adding an organic solvent, and carrying out heating and stirring for dissolving to obtain a quaternary ammonium salt solution; (2) transferring the quaternary ammonium salt solution to a constant-pressuredropping funnel under the protection of nitrogen, dropwise adding the quaternary ammonium salt solution into the reactor, and carrying out a heating reflux reaction for 2-6 hours; and (3) after the reaction is finished, adding a non-polar alkane with an equal volume into the solution, carrying out filtering, and removing the solvent from the filtrate to obtain a waxy solid, namely the quaternaryammonium aluminum hydride. The method is simple in process, short in reaction time, convenient in purification and high in yield.

Owner:LIMING RES INST OF CHEM IND

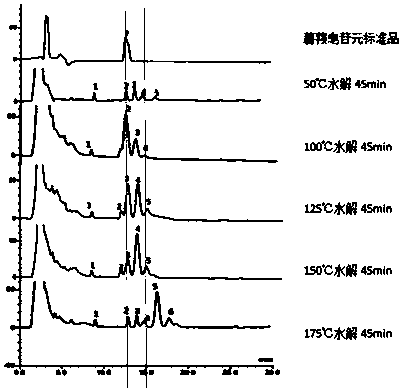

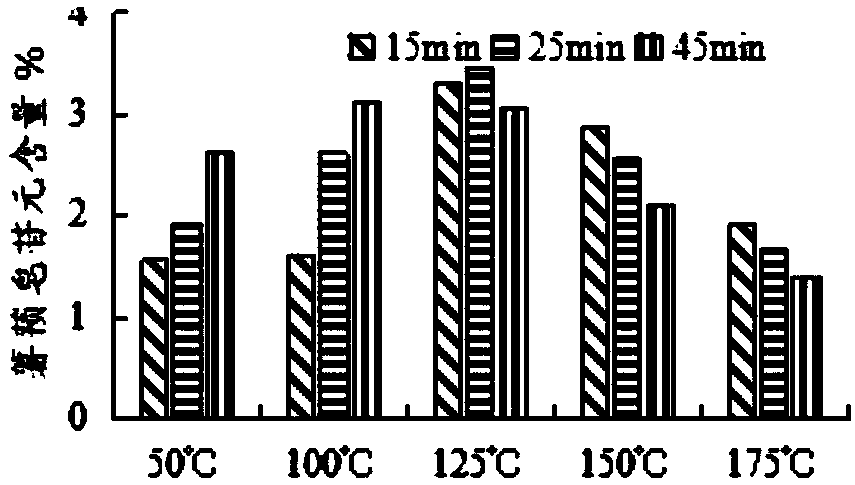

Method for pressurized ethanol/water extraction of diosgenin

InactiveCN108570092ALow impurity contentEasy to separate and purifySteroidsBulk chemical productionSolventIonic liquid

The invention discloses a method for extracting and preparing diosgenin from Dioscorea nipponica Makino or other Dioscoreaceae plants, belonging to the technical fields of deep processing of agricultural products and medicine. The method comprises the following steps: pulverizing Dioscorea nipponica Makino or other Dioscoreaceae plants according to a conventional method, adding the pulverized plants into a pressurized extraction tank, then adding a proper amount of ethanol / water as a solvent, adding acidic ionic liquid as a catalyst, carrying out extraction at a certain pressure and a certaintemperature for a certain period of time, cooling extract room temperature after extraction, carrying out filtering to remove herbal residues, appropriately concentrating a filtrate, allowing concentrated liquid to passed through a macroporous resin column, carrying out washing with water to remove acidic ionic liquid, then carrying out elution by using ethanol with an appropriate concentration, and subjecting eluate to concentration and drying so as to obtain diosgenin. According to the method, the acidic ionic liquid is used for replacing commonly used inorganic acid, so the problems of excessive acid consumption and serious pollution environment in modern industrial preparation of diosgenin are overcome; at the same time, elution with the macroporous resin column is used for replacing gasoline or petroleum ether extraction, so the problem of usage of flammable and explosive solvents is overcome; and the acidic ionic liquid and macroporous resin can be recycled. The method has the characteristics of safety, conservation of cost and environmental protection.

Owner:QINGDAO UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com