Penicillin fermentation process failure monitoring method based on recursive kernel principal component analysis

A technology for penicillin fermentation and nuclear principal component analysis, which is applied in special data processing applications, instruments, electrical digital data processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0124] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

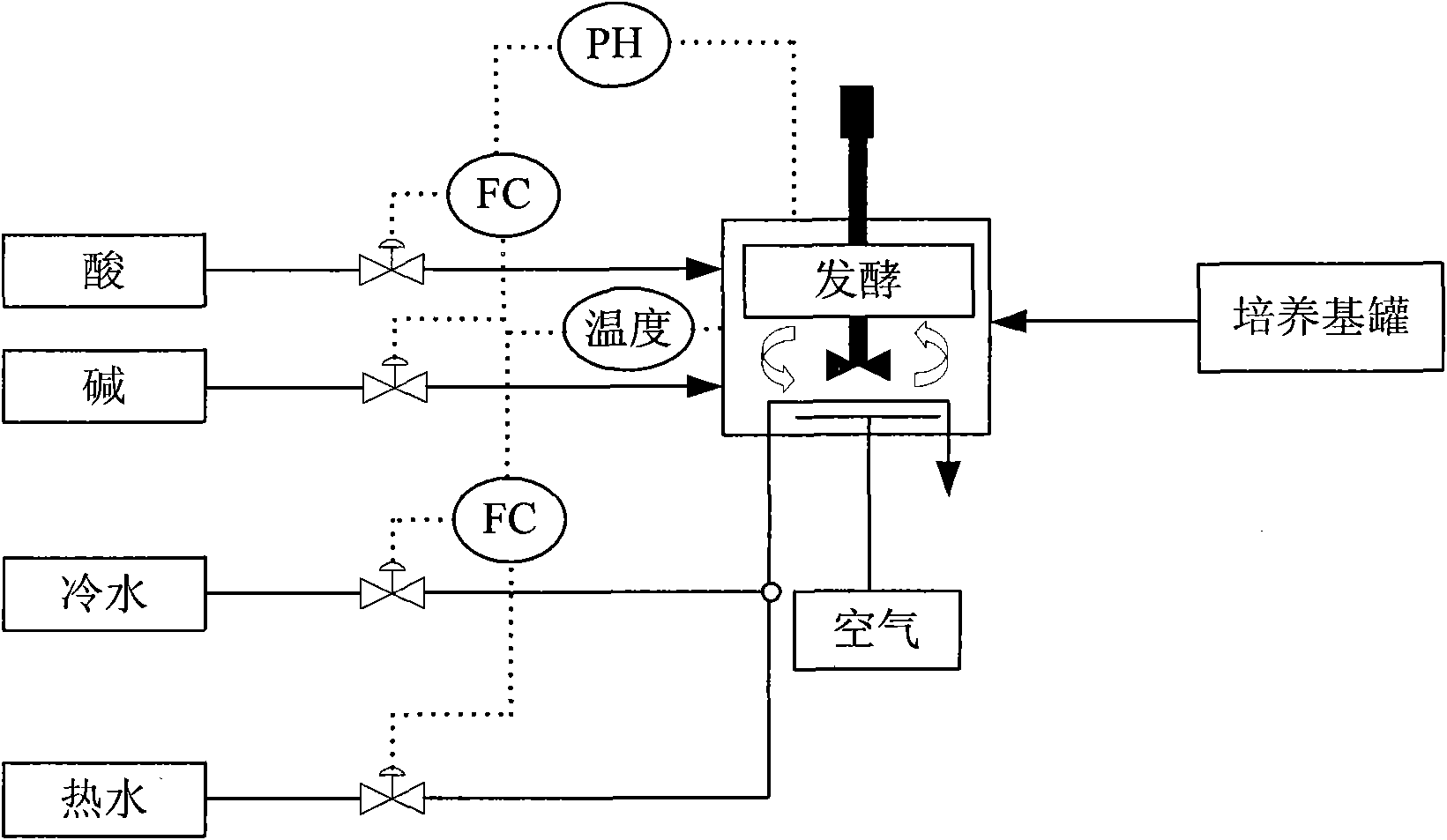

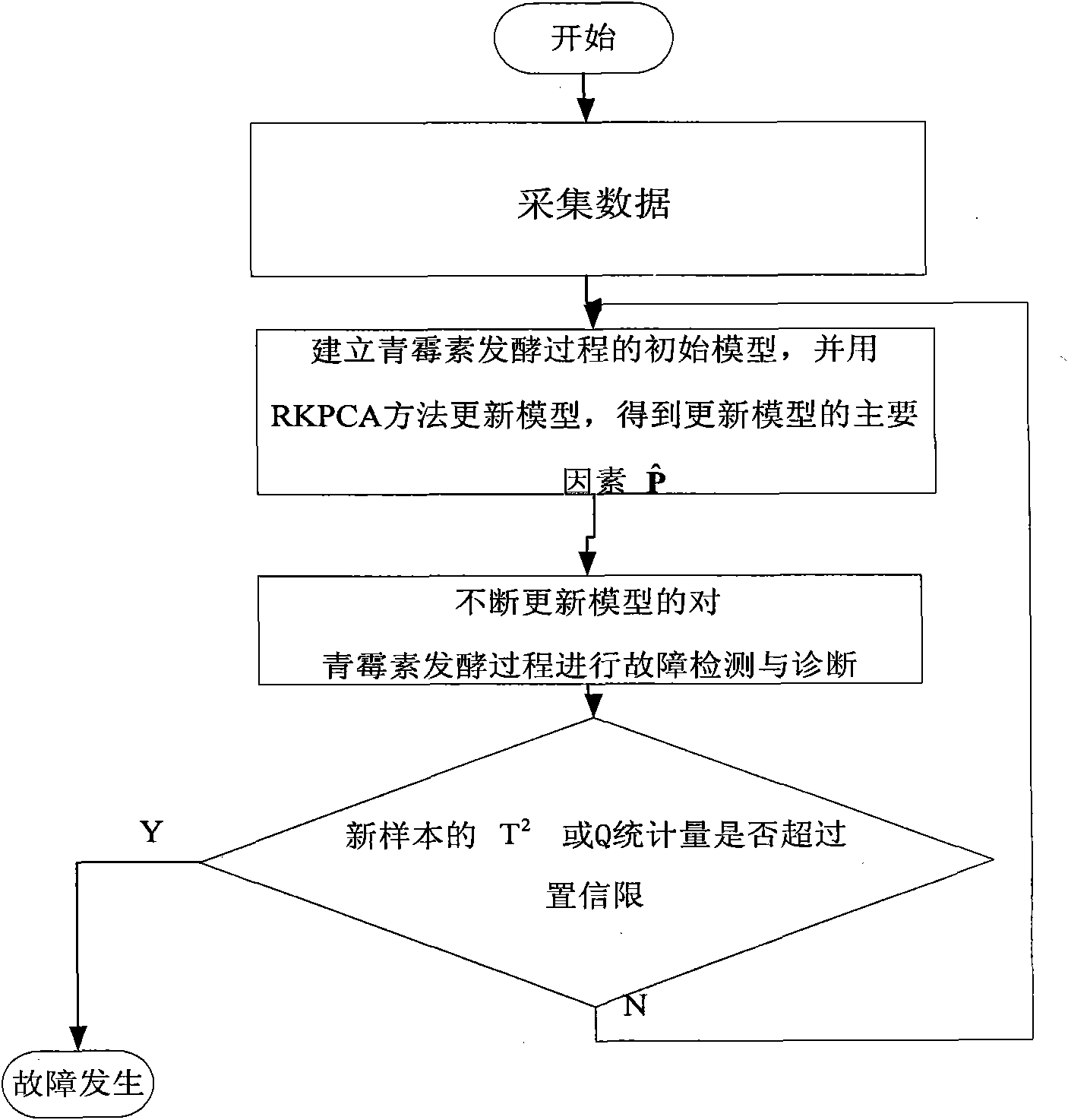

