Patents

Literature

131results about How to "Raise the fermentation unit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Actinoplanessp. strain and its use in preparation of fidaxomicin

ActiveCN103320355ARaise the fermentation unitSingle fermentation componentBacteriaMicroorganism based processesChromatographic separationFiltration

The invention discloses an Actinoplanessp. strain and its use in preparation of fidaxomicin. The Actinoplanessp. strain is entophytic Actinoplanessp. N12W0304, is preserved in the China general microbiological culture collection center (CGMCC) on December 26, 2012 and has a preservation number of CGMCC No.7043. A fidaxomicin production process comprises the following steps of preparing an Actinoplanessp. N12W0304 seed solution and fermentation broth, carrying out centrifugation of the fermentation broth to obtain mycelia, carrying out extraction, condensation, dissolution, filtration, resin adsorption and drying of the mycelia to obtain a fidaxomicin crystal crude product, dissolving the fidaxomicin crystal crude product, and carrying out liquid chromatographic separation and pressure-reduction drying of the solution to obtain a fidaxomicin refined product. Under the fermentation conditions, the Actinoplanessp. strain has a fidaxomicin fermentation unit which is more than 1400mg / L and is higher than the fidaxomicin fermentation yield reported at present. The fidaxomicin fermentation process provided by the invention is simple, is suitable for industrial production and realizes a total product yield of 60%.

