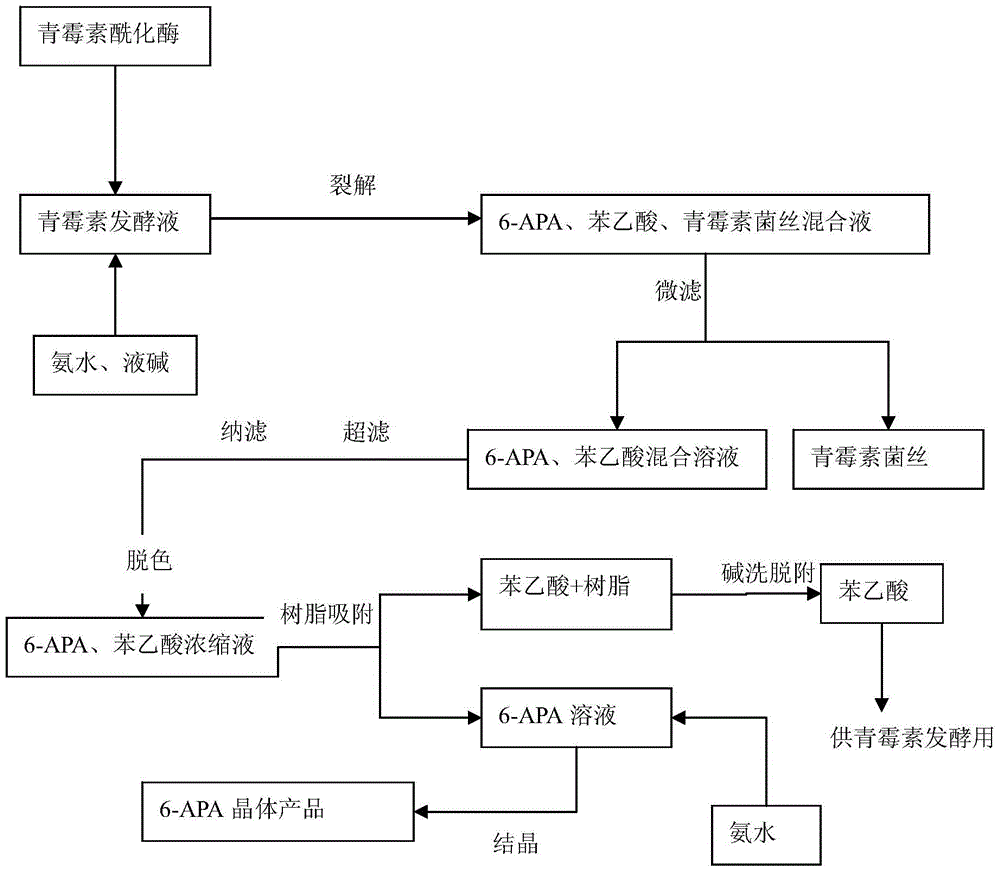

A method for directly preparing 6-aminopenicillanic acid from penicillin fermentation broth

A fermentation technology of aminopenicillanic acid and penicillin, which is applied in the field of biomedicine, can solve problems such as environmental hazards, high energy consumption, and low membrane filtration flux, so as to reduce energy consumption and cost, avoid environmental pollution, and improve membrane flux. volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 The preparation method of 6-aminopenicillanic acid of the present invention

[0034] Place 1000mL of penicillin fermentation broth with a concentration of 100000u / mL in a stirring reactor whose temperature is controlled at 28-30°C, and stir. When the temperature of the fermentation broth reaches 28-30°C, add penicillin to acylate for cleavage, and continuously add ammonia water with a concentration of 10% dropwise during the cleavage process to maintain the pH value in the reactor at about 7.0. When the addition of ammonia water is stopped When the pH value in the reactor remained constant within the last 20 min, the reaction was terminated.

[0035] The mixed solution after the cleavage reaction was passed through a 10-micron filter and a 1-micron filter to remove solid penicillin hyphae. Then the mixed solution is sequentially passed through an ultrafilter with a molecular weight cutoff of 30000-50000 Daltons and an ultrafilter with a molecular weight cu...

Embodiment 2

[0041] Embodiment 2 The preparation method of 6-aminopenicillanic acid of the present invention

[0042] Place 1000mL of penicillin fermentation broth with a concentration of 100000u / mL in a stirred reactor whose temperature is controlled at 30-32°C, and stir. When the temperature of the fermentation broth reaches 30-32°C, add penicillin to acylate for cleavage, and continuously add ammonia water with a concentration of 5% dropwise during the cleavage process to maintain the pH value in the reactor at about 7.4. When the addition of ammonia water is stopped When the pH value in the reactor remained constant within the last 20 min, the reaction was terminated.

[0043] The mixed solution after the cleavage reaction was passed through a 10-micron filter and a 1-micron filter to remove solid penicillin hyphae. Then the mixed solution is sequentially passed through an ultrafilter with a molecular weight cutoff of 30000-50000 Daltons and an ultrafilter with a molecular weight cuto...

Embodiment 3

[0049] Embodiment 3 The preparation method of 6-aminopenicillanic acid of the present invention

[0050] Place 1000mL of penicillin fermentation broth with a concentration of 100000u / mL in a stirred reactor whose temperature is controlled at 34-36°C and stir. When the temperature of the fermentation broth reaches 34-36°C, add penicillin to acylate for cleavage, and continuously add ammonia water with a concentration of 8% dropwise during the cleavage process to keep the pH value in the reactor at about 8.0. When the pH value in the reactor remained constant within the last 20 min, the reaction was terminated.

[0051] The mixed solution after the cleavage reaction was passed through a 10-micron filter and a 1-micron filter to remove solid penicillin hyphae. Then the mixed solution is sequentially passed through an ultrafilter with a molecular weight cutoff of 30000-50000 Daltons and an ultrafilter with a molecular weight cutoff of 3000-5000 Daltons to remove impurities such a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com