Airlift type loop reactor and method for penicillin fermentation by using the same

A loop reactor and penicillin fermentation technology, which is applied in the field of penicillin fermentation, can solve the problems of excessive atmospheric velocity, high energy consumption, and reduced process economy, achieve a small proportion of autolysis, overcome easy agglomeration, and reduce bacterial contamination rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

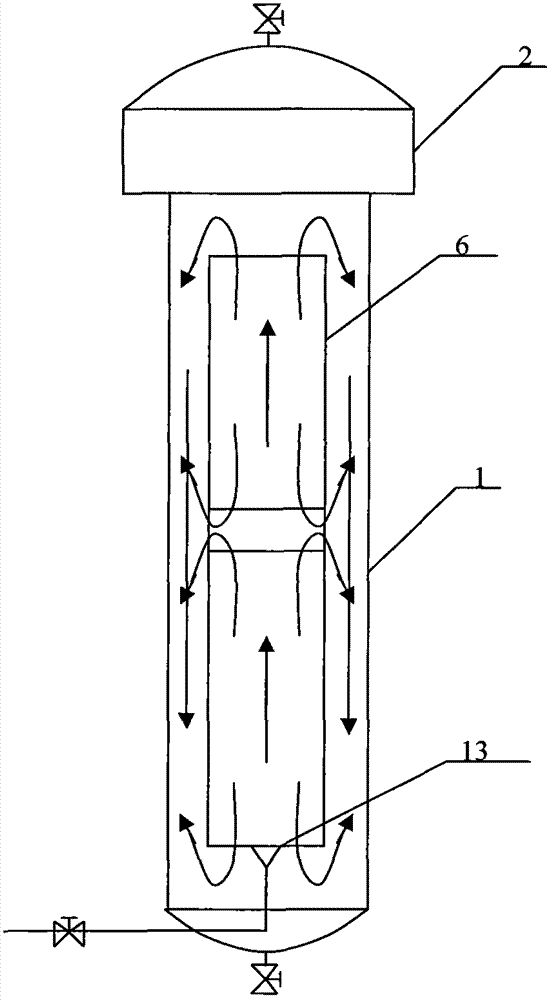

[0027] airlift loop reactor

[0028] For attached Figure 1-4 The description of each part is as follows:

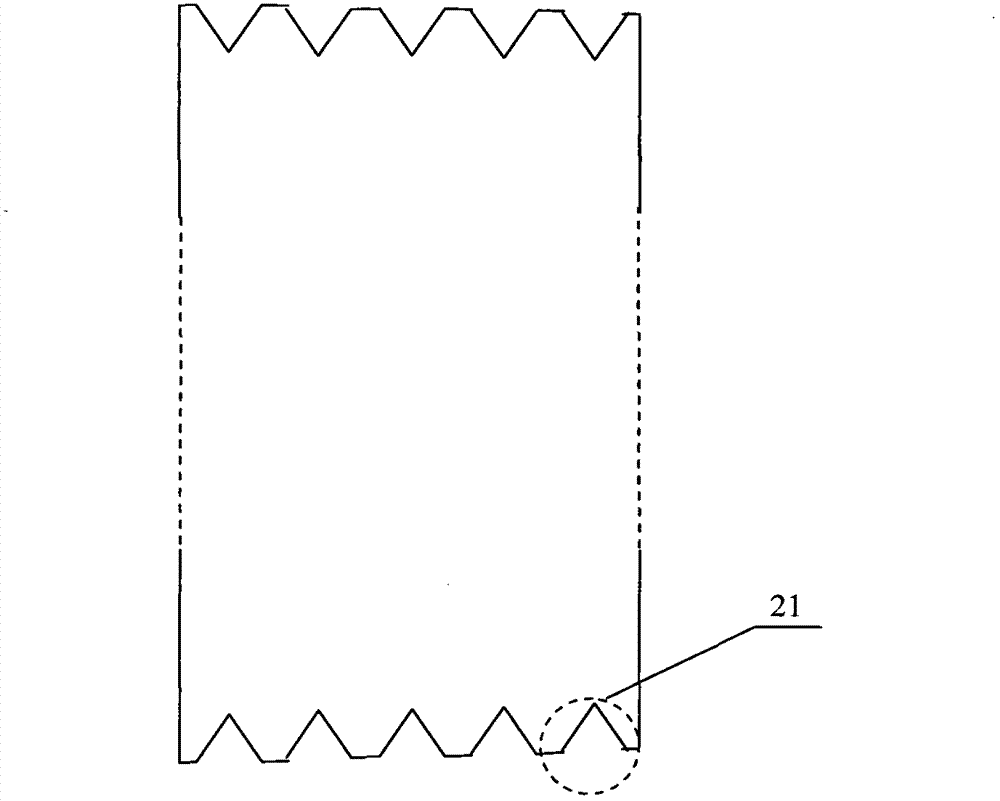

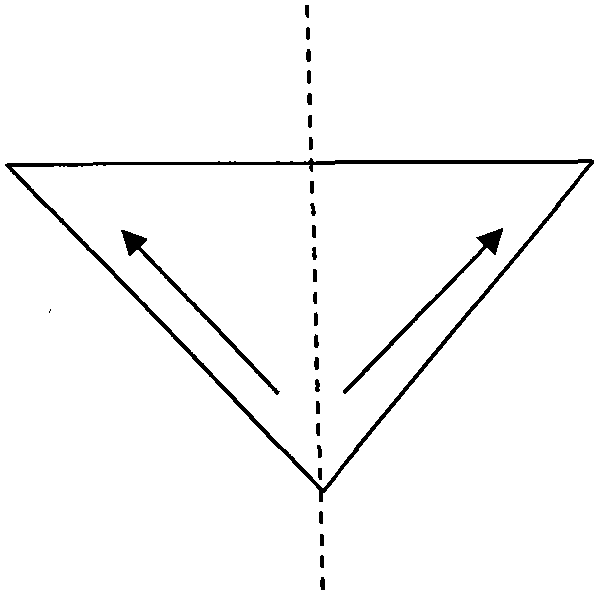

[0029] 1-reaction section, 2-gas-liquid separation section, 3-reactor top cover, 4-reactor bottom head, 5-heat exchange jacket, 6-drain tube, 7-drain tube opening, 8- Feed inlet, 9-circulating water inlet, 10-circulating water outlet, 11-sight glass liquid level gauge, 2-positioning bracket on the guide tube, 13-gas distributor, 14-under the guide tube bracket, 15-inlet Air pipe, 16-discharge port, 17-flow inlet, 18-flow inlet steam protection, 19-exhaust port, 20-safety valve, 21-notch design

[0030] The present invention specifically improves the design of various parts of the airlift loop reactor, and the specific operation of the reaction tank is consistent with that of the general airlift loop reactor.

Embodiment 2

[0032] A method for fermenting penicillin by using a 200L air-lift loop reactor. After the seed culture is completed, the seed is inserted into the air-lift internal loop reactor according to the inoculation amount of 8-10% (v / v) to start fermentation. The fermentation temperature is 26°C; the pH is 6.5±0.1; the aeration ratio of the fermentation process is 2.8vvm, and the dissolved oxygen is controlled above 30%; the fermentation pressure is 0.1Mpa; the fermentation cycle is 165h; about.

[0033] During penicillin fermentation using a 200L airlift loop reactor, the additional carbon source is glucose, the glucose concentration is 83% (w / v), and the amount of glucose added during the operation is 1.8L / h; the additional nitrogen source is sulfuric acid Ammonium, the concentration of ammonium sulfate is 37% (w / v), and the amount of ammonium sulfate added during operation is 0.19L / h; The supplementary amount of phenylacetic acid in the process is 0.19L / h. After the fermentation...

Embodiment 3

[0035] A comparative experiment was carried out using a 200L mechanically stirred fermenter. After the seed culture is completed, the inoculation amount of 8-10% (v / v) is inserted into a stirring fermenter to start fermentation. The fermentation temperature is 25°C; the pH is 6.4±0.1; the stirring speed is 380r / min; the aeration ratio of the fermentation process is 1.3vvm, and the dissolved oxygen is controlled above 30%; Mycelium concentration is about 40%. During the penicillin fermentation process using a 200L mechanically stirred fermenter, the supplementary carbon source is glucose, the glucose concentration is 83% (w / v), and the supplementary amount of glucose during operation is 1.7L / h; the supplementary nitrogen source is ammonium sulfate , the concentration of ammonium sulfate is 36% (w / v), and the amount of ammonium sulfate added during operation is 0.21L / h; the added precursor substance is phenylacetic acid, and the concentration of phenylacetic acid is 36% (w / v). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com