Patents

Literature

94 results about "Penicillin fermentation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

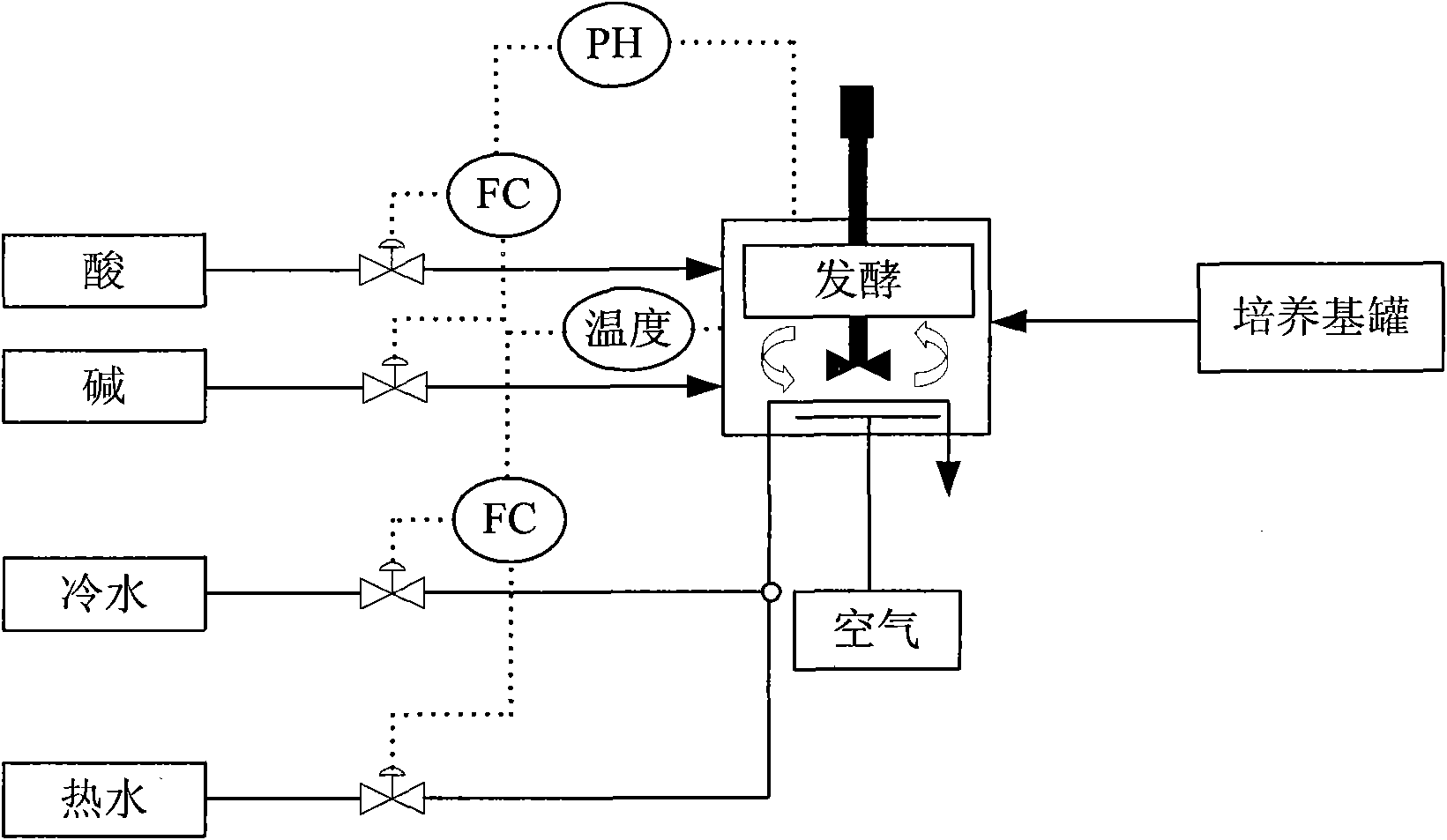

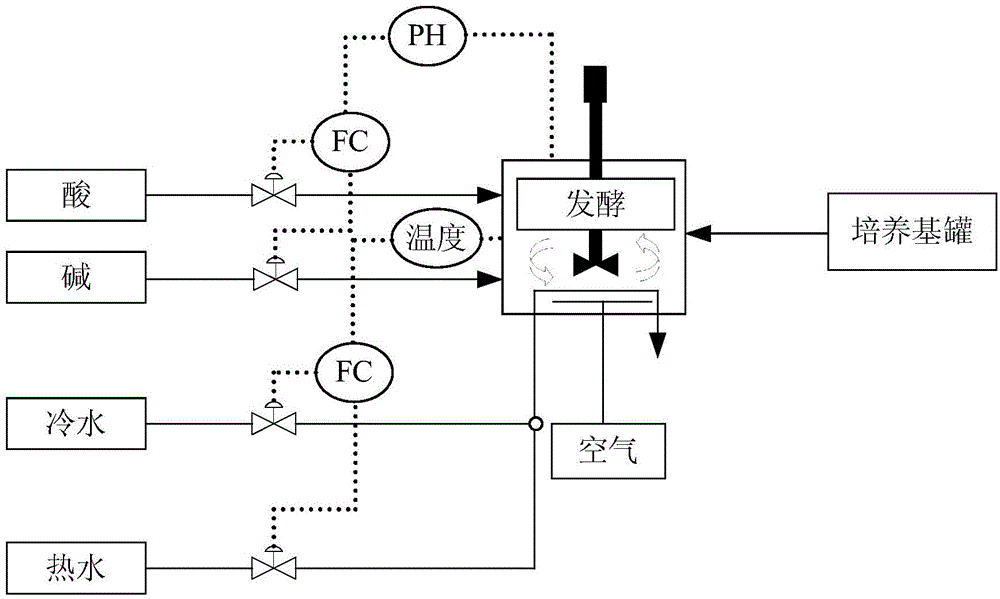

Fermentation is the technique used for the commercial production of penicillin. It is a fed-batch process that is carried out aseptically in stainless steel tank reactors with a capacity of 30 to 100 thousand gallons.

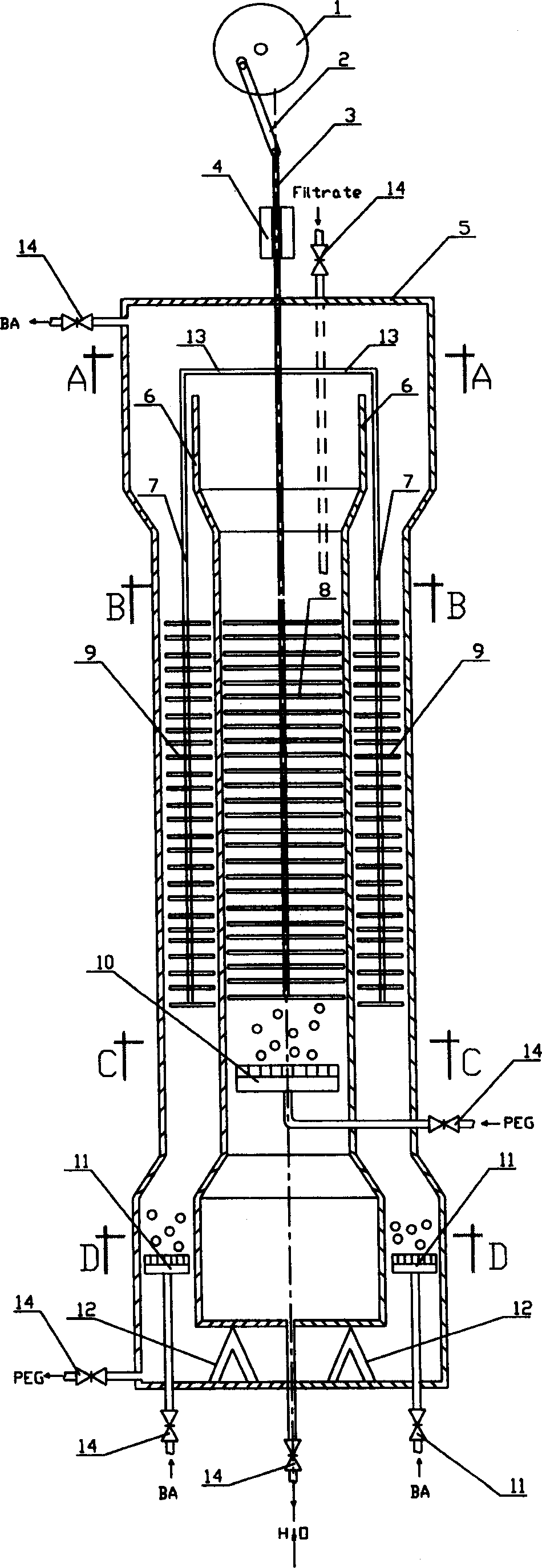

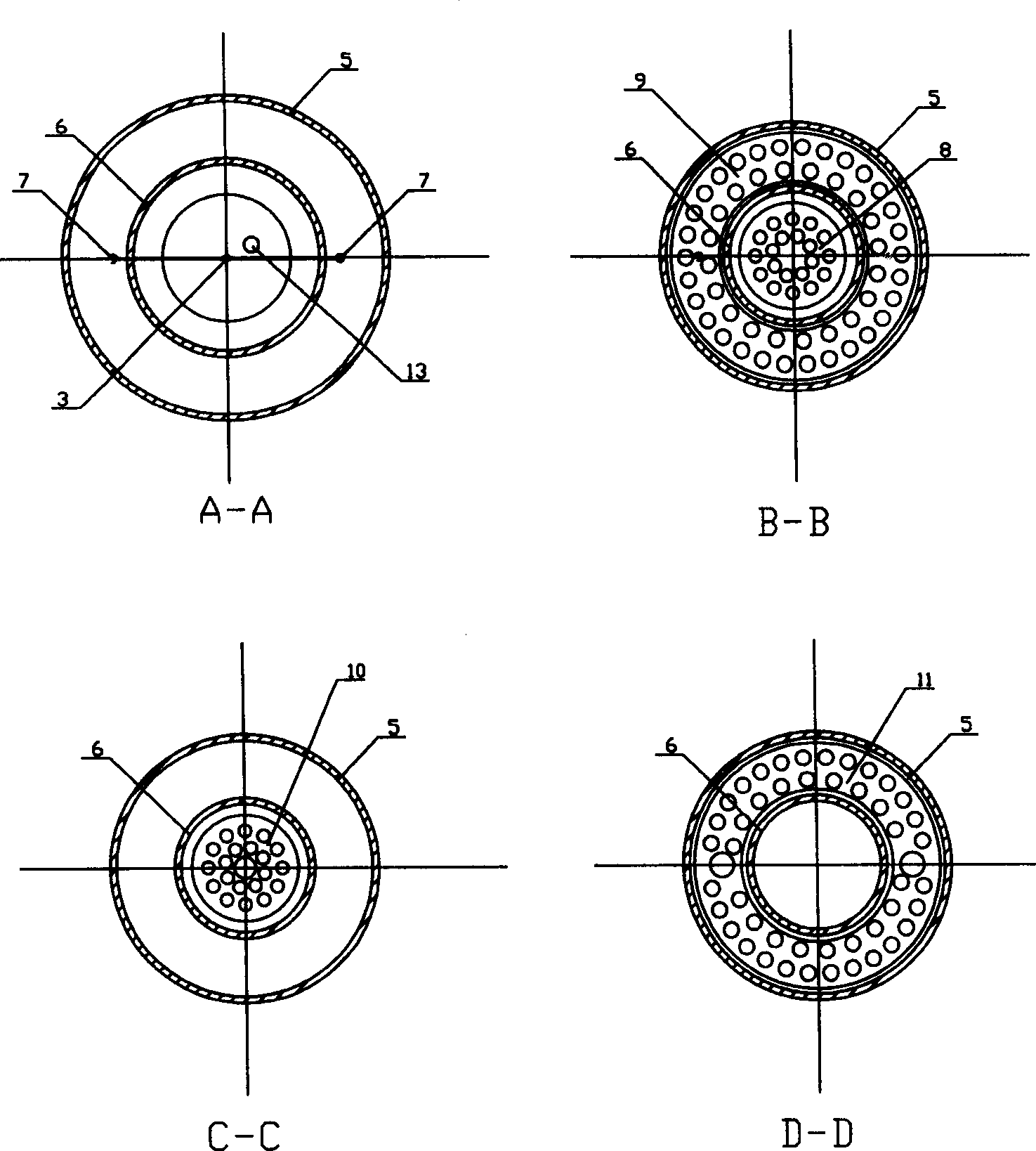

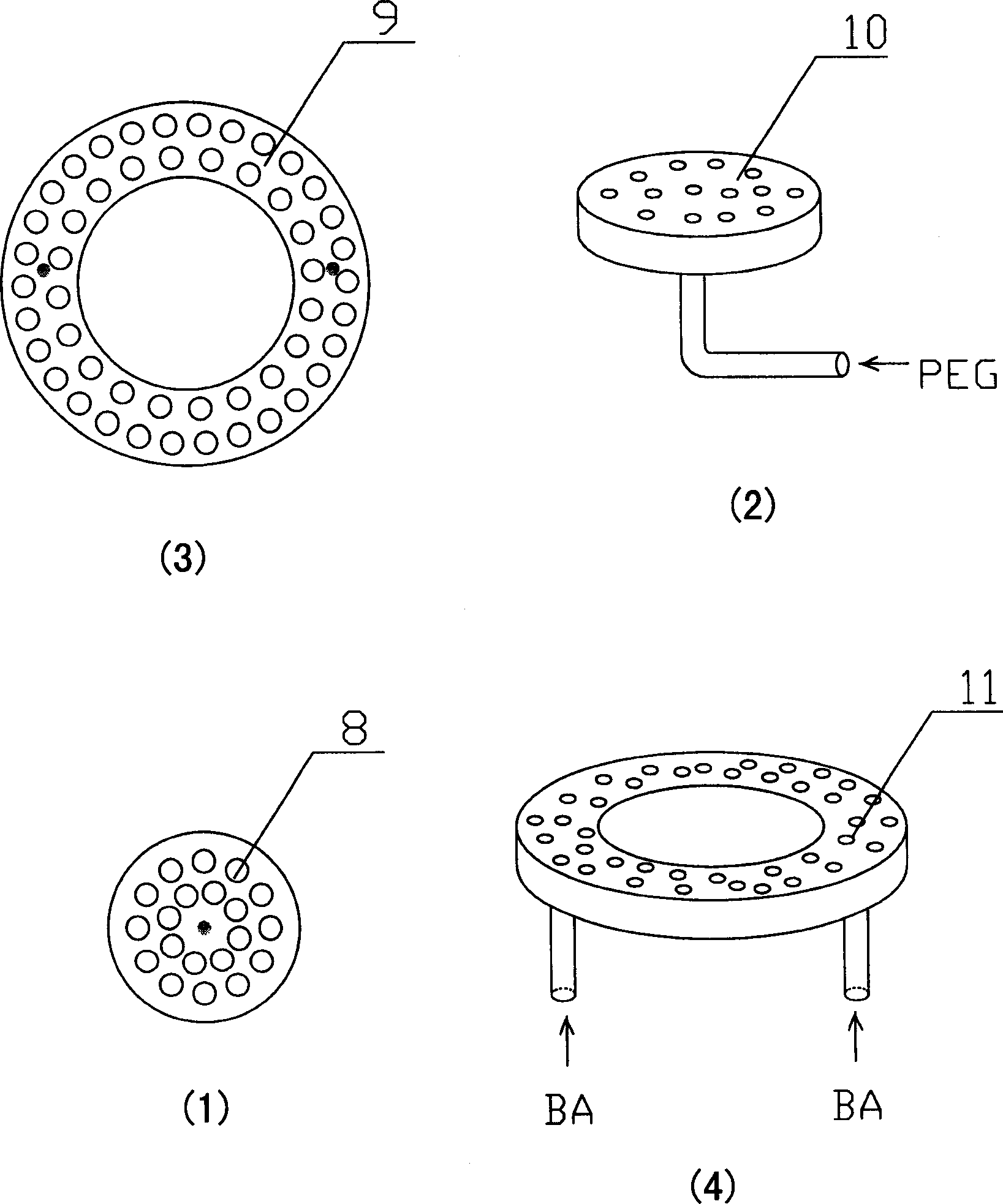

Liquid-liquid-liquid three phase continuous extraction vibrating sieve plate tower

InactiveCN1442223AImprove throughputImprove efficiencyLiquid solutions solvent extractionThree-phaseTower

A vibrating sieve-platte tower for three-phase (liquid-liquid-liquid) continuous extractions is suitable for a system containing solid and liquid easy to emulsify is composed of mechanical transmission unit, tower body, sieve plate, liquid-phase disperser and auxiliary unit. Its advantages are simple structure, flexible operation, easy regulation and low cost.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

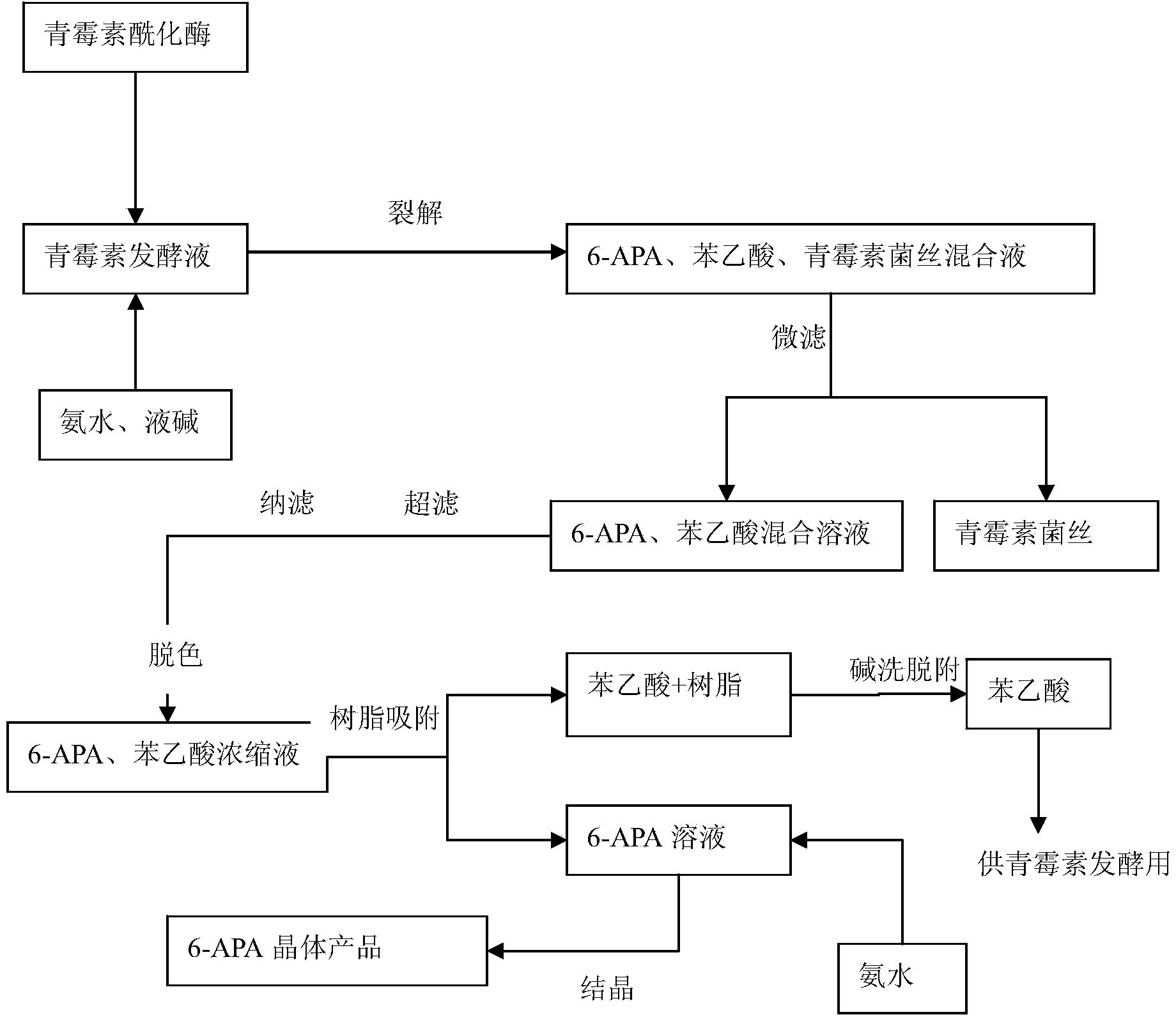

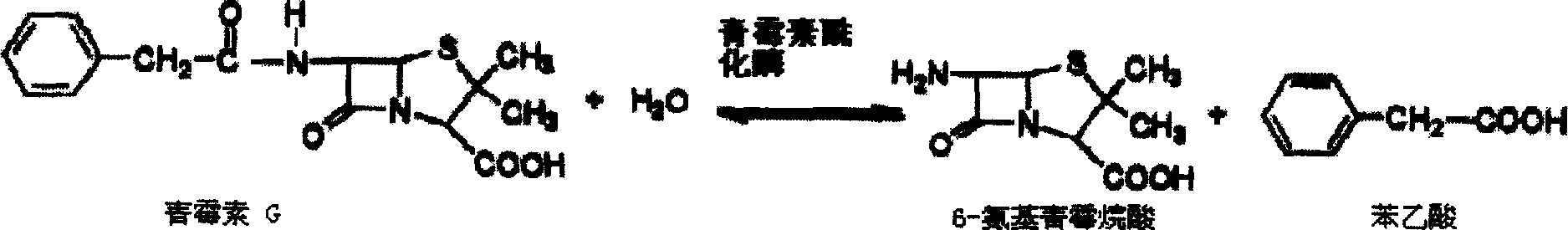

Method using penicillin fermentation liquor for direct preparation of 6-aminopenicillanicacid

ActiveCN104004002AAvoid pollutionLow Filtration FluxOrganic chemistryFermentationOrganic solventHigh energy

The invention belongs to the biological medicine field, and relates to a method using penicillin fermentation liquor for direct preparation of 6-aminopenicillanicacid. Preparation methods of the 6-aminopenicillanicacid in the prior art have the technical problems of large environmental pollution, high energy consumption, low product yield and the like; in order to overcome the technical problems, the invention provides the method using the penicillin fermentation liquor for direct preparation of the 6-aminopenicillanicacid, the method avoids use of butyl acetate, n-butyl alcohol and other organic solvents, improves the product yield, reduces the energy consumption in the process of preparation, is a green energy-saving 6-aminopenicillanicacid production method, and is very suitable for popularization and application in industry.