Owner:NCPC NEW DRUG RES & DEV

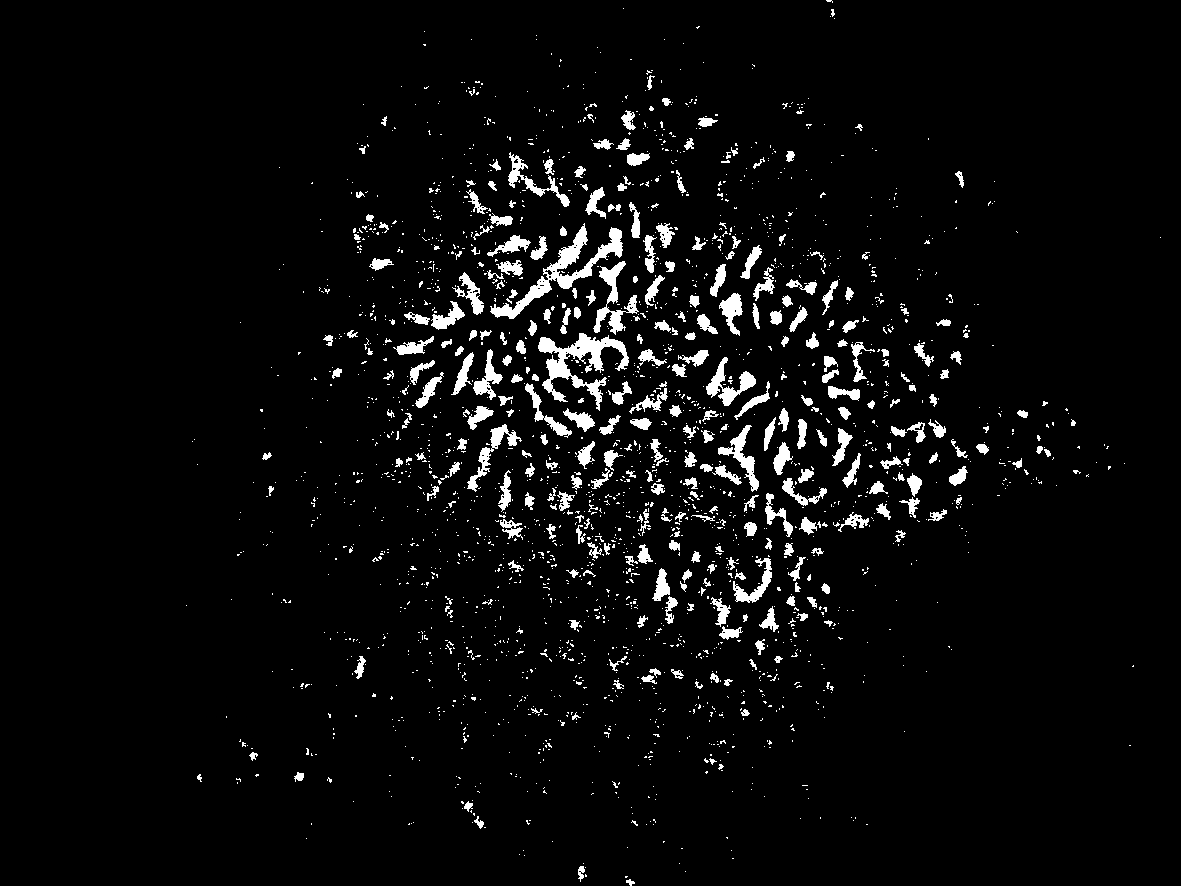

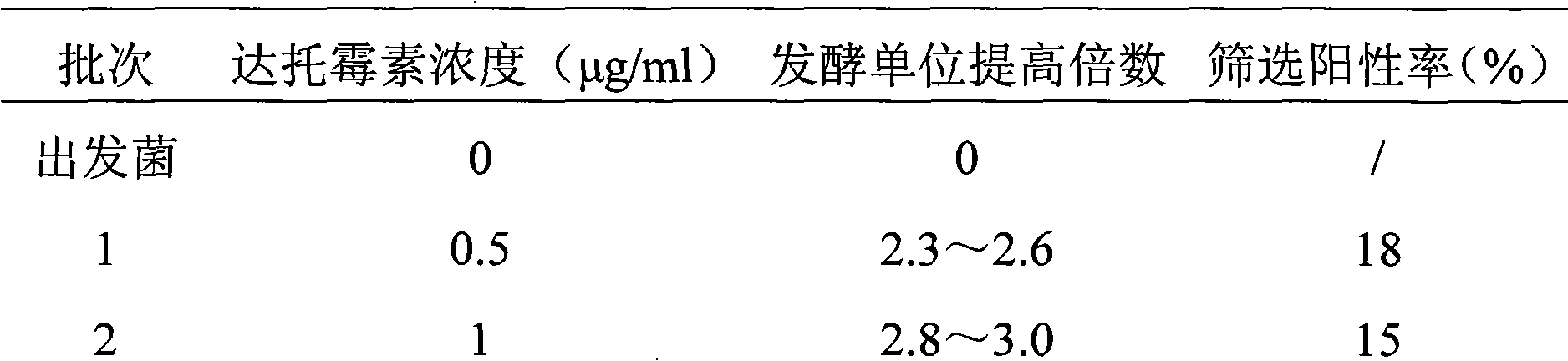

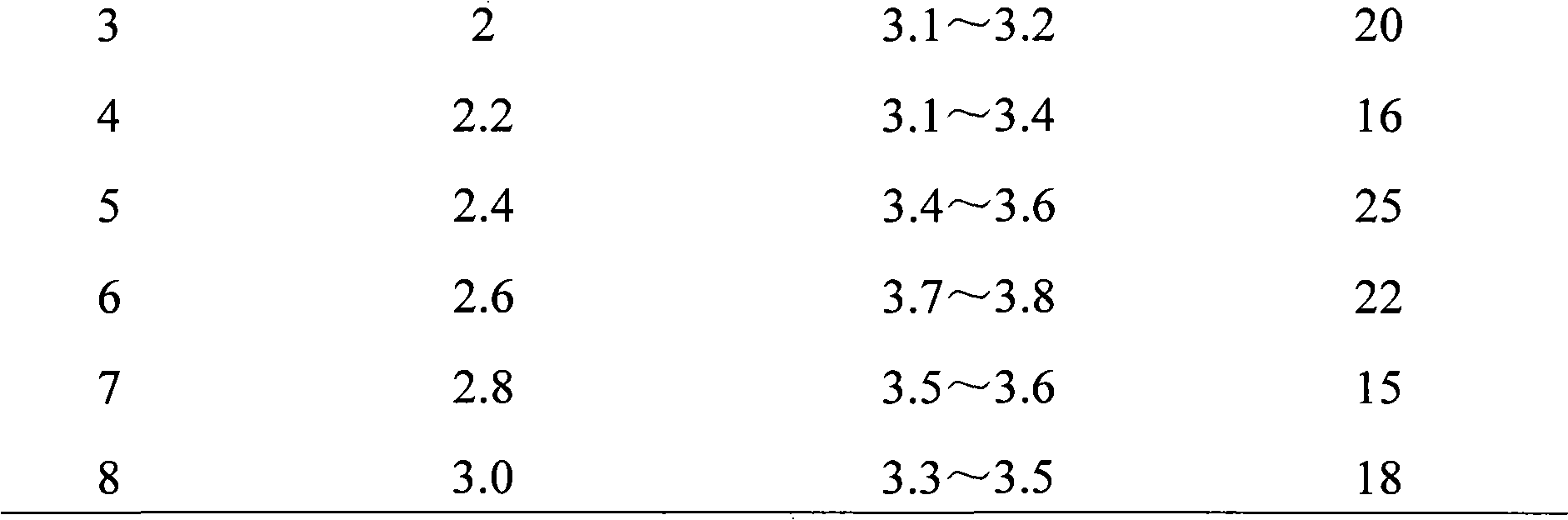

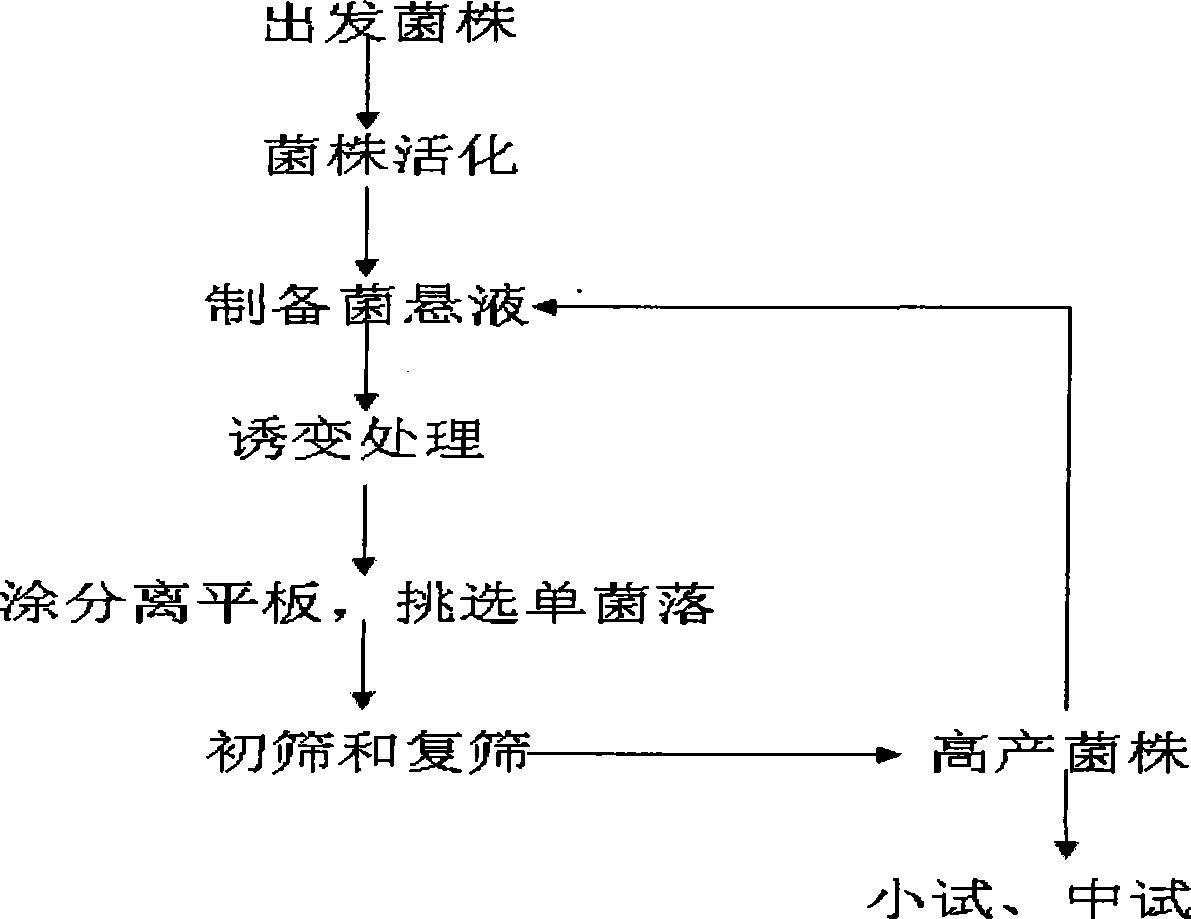

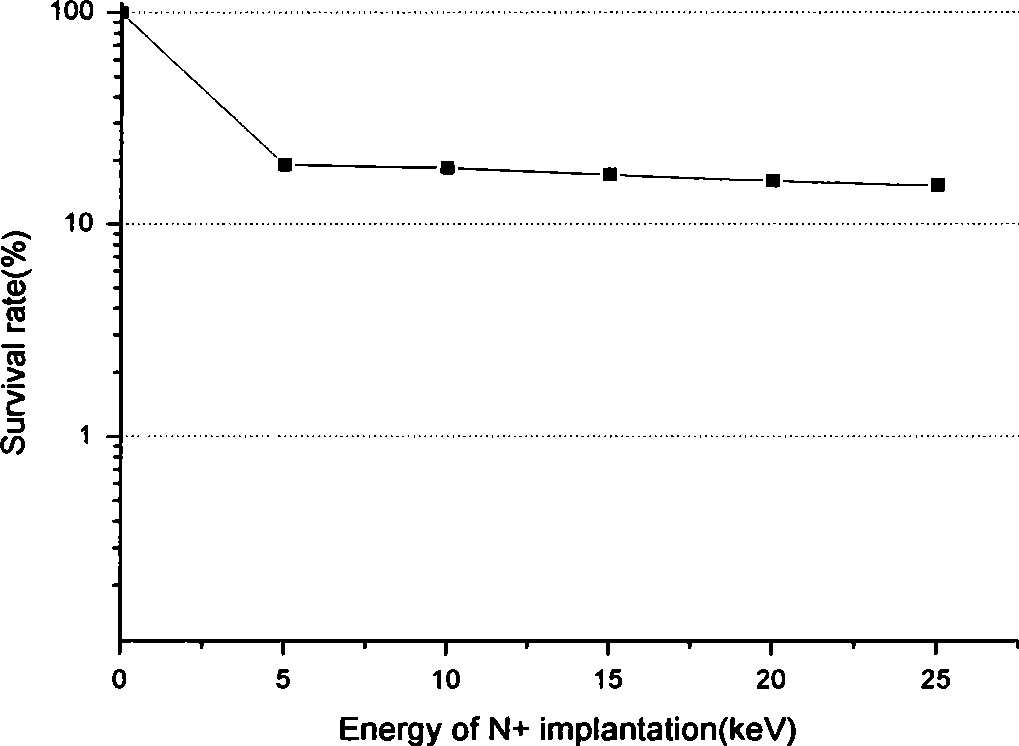

Process for selecting cultivating high yield strain of datomycin by laser inducing rose sporestreptomycete

InactiveCN1793356ASimple equipmentEasy wayBacteriaMicroorganism based processesMutagenic ProcessCulture mediums

The invention discloses a method used laser mutagenic streptomyces roseosporus to breed daptomycin high yield strain breeding. It belongs to strain mutagenesis breeding technology. The method includes the following steps: forming spore suspension; loading in aseptic quartz groove; irradiating by He-Ne laser for certain time; coating on Gao-NO.1 culture medium flat after diluting by aseptic water to culture pure streptomyces roseosporus; selecting out pure strain; and transferring it to liquid fermentation medium to culture high yield strain. The invention has the advantages of simple device, practical method, and safe operation. Its mutagenesis effect is far better than traditional physical chemistry mutagenesis method. Compared with original strain, the fermentation unit of the formed streptomyces roseosporus can rise by 0.5-3.3 times.

