Penicillin fermentation process quality related fault detection method

A penicillin fermentation and process quality technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as low fault detection effect and inability to distinguish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] In the following, the present invention will be specifically described through exemplary embodiments. It should be understood, however, that elements, structures and characteristics of one embodiment may be beneficially incorporated in other embodiments without further recitation.

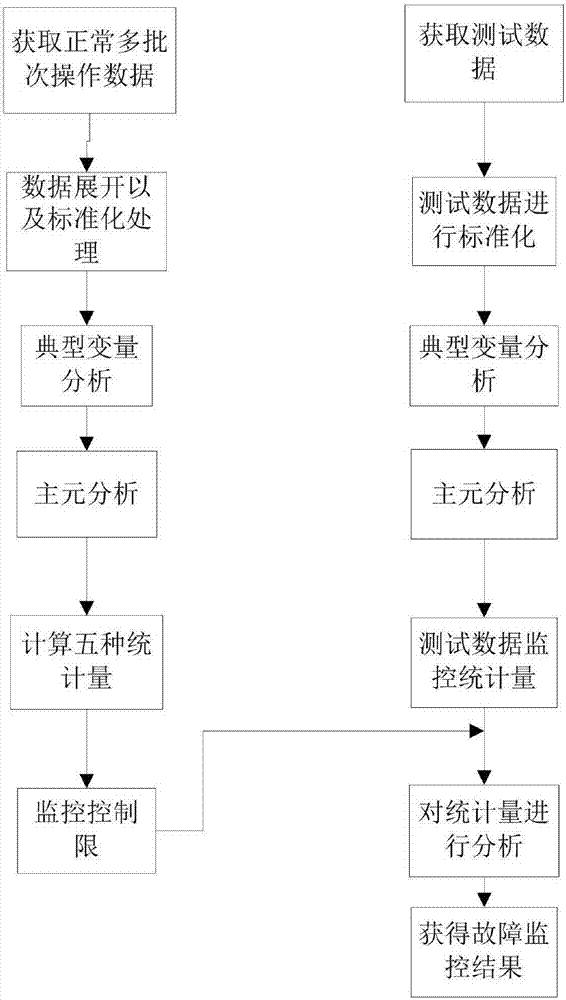

[0065] see figure 1 , figure 2 , the present invention discloses a method for detecting quality-related faults in a penicillin fermentation process, comprising the following steps:

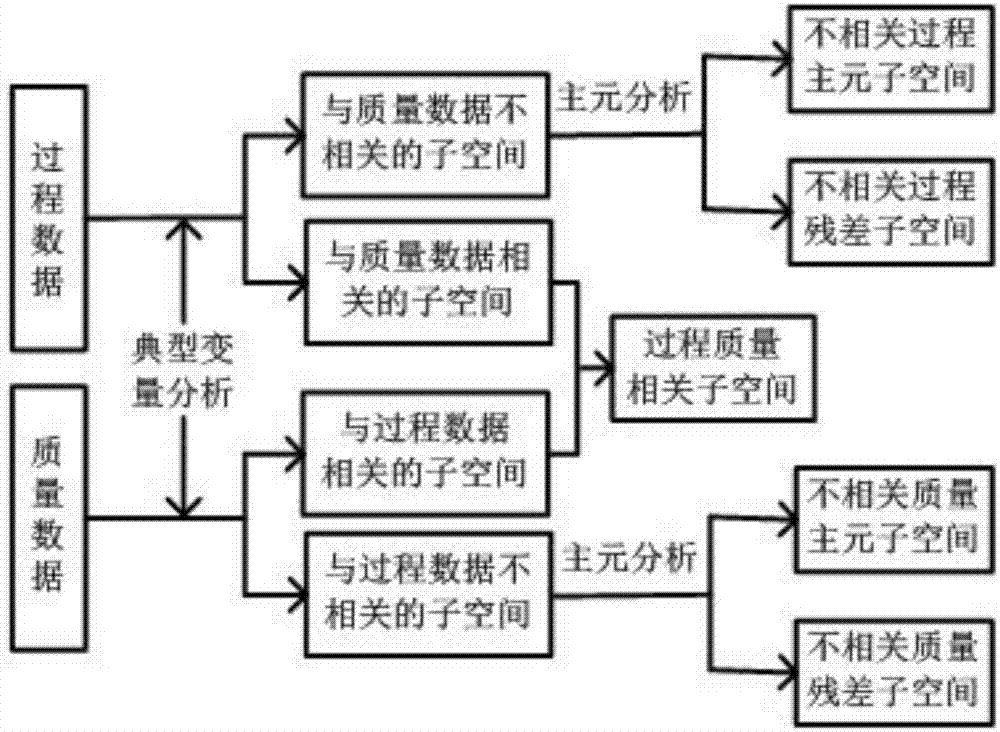

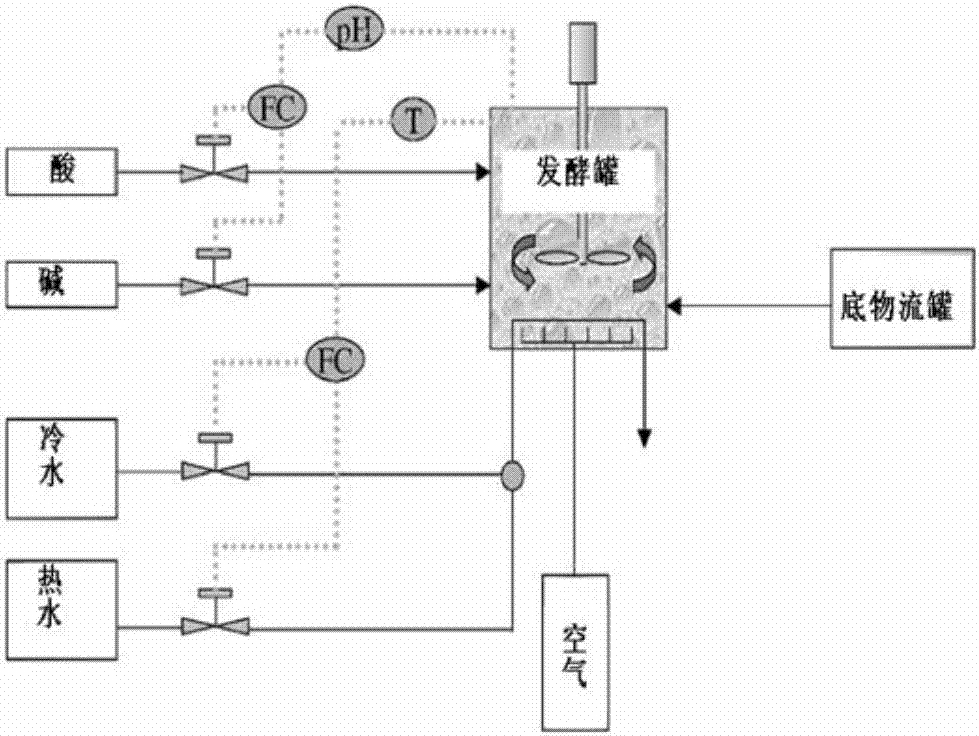

[0066] (1) Collect data under normal operating conditions of multiple batches in the penicillin fermentation process, and divide them into process data sets X 0 (I×J×K) and quality data set Y 0 (I×M×K), where I represents the number of batches, J represents the number of process variables, M represents the number of quality variables, and K represents the number of samples; the process data set X 0 (I×J×K) and quality data set Y 0 (I×M×K) is expanded and standardized to obtain a new normal operating proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com