Owner:TIANJUSHI ENG TECH GROUP +1

Penicillin fermentation process fault monitoring method based on MLLE-OCSVM

InactiveCN106709214AReduce false positivesImprove accuracyDesign optimisation/simulationSpecial data processing applicationsLocal linearHigh dimensional

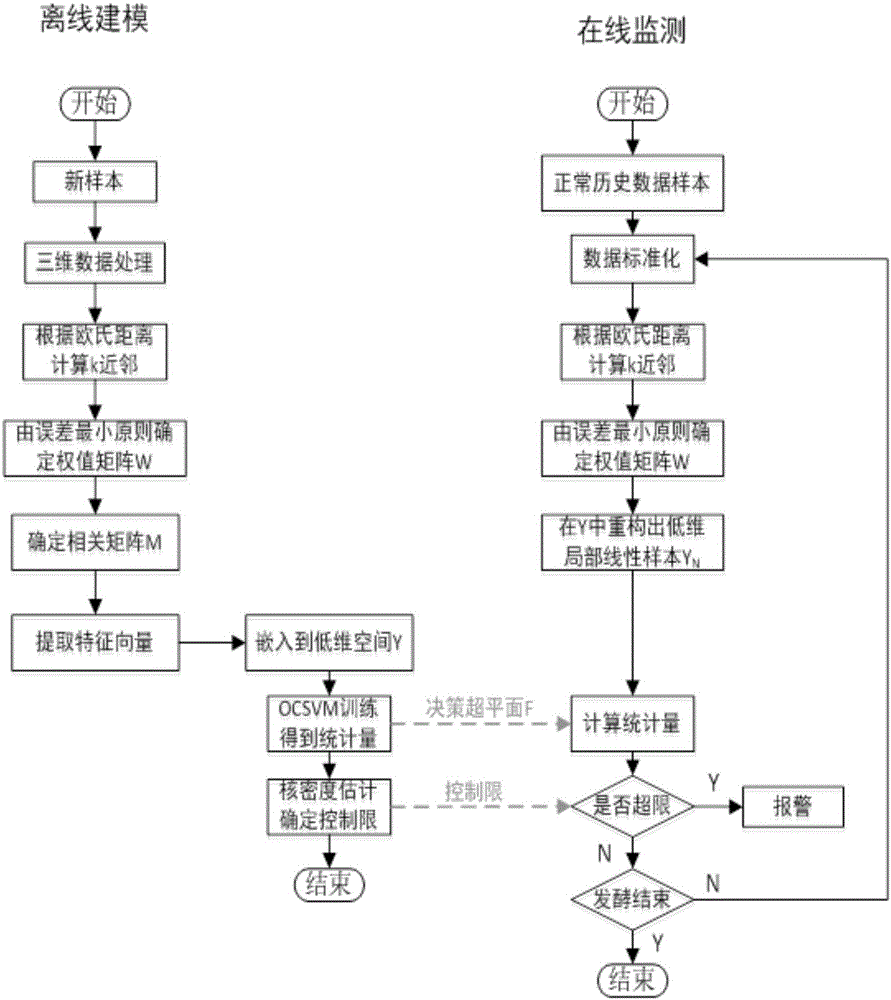

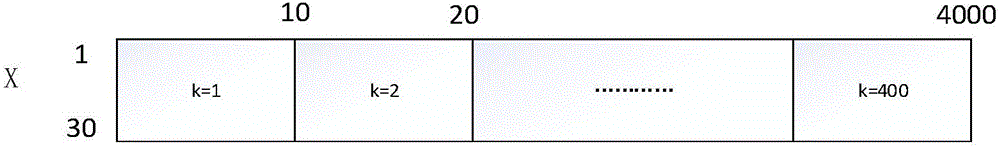

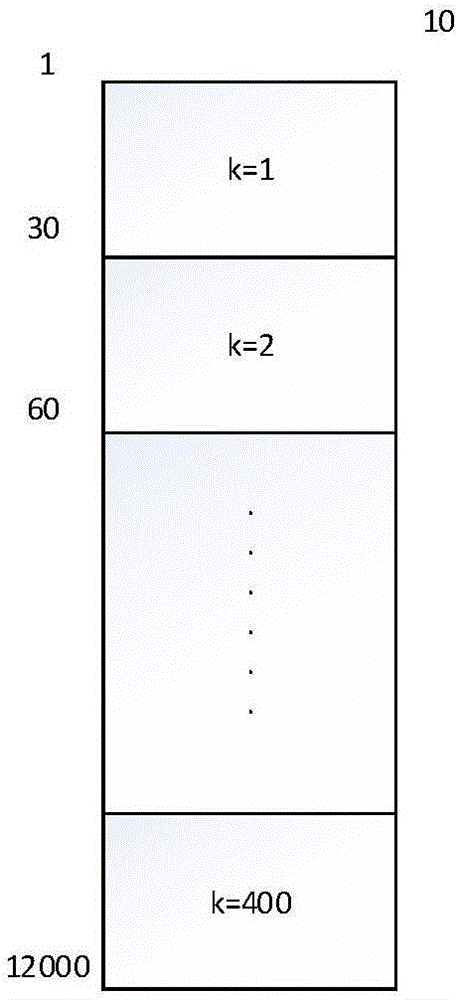

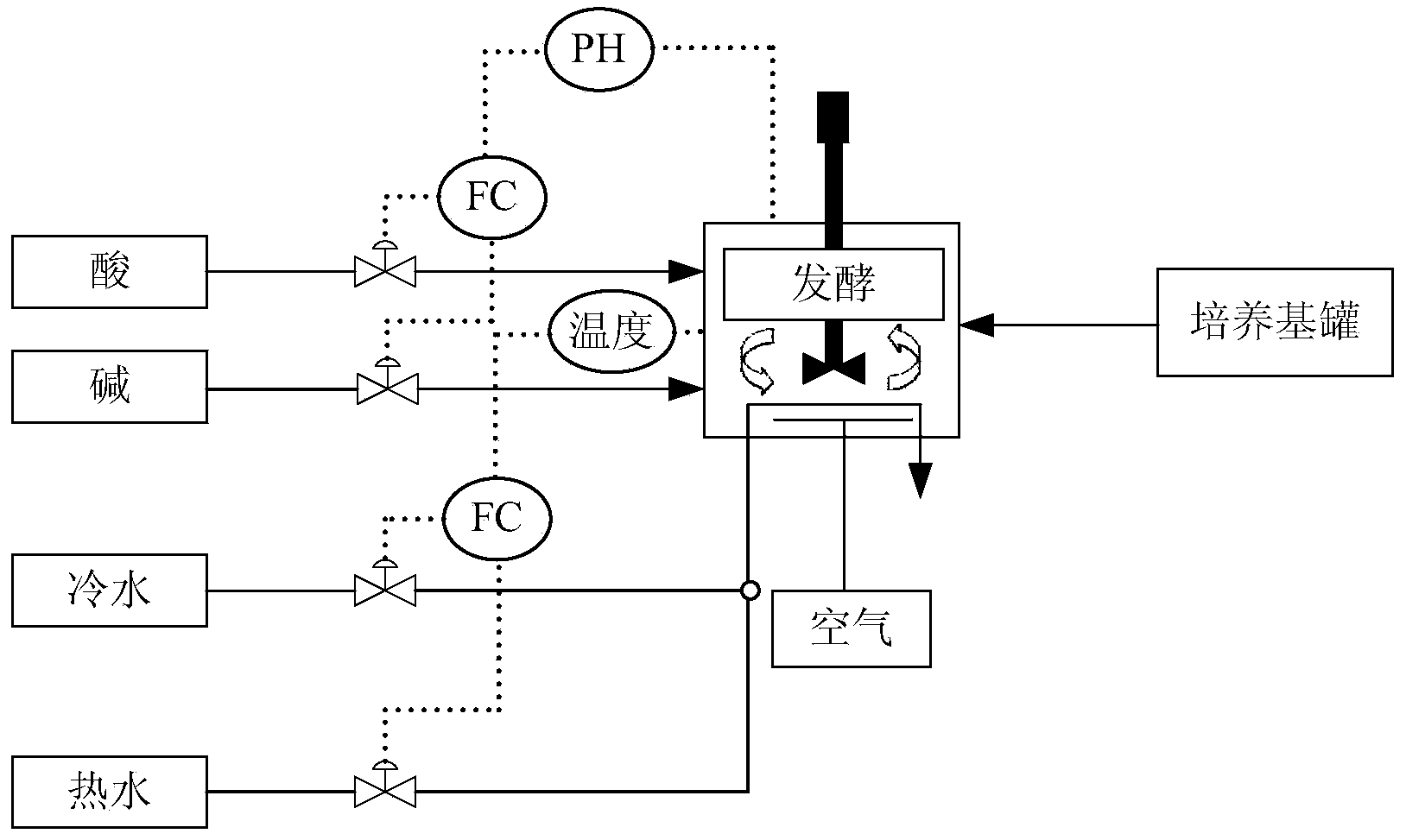

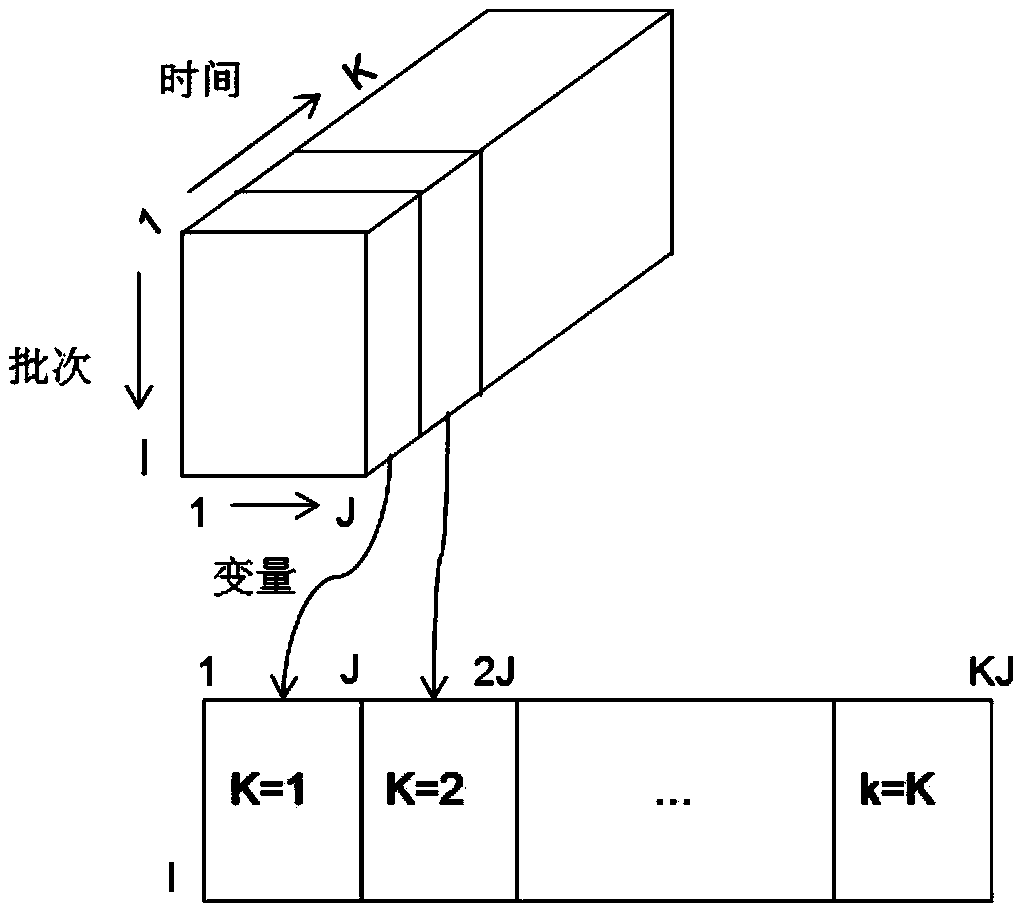

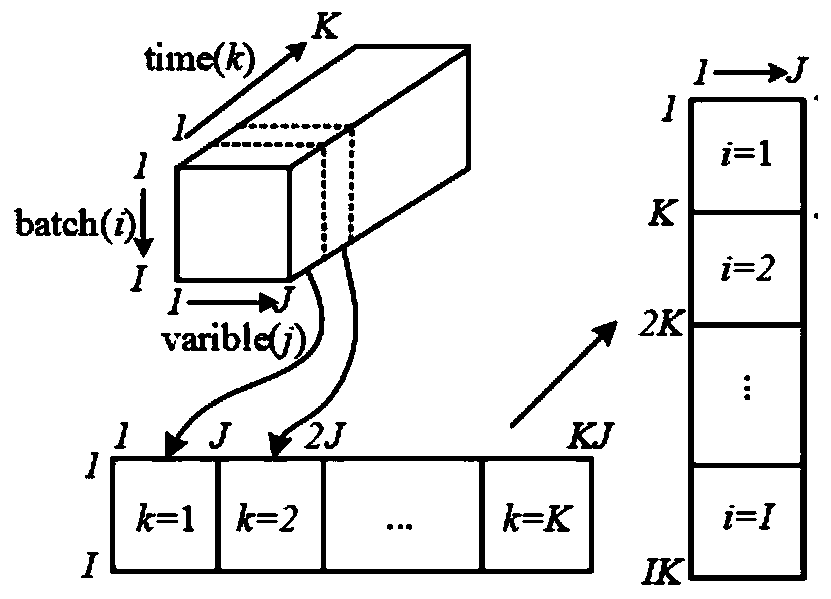

The invention discloses a penicillin fermentation process fault monitoring method based on MLLE-OCSVM, and relates to the technical field of the fault monitoring of the data drive. The method comprises two phases of off-line modeling and on-line monitoring. The off-line modeling comprises the following steps: firstly processing the three-dimensional data of the fermentation process; using a local linear embedding method (MLLE) in a manifold learning algorithm to execute the feature extraction to an original high dimensional data sample later; and finally using a one-class support vector machine (OCSVM) to execute the modeling construction monitoring statistics, and using a kernel density estimation method to determine the control limit. The on-line monitoring comprises the following steps: processing the newly-collected data according to the model, calculating the statistics and comparing with the control limit, and judging whether the fermentation process is run normally. The method does not need to assume that the fermentation process variable complies with the specific distribution of gauss or non-gauss, and the accuracy rate of the fault monitoring is higher.

Owner:BEIJING UNIV OF TECH

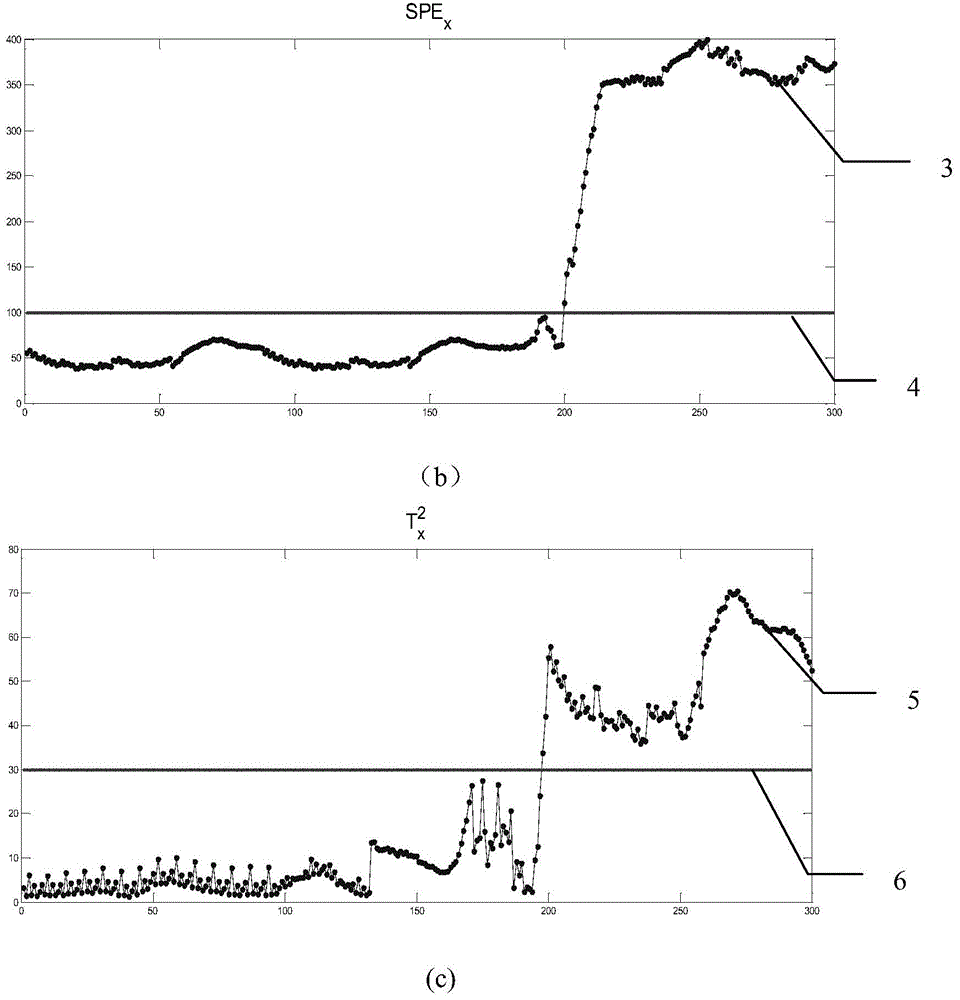

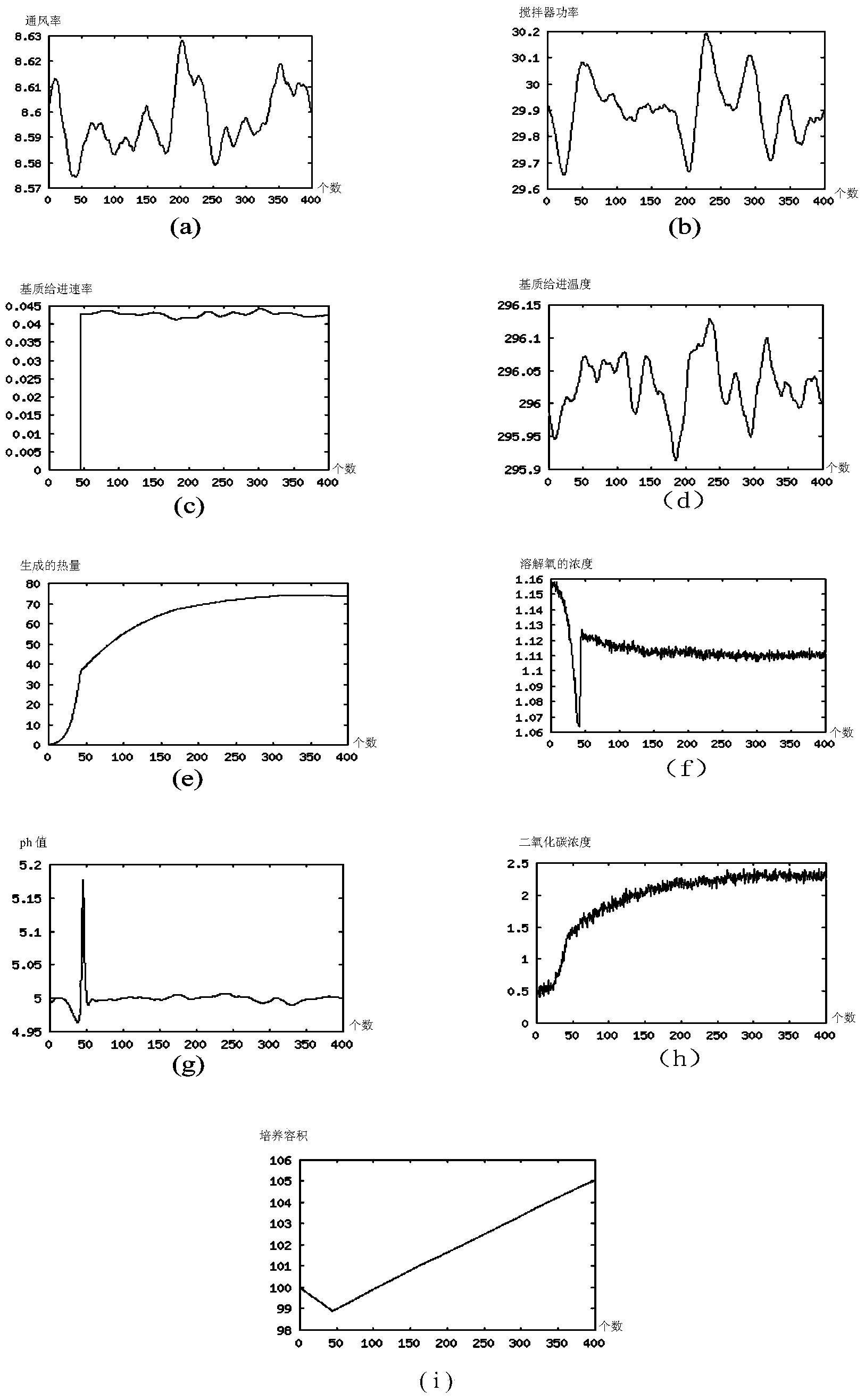

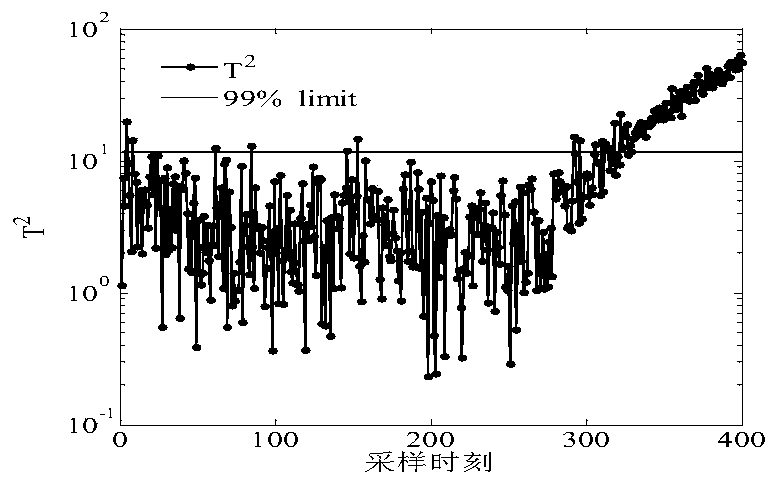

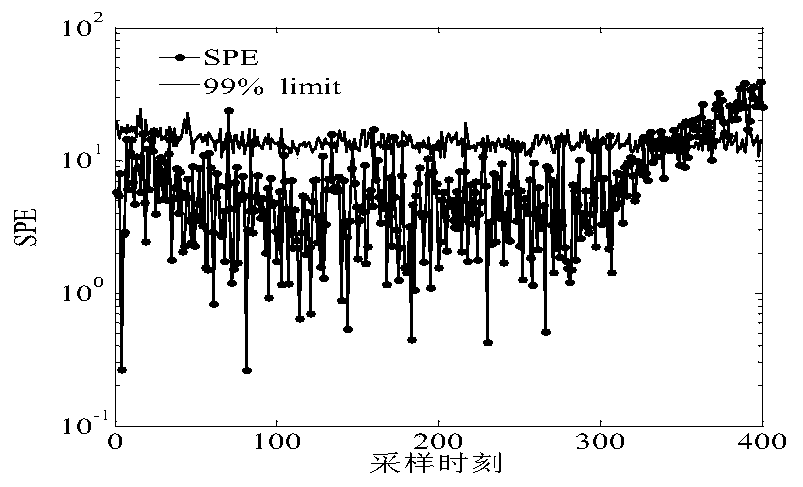

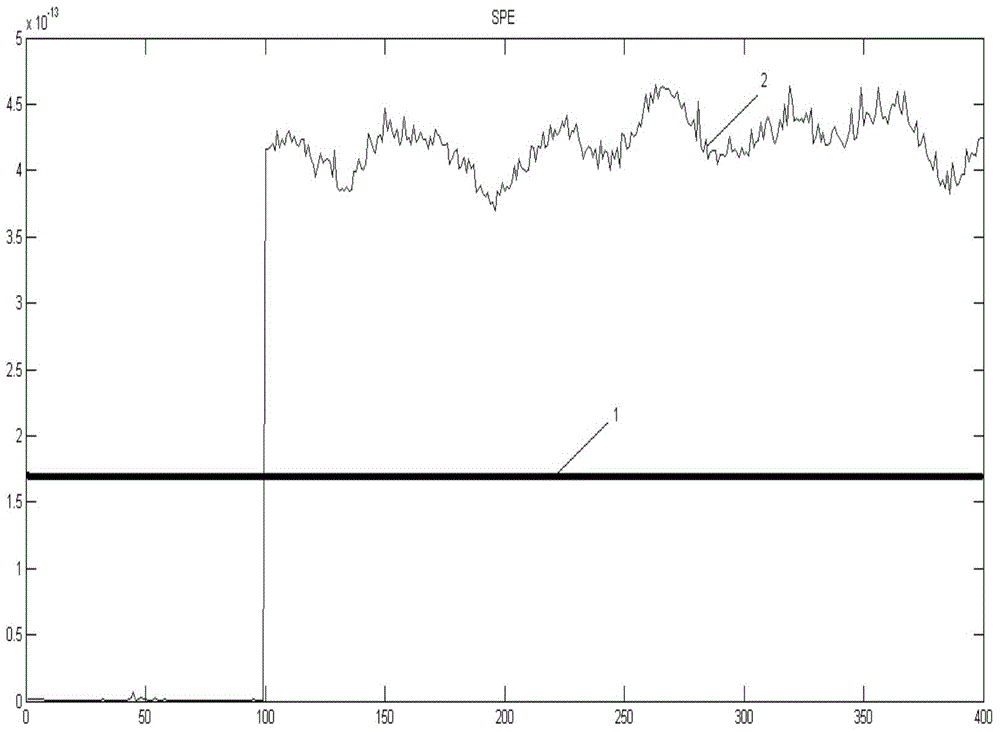

Penicillin fermentation process failure monitoring method based on recursive kernel principal component analysis