Owner:TIANJIN UNIV

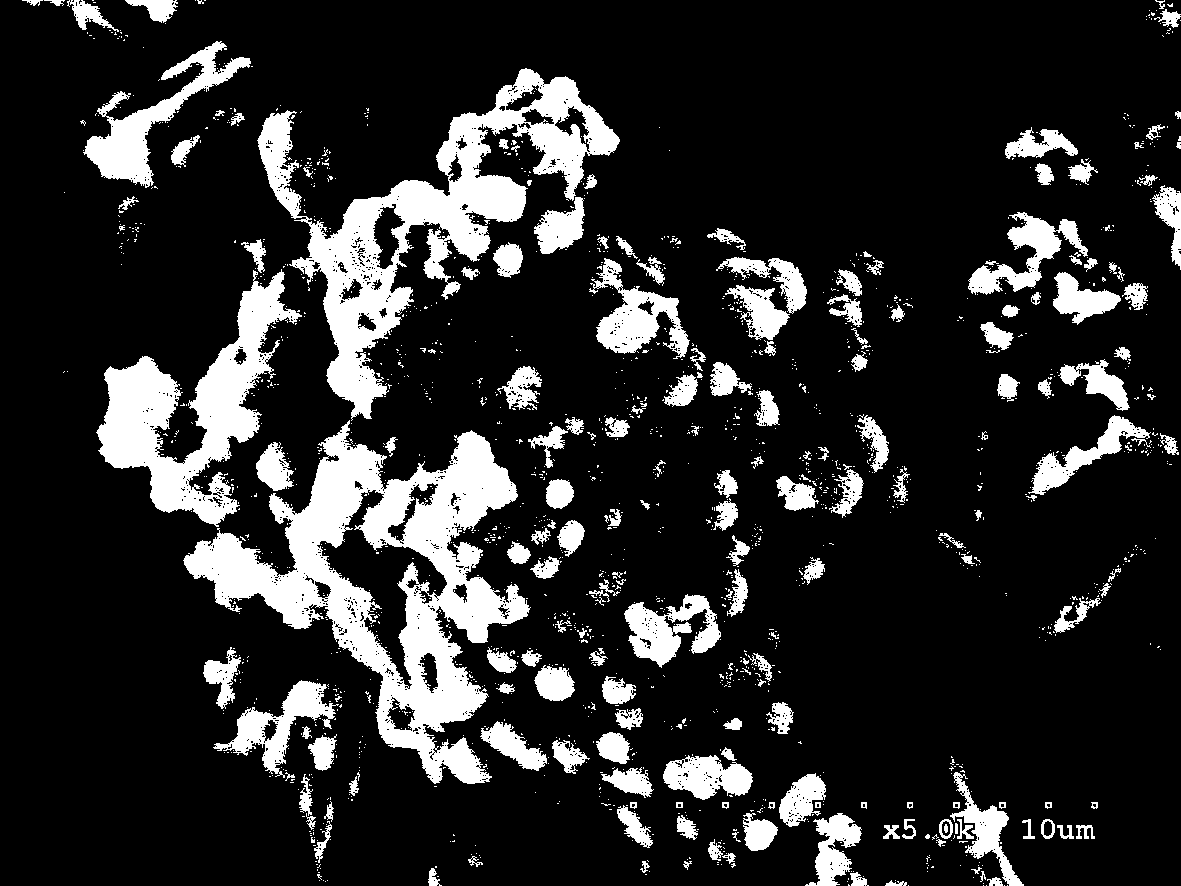

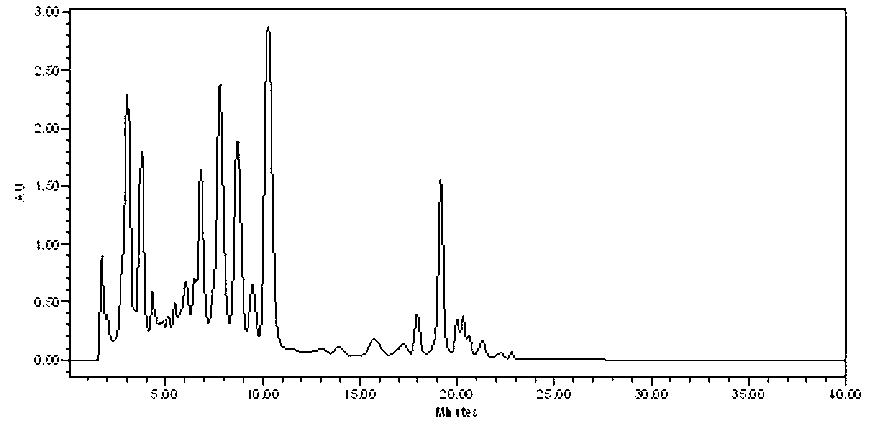

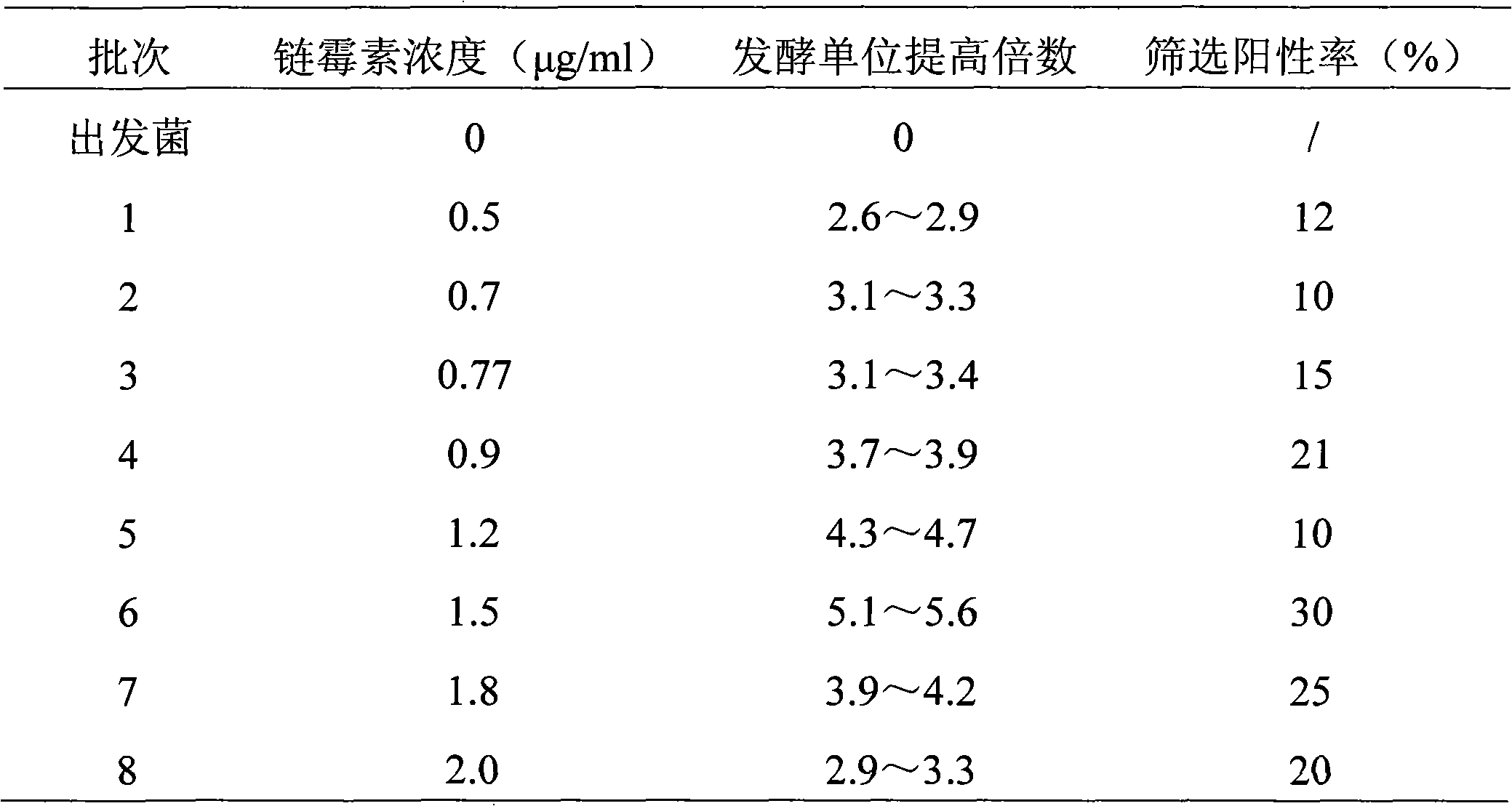

Screening method for breeding Streptomyces roseosporus strains producing Daptomycin and obtained strains

InactiveCN101892287AImprove screening efficiencyReduce manufacturing costBacteriaMicrobiological testing/measurementStreptomycesWild type

The invention discloses a screening method for breeding Streptomyces roseosporus strains producing Daptomycin and the obtained strains. The screening method comprises the following steps of: 1) coating bacteria liquid of wild Streptomyces roseosporus or mutant strains thereof subjected to mutagenesis on a solid panel containing streptomycin and / or Daptomycin, and culturing to obtain streptomycin and / or Daptomycin tolerant Streptomyces roseosporus; and 2) respectively selecting a single colony of the streptomycin and / or Daptomycin tolerant Streptomyces roseosporus for shake flask fermentation, detecting the Daptomycin content in fermented materials, and selecting strains with the Daptomycin content higher than that of starting strains. The screening method has the advantages of directivity, intuition, simpleness, quickness, high efficiency, great reduction of workload, and acceleration of strain breeding process. The Daptomycin fermentation unit of the screened Streptomyces roseosporus strains is obviously improved, which can be improved by more than 5 times to the maximum.

Owner:SHANGHAI INST OF PHARMA IND

Industrial fermentation method of riboflavin

ActiveCN102154426AIncreased industrial fermentation unitsImproving the process conditions of fed-batch fermentationFermentationGLUCOSE LIQUIDCulture mediums

The invention discloses an industrial fermentation method of riboflavin, which comprises the following steps of: filling a seed culture medium into a 10m<3> seed tank, and performing oxic cultivation; and filling a fermentation medium into a 200m<3> fermentation tank for fermentation, mechanically stirring, adding sterilization starch glucose liquid, stopping fermenting till that the glucose is completely consumed or the dissolved oxygen is raised to be 60%, and extracting the riboflavin from the fermentation liquid. After the industrial fermentation method is used, the conventional riboflavin material-supplementing fermentation technology is changed, the low-concentration raw material cultivating bacteria is adopted, the material is quantificationally supplemented according to the changeof the dissolved oxygen of the fermentation solution, the excessive multiplication of the thallus can be effectively controlled, the deviation of the optimum control temperature caused by the excessive supersession can be avoided, the defects of the insufficient ventilation and oxygen supply can be remitted, and the thallus vigor can be kept, so that the indusial fermentation unit of the riboflavin is improved by more than 18g / L, and the yield is increased by 20% compared with the common fermentation.

Owner:GUANGJI PHARMA MENGZHOU

Preparation method for tetracycline

ActiveCN104342477AHigh yieldReduce usageMicroorganism based processesFermentationStreptomyces auratusOrganic solvent

The invention discloses a preparation method for tetracycline. The preparation method comprises the following specific steps of preparing a streptomyces aureus strain and then performing seed shake-flask culture and seed tank culture; when culture is performed for 20-26 hours, converting the culture mode into fermentation culture; when the pH value reaches 5.6-7.6, the total titer is not smaller than 8,000U / ml, the total saccharides content is not greater than 2.0 percent, the quantity of amino nitrogen is greater than 50mg / 100mL, and the filtering velocity is not smaller than 5mL / 5min, ending the fermentation and discharging from a tank; finally, filtering with a plate frame, decoloring ion exchange resin, crystallizing and performing air current drying to obtain the tetracycline. According to the preparation method disclosed by the invention, a fermentation process is simple, the fermentation unit can be effectively improved, the yield is improved, and the production cost is reduced; meanwhile, the use of chemical organic solvent is avoided.

Owner:金河生物科技股份有限公司

White rot fungi, breeding method and use thereof

InactiveCN101469312AStable enzyme productionShort cycleFungiMutant preparationFiberAutomatic control

The invention relates to Trametes Versicolor YS-L613 and a breeding method and application thereof. The Trametes Versicolor YS-L613 is prepared by the method through mutation breeding. The breeding method is to take Trametes Versicolor as a starting strain, adopt composite mutation breeding technology which combines UV, 60 CO, ultraviolet rays, nitrosoguanidine, ion implantation and microwave treatment, and breed the YS-L613 strain for high-yield production of laccase. The invention performs breeding operation through physiochemical treatment methods such as ion implantation, the ultraviolet rays and mutagen, finally obtains the YS-L613 strain for high-yield production of the laccase, and adopts experimental automatic control technology, strain fermentation control technology and strain extraction technology to develop laccase products. As proved by experiments of the laccase in pulp bleaching, fiber modification and pulp deinking, utilization of the laccase in the paper-making industry can improve the quality of paper, reduce environmental pollution and save the cost.

Owner:HENAN YANGSHAO BIOCHEM ENG

Culture medium for producing acetylisovaleryltylosin by fermenting streptomyces thermotolerans and fermentation method

ActiveCN103276031ARefined fermentation levelDefine Process Control ParametersMicroorganism based processesFermentationBiotechnologyMicrobiology

The invention relates to a culture medium for producing acetylisovaleryltylosin by fermenting streptomyces thermotolerans and a fermentation method. According to the culture medium and the fermentation method, a culture medium formula and a production technology are confirmed, and stable and high-efficiency production of acetylisovaleryltylosin is realized. In addition, the culture medium and the production technology can raise a fermentation unit, shorten the fermentation period, and increase the yield of acetylisovaleryltylosin.

