Angle similarity stage division and monitoring method in microbial pharmacy process

A technology of microorganisms and similarity, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as nonlinear data loss, false alarms, and missed alarms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

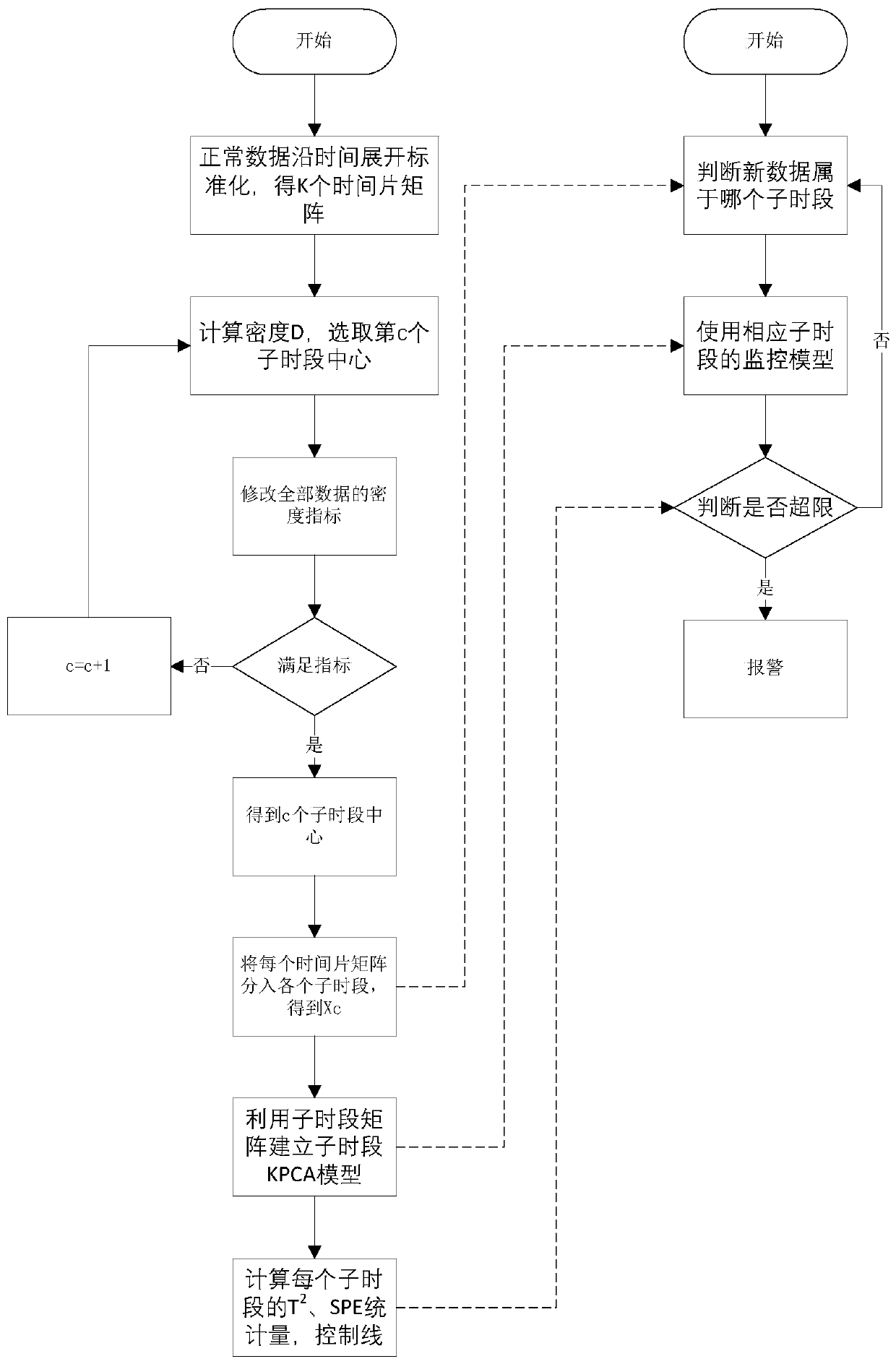

Method used

Image

Examples

Embodiment Construction

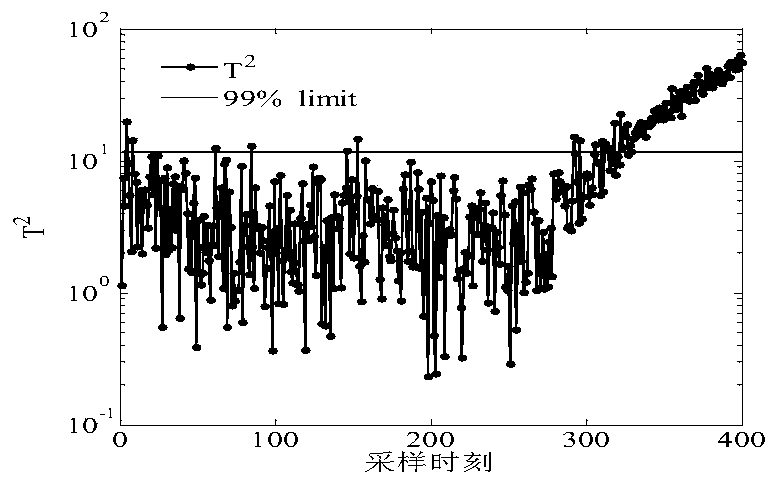

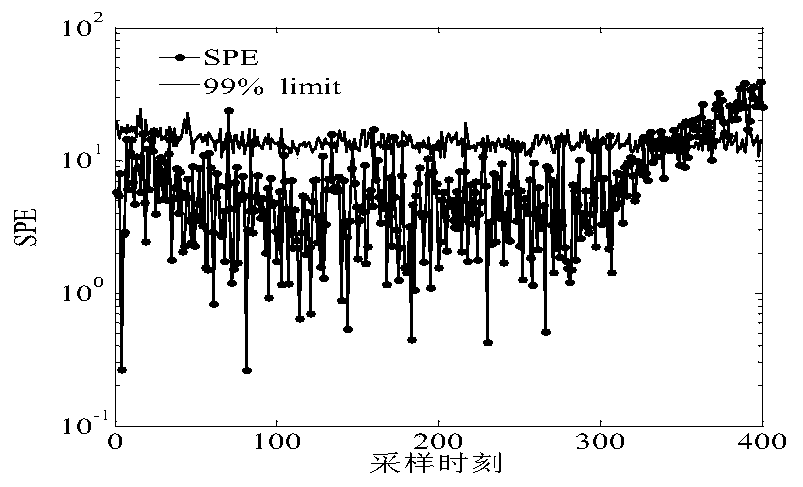

[0055] The penicillin fermentation simulation platform PenSim2.0 is used as the simulation test platform of this method. The main purpose of the experiment here is to prove the following points: (1) The monitoring model established based on the stage has effective fault monitoring capabilities; (2) The monitoring model established based on the stage Facilitate the diagnosis of intermittent process faults.

[0056] A comprehensive test is carried out on the monitoring strategy proposed by the present invention. The reaction time of each batch of penicillin fermentation is 400h, and the sampling interval is 1 hour, that is, K=400. In this paper, 10 process variables are selected for monitoring, that is, J=10. See Table 1 for details. Number of batches I=30.

[0057] Table 1 Sampling variables

[0058]

[0059]

[0060] Applying the method of the present invention to the simulation object of the penicillin fermentation process includes two steps of off-line modeling and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com