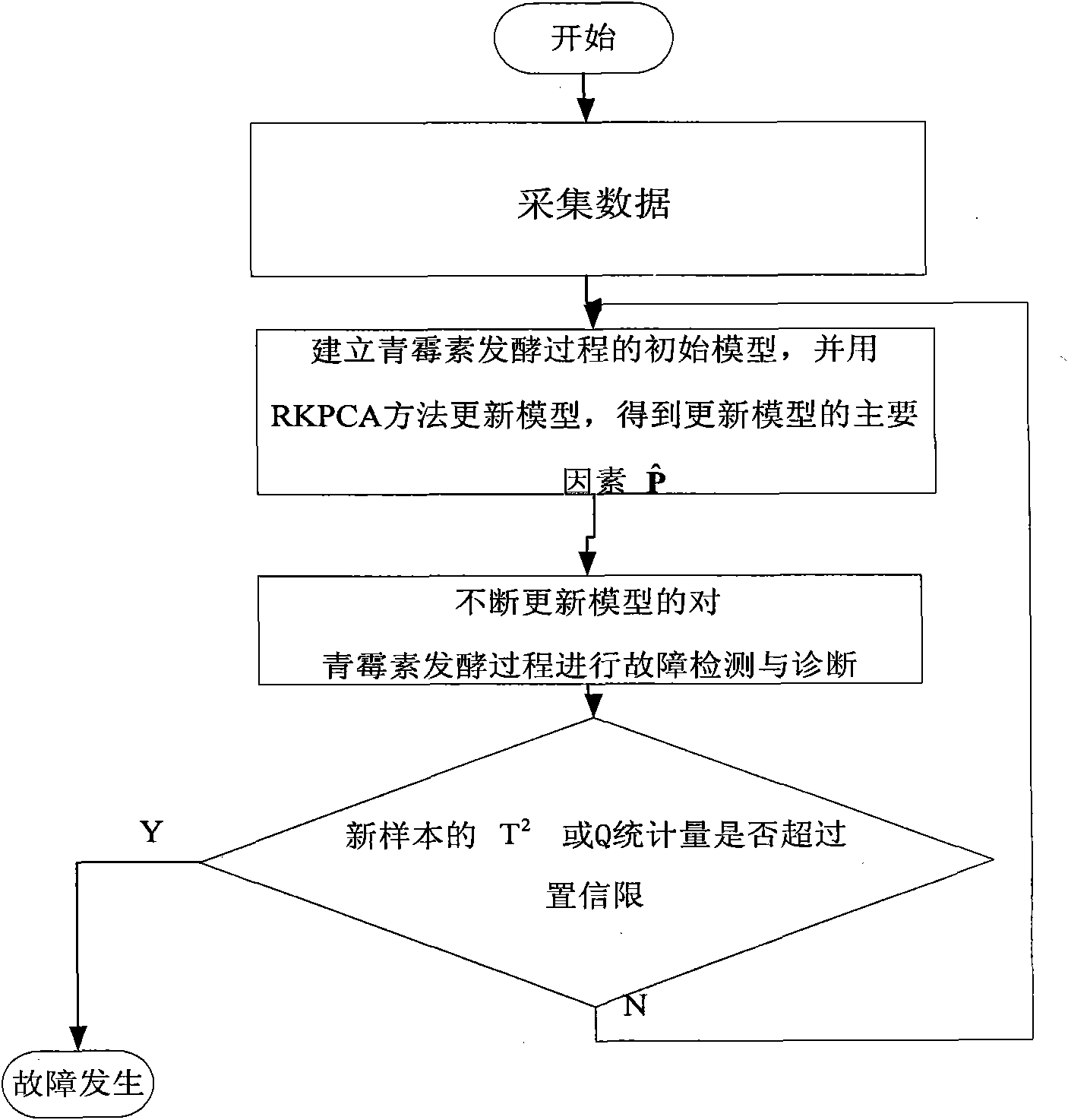

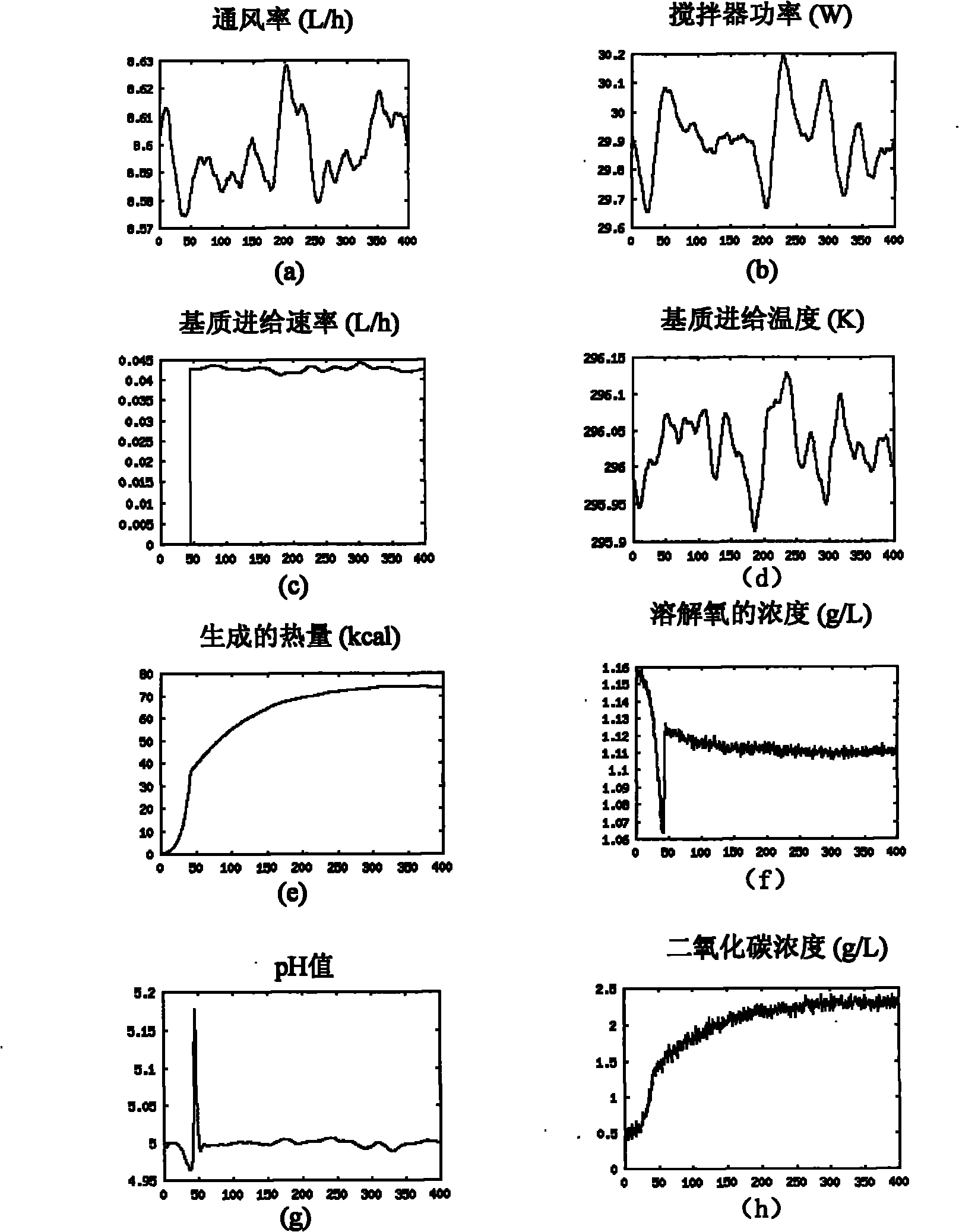

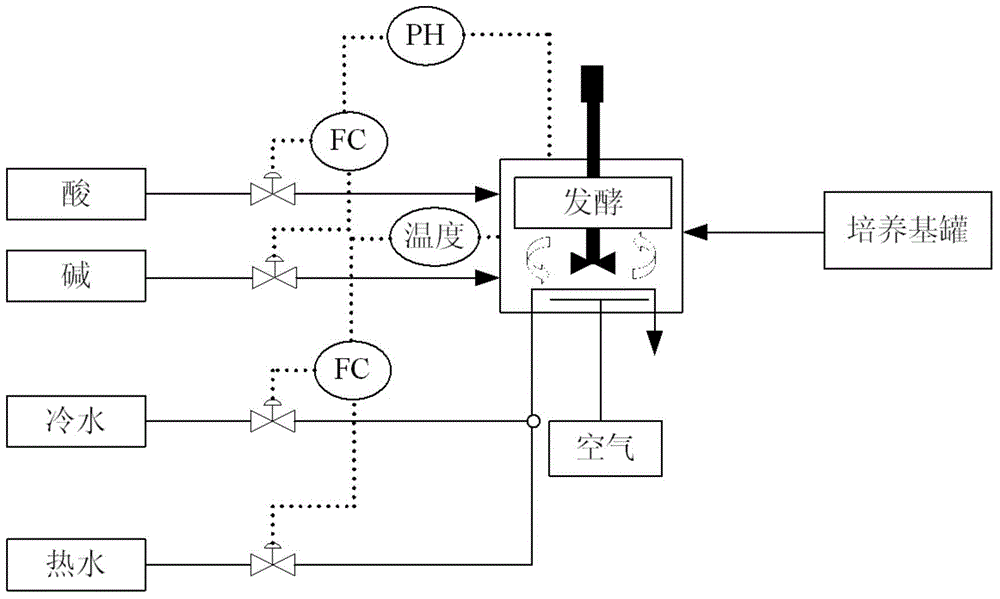

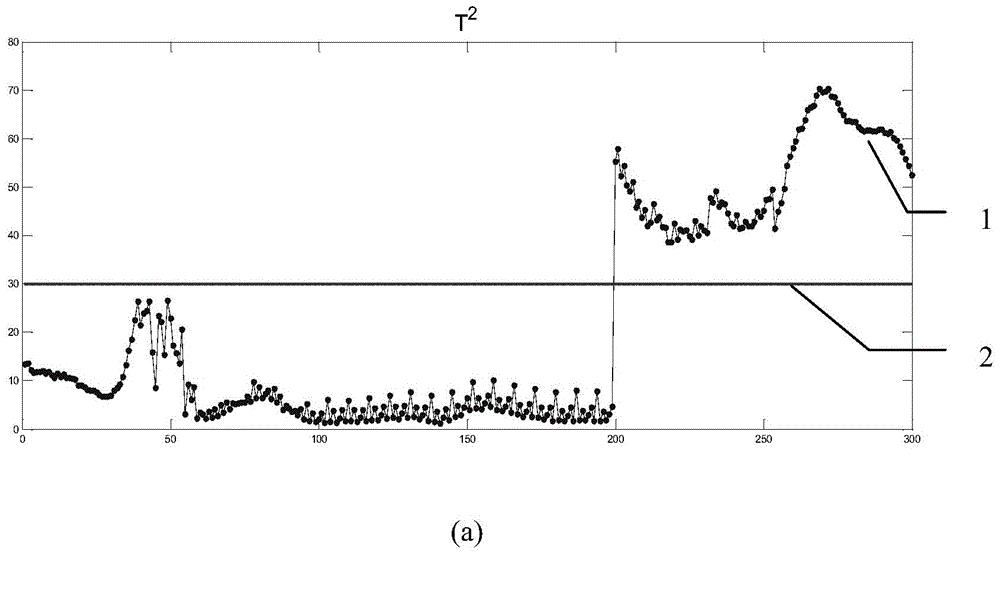

InactiveCN101964021ASolve nonlinear problemsReduce false alarmsSpecial data processing applicationsCovarianceRecursive computation

The invention relates to a penicillin fermentation process failure monitoring method based on recursive kernel principal component analysis (RKPCA), which belongs to the technical field of failure monitoring and diagnosis. The method comprises the following steps: acquiring the ventilation rate, stirrer power, substrate feed rate, substrate feed temperature, generated heat quantity, concentrationof dissolved oxygen, pH value and concentration of carbon dioxide; and establishing an initial monitoring model by using the first N numbered standardized samples, updating the model by a RKPCA method, and computing the characteristic vectors to detect and diagnose the failure in the process of continuous annealing, wherein when the T2 statistics and SPE statistics exceed the respective control limit, judging that a failure exists, and otherwise, judging that the whole process is normal. The method mainly solves the problems of data nonlinearity and time variability; and the RKPCA method is used for updating the model by carrying out recursive computation on the characteristic values and characteristic vectors of the training data covariance. The result indicates that the method can greatly reduce the false alarm rate and enhance the failure detection accuracy.

Owner:NORTHEASTERN UNIV

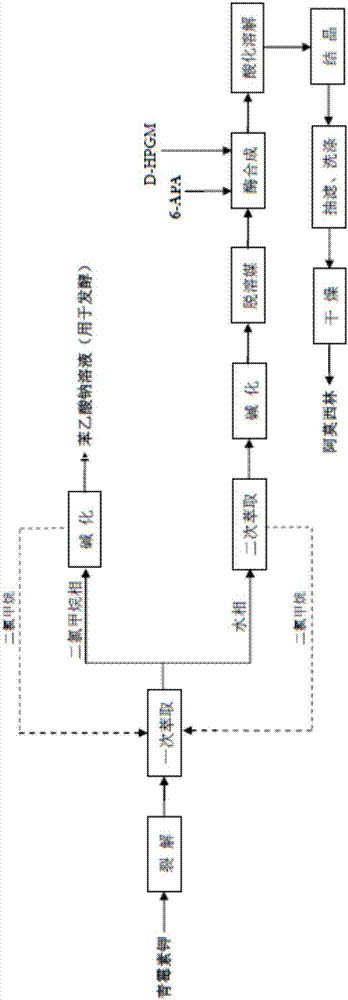

Preparation method for 6-amino penicillanic acid

The invention discloses a preparation method for 6-amino penicillanic acid, which comprises the following steps: a, performing ultrafiltration membrane separation and nanofiltration membrane concentration on a penicillin fermentation liquor to obtain a concentrated filter liquor; b, placing the concentrated filter liquor into a reaction tank, adding an immobilized penicillin acylase 4MU / m<3> concentrated filter liquor and performing conversion reaction to obtain a 6-amino penicillanic acid conversion solution; c, performing actived carbon decoloration and filtering on the conversion solution to obtain a 6-amino penicillanic acid filter liquor; and d, adding seed grain into the 6-amino penicillanic acid filter liquor obtained through the procedures in the step c, growing the grain, crystallizing, filtering, washing and drying. The preparation method has the advantages of simple process flow, easiness for operation, safety, environmental protection, and capabilities of effectively improving the yield of 6-APA, reducing the production cost and improving the labor productivity.

Owner:NORTH CHINA PHARMA COMPANY

Penicillin fermentation process fault diagnosis method based on kernel partial least squares reconstitution

The invention provides a penicillin fermentation process fault diagnosis method based on kernel partial least squares reconstitution. The method comprises the following steps that: off-line historical normal data in the penicillin fermentation process is collected; a penicillin fermentation process operating variable off-line historical normal data set and a penicillin fermentation process state variable off-line historical normal data set are respectively normalized and standardized; an improved kernel partial least squares method is used for building a fault monitoring model of the penicillin fermentation process; faults in the penicillin fermentation process are monitored on line; a penicillin fermentation process fault correlation direction model based on the improved kernel partial least squares reconstitution is built; and the penicillin fermentation process fault diagnosis is carried out. According to the method provided by the invention, an input space is divided into a principal element space directly relevant to the output, a principal element space irrelevant to the output and a residual error space irrelevant to the output. Compared with a traditional method, the penicillin fermentation process fault diagnosis method has the advantages that input variables relevant to the output are monitored, and variables relevant to the input are also precisely monitored.