Owner:宁夏泰瑞制药股份有限公司

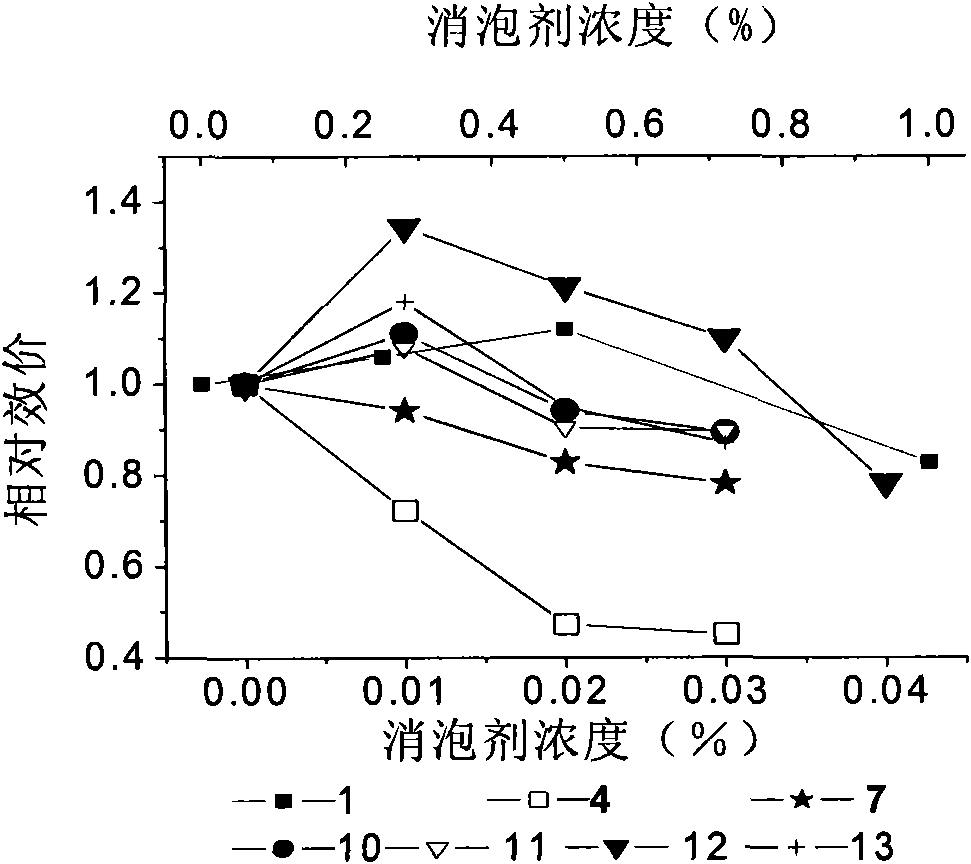

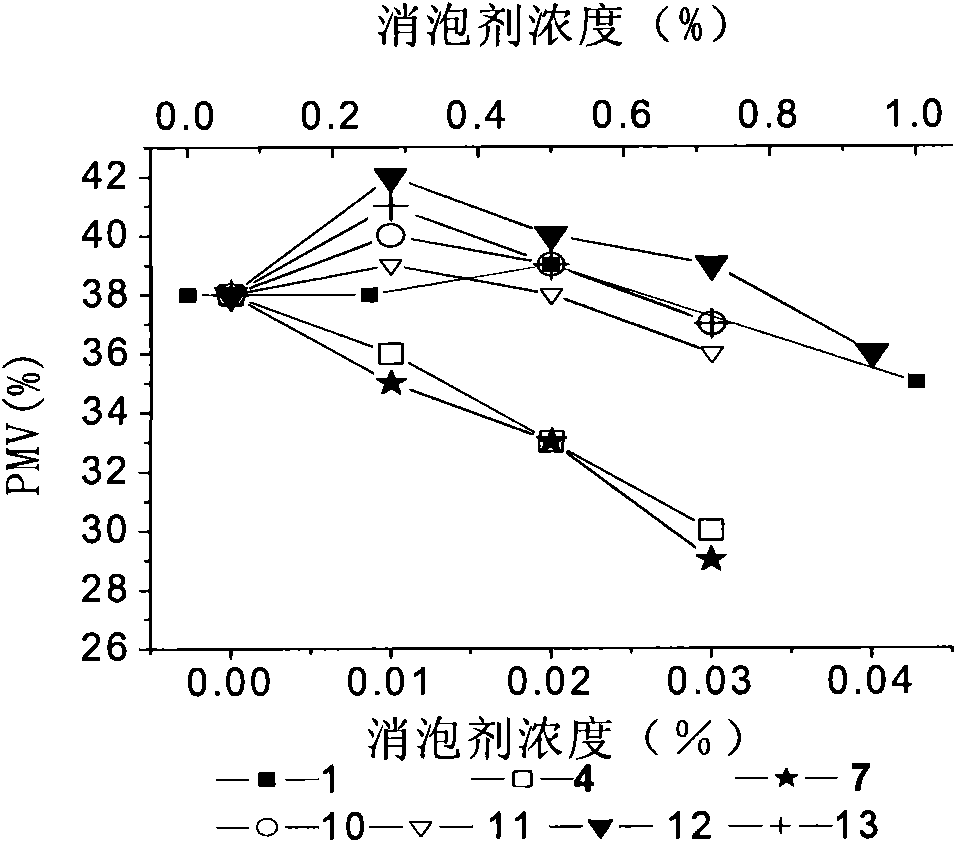

New purpose of foam killer

InactiveCN101560540AEasy to useGood defoamingFermentationFoam dispersion/preventionMacrolide resistanceAntibiotics

The invention discloses the functions of breaking foam, restraining foam and accelerating biosynthesis of polyether modification polysiloxane substance in the zymolysis process of macrolide antibiotic producing bacteria. The invention also discloses a use method of the polyether modification polysiloxane substance.

Owner:EAST CHINA UNIV OF SCI & TECH +1

Method for preparing apramycin through fermentation

InactiveCN104232709AIncrease productionRaise the fermentation unitMicroorganism based processesFermentationMicroorganismCorn steep liquor

The invention discloses a method for preparing apramycin through fermentation. The method comprises the following steps: performing slant culture, culturing a seed liquid, and performing fermentation culture. The method is simple to operate, and due to replenishment of corn steep liquor in the fermentation culture, the fermentation unit of apramycin is greatly increased. The fermentation unit in apramycin prepared by the method can be up to 8400U / mL.

Owner:HEBEI SHENGXUE DACHENG PHARMA

Fermentation medium and fermentation method of producing A40926 with Nonomuraea.sp by fermentation

InactiveCN102234675AIncrease productionRaise the fermentation unitMicroorganism based processesFermentationNitrogen sourceCarbon source

The invention provides a fermentation medium and a corresponding fermentation method in favor of efficiently producing an antibiotic A40926 with Nonomuraea.sp by fermentation. The fermentation medium comprises a carbon source and a nitrogen source, wherein, the carbon source is an organic carbon source with the content of 5-180g / L, the nitrogen source is an organic nitrogen source with the content of 2-210g / L, and the contents are measured as the total volume of the medium. By optimizing the components and ratio of carbon and nitrogen source of the fermentation medium, the cultural temperature, PH value and other fermentation parameters are optimized, so that the output of the A40926 is greatly improved. According to the method provided by the invention, the fermentation unit of the A40926 is greatly improved, so that the method is suitable for large-scale production of the A40926.