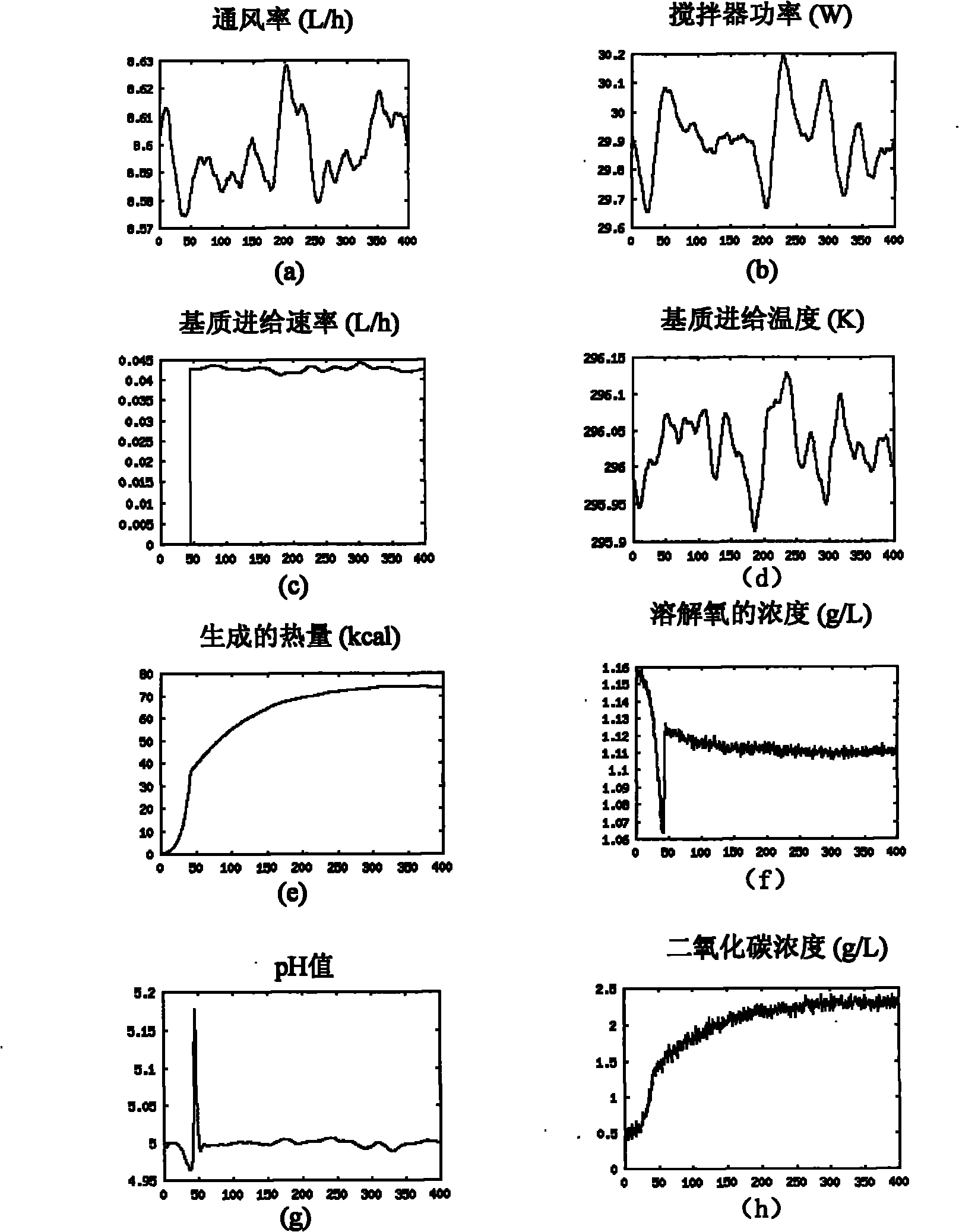

[0125] The penicillin fermentation process is a metabolic activity in which penicillin-producing bacteria grow and synthesize antibiotics under suitable fermentation conditions such as medium, pH value, temperature, air flow, and stirring. figure 1 It is a schematic diagram of the fermentation process of penicillin production, in which the controlled variables include the pH value and temperature of the fermenter, which are controlled at a certain value by manipulating the variables: acid, alkali flow, cold and hot water flow, mainly using the controller FC Control the opening of acid and alkali flow and cold and hot water valves to adjust pH and temperature. During the fermentation of penicillin, the temperature and pH value are controlled by closed-loop control, while the feed is controlled by open-loop fixed value. The duration of each batch of penici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com