Owner:NORTHEASTERN UNIV

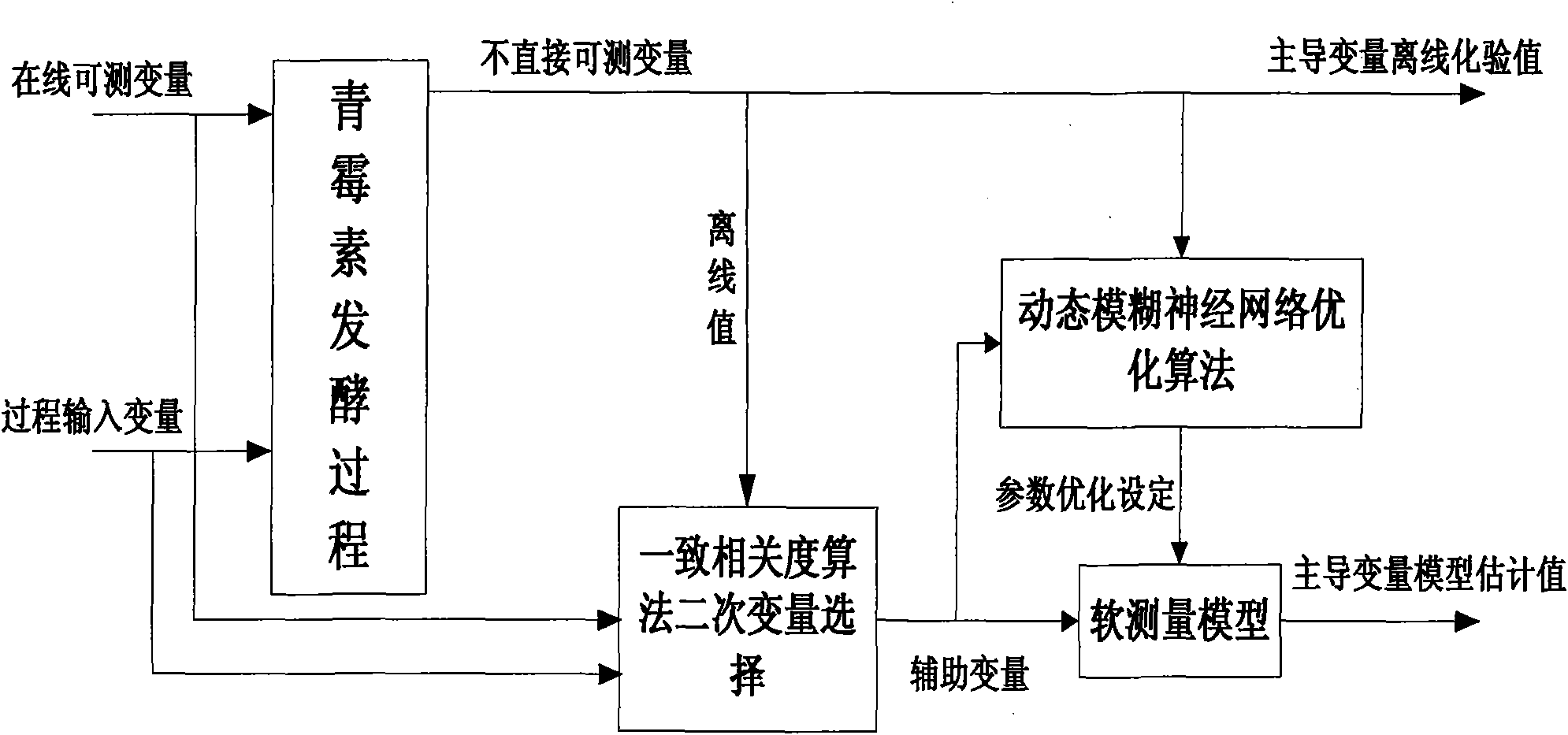

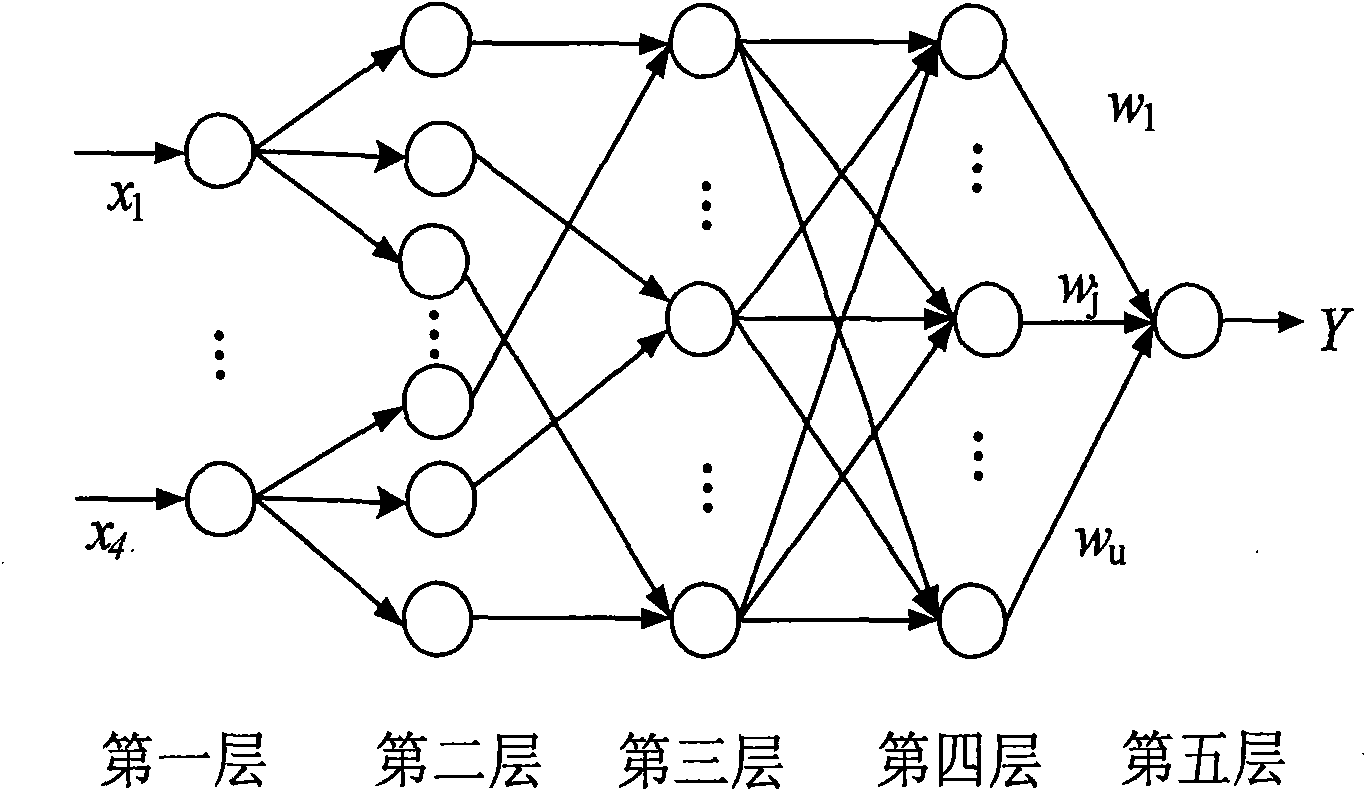

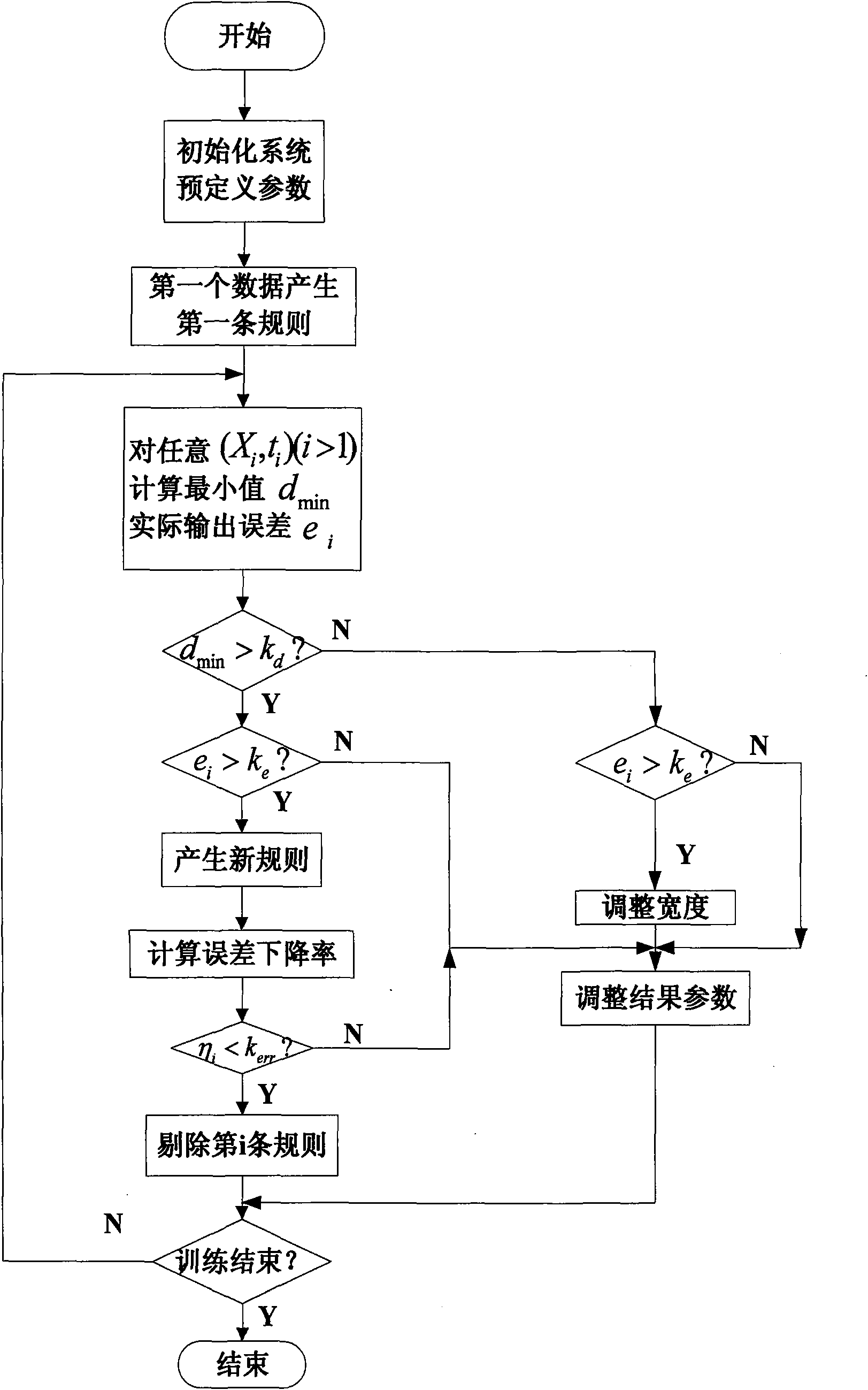

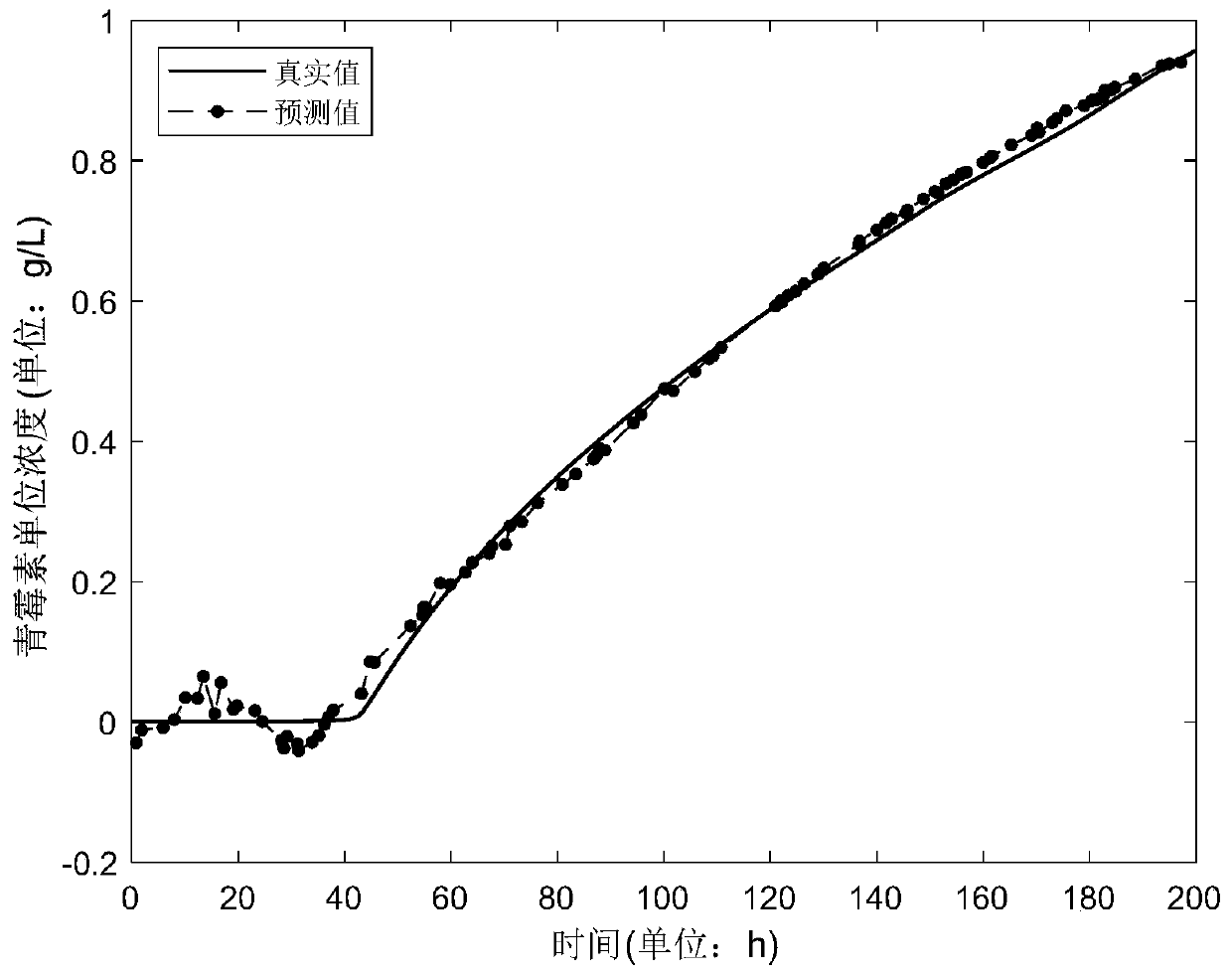

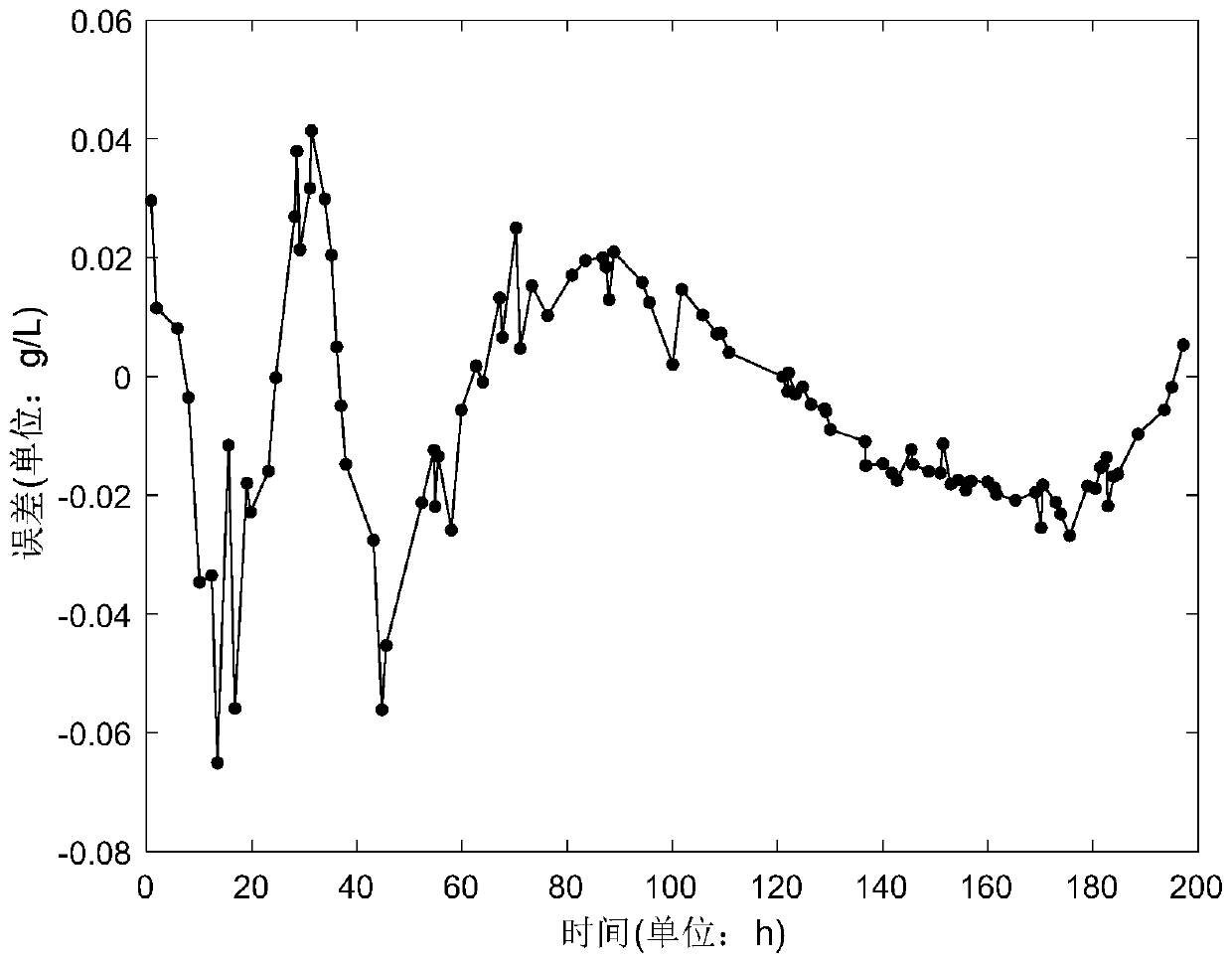

Dynamic fuzzy neural network based penicillin fermentation process soft measuring modeling method

InactiveCN101929993ARealize online soft measurementReduce complexityBiological modelsMaterial analysisAnalysis of algorithmsMachine learning

The invention discloses a dynamic fuzzy neural network based penicillin fermentation process soft measuring modeling method. The method comprises the following steps of: determining an on-line measurable variable, a process input variable and an indirect measurable variable requiring an off-line assay of a penicillin fermentation process; analyzing the relevancy of the process input variable and the on-line measurable variable with a dominant variable with a coincident relevance algorithm by using the indirect measurable variable as the dominant variable; carrying out secondary variable selection to determine an auxiliary variable; and finally, establishing a soft measuring model by using a dynamic fuzzy neural network and optimizing the parameters of the model, wherein the determined auxiliary variable is used as an input variable of the soft measuring model and the dominant variable is used as an output variable. The invention overcomes the defect of serious dependence on experiential selection of the traditional fuzzy neural network in the aspects of establishing an initial model, determining rule numbers, and the like, reduces the complexity of the soft measuring model, further improves the model stability and has good modeling precision.

Owner:JIANGSU UNIV

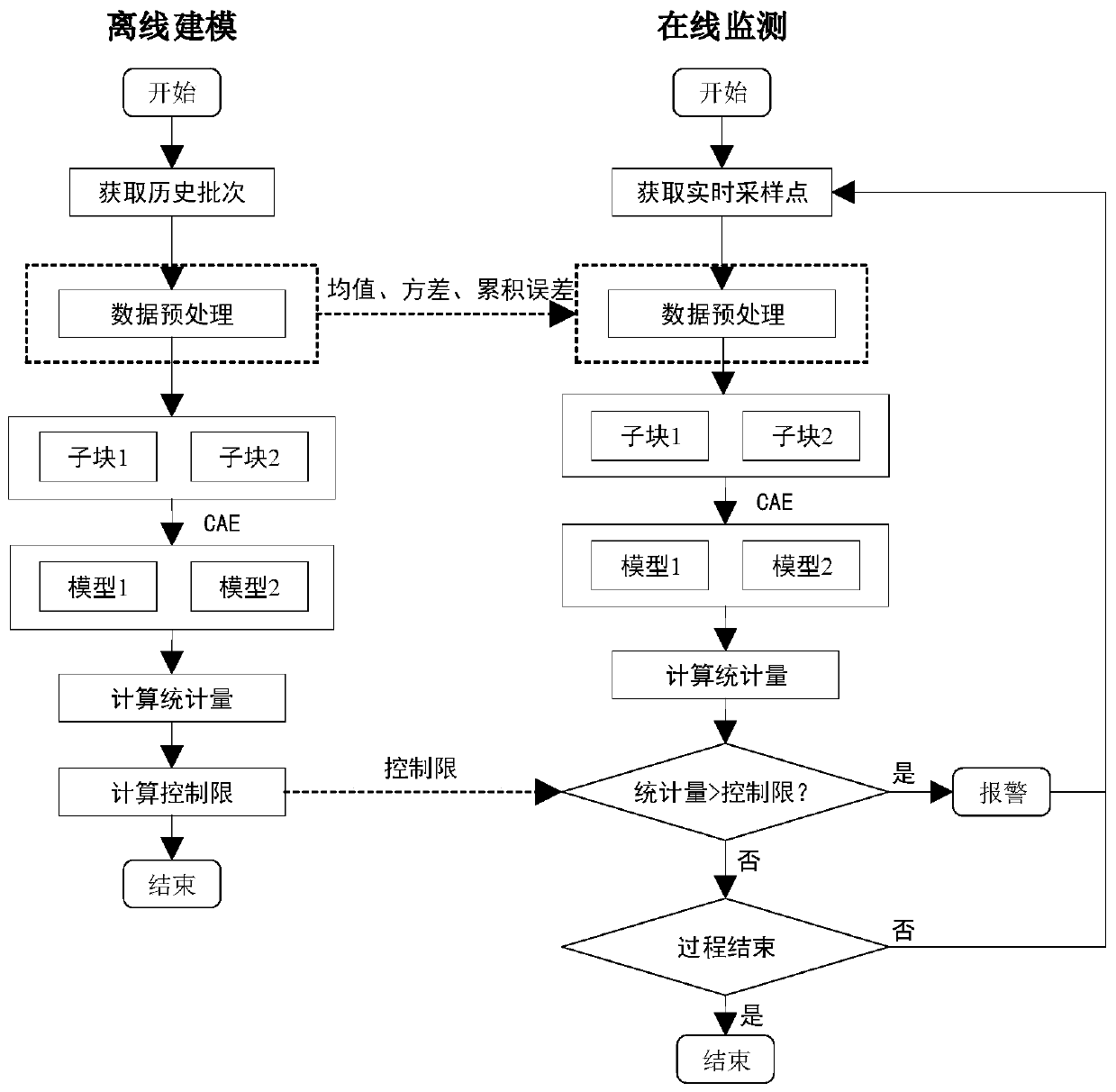

Method for monitoring faults in fermentation process based on MICA-OCSVM

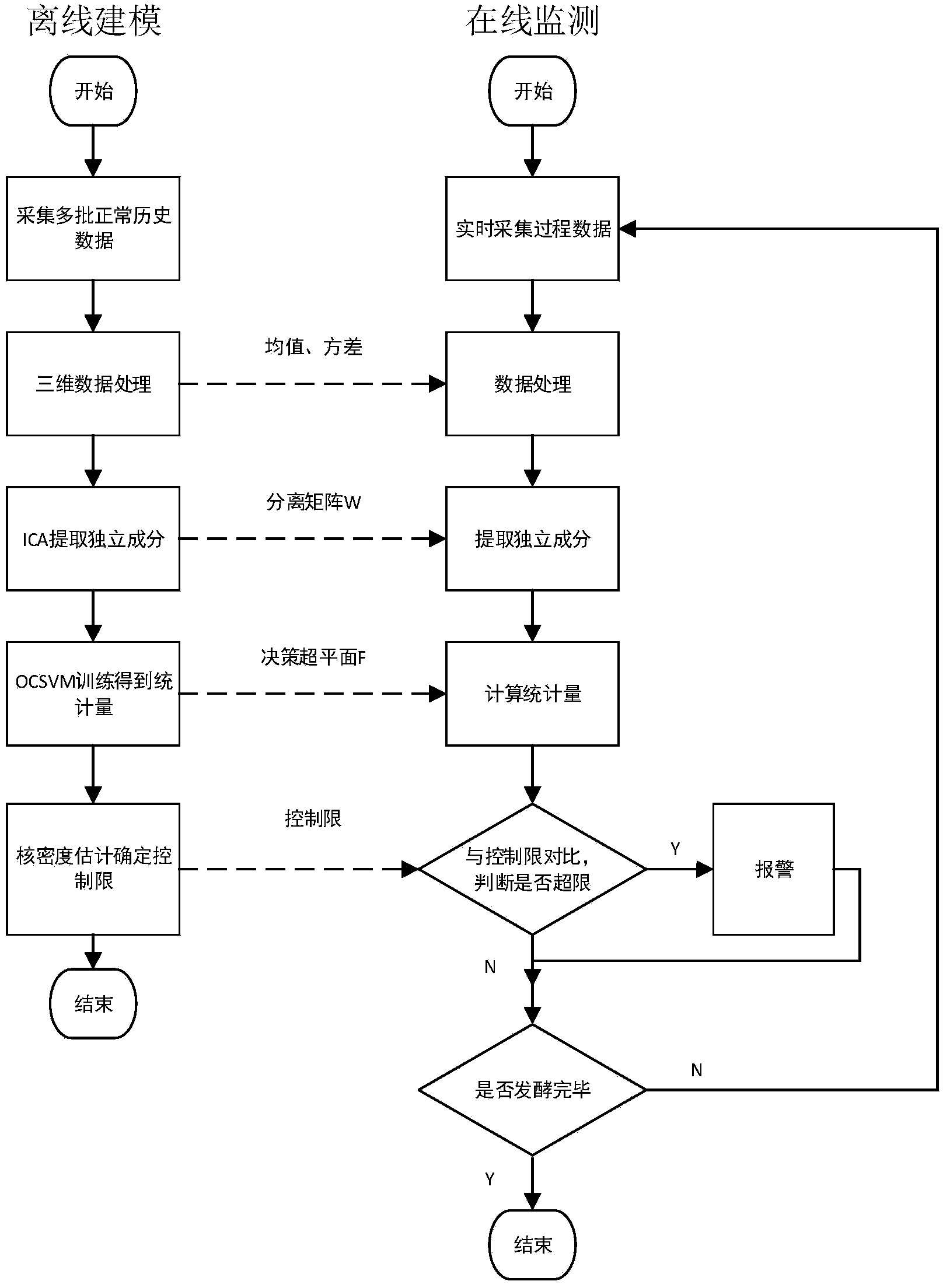

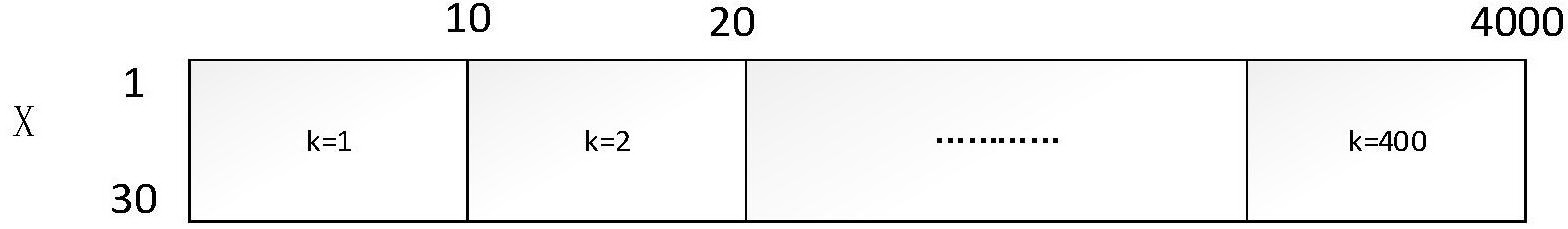

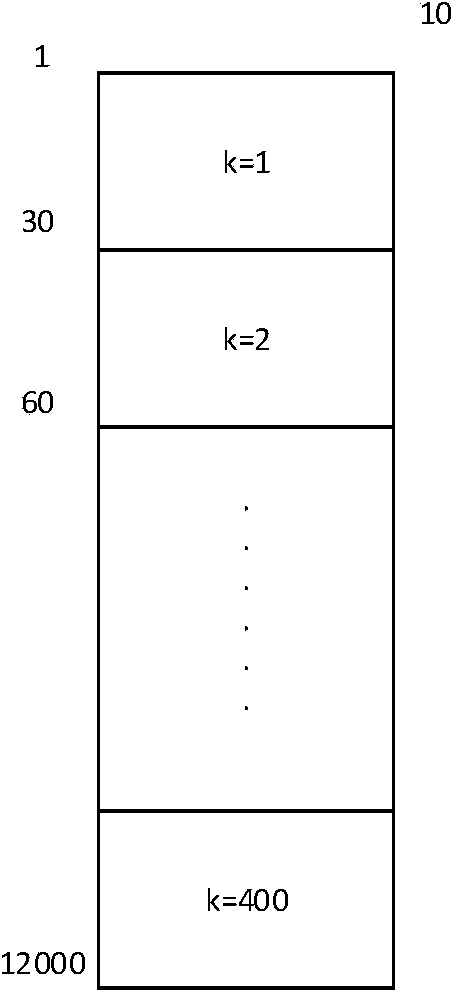

ActiveCN103838217AReduce false positivesImprove accuracyTotal factory controlProgramme total factory controlIndependent elementIndependent component analysis

The invention discloses a novel method for achieving real-time fault monitoring on a penicillin fermentation process. In order to guarantee safety and stability of the penicillin fermentation process, it is necessary to establish an effective process monitoring scheme to detect abnormal phenomena timely. The method comprises two steps of off-line modeling and on-line monitoring. The step of off-line modeling comprises the steps of firstly carrying out processing on three-dimensional data of the fermentation process, then extracting independent element information of the data by adopting ICA, and finally carrying out modeling by utilizing OCSVM to structure monitoring statistical magnitude and determining a control limit by utilizing a kernel density estimation method. The step of on-line monitoring comprises the steps of carrying out processing on newly collected data according to a model, calculating the statistical magnitude of the data, and comparing the statistical magnitude and the control limit to judge whether the fermentation process runs normal or not. According to the method for monitoring the faults in the fermentation process based on the MICA-OCSVM, the assumption that a fermentation process variable subjects to Gaussian distribution or non-Gaussian distribution or other distributions is not needed, and the accuracy rate of fault monitor is high.

Owner:BEIJING UNIV OF TECH

Process for preparing straight-through 6-aminopenicillanic acid

InactiveCN101735243AAvoid disadvantagesLarge amount of deesterificationOrganic chemistryFermentationGas phasePressure reduction

The invention discloses a process for preparing straight-through 6-aminopenicillanic acid, which comprises the following steps: a, filtering and acidizing penicillin fermentation solution, extracting the penicillin fermentation solution by using butanol, and concentrating and decoloring the extract to obtain butyl ester extracting solution of penicillin; b, back extracting the butyl ester extracting solution of the penicillin by using alkali solution to obtain brine solution of penicillin (heavy phase or RB for short); c, continuously injecting the brine solution of the penicillin into a degreasing tower in a vacuum pressure reduction state to convert the butyl ester into a gas phase from the brine solution of the penicillin, discharging the degreased brine solution of the penicillin out of a pressure reduction system from the bottom of the tower to a storage tank with a cooling device, and cooling the degreased brine solution of the penicillin for later use; and d, performing enzymatic conversion on the degreased brine solution of the penicillin, then adding 6-APA crystal seeds into the solution, growing the crystals, crystallizing the solution, and drying the crystals.

Owner:NORTH CHINA PHARMA COMPANY

Flocculation pretreatment method for penicillin fermentation waste water

ActiveCN101811791ASimple methodLow costMultistage water/sewage treatmentWater/sewage treatment by neutralisationHigh concentrationSludge cake

The invention discloses a flocculation pretreatment method for penicillin fermentation waste water, which is suitable for the pre-treatment of high-concentration bacterium slurry residual liquid generated in a penicillin fermentation process and mainly comprises the following steps: a, adjusting the quality of the waste water with a counter-ion auxiliary agent; b, performing flocculation reaction with a high-molecular organic flocculating agent, namely polyacrylamide; and c, performing solid-liquid separation. The counter-ion auxiliary agent is one of CaO, Ca(OH)2, polymeric silicate, polyaluminium chloride or tannin. By the method, the content of SS and COD in the waste water, which affect biochemical treatment, can be greatly decreased; subsequent biochemical treatment difficulty is effectively reduced; the treated waste water can meet the requirements of the subsequent biochemical treatment; and the water content of sludge cakes after the solid-liquid separation is more lower at the same time. Compared with other pre-treatment methods for the waste water generated in a penicillin production process, the method of the invention has better effect and more simple operation.