Owner:SHANGHAI INST OF PHARMA IND CO LTD

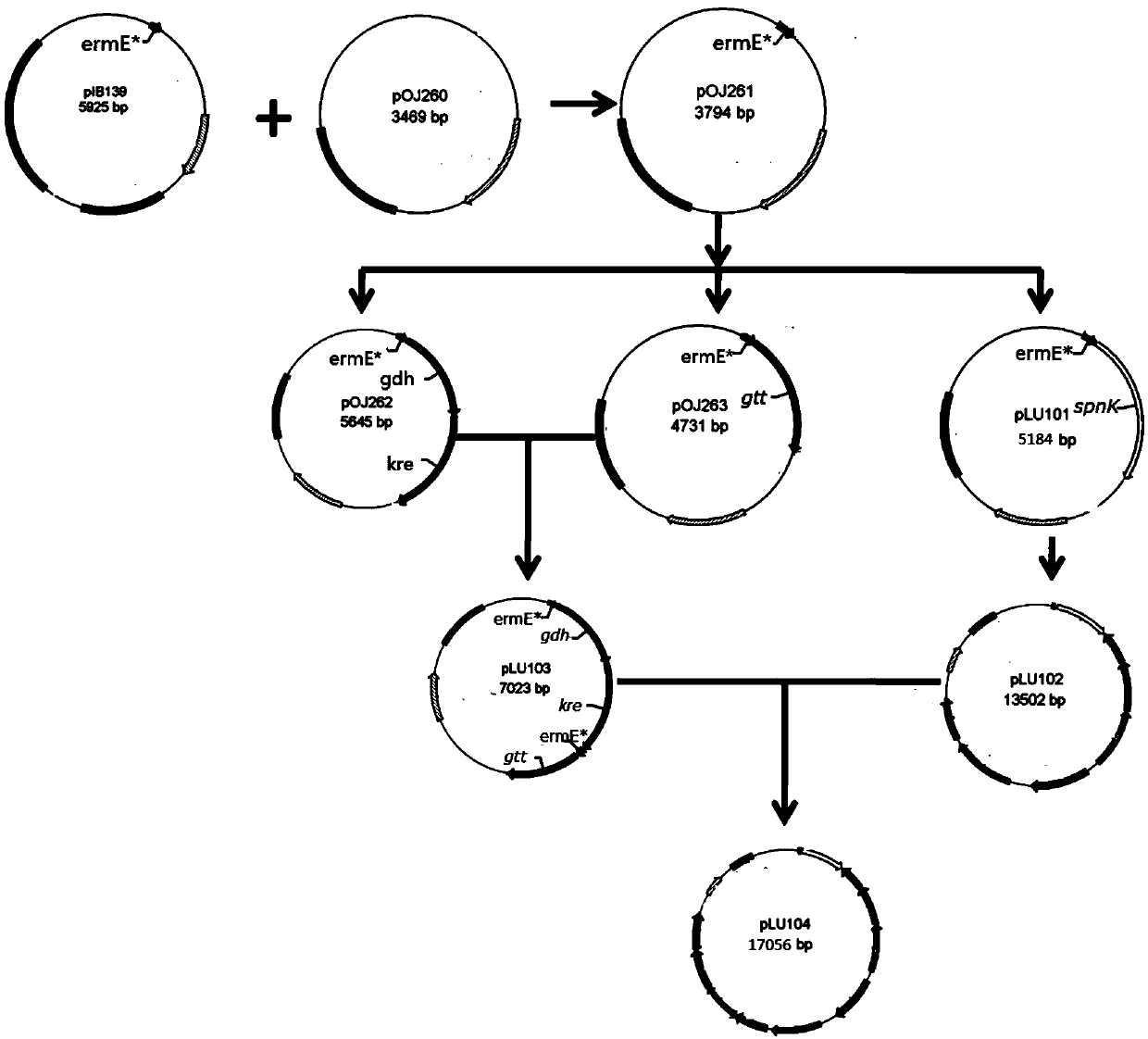

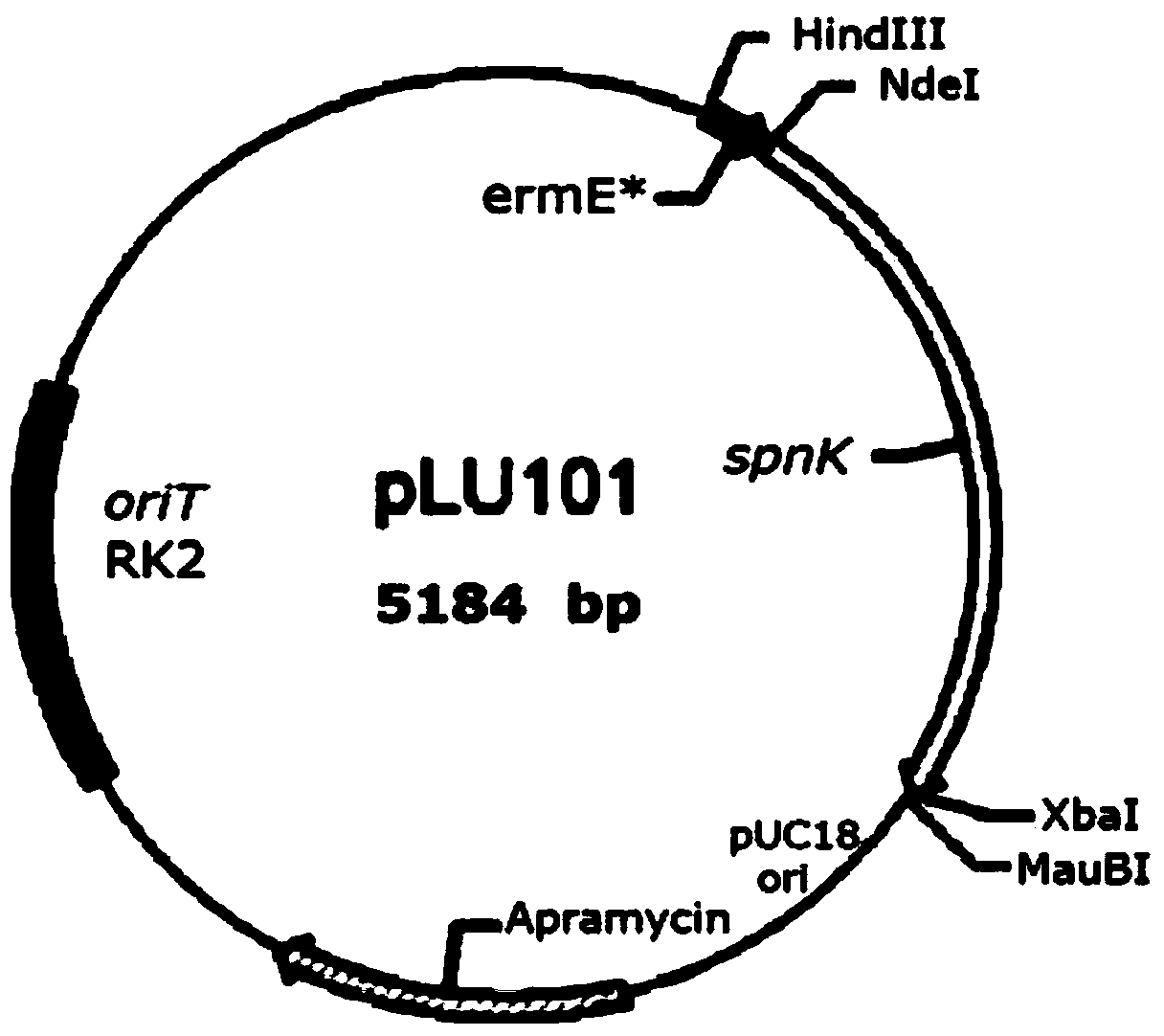

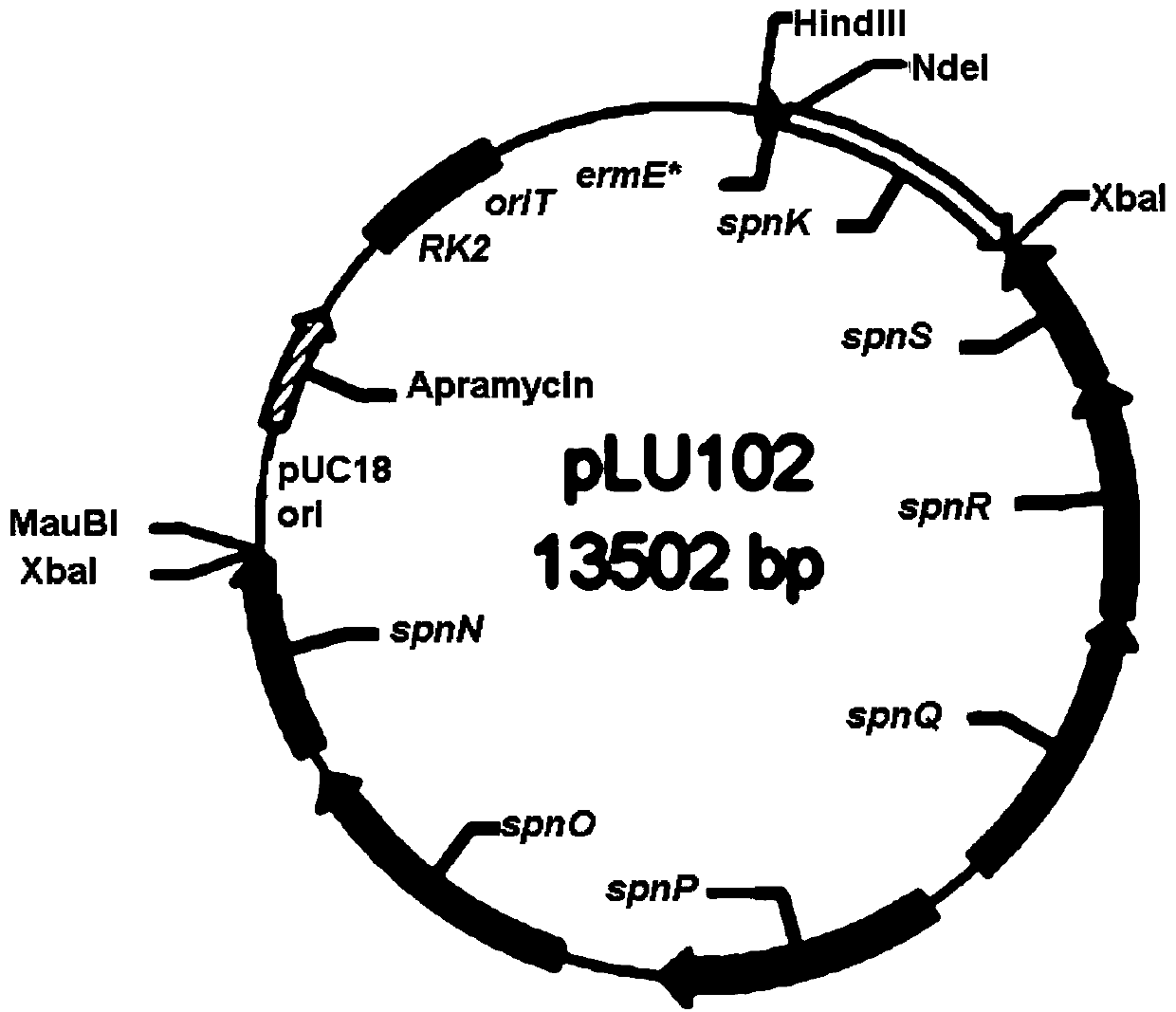

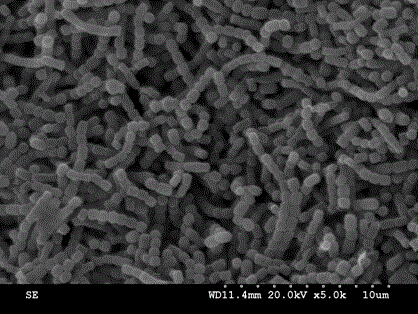

Genetically engineered bacterium capable of increasing yield of spinosads as well as construction method and application

ActiveCN103740631AHigh activityIncrease productionBacteriaMicroorganism based processesEscherichia coliBiotechnology

The invention discloses a genetically engineered bacterium capable of increasing the yield of spinosads as well as a construction method and an application. The construction method of the genetically engineered bacterium capable of increasing the yield of spinosads comprises the following steps: (1) inserting an spnk expression cassette into an escherichia coli-saccharopolyspora spinosa shuttle plasmid pOJ260 to construct a recombinant plasmid pLU101; (2) guiding the recombinant plasmid pLU101 into saccharopolyspora spinosa ATCC49460, and integrating the recombinant plasmid with a genome through homologous recombination, thus obtaining the genetically engineered bacterium capable of increasing the yield of spinosads and naming the genetically engineered bacterium LU101. The genetically engineered bacterium constructed by the method can increase the yield of spinosads.

Owner:TIANJIN UNIV

Modified vegetable fat and its application in erythromycin fermentation process

ActiveCN102732383AImprove utilization speedUse fastFatty acid chemical modificationFermentationBiotechnologyVegetable oil

The invention relates to a modified vegetable fat and its application in an erythromycin fermentation process. The modified vegetable fat is prepared by: mixing vegetable fat with water and lipase, with the water and the lipase respectively accounting for 20-50wt% and 0.1-0.5wt% of the vegetable fat, conducting heat preservation for 4-6 hours at PH of 5.5-8.5 and a temperature of 35-45DEG C, and carrying out standing and layering so as to obtain a fat layer, i.e. the modified vegetable fat, which has an enzymolysis rate of 30-60% and an acid value of 50-100mgKOH / g. In the invention, natural vegetable fat is modified, and lipase is utilized to make the fat in fermentation, the oil system is decomposed into mixed fat composed of free fatty acid, glycerol and monoglyceride or diglyceride andthe like, so that the fat residue in an erythromycin fermentation solution is reduced, the fat utilization speed is enhanced, and the oxygen consumption during fermentation is reduced, thus effectively improving the fermentation titer and reducing the fermentation cost.

