Penicillin fermentation production process multi-model monitoring system based on near infrared spectroscopy technology

A technology of near-infrared spectroscopy and penicillin fermentation, applied in the field of online detection of near-infrared spectroscopy of liquid fermentation, can solve the problems of unguaranteed accuracy, difficult real-time online detection, and difficult detection of instruments, so as to improve the level of automation, save investment costs, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In the following, the present invention will be further described and explained in conjunction with the accompanying drawings and examples, so that those skilled in the art can better understand the present invention.

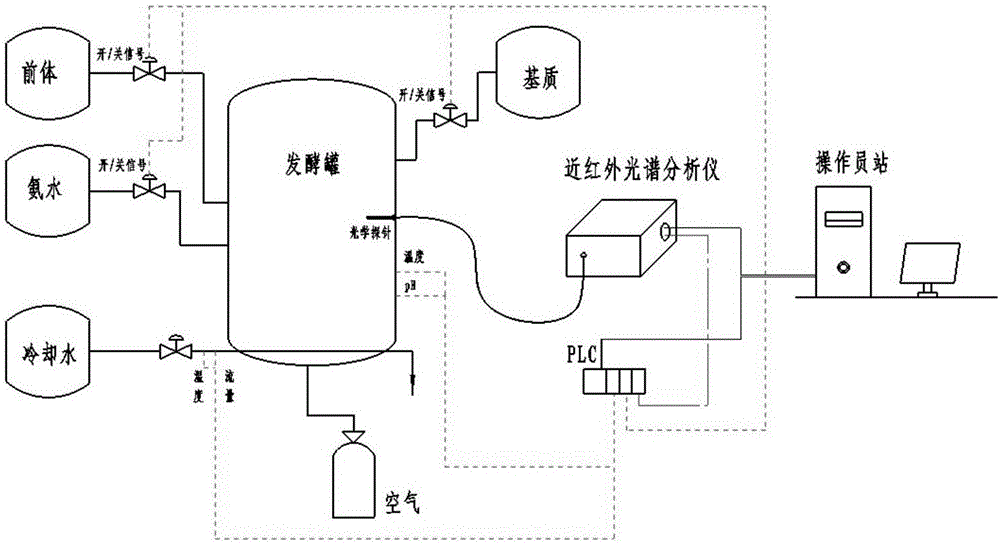

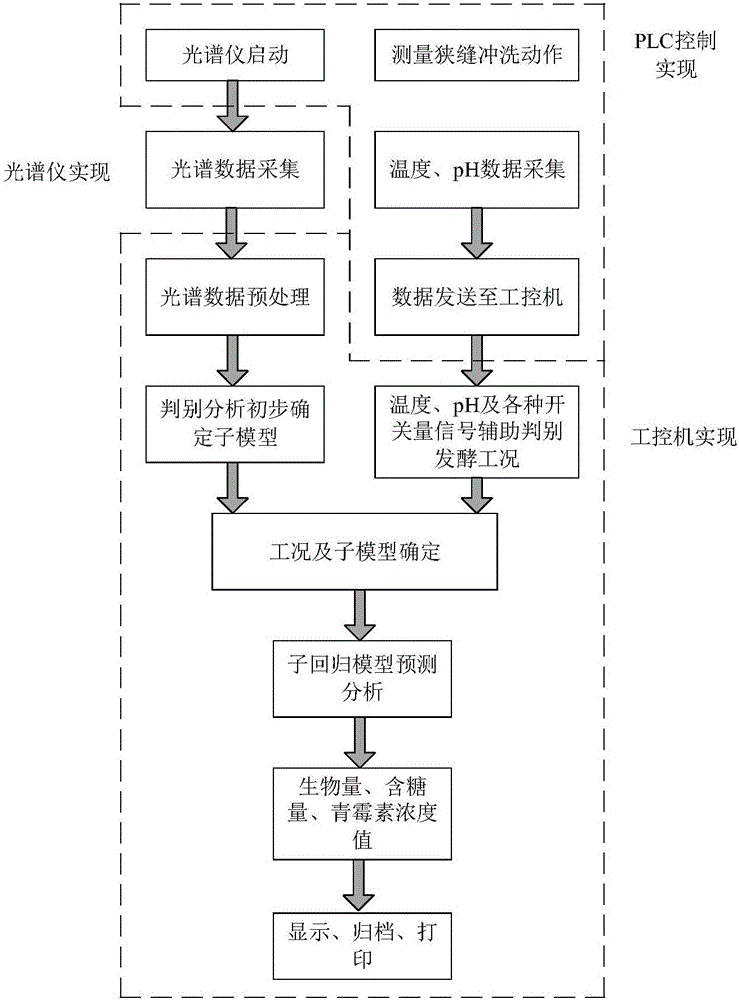

[0027] figure 1 The hardware structure diagram of the system described in the present invention is provided, and its working principle is: the spectrometer is connected with the industrial computer through a dedicated USB interface, and connected with the PLC through the RS232 port; the PLC and the industrial computer are also connected through the RS232 port to realize mutual communication . The optical fiber probe equipped with the spectrometer is inserted into the middle of the fermenter tank 30cm, and equipped with a flushing device. PT100 thermal resistance is used for temperature detection, equipped with a corresponding temperature transmitter, the output signal is 4-20mA, a total of three channels, which are the temperature of the fermentation ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com