Owner:河北协同环境科技有限公司

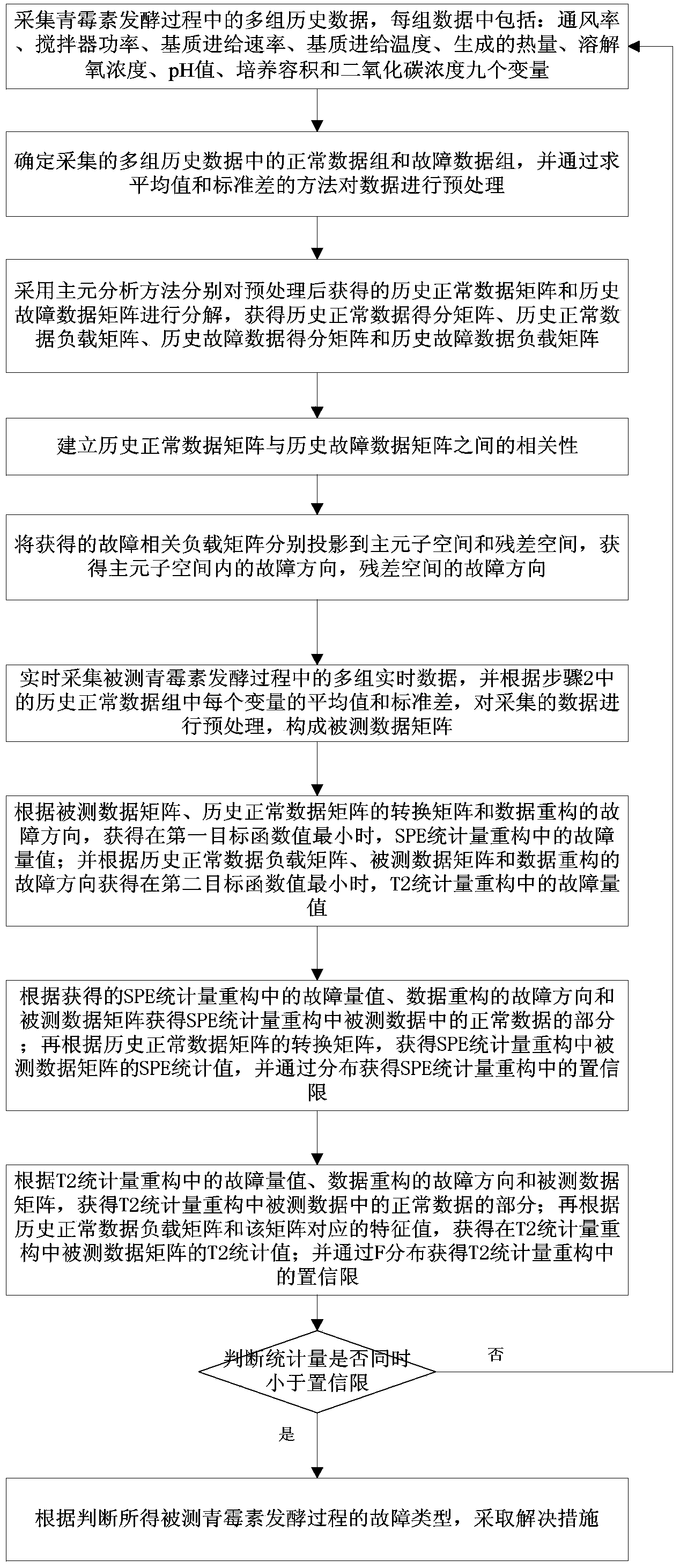

Penicillin fermentation process fault monitoring method based on reconstruction discriminatory analysis

InactiveCN103729562AImprove accuracyQuality improvementSpecial data processing applicationsNormal conditionsComputer science

The invention provides a penicillin fermentation process fault monitoring method based on reconstruction discriminatory analysis and belongs to the field of fault monitoring and diagnostic technologies. The method includes the steps of analyzing the correlation between normal data and fault data to obtain the direction of a fault having greatest influences on normal conditions, eliminating the fault in the data according to the contribution direction of the fault, namely, restoring an industrial condition model to the normal condition, recognizing the type of the fault, and restoring an actual working condition to the normal condition through actual fault solving measures. According to the method, the correlation between the fault and the normal condition is analyzed, so that the monitoring accuracy is greatly improved, safety guarantees are enhanced for the complex industrial process, losses are reduced and the product quality is improved.

Owner:NORTHEASTERN UNIV

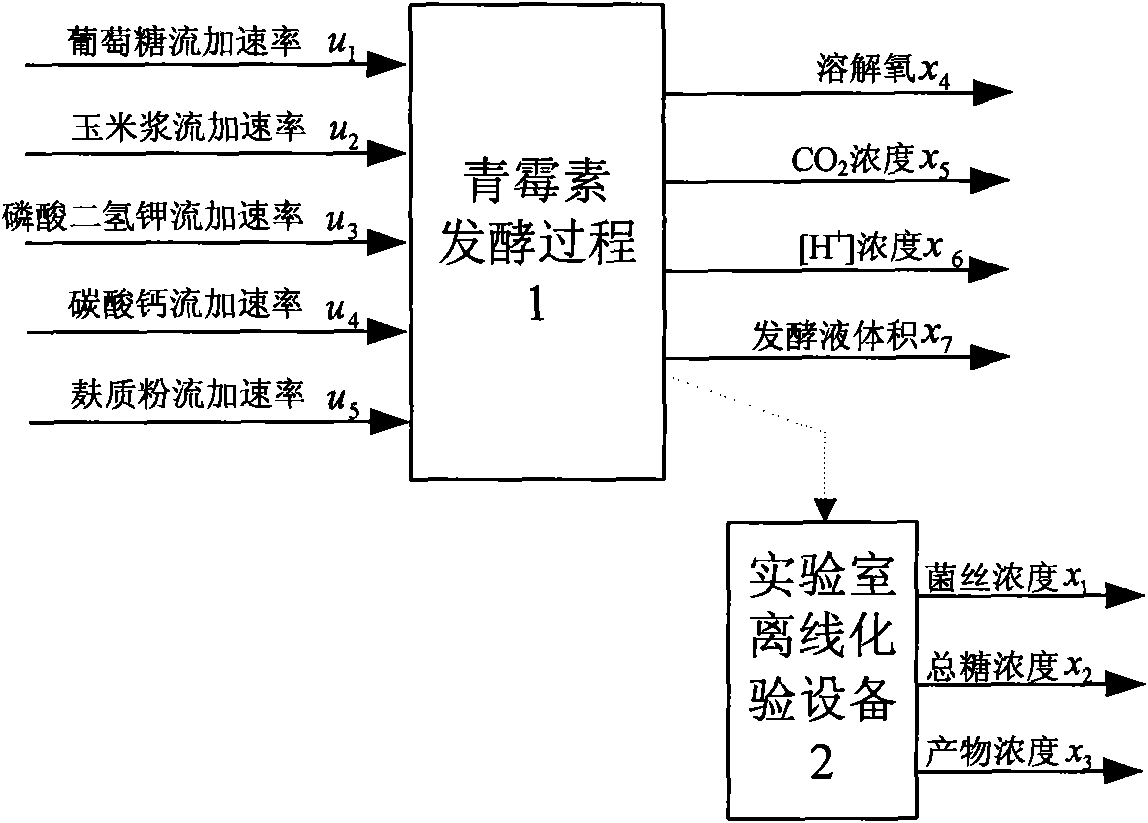

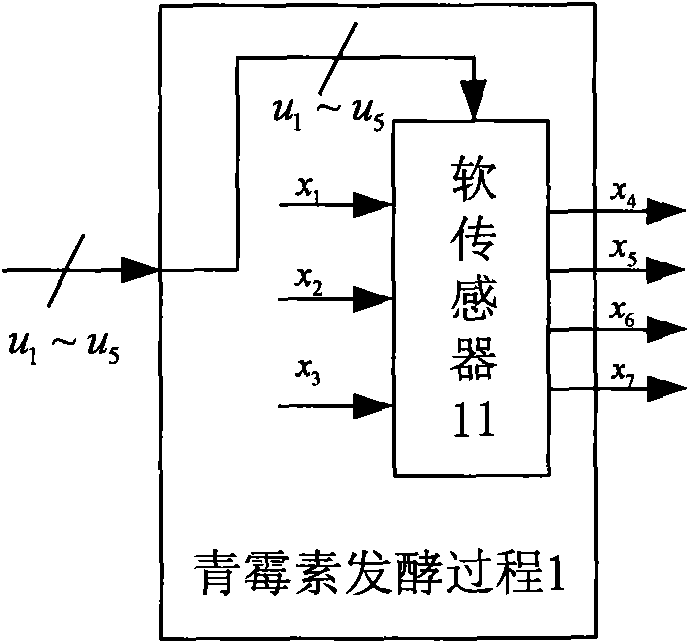

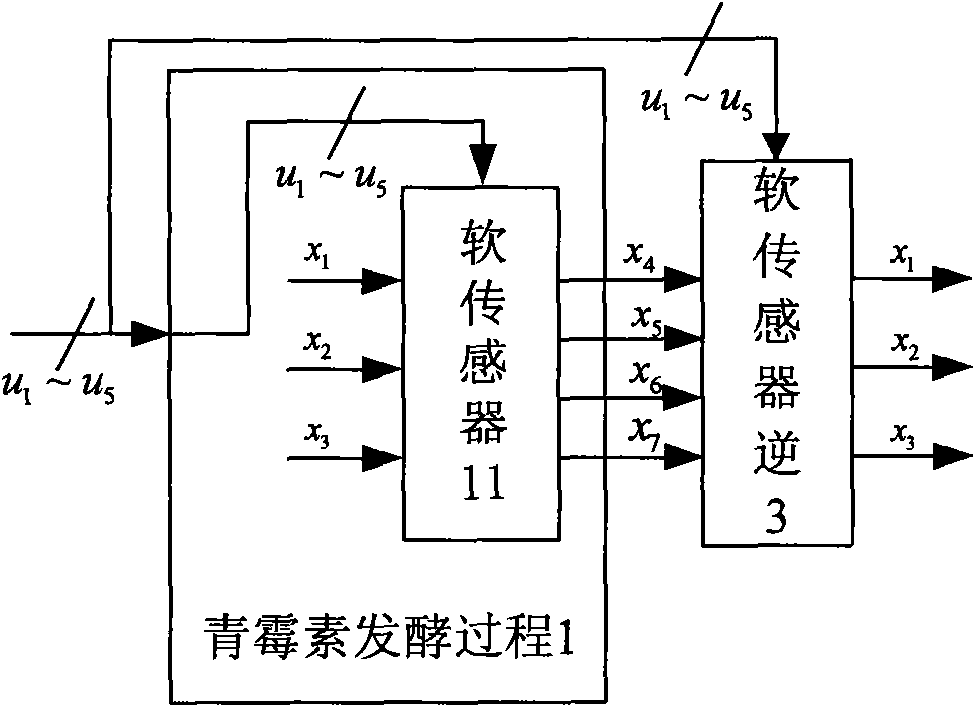

Soft-sensing method of crucial biochemical quantity in penicillin fermentation process based on fuzzy neural inverse and system structure thereof

InactiveCN101587350AHigh precisionReduce mistakesPhysical realisationTotal factory controlDifferentiatorEngineering

Soft-sensing method of crucial biochemical quantity in penicillin fermentation process based on fuzzy neural inverse and system structure thereof is a method for resloving the problem that the crucial biochemical quantity in penicillin fermentation process is difficult to be measured by physical sensor on-line and real-time. Fuzzy neural inverse soft-sensing method establishes a soft-sensor (11) model based on a kinetic equation in penicillin fermentation process (1), on this basis eatablishes an inverse model of the soft-sensor according to inverse system method, and then uses static fuzzy neural network (41) and a differentor to establish fuzzy neural inverse (4) through a free parameters determined by training the static fuzzy neural network, then the soft-sensor inverse is implemented, finally links the fuzzy neural inverse after the penicillin fermentation process to implement on-line and real-time soft-sensing of fungi concentration x[1], substrate concentration x[2] and products concentration x[3]. Specific implementation of the fuzzy neural inverse is the constructed fuzzy neural inverse system applies embedded microprocessor ARM processor.

Owner:JIANGSU UNIV

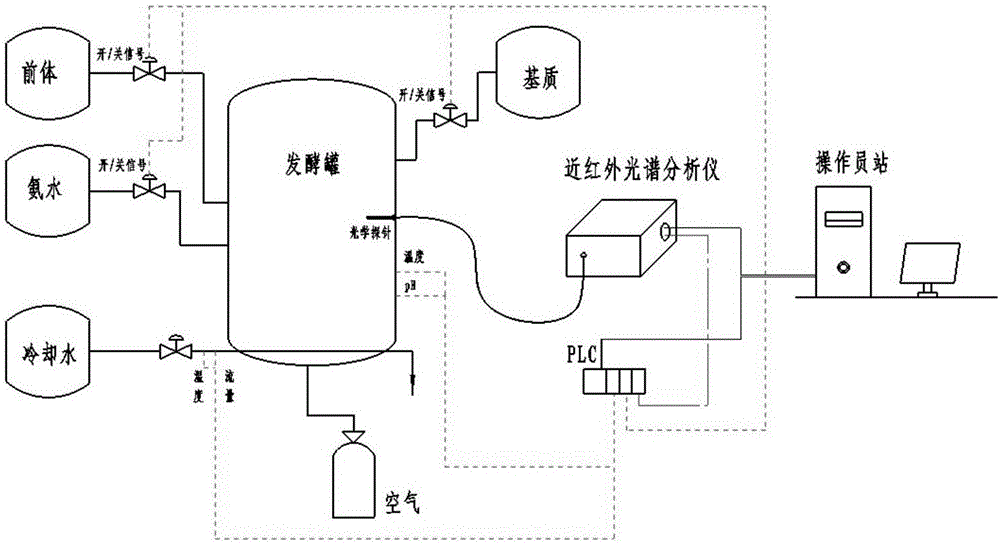

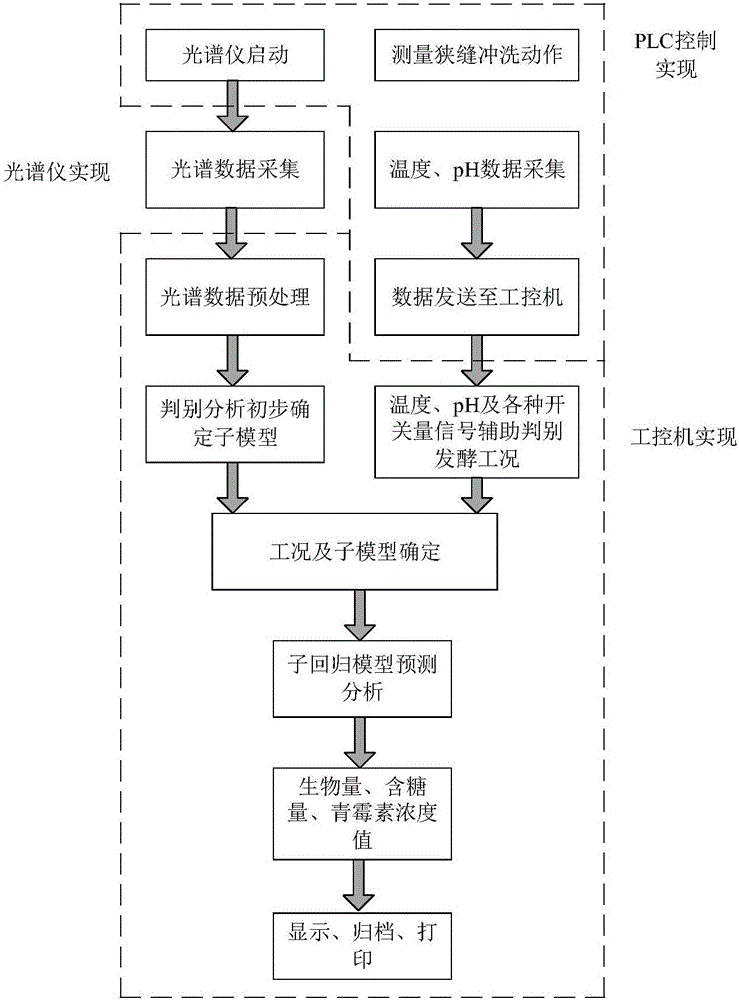

Penicillin fermentation production process multi-model monitoring system based on near infrared spectroscopy technology

ActiveCN106645009AIncrease the level of automationRealize online detectionMaterial analysis by optical meansBiotechnologyFt ir spectra

The invention discloses a penicillin fermentation production process multi-model monitoring system based on a near infrared spectroscopy technology, and belongs to the crossing field of near infrared spectroscopy and penicillin process monitoring. A multi-model analysis method based on the near infrared spectroscopy technology realizes the real-time on-line detection and monitoring on biochemical indexes of fermentation liquid biomass, sugar content, nitrogen content, penicillin concentration and the like in the penicillin fermentation process; the precise value and change trends can be obtained. According to the technical scheme provided by the invention, the penicillin fermentation monitoring system comprises a hardware device consisting of a near infrared spectrograph, a PLC (programmable logic controller) and an industrial personal computer, and a software part consisting of a distinguishing model, a regression model and the like formed by a chemical metrology method. Each part works in a cooperated way; the structure is clear; the system is complete; the automation degree of the penicillin fermentation process can be well improved.

Owner:JIANGNAN UNIV

6-aminopenicillanic acid preparation method

The invention discloses a process for preparing 6-aminopenicillanic acid, which comprises the following steps: (1) filtering the penicillin fermentation liquid, acidifying, extracting and concentrating with butanol, decoloring to obtain butyl extract of penicillin, (2) subjecting butyl extract of penicillin to back extraction with alkaline solvent, obtaining aqueous solution of penicillin salts, (3) degreasing the aqueous solution of penicillin salts, (4) loading the degreased aqueous solution of penicillin salts into penicillin acylated enzyme retort for enzyme conversion, charging 6-APA seeds, cultivating quartz, crystallizing and drying.

Owner:NORTH CHINA PHARMA GROUP CORP

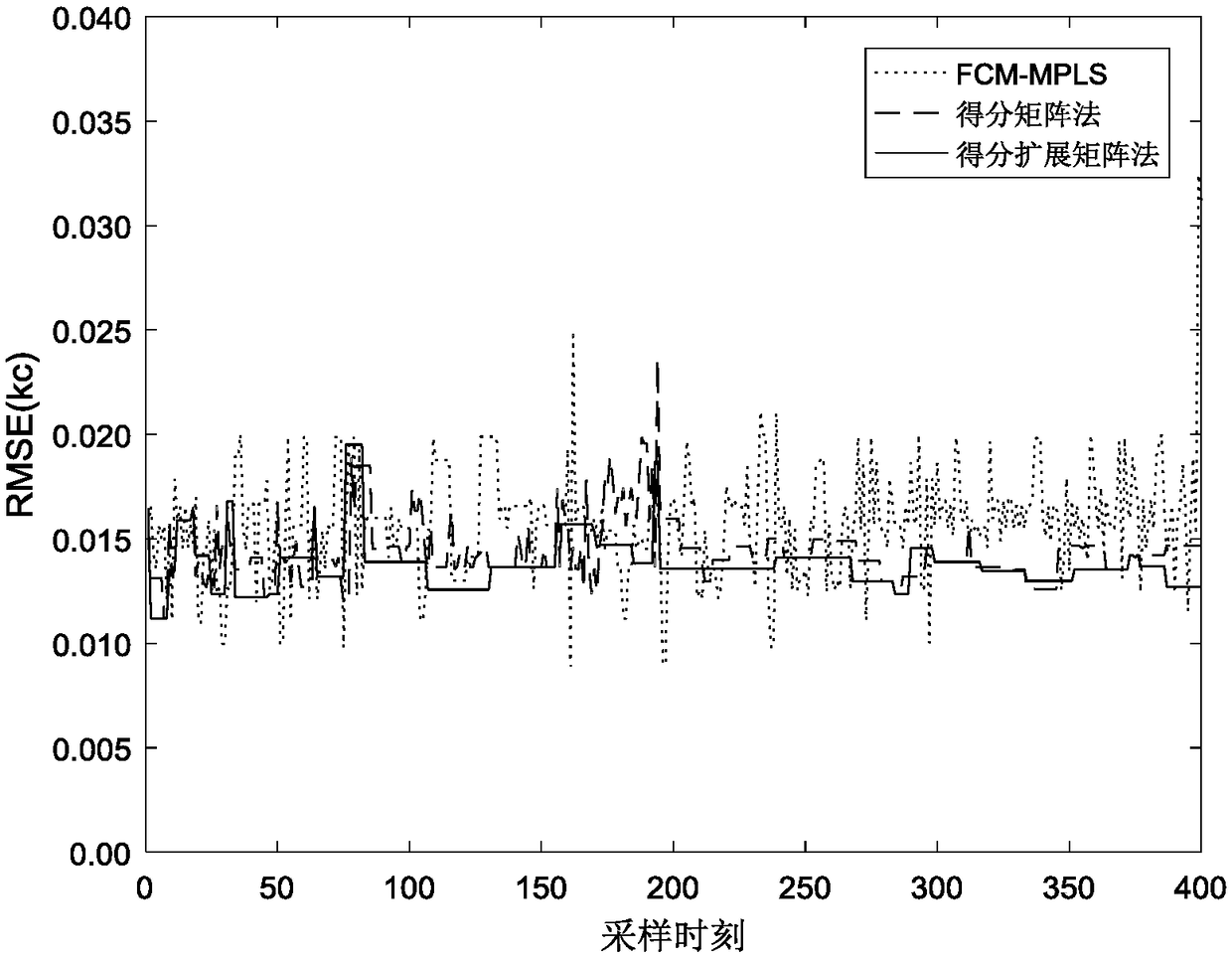

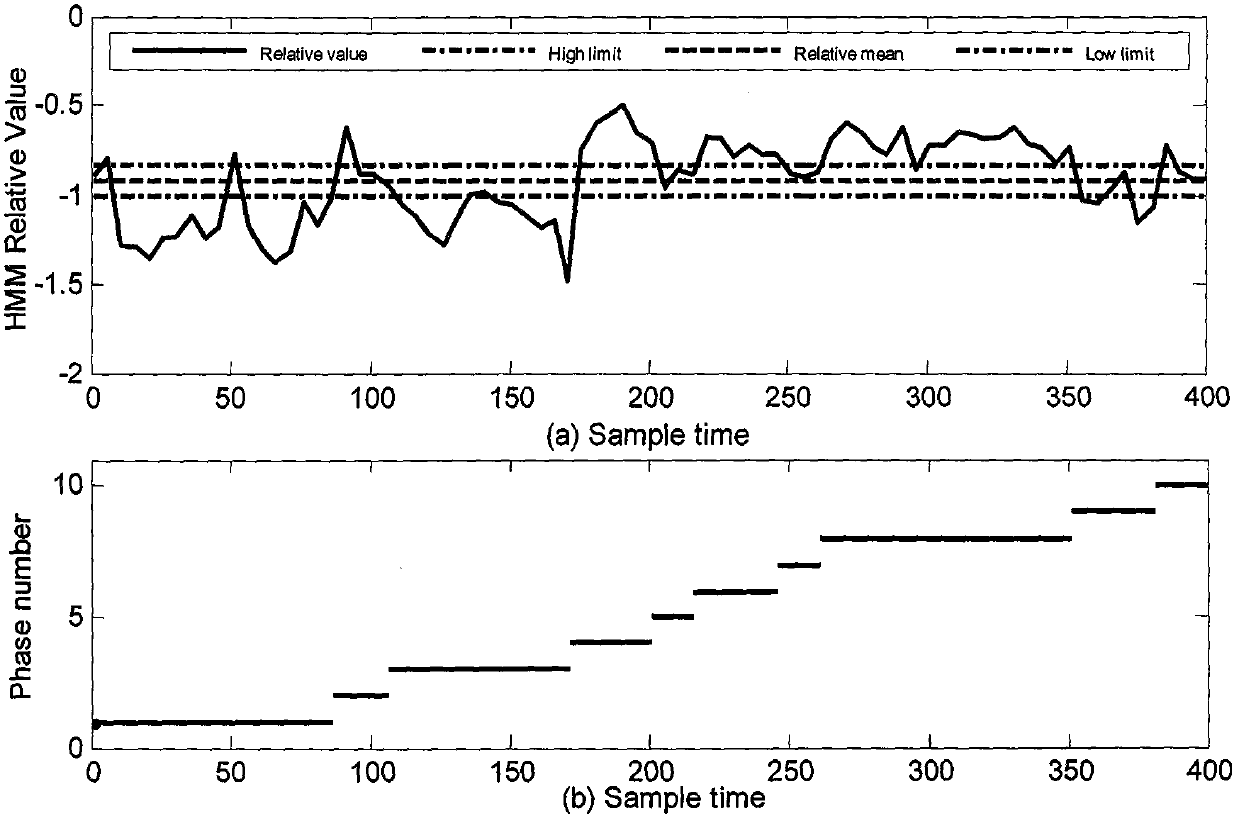

Fermentation process stage division method based on scoring matrices

ActiveCN109308063AHigh precisionTotal factory controlProgramme total factory controlEscherichia coliMatrix method

Owner:BEIJING UNIV OF TECH

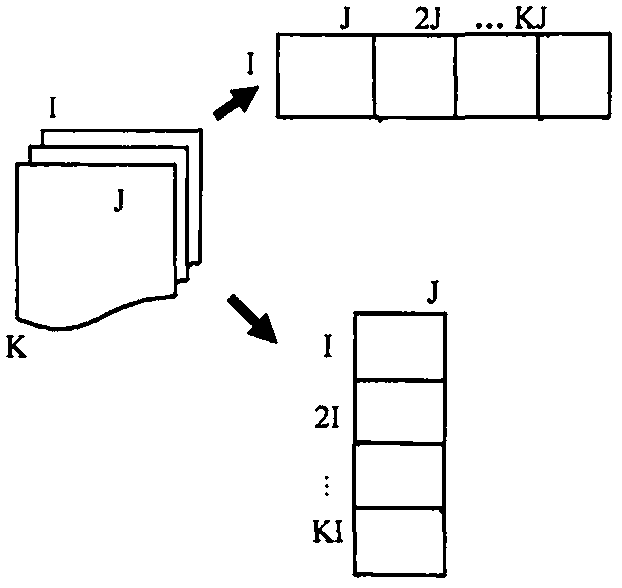

Stage division and fault detection method based on correlation analysis

ActiveCN108664009AGuaranteed comparabilityEnsure consistencyElectric testing/monitoringTransition stageDistribution characteristic

The invention relates to a stage division and fault detection method based on correlation analysis. The method uses the change degree of information in the time slice matrix of a stable stage and a transition stage of an industrial process to identify multiple stages of the reaction duration of the whole industrial process. The method comprises the steps of arranging and standardizing historical batch data in a variable expansion mode, unfolding according to a batch mode, the unfolded time slice matrix comprising time-varying characteristics of an industrial process, and carrying out time sequence stage division according to distribution characteristics of evaluation values. After phase division is carried out, a model is established for each duration stage to monitor quality-related faults, carry out residual information subspace extraction on the industrial process variables, and monitor the abnormity irrelevant to quality in the industrial process. The method is applied to an industrial penicillin fermentation industrial process, which shows that the method has better monitoring performance and forecast capability.