Owner:NINGXIA QIYUAN PHARMA

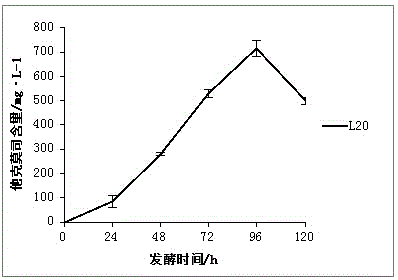

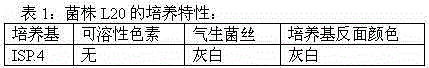

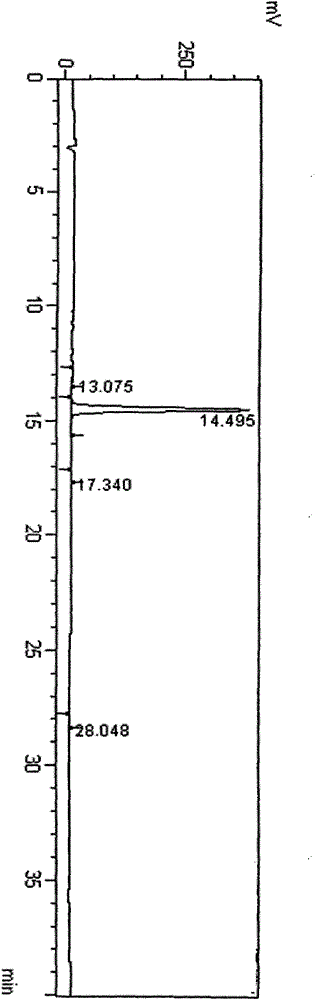

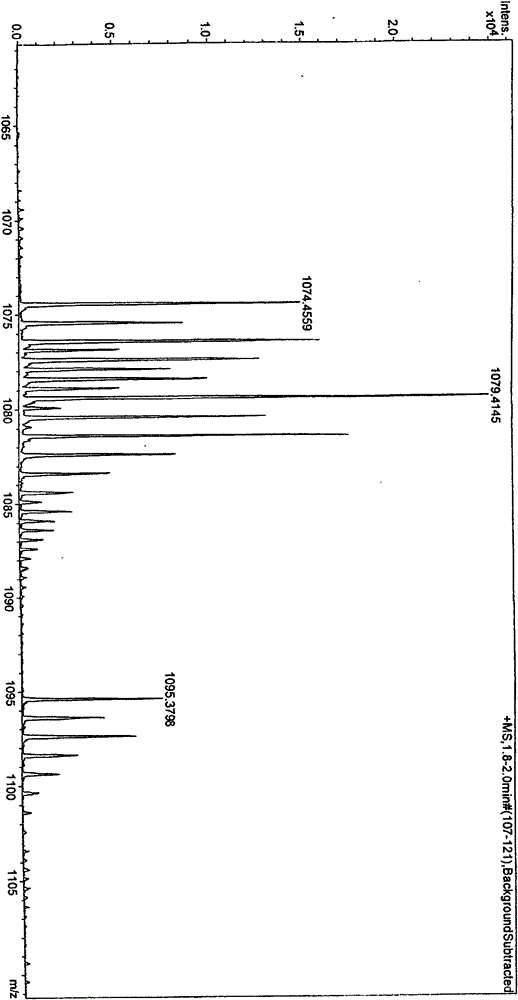

Gene engineering strain streptomyces tsukubaensis L20 and application thereof

ActiveCN105154382AHigh expressionIncrease productionBacteriaMicroorganism based processesMicroorganismMicrobiology

The invention provides a gene engineering strain streptomyces tsukubaensis L20 and application thereof. The gene engineering strain streptomyces tsukubaensis L20 is preserved in China General Microbiological Culture Collection Center; the preservation date is August 19, 2015; the preservation number is CGMCC No. 11252. The gene engineering strain streptomyces tsukubaensis L20 is relatively stable in inheritable character and fermentation unit, the culture and fermentation conditions are suitable for industrialized production, and the fermentation unit reaches a high level; the gene engineering strain streptomyces tsukubaensis L20 is utilized for improving the expression amount of a rate-limiting enzyme in a tacrolimus biosynthetic pathway through gene engineering, and serves as the rate-limiting enzyme during gene engineering of the tacrolimus biosynthetic pathway to improve the yield of tacrolimus, so that the cost of an industrialized production process can be reduced, and the fermentation unit of tacrolimus can be improved by 30%.

Owner:ZHEJIANG UNIV

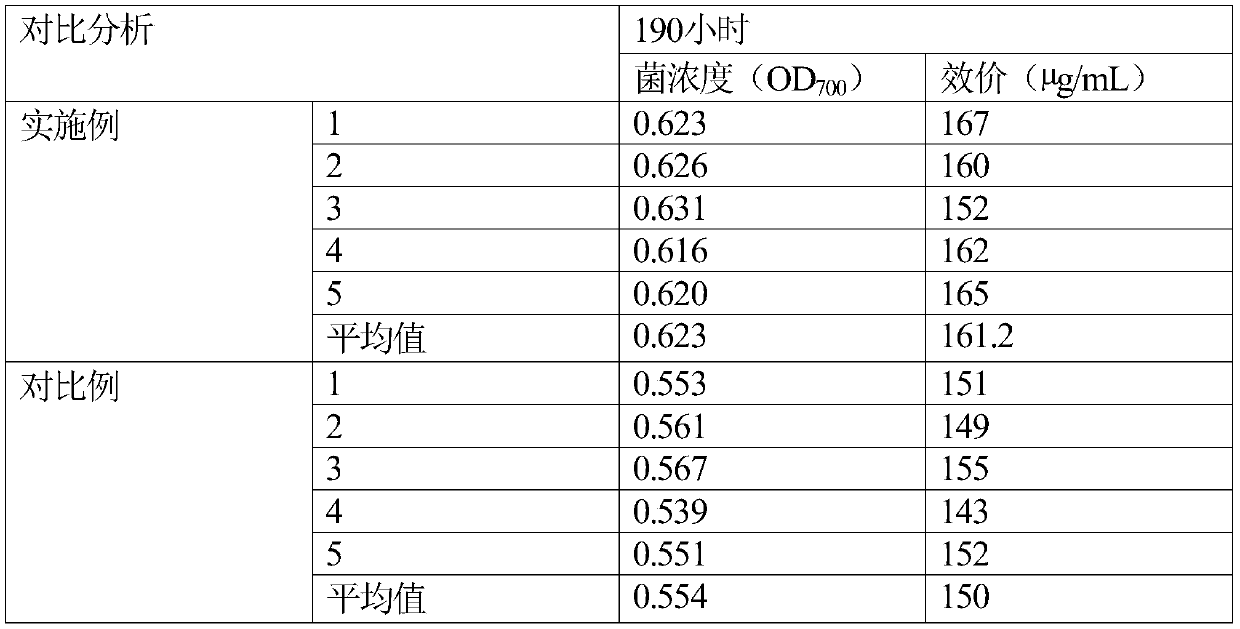

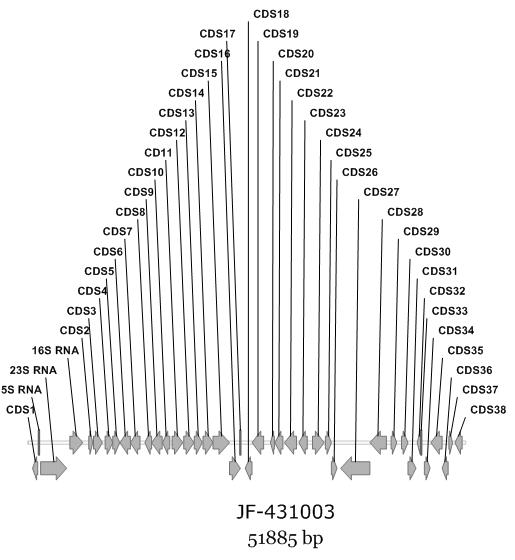

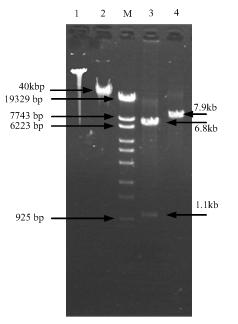

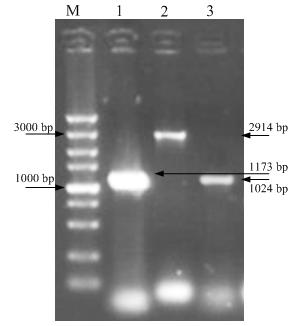

Actinoplanes strain and application thereof

ActiveCN104560766AIncrease productionRaise the fermentation unitAntibacterial agentsBacteriaClostridium difficile (bacteria)Bacterial strain