Owner:HUZHOU TEACHERS COLLEGE

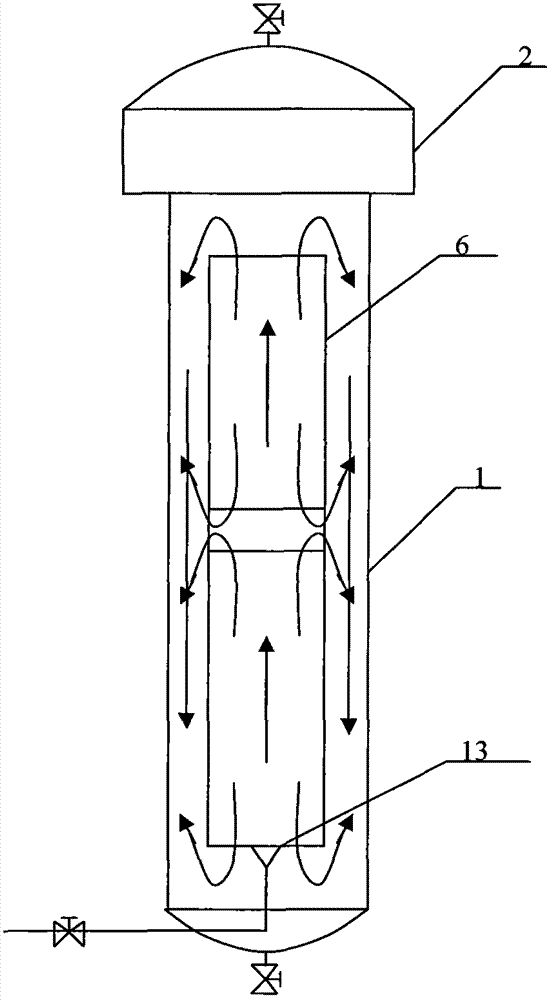

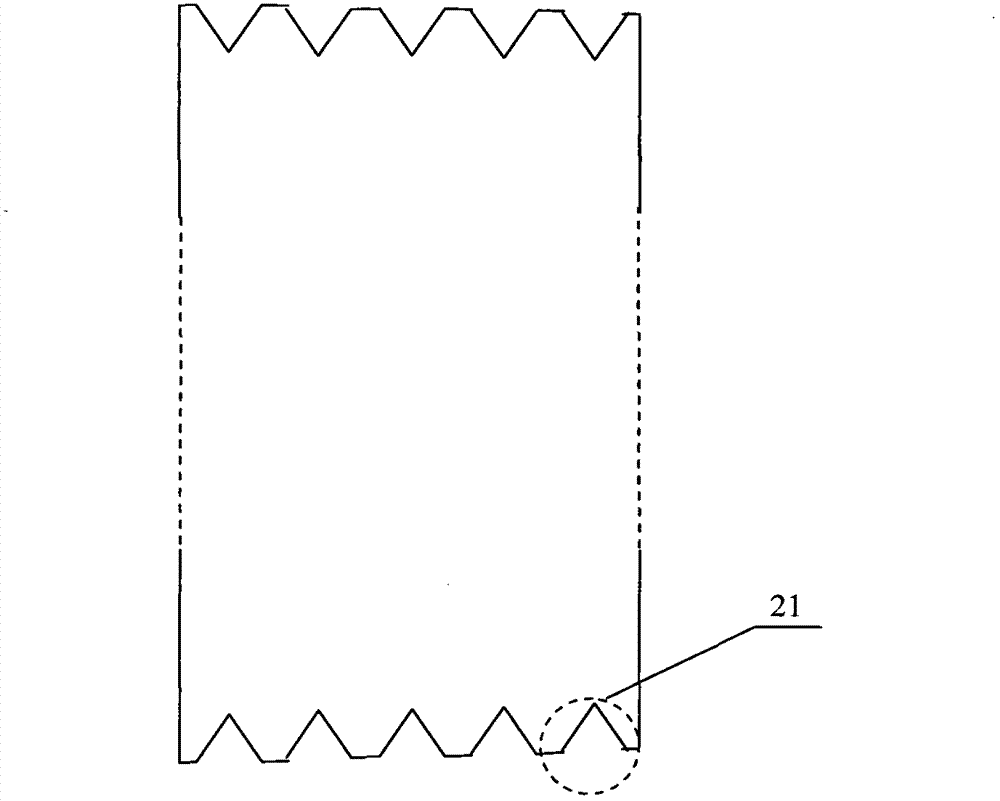

Airlift type loop reactor and method for penicillin fermentation by using the same

InactiveCN102732416AFacilitated DiffusionOvercoming problems such as easy to form groupsBioreactor/fermenter combinationsBiological substance pretreatmentsDiameter ratioTower

The present invention discloses an airlift type loop reactor and a method for penicillin fermentation by using the airlift type loop reactor. The lower part of the tower body of the airlift type loop reactor is the reaction section, and the upper part is the expanded gas-liquid separation section, wherein a height ratio of the gas-liquid separation section to the reaction section is 0.15-0.25, a diameter ratio is 1.25-1.42, a ratio of the total height of the tower body to the inner diameter of the reaction section is 4.5-8, a ratio of the inner diameter of a draft tube to the inner diameter of the tower body is 0.5-0.78, and a height ratio of the draft tube to the reaction section is 0.9-0.65. In the airlift type loop reactor, air is introduced, and a strain producing penicillium chrysogenum is adopted to produce penicillin, wherein the fermentation temperature is 20-30 DEG C, the pH value is 6.0-7.0, the fermentation pressure is 0.08-0.1 MPa, the ventilation ratio is controlled to 0.8-3 vvm, and the fermentation time is 160-170 hours.

Owner:INNER MONGOLIA CHANGSHENG PHARMA

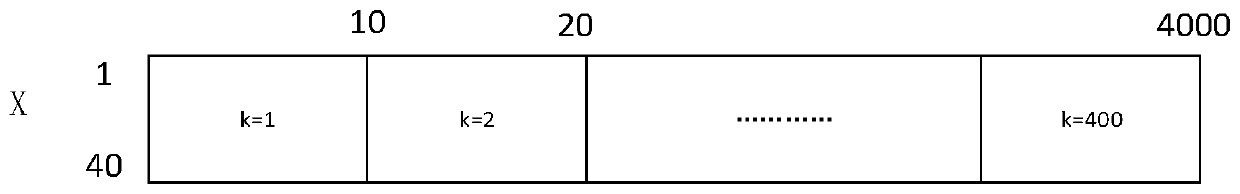

Fermentation process fault monitoring method based on multiple contraction automatic encoders

InactiveCN111324110AReduce diggingReduce complexityProgramme controlElectric testing/monitoringMutual informationFermentation

The invention discloses a new method for carrying out real-time fault monitoring on a penicillin fermentation process. The new method comprises two stages of ''offline modeling'' and ''online monitoring''. The ''offline modeling'' comprises the following steps: expanding historical three-dimensional data into a two-dimensional data matrix; carrying out related sub-block division on accumulated error data by using mutual information (MI); and modeling and monitoring each sub-space by using a contraction auto-encoder (CAE) on the basis of the related sub-block division. The ''online monitoring''comprises the following steps: processing newly collected data according to a model; calculating statistics of the newly collected data, comparing the statistics with a control limit to judge whethera fermentation process runs normally or not; and finally constructing comprehensive statistics to fuse monitoring results of different subspaces together, and carrying out comprehensive analysis. According to the method, the sub-blocks are constructed by using the accumulated errors and the mutual information so that system complexity is effectively reduced, and fault monitoring sensitivity is improved; and a block dividing monitoring model reflects more local information in the process, and faults are easier to monitor.

Owner:BEIJING UNIV OF TECH

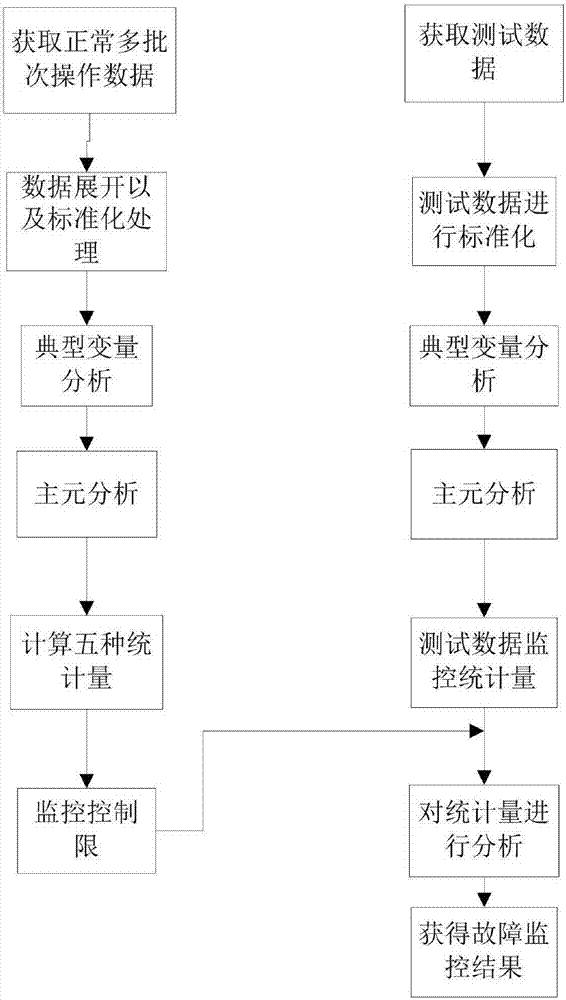

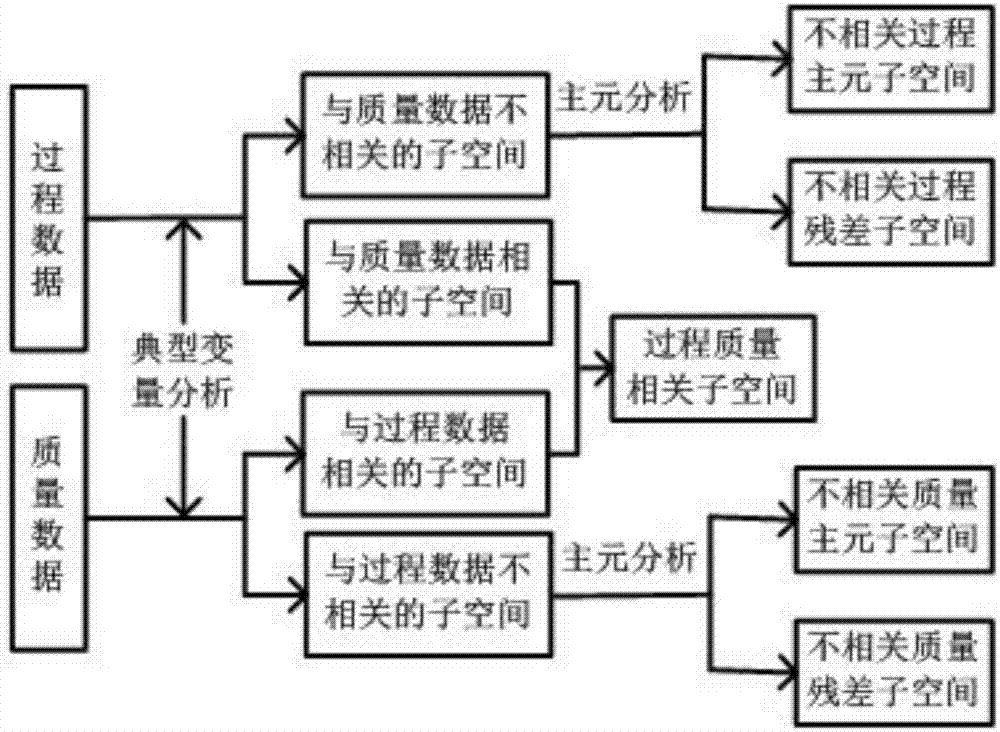

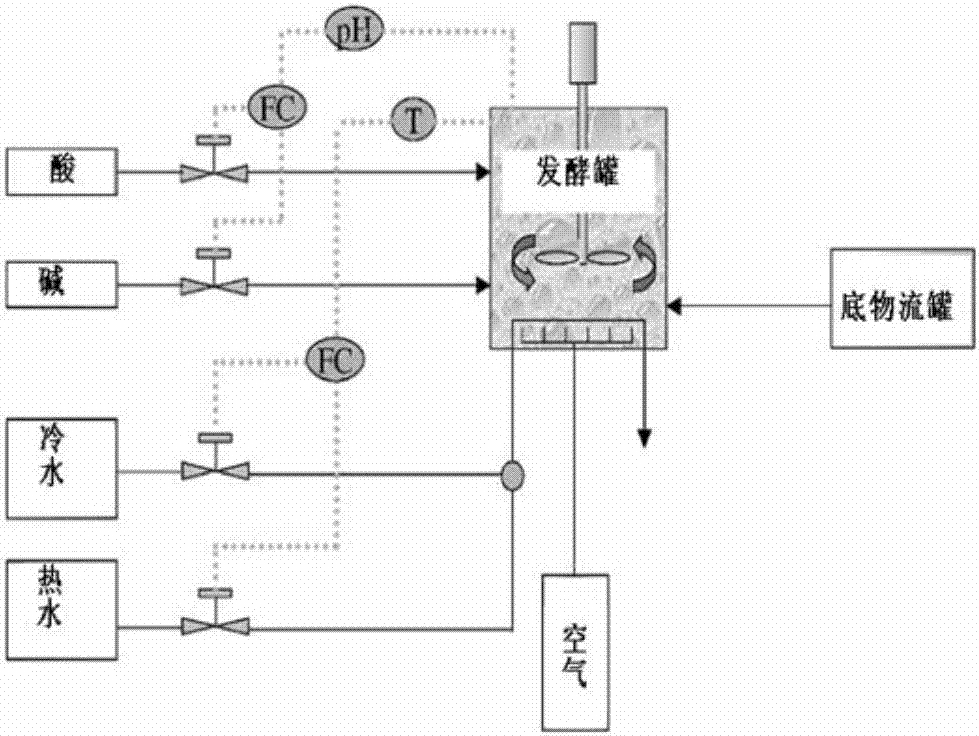

Penicillin fermentation process quality related fault detection method

InactiveCN107122611ARealize Simultaneous MonitoringRealize fine monitoringChemical machine learningSpecial data processing applicationsData setProcess quality

The invention relates to a penicillin fermentation process quality related fault detection method. The method comprises the steps of collecting multiple batches of data in a normal operation condition, dividing the data into a process data set and a quality data set, and performing expansion and standardization to obtain new process data set and quality data set of normal operation; performing multi-subspace typical variable analysis on the process data and the quality data of the normal operation to obtain five subspaces and five statistics variables, and calculating a threshold of monitoring statistics; collecting real-time running data, and performing standardization to obtain new process data set and quality data set; and executing the multi-subspace typical variable analysis on the real-time running data, and by analyzing the condition that the monitoring statistics of the five subspaces exceed the threshold, obtaining a fault detection result. According to the method, based on typical variable analysis, and by further considering variance information and performing five-subspace mapping on original data, fine fault detection can be realized, so that whether the quality is influenced by process faults or not is judged.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

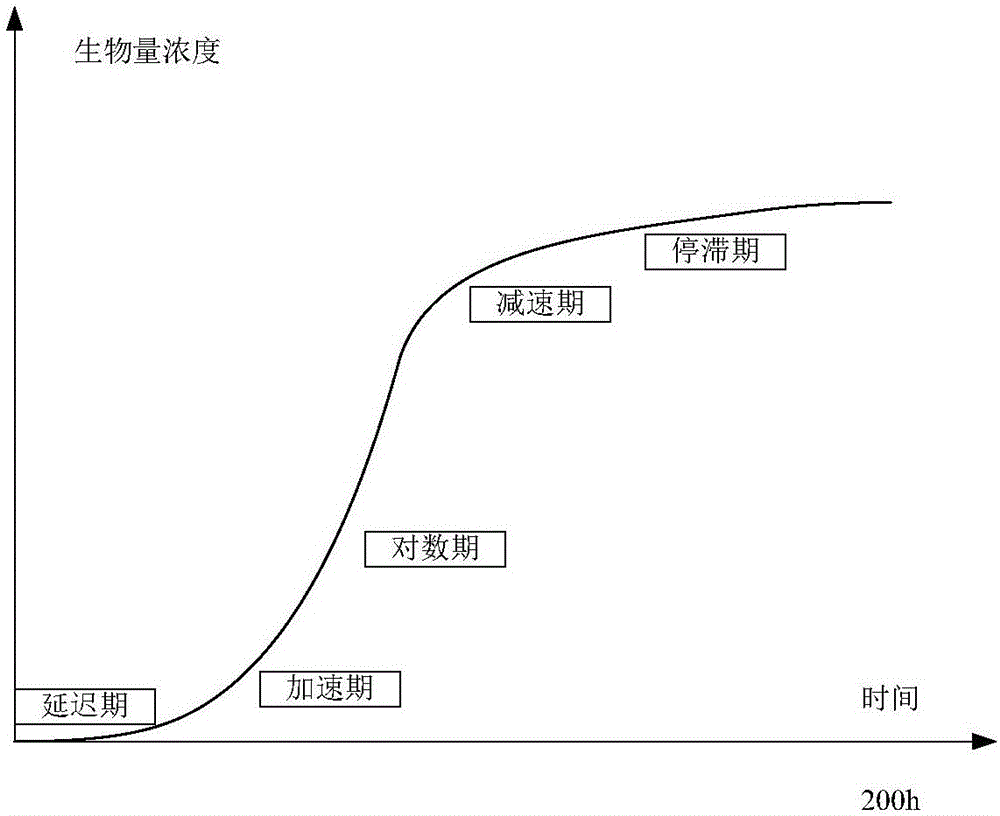

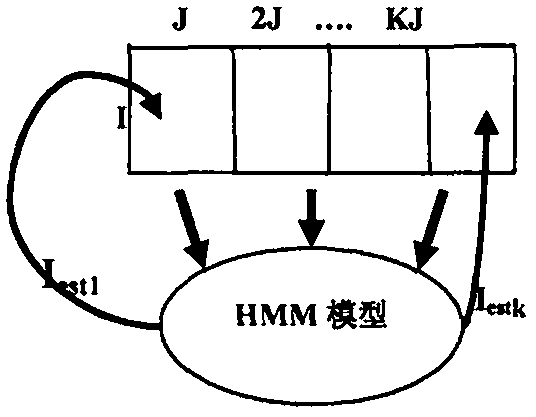

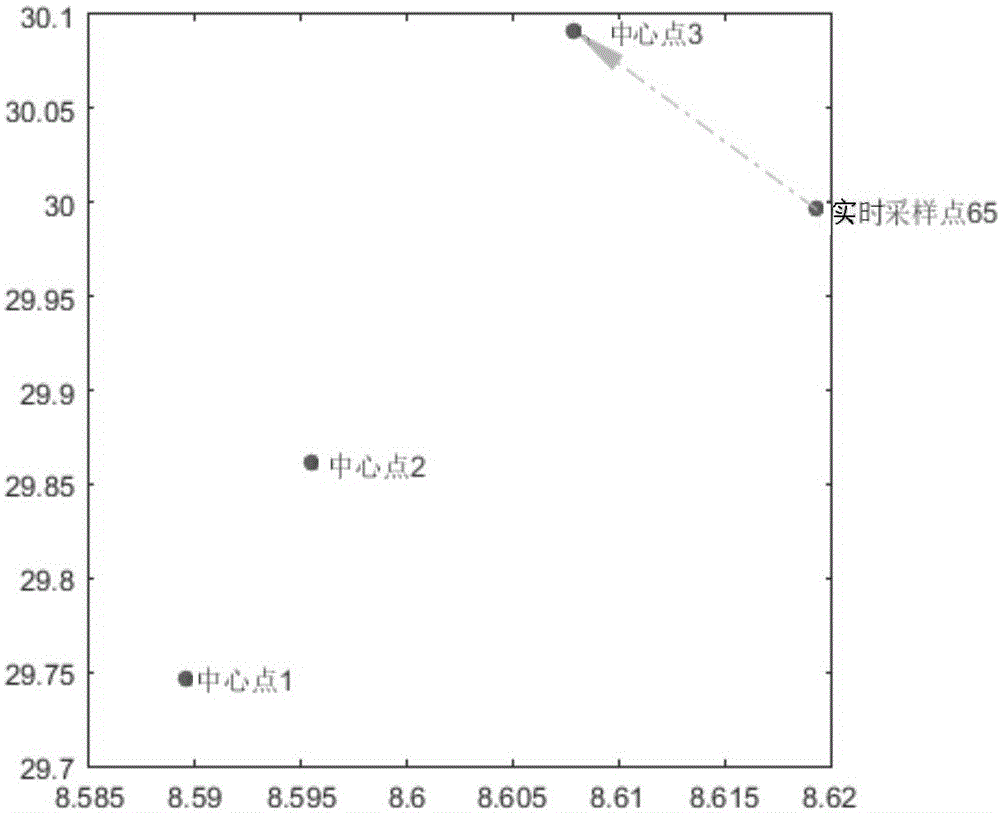

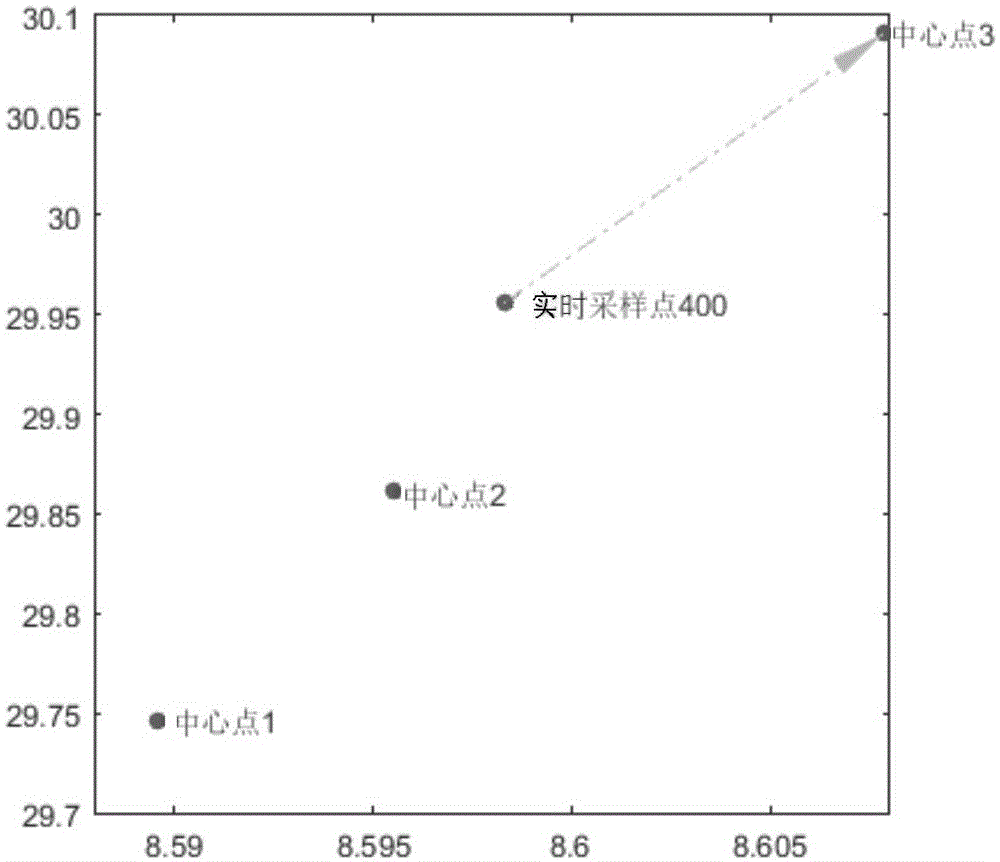

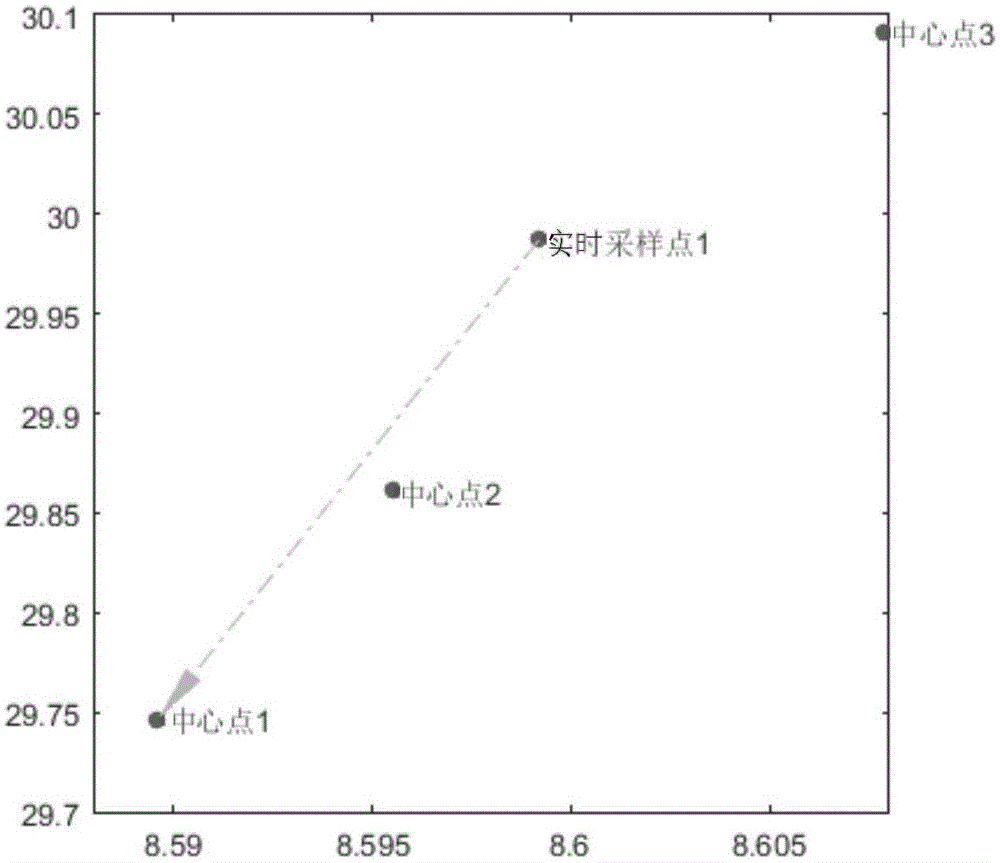

Information transmission based phase affiliation judgment method for real time sampling points in intermittent process

ActiveCN105159247AEffective allocationReduce mistakesTotal factory controlProgramme total factory controlInformation transmissionMultivariate statistics

An information transmission based phase affiliation judgment method for real time sampling points in an intermittent process relates to the technical field of data driving based on multivariate statistics process monitoring (MSPM). According to the invention, phase affiliation judgment of the real time sampling points subjected to online monitoring is realized on the basis of failure detection in a multi-phase intermittent process and the monitoring performance is improved. In order to guarantee the safe and stable operation of a penicillin fermentation process and also to improve the effectiveness of a prior penicillin fermentation process monitoring method, segmentation modeling on batch data of the fermentation process is an effective means for improving model precision. According to the invention, aiming at a problem of how to choose a monitoring model of a corresponding phase accurately for the real time monitoring sampling points during online monitoring by the segmentation modeling in the penicillin fermentation process mainly and through calculating message scales of the clustering centers obtained through calculating online real time sampling points and offline phase division, stable phase affiliation results are output stably through information iteration and model selection during online monitoring can be guided.

Owner:BEIJING UNIV OF TECH

Demulsifier for oil-water separation of fermented liquid

InactiveCN1389291AGood demulsification effectReduce dosageTransportation and packagingMixingDemulsifierEther

The demulsifier for demulsification of penicillin fermenting liquor is characterized by that it is made from 50-80% of acidamide, 20-50% of alkylamine polyethenoxy ether and 0-20% of additive by mixing. It overcomes the defect of demulsifier formed by simple-kmixing deic acid, polyethylene amine and alkyl diethanolamine, and possesses strong desmulsification power, not only possesses high demulsification efficiency, but also can economize production cost, and can raise yield, can make yield stable in above 94%, and has good impurity-removing rate.

Owner:江苏金特耐科技有限公司

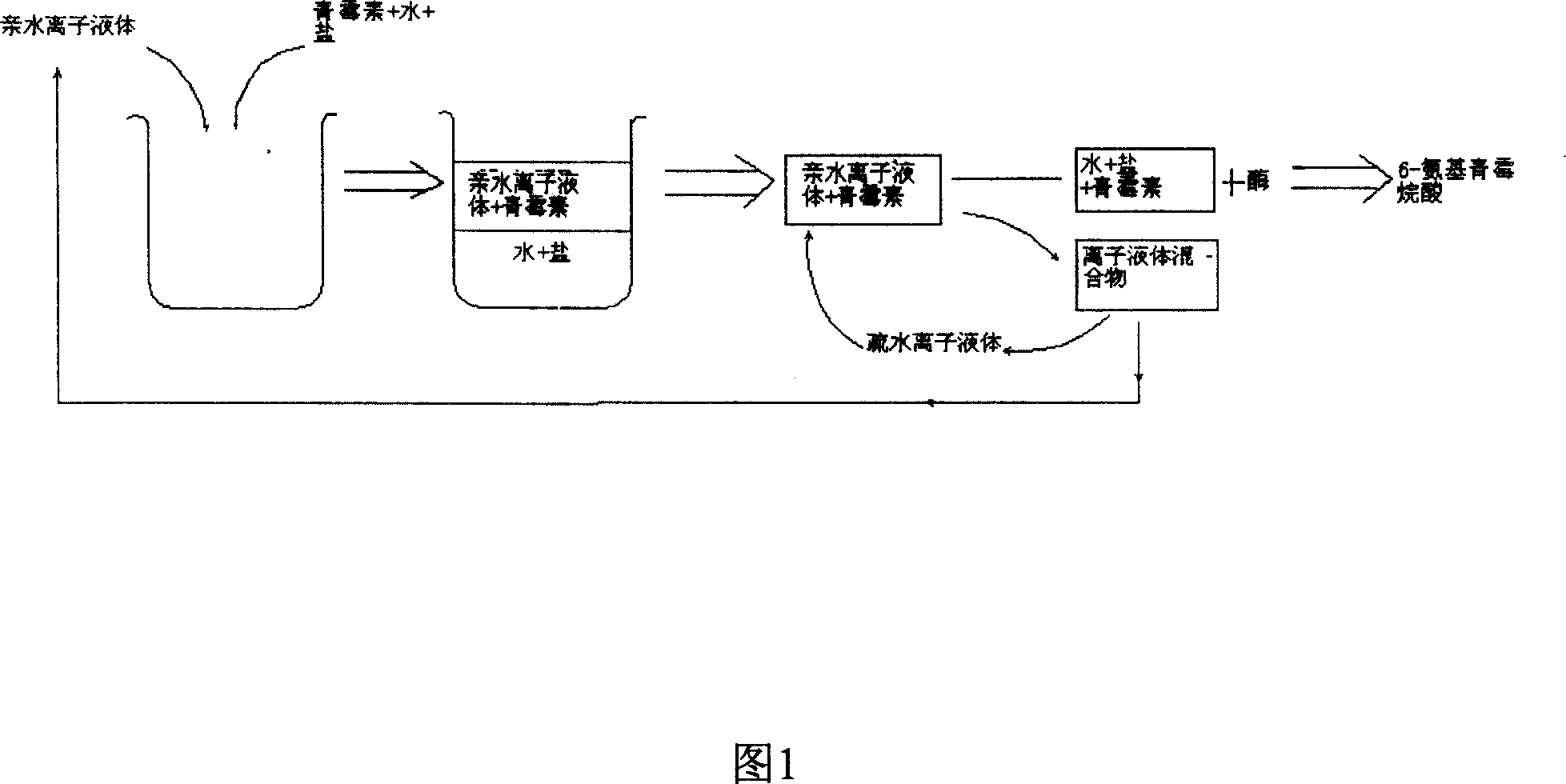

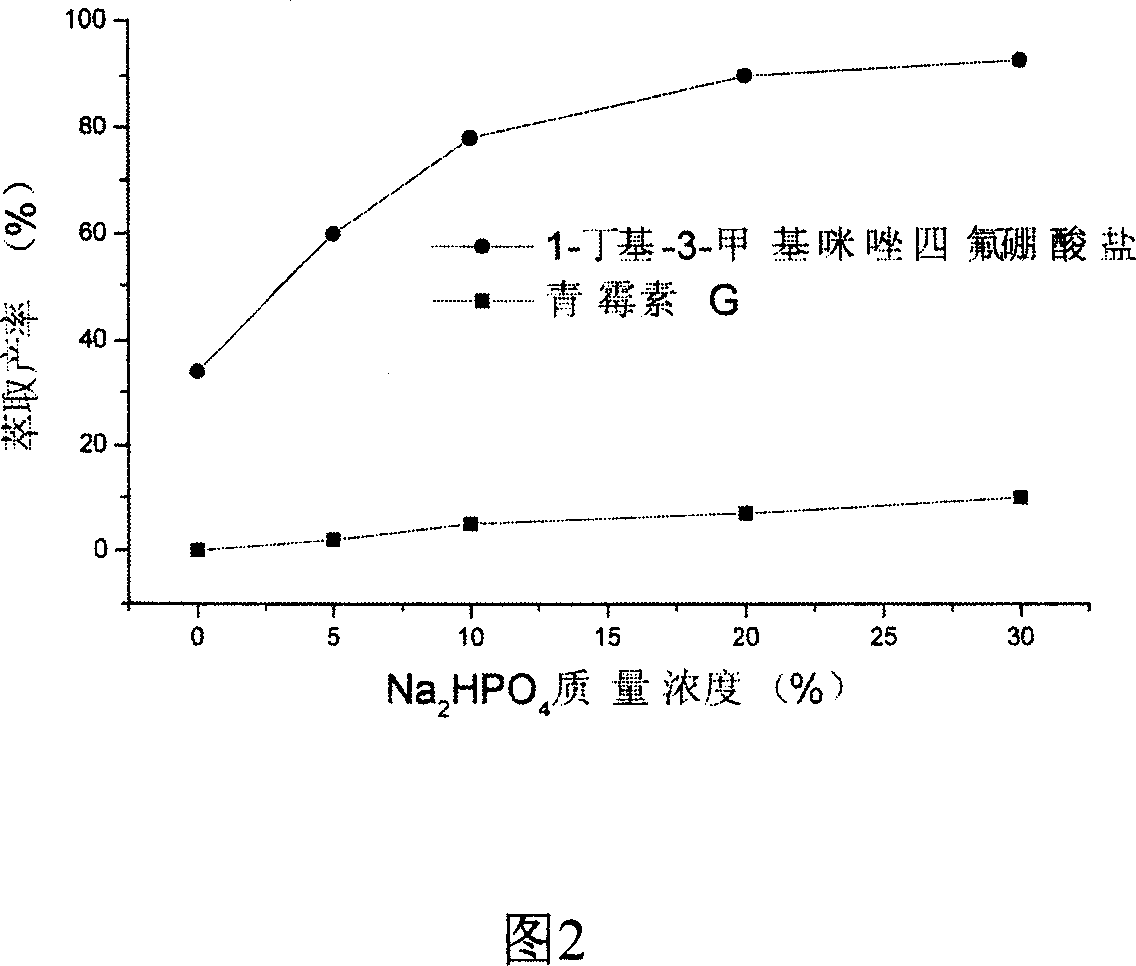

Method of preparing semisynthetic antibiotic 6-amino penicillanic acid by ion liquid extraction penicillin and enzymic catalytic reaction coupling

InactiveCN1948316AAchieve separationReduced hydrophilic ionic liquid contentOrganic chemistryFermentationOrganic solventHydrophile

The present invention relates to a technological process for preparing semi-synthetic antibiotic 6-aminopenicillanic acid by utilizing integrative process composed of penicillin fermentation liquor extraction and enzymatic catalysis reaction. It is characterized by that it utilizes the aqueous two-phase formed by hydrophilic ionic liquor to make penicillin be extracted into the upper phase containing ionic liquor, then utilizes hydrophobic ionic liquor to make secondary extraction so as to make the hydrophilic ionic liquor be extracted into hydrophobic phase, and the penicillin aqueous solution of raffinate phase can be directly undergone the process of enzymatic catalysis reaction, the enzyme activity can be up to above 80%.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

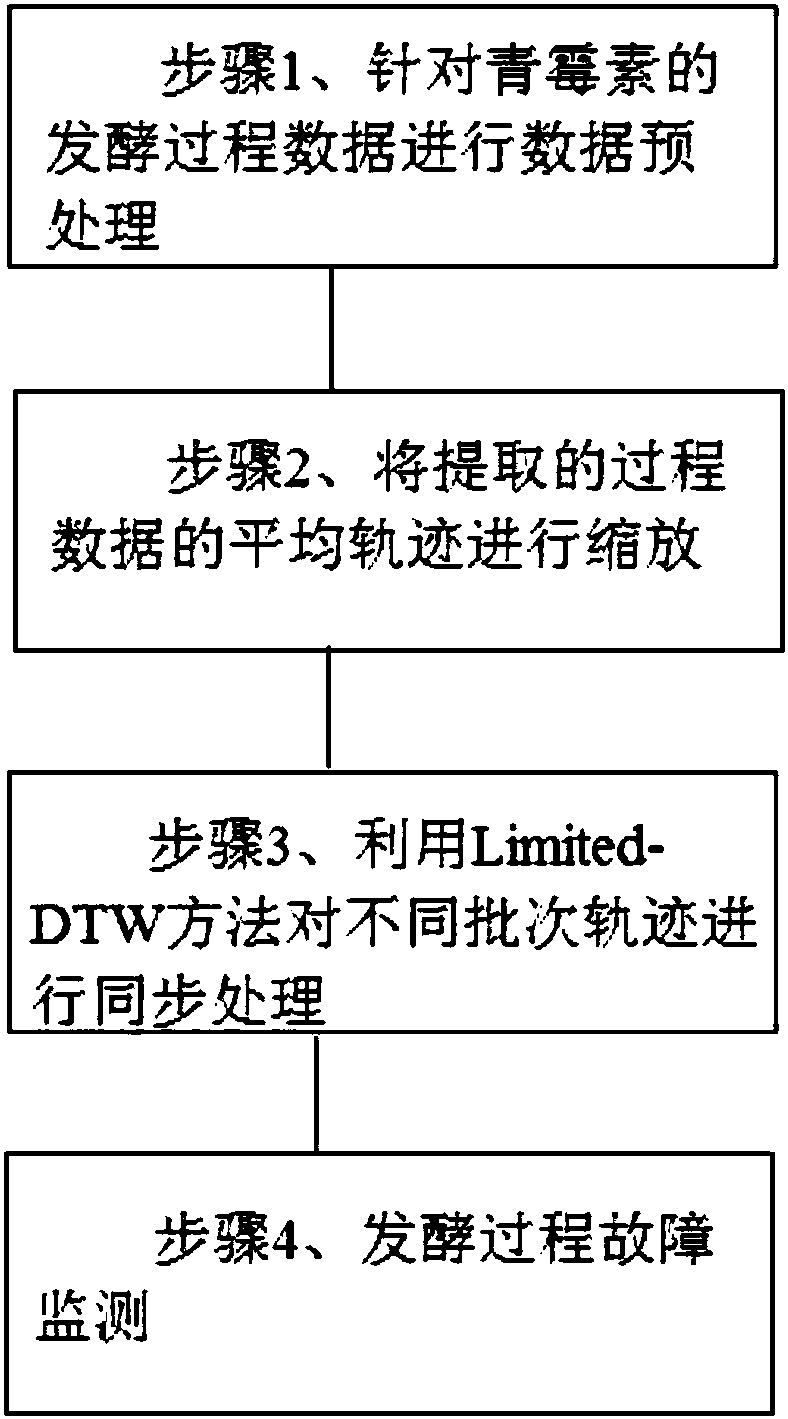

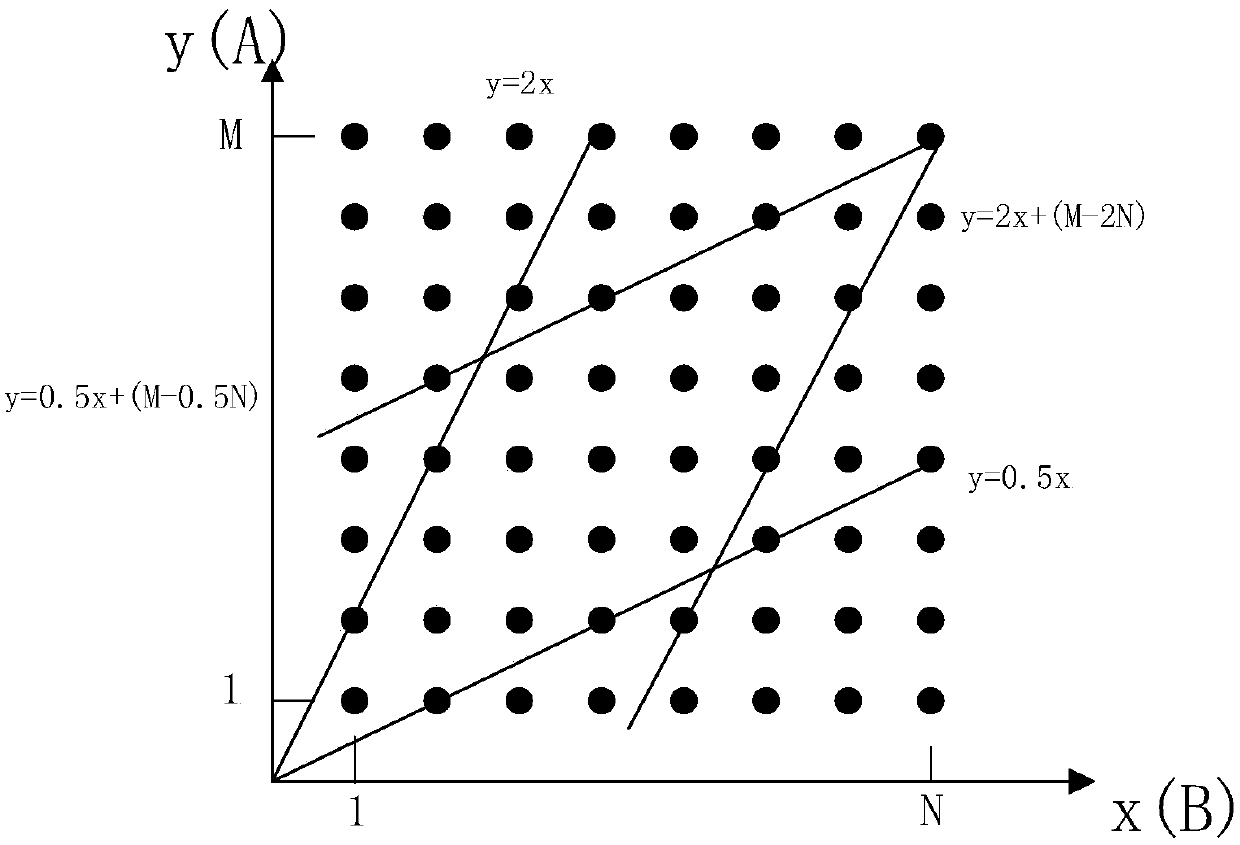

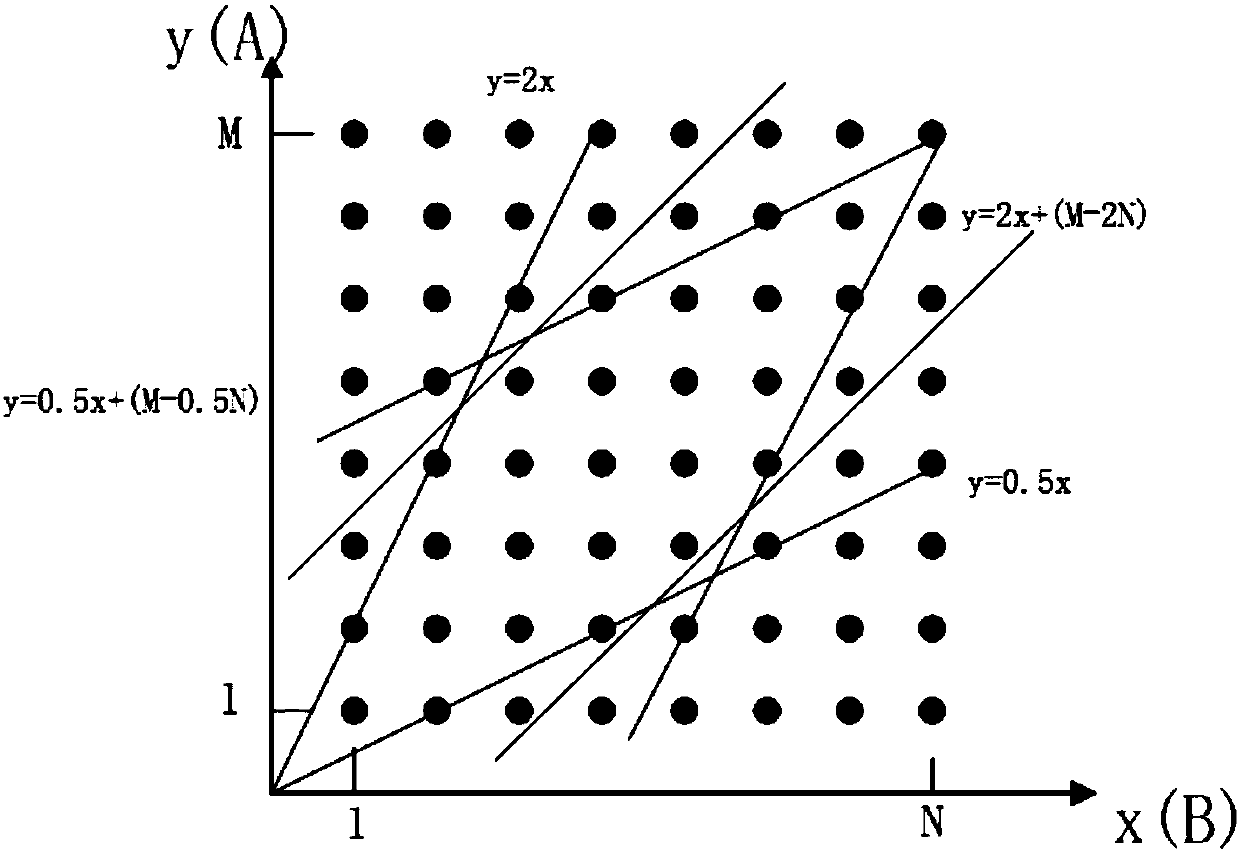

Fault detection method of MKPCA batch process based on Limited-DTW

ActiveCN106990768AReduce search rangeImprove real-time performanceTotal factory controlProgramme total factory controlRecombinant escherichia coliComputer science

The invention discloses a fault detection method of an MKPCA batch process based on Limited-DTW. In order to overcome the inherent shortcomings of the batch unequal length of the intermittent process, and in order to overcome the serious defects of the traditional method of solving the inter-batch synchronization problem such as data waste, and the distortion of the variable autocorrelation and the cross-correlation relation between the variables of the original process, the method introduces the global path limit and the distortion threshold limit to improve the dynamic time warping (DTW) method, so as to avoid the monitoring shortcomings of the long-term operation of the algorithm and to solve the complexity of the processing and the practical application difficulty caused by the off-line performance. Limited-DTW and an MKPCA-based monitoring method are combined for offline and online implementation. The experiment design is completed by the penicillin fermentation simulation platform and the recombinant Escherichia coli practical production process, and the result displays the feasibility and validity of the method provided by the invention.

Owner:BEIJING UNIV OF TECH

Pesticide fertilizer for danshen root GAP standard planting and production method thereof

ActiveCN104058880AHas a killing effectNo pollutionFertilizer mixturesCelastrus orbiculatusNicotiana tabacum

The invention discloses a pesticide fertilizer for danshen root GAP standard planting and a production method thereof. The pesticide fertilizer is prepared from the following raw materials: humic acid, urea, calcium superphosphate, potassium chloride, manganese sulfate, boric acid, penicillin fermentation residues, tobacco processing residues, red pepper processing residues, tea processing residues, pepper seed, anise seed, black pepper seed, lightyellow sophora root, chicken feet golden thread, szechwan chinaberry fruit and oriental bittersweet root. The pesticide fertilizer can be used for providing nutrition for danshen root, has a killing effect on harmful organisms, and is the pesticide fertilizer which is pollution-free, safe and sanitary and residue-free, and can not cause pollution to the environment.

Owner:山东康花生物开发有限公司

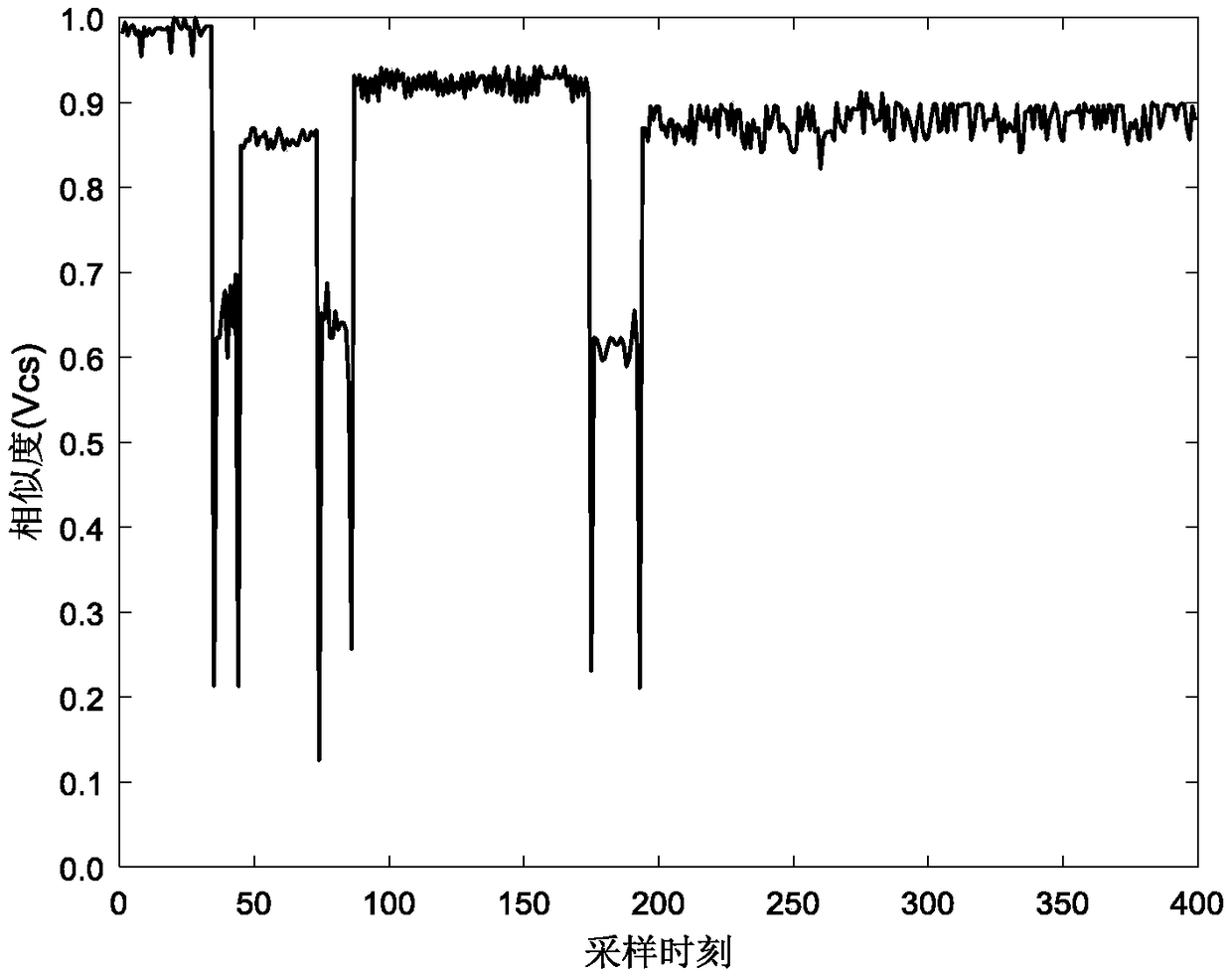

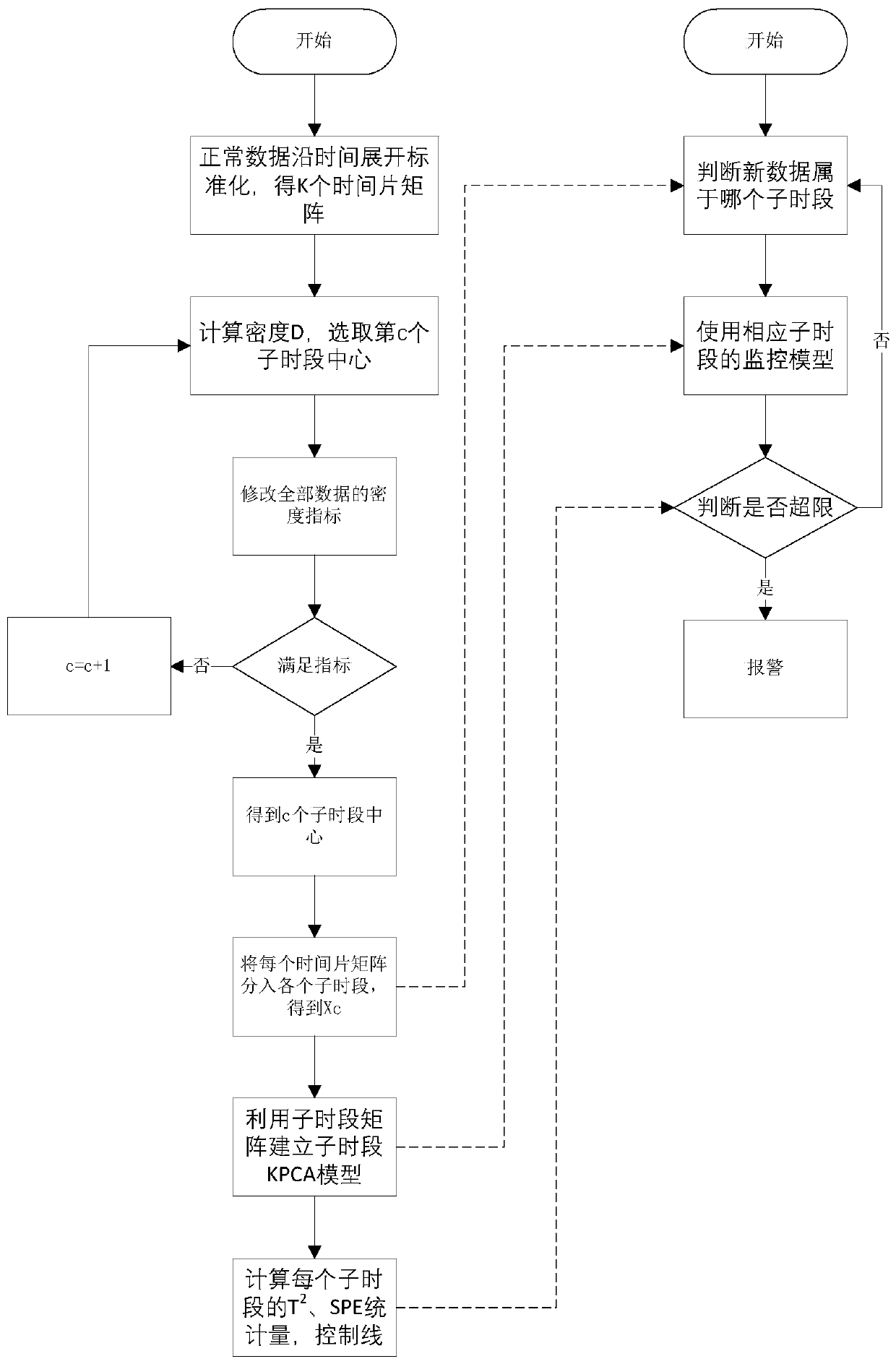

Angle similarity stage division and monitoring method in microbial pharmacy process

PendingCN110032799AReduce false alarm rateReduce false negative rateCharacter and pattern recognitionDesign optimisation/simulationPharmacyControl limits

The invention discloses an angle similarity stage division and monitoring method in a microbial pharmacy process. In order to better process multi-stage characteristics in the penicillin fermentationprocess, an effective fault monitoring model based on a multi-stage division method is established. The method comprises two stages of off-line modeling and on-line monitoring. The off-line modeling comprises the following steps: firstly, expanding three-dimensional data of a fermentation process along a time axis; dividing the data into C0 sub-periods; and then establishing respective KECA modelsby using the sub-period data, finally calculating T2 and SPE statistics of the data, and determining the control limit of the statistics in each period. The on-line monitoring comprises the steps ofprocessing newly collected data according to a model, dividing the data into sub-periods, calculating the statistics of the data, and comparing the statistics with a control limit to judge whether theproduction process is faulty or not. According to the method, the multi-stage characteristics of the intermittent process are fully considered, and the fault monitoring accuracy is satisfactory.

Owner:BEIJING UNIV OF TECH

Fertilizer pesticide composition for platycodon grandiflorum GAP standard planting and preparation method for fertilizer pesticide composition

InactiveCN104072242AHas a killing effectNo pollutionFertilizer mixturesCelastrus orbiculatusNicotiana tabacum

The invention discloses a fertilizer pesticide composition for platycodon grandiflorum GAP standard planting and a preparation method for the fertilizer pesticide composition. The fertilizer pesticide composition is prepared from the following raw materials: dry and fermented chicken manure, ammonium sulfate, calcium superphosphate, potassium sulfate, zinc sulfate, boric acid, an offal material of fermented anka penicillin, an offal material of processed tobacco, an offal material of processed hot peppers, an offal material of processed tea leaves, pepper seeds, star anise seeds, black pepper seeds, radix sophorae flavescentis, chicken foot coptis chinensis, chinaberry fruit and celastrus orbiculatus. According to the invention, the fertilizer pesticide composition can not only provide nutrition for the platycodon grandiflorum, but also have the function of killing pests, so that the fertilizer pesticide composition is an agrochemical fertilizer which is pollution-free, safe and sanitary, and residue-free and does pollute environment.

Owner:贵阳智仁源生物有机肥业有限公司

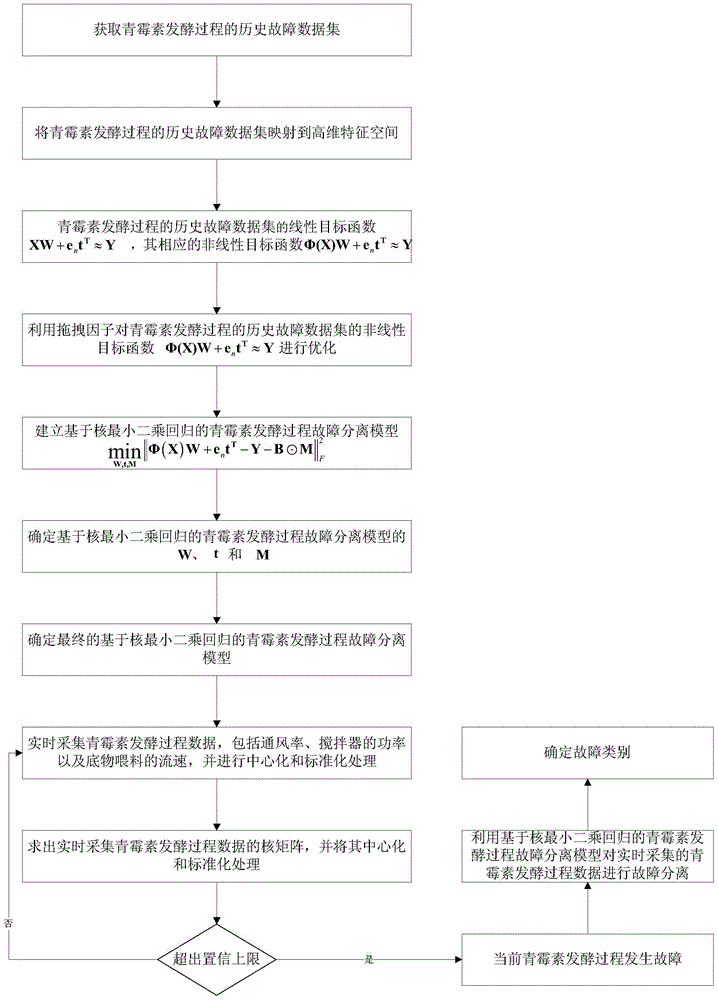

Penicillin fermentation process fault isolation method based on kernel least square regression

InactiveCN104133990ATroubleshootingTroubleshooting Troubleshooting IssuesSpecial data processing applicationsData setComputer science

The invention provides a penicillin fermentation process fault isolation method based on kernel least square regression. The method comprises the following steps of: obtaining a penicillin fermentation process historical fault data set; building a kernel least square regression learning model according to the penicillin fermentation process historical fault data set, wherein the input of the model is the penicillin fermentation process historical fault data set, and the output of the model is a penicillin fermentation process fault category; collecting penicillin fermentation process data in real time and judging whether faults occur in the current penicillin fermentation process or not; and carrying out fault isolation on the real-time collected penicillin fermentation process data by utilizing a penicillin fermentation process fault isolation model based on the kernel least square regression, and determining the fault category. The penicillin fermentation process fault isolation method has the advantages that through the introduction of the kernel least square regression, nonlinear data is mapped to a linear space, so that the fault monitoring and fault diagnosis problems of a nonlinear space are solved, and the fault category can be isolated at higher precision.

Owner:NORTHEASTERN UNIV

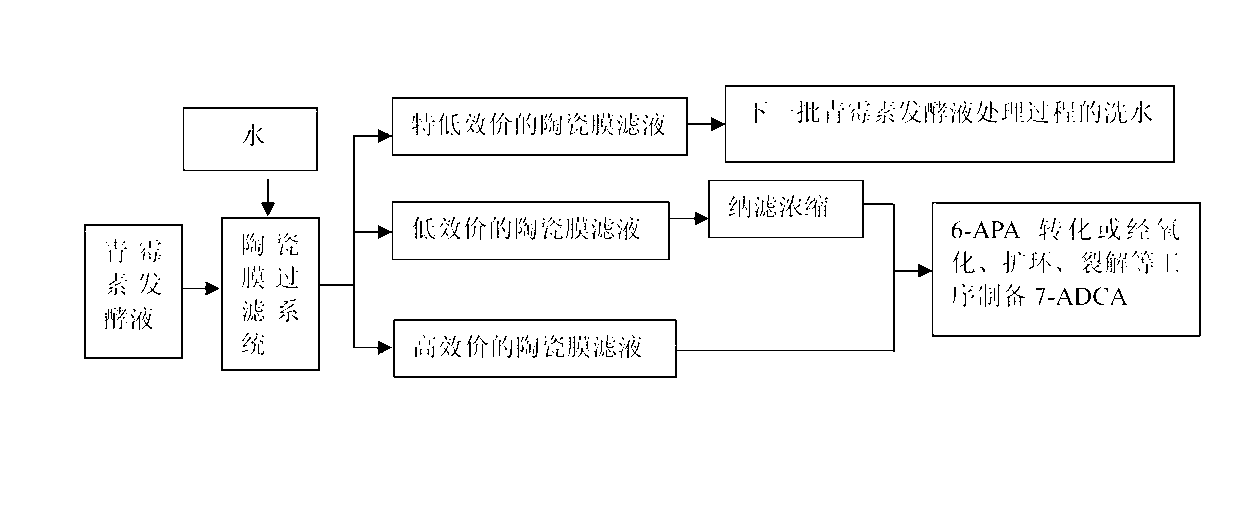

Penicillin fermentation broth treating technology

ActiveCN103214498ADetermining the concentrationDetermine the quantitySemi-permeable membranesOrganic chemistryCross-flow filtrationCephalosporanic Acids

The invention discloses a penicillin fermentation broth treating technology, which comprises the following steps of: cooling an original penicillin fermentation broth, filtering the cooled penicillin fermentation broth by a closed ceramic-membrane cross-flow filtration system, and collecting high-titer ceramic-membrane filtrate; during filtration, when the wet solid content in the penicillin fermentation broth is enhanced to 1.8-2 times that of the original fermentation broth, adding water with weight accounting for 2 times that of the original fermentation broth for dialyzing to obtain and collect low-titer ceramic-membrane filtrate, and then nano-filtering, concentrating and dewatering the low-titer ceramic-membrane filtrate for later use; continuing to add water with weight accounting for 2 times that of the original fermentation broth for dialyzing to obtain and collect ultra-low-titer ceramic-membrane filtrate; stopping filtration until the titer of penicillin in the penicillin fermentation broth is low to 500-800U; collecting bacterium dregs intercepted by the ceramic-membrane filtration system; putting the high-titer ceramic-membrane filtrate in 6APA (6-aminopenicillanic acid) for conversion or oxidization, ring enlargement and cracking, thus preparing 7-ADCA (7-aminodeacetoxy cephalosporanic acid); and collecting the obtained bacterium dregs and adding engineering bacteria for decomposing the bacterium dregs.

Owner:河北美邦工程科技股份有限公司 +1

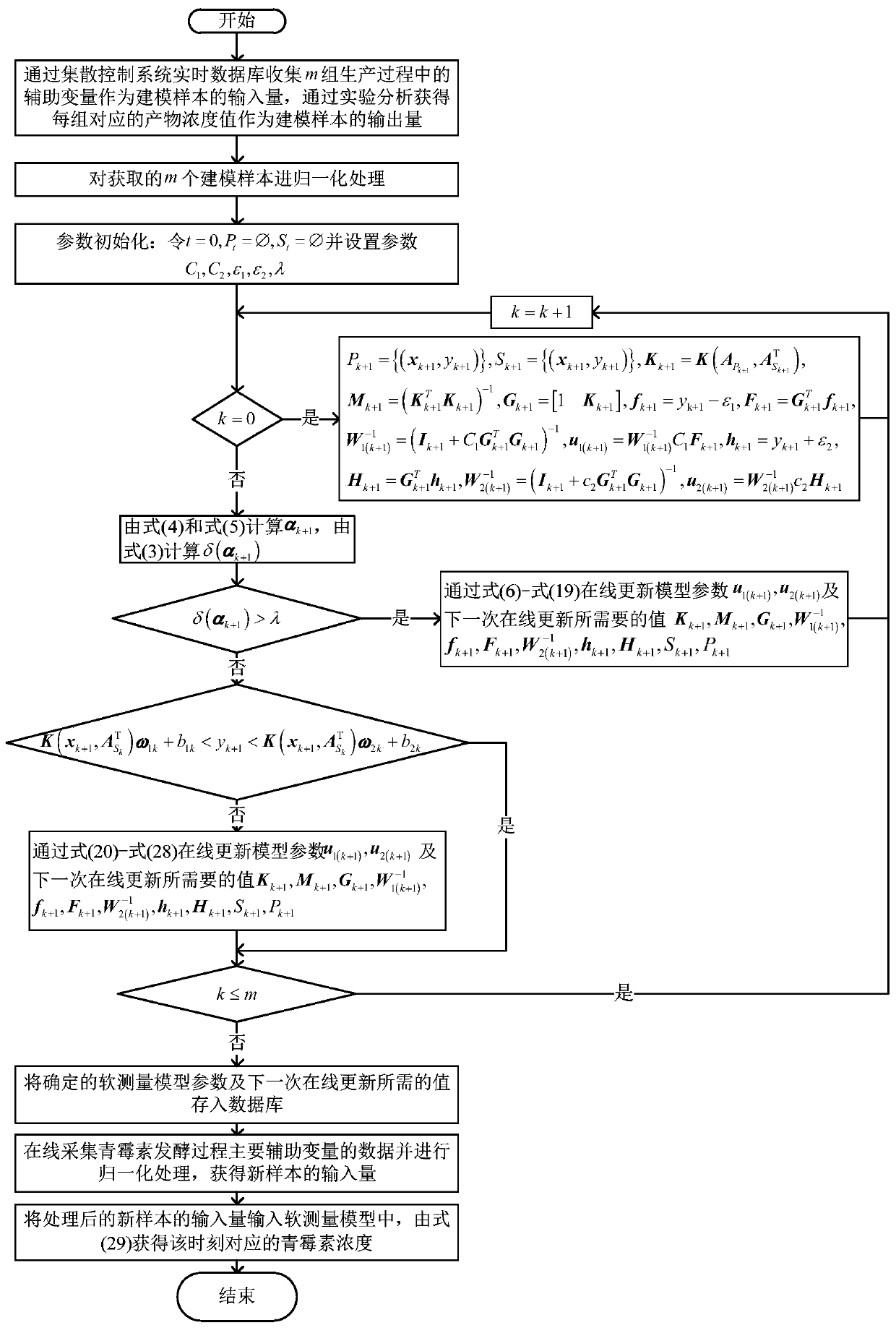

Fermentation process soft measurement method based on online twin support vector regression machine

ActiveCN110908361AProgramme controlElectric testing/monitoringIndustrial fermentationBiochemical engineering

The invention provides a fermentation process soft measurement method based on an online twin support vector regression machine, and belongs to the field of industrial fermentation production processsoft measurement modeling and application. The method comprises the following steps: firstly, normalizing auxiliary variables in a penicillin production process, and then carrying out soft measurementmodeling based on an online twin support vector regression machine on a nonlinear relationship between the auxiliary variables and the penicillin concentration of a product. Through performing on-line soft measurement on the penicillin concentration of a product difficult to measure through auxiliary variables easy to measure in the fermentation process, the method is very efficient for updatingthe model, and the method is provided for on-line real-time measurement of the penicillin concentration of the product in the penicillin fermentation production process. According to the soft measurement method, the real-time performance of online prediction can be improved, the model updating time is shortened, the prediction precision is high, and the method can be effectively used for guiding penicillin production.

Owner:JIANGNAN UNIV

Method for synthesizing amoxicillin and generating byproduct of sodium phenylacetate solution by using semi-direct method

InactiveCN107988306AHigh yieldImprove product qualityOrganic compound preparationCarboxylic acid salt preparationPhenylacetic acidBenzylpenicillin potassium

The invention relates to a method for synthesizing amoxicillin and generating a byproduct of a sodium phenylacetate solution by using a semi-direct method and belongs to the technical field of medicine preparation. The method comprises the following steps: splitting benzylpenicillin potassium into 6-APA (Amino Penicillanic Acid) and phenylacetic acid under the action of penicillin acylase, extracting a splitting solution with dichloromethane to separate 6-APA from the phenylacetic acid, putting ammonia water into an extraction water phase, adjusting the pH value of a material liquid to be neutral, removing the dichloromethane, putting the solid 6-APA into the obtained 6-APA dissolving liquid, and synthesizing the amoxicillin together with D-methyl p-hydroxyphenylglycinate under the actionof amoxicillin synthetase. A sodium phenylacetate solution can be prepared by alkalizing the dichloromethane obtained by extracting the splitting solution, the sodium phenylacetate solution can be directly applied to fermentation production of penicillin, the step of recycling the phenylacetic acid is avoided, and the production cost is reduced.

Owner:INNER MONGOLIA CHANGSHENG PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com