Owner:ZHEJIANG HISUN PHARMA CO LTD

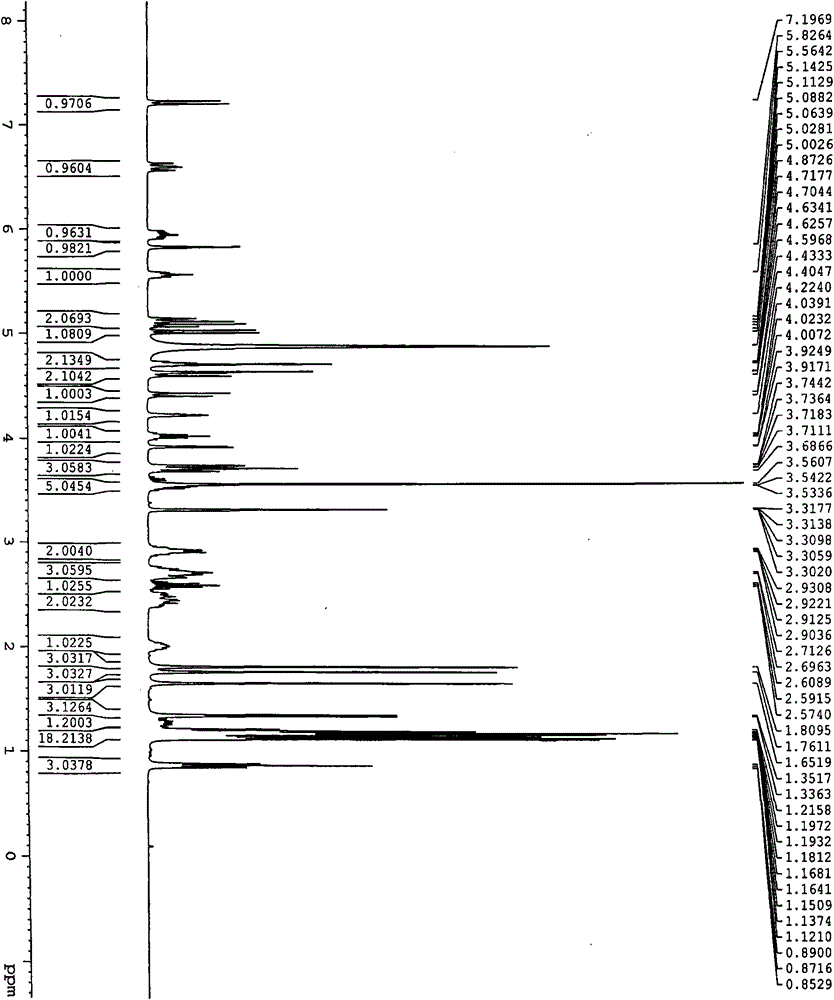

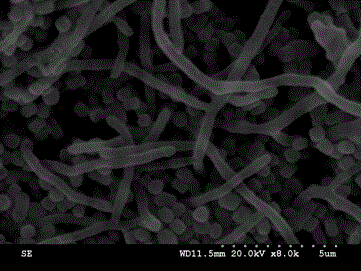

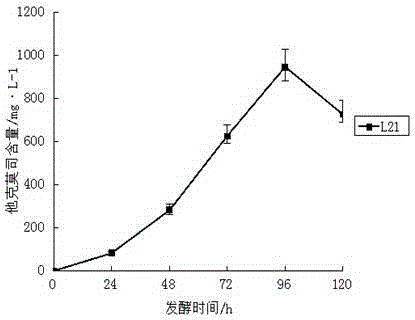

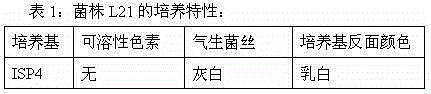

Genetic engineering strain Streptomyces tsukubaensis L21 and application thereof

ActiveCN105176904AHigh copy numberIncrease productionBacteriaMicroorganism based processesBiotechnologyGenetic engineering

The invention provides genetic engineering strain Streptomyces tsukubaensis L21. The fungus preservation unit is CGMCC (China General Microbiological Culture Collection Center), the preservation date is August 19, 2015, and the preservation number is CGMCC No. 11253. According to the genetic engineering strain Streptomyces tsukubaensis L21, the strain genetic character and the fermentation unit are stable, culture and fermentation conditions are suitable for industrial production, and the fermentation unit is high. The copy number of specific controlling genes in the Tacrolimus creature biosynthetic pathway is increased through genetic engineering, and the genes improve rate-limiting enzyme in the Tacrolimus creature biosynthetic pathway so as to increase the Tacrolimus yield, reduce the cost in the industrial production process and improves the Tacrolimus fermentation unit to 945 mg / L.

Owner:ZHEJIANG UNIV

Process for preparing oxytetracycline single colony frozen bacteria

ActiveCN101831396AReduce the number of passagesReduce aseptic operationsBacteriaMicroorganism based processesSporeFreeze-drying

The invention discloses a process for preparing oxytetracycline single colony frozen bacteria, which comprises the following steps of: preparing a plating medium from 3.5 to 4.5 percent of whole meal flour, 0.1 to 0.3 percent of yeast extract powder, 0.1 to 0.3 percent of monopotassium phosphate, 1.5 to 2.5 percent of agar and the balance of water in a certain proportion; cultivating single colony; preparing single colony frozen bacteria from the cultivated single colony; and performing shaking preliminary screening and shaking secondary screening to select the single colony frozen bacteria with strong production capacity to finally prepare freeze-drying tube strains for production. The plating medium can cultivate the single colony with large colony diameter and large numbers of conidium. Single colony spore suspension is directly used for preparing the single colony frozen bacteria. The process of the invention reduces passage times of the strain in the rejuvenation breeding process and the preparation process, prevents strain degeneration, improves the preservation effect and finally fulfills the aim of improving the working efficiency, increasing the yield and reducing the consumption.

Owner:CHIFENG PHARMA CO LTD

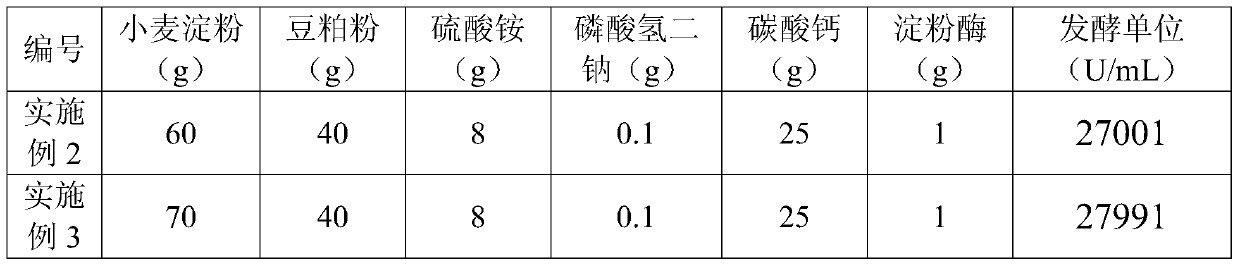

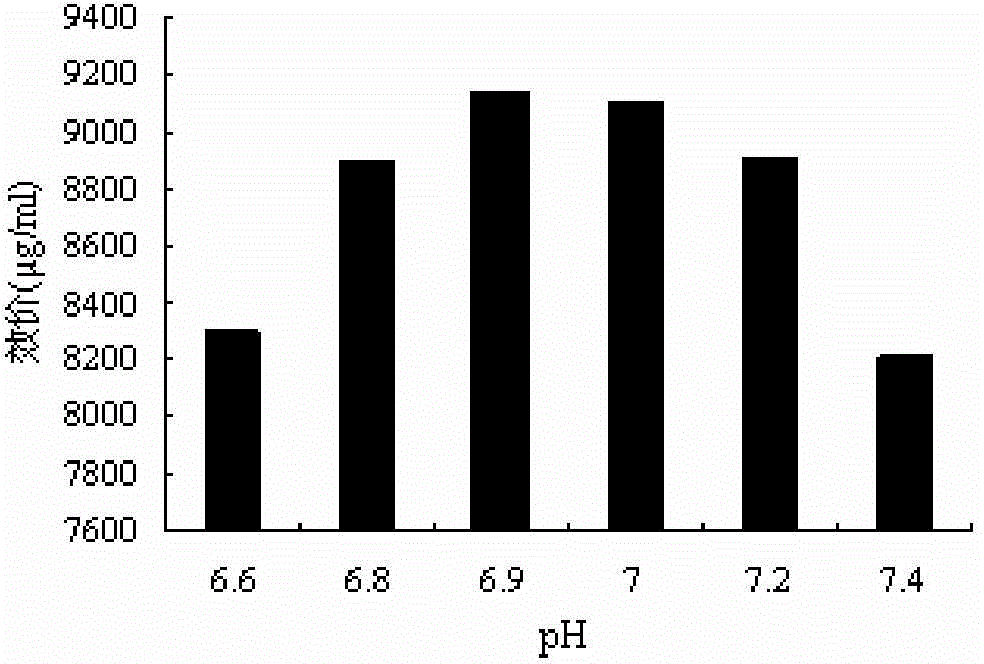

Fermentation medium used in neomycin production adopting fermentation method

InactiveCN104195201ARaise the fermentation unitEfficient use ofMicroorganism based processesFermentationInorganic saltsNeomycin

The invention discloses a fermentation medium used in the neomycin production adopting a fermentation method. The fermentation medium comprises an organic carbon source, an organic nitrogen source, inorganic salt and amylase, wherein the concentration of the organic carbon source is 60-110 g / L. After neomycin is produced by using the fermentation medium, the fermentation unit of the obtained neomycin can reach more than 33,310 U / mL, so that the profits of neomycin production enterprises can be greatly increased and the fermentation medium has a broad application prospect.

Owner:HEBEI SHENGXUE DACHENG PHARMA

Method for measuring liquid level of fermentation tank

ActiveCN102080979ATimely and lesser useScientific defoamingLevel indicators by pressure measurementContinuous measurementFermentation

The invention discloses a method for continuously measuring a liquid level of a fermentation tank. The method is implemented by measuring the average density correction factor k. By using the measurement method, the liquid level height of the fermentation tank and the liquid level variation rate of the fermentation tank can be monitored during the whole course, defoaming can be more scientifically carried out, i.e. a defoamer can be used more properly with less amount, thus no liquid escaping phenomenon is generated, the liquid surface can be in the highest safe height, and the advantages of improving fermentation unit, relieving subsequent extraction process load and providing and reducing energy consumption is obvious.

Owner:HUBEI MAGIC HEALTH TECH CO LTD

Culture medium and culture method for producing spinosad by fermenting saccharopolyspora spinosa

PendingCN111484959AGood fermentation processGood control parametersBacteriaMicroorganism based processesBiotechnologyMicrobiology

The invention relates to a culture medium and a culture method for producing spinosad through fermentation of saccharopolyspora spinosa. A carbon source, a nitrogen source and optimal compatibility ratio in a primary seed medium, a secondary seed medium and a fermentation medium for production of spinosad through fermentation of the saccharopolyspora spinosa in a three-stage fermentation mode areconfirmed. By utilizing the culture medium formula and the fermentation control process provided by the invention, the fermentation unit of rice spinosad can be improved, the fermentation cost is reduced, the sources of raw materials and auxiliary materials are furthest reduced and are not influenced by the environment, sufficient supply of the raw materials and the auxiliary materials is ensured,and stable and efficient production of the spinosad is realized.

Owner:NINGXIA TAIYICIN BIOTECH CO LTD

Semi-solid fermentation method of natamycin and natamycin extracting method

InactiveCN101555511BHigh yieldIncrease profitSugar derivativesMicroorganism based processesWastewaterStrong acids

The invention provides a semi-solid fermentation method of natamycin, which adopts porous particle-style substance as a carrier of fermentation substrate. The method comprises the steps of: adopting the porous particle-style substance as the carrier to absorb substrate substance to be inoculated with natamycin-producing strain for semi-solid fermentation; locally drying fermentation materials in air after the semi-solid fermentation is finished; and finally obtaining natamycin powder after processes of packing in column for dipping, leaching, exsolution, dilution precipitation and spraying-drying. The method for producing natamycin requires simple equipment, and the fermenting unit is high and the utilization rate of materials is also high; the extraction process avoids application of strong acid and strong alkali; and the yielding rate of natamycin is high and the method basically avoids discharge of wastewater and waste residue so as to meet the energy-saving and emission-reducing requirements of environment-protection.

Owner:武汉乐立基生物科技有限责任公司

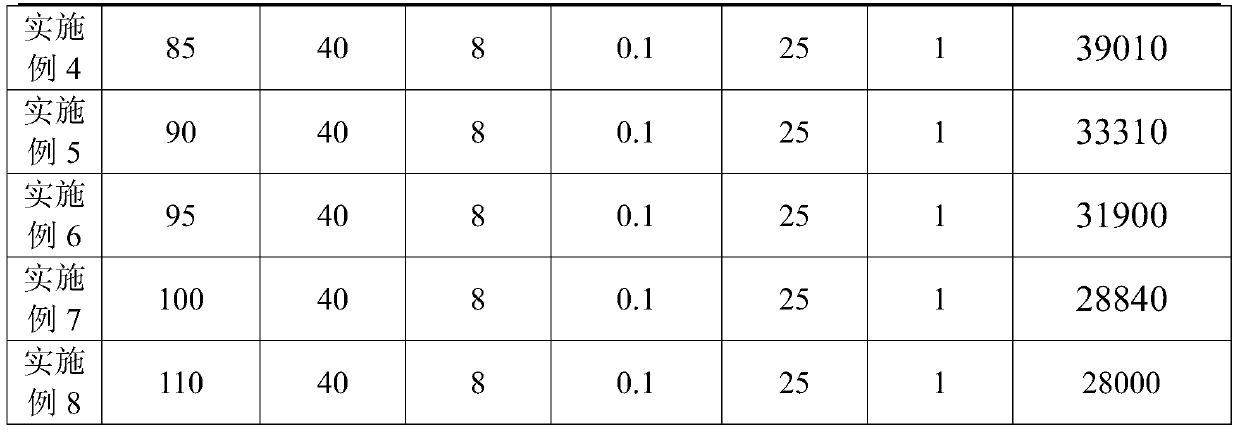

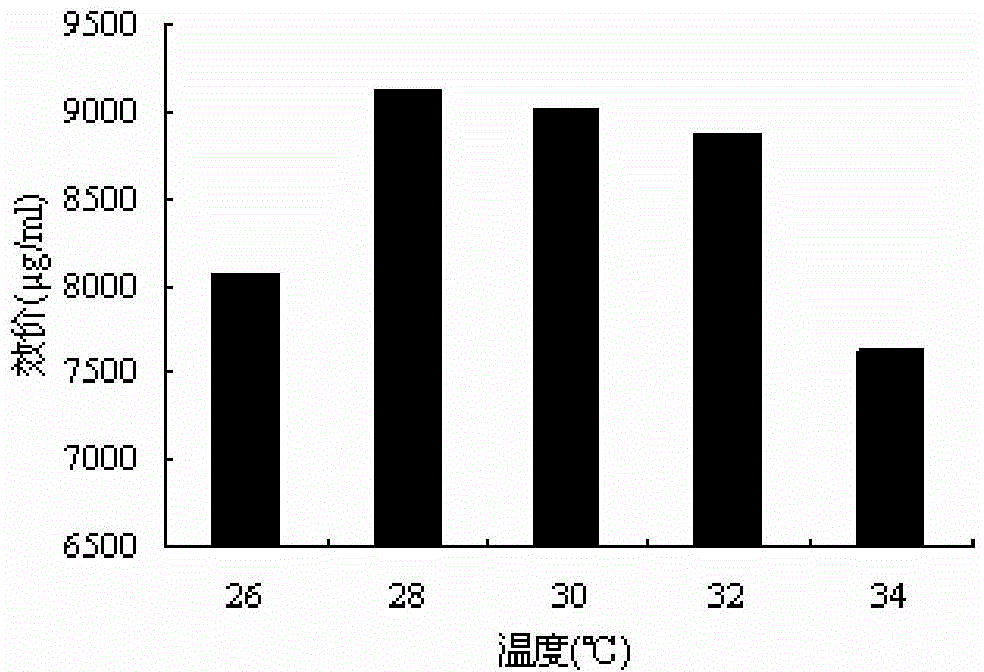

Fermentation medium for fermentation production of antibiotic calicheamicin gamma1 I, fermentation method suitable for the fermentation medium and use of the fermentation medium

InactiveCN102747115AIncrease productionOptimize culture temperatureMicroorganism based processesFermentationNitrogen sourceSugar

The invention provides a fermentation medium for fermentation production of an antibiotic calicheamicin gamma1 I. The fermentation medium comprises one or more organic carbon sources and one or more organic nitrogen sources, wherein based on a total volume of the fermentation medium, the content of the one or more organic carbon sources is in a range of 5 to 130g / L and is preferably in a range of 20 to 110g / L; the content of the one or more organic nitrogen sources is in a range of 2 to 150g / L, is preferably in a range of 4 to 60g / L and is more preferably in a range of 15 to 40g / L; the one or more organic carbon sources are selected from cane sugar, molasses, glycerin and corn starch; and the one or more organic nitrogen sources are selected from fine bean meal and corn steep powder. The invention also provides a fermentation method for fermentation production of an antibiotic calicheamicin gamma1 I by the fermentation medium and a use of the fermentation medium. The fermentation medium greatly provides fermentation titer units of calicheamicin gamma1 I, improves production efficiency, reduces a production cost, and is suitable for large-scale production of calicheamicin gamma1 I.

Owner:SHANGHAI INST OF PHARMA IND

Method for breeding selection of high yield strain of Wanlongmycin by using ion in low energy to induce mutation of gray variant streptomycete

InactiveCN101092601AMutagenesis method is goodRaise the fermentation unitBacteriaMutant preparationBacterial strainStreptomycin

This invention discloses low-energy ion implantation method for mutagenizing Streptomyces griseovariablis to obtain high-yield wanlongmycin-producing bacterium. The method comprises: spreading Streptomyces griseovariablis spore suspension in a sterile culture dish at room temperature, drying in sterile condition, performing ion implantation with nitrogen ion beam, washing with sterile water, diluting, spreading in Gause's medium No.1 containing streptomycin, culturing, selecting well grown single strains, inoculating into a liquid culture medium, and culturing to obtain Streptomyces griseovariablis with high genetic stabilityand high wanlongmycin yield. The method has such advantages as simple process, high safety and good mutagenic effect. The fermentation efficiency of the obtained bacterial strain is 20-90% higher than the original strain.

Owner:PLANT PROTECTION RES INST OF GUANGDONG ACADEMY OF AGRI SCI

Fermentation culture medium and fermentation method for improving enramycin yield

ActiveCN104131054ASolve the problems of high production cost and unsatisfactory fermentation levelRaise the fermentation unitMicroorganism based processesFermentationNitrogen sourceStreptomyces fungicidicus

The invention provides a fermentation culture medium for improving enramycin yield. The content of organic carbon sources in the fermentation culture medium is 40-80 g / L; the content of organic nitrogen sources in the fermentation medium is 10-60 g / L. The invention also provides a method for fermentation production of enramycin, wherein the method comprises the steps of inoculating the fermentation culture medium with a streptomyces fungicidicus seed liquid, carrying out liquid fermentation, and after carrying out fermentation culture for 192-240 hours, extracting enramycin from the fermentation liquid. The fermentation culture medium and the fermentation method greatly improve the fermentation unit of enramycin, and are suitable for large-scale production of enduracidin.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

Semi-solid fermentation method of natamycin and natamycin extracting method

InactiveCN101555511AHigh yieldIncrease profitSugar derivativesMicroorganism based processesWastewaterSemi solid

The invention provides a semi-solid fermentation method of natamycin, which adopts porous particle-style substance as a carrier of fermentation substrate. The method comprises the steps of: adopting the porous particle-style substance as the carrier to absorb substrate substance to be inoculated with natamycin-producing strain for semi-solid fermentation; locally drying fermentation materials in air after the semi-solid fermentation is finished; and finally obtaining natamycin powder after processes of packing in column for dipping, leaching, exsolution, dilution precipitation and spraying-drying. The method for producing natamycin requires simple equipment, and the fermenting unit is high and the utilization rate of materials is also high; the extraction process avoids application of strong acid and strong alkali; and the yielding rate of natamycin is high and the method basically avoids discharge of wastewater and waste residue so as to meet the energy-saving and emission-reducing requirements of environment-protection.

Owner:武汉乐立基生物科技有限责任公司

Preparation method of monensin premix

ActiveCN104313079AHigh yieldReduce manufacturing costMicroorganism based processesFermentationMicroscopic examMonensin

The invention discloses a preparation method of a monensin premix. The preparation method comprises the following specific steps: preparing cinnamon streptomyce strain; seed flask culture and seed tank culture are performed; when the age of the seed is 20-24h, the pH of a culture solution is 6.6-7.1, the biomass is above 10%, and microscopic examination shows that mycelia are thick and reticular, are stretched and darkly stained and are free of foreign bacteria, performing fermentation culture is performed; when the residual oil amount is below 0.7%, the biomass is above 40%, the mycelium concentration is 40-50%, and the monensin titer is not lower than 40000U / mL, fermentation is finished; monensin is extracted by a one-step spray drying method, wherein the prepared finished monensin product has the monensin content of above 20% and the grain rate of above 75%. According to the preparation method, the fermentation process is simple, so that the fermentation unit can be effectively increased and the production cost can be reduced; usages of an animal-derived nitrogen source and a chemical organic solvent are avoided.

Owner:金河生物科技股份有限公司

Method for improving yield of vitamin B12 based on regulation of ammonia nitrogen index

PendingCN110205350AMaintain nutrientsSolve growthMicroorganism based processesFermentationHigh concentrationVitamin B12

Provided is a method for improving the yield of vitamin B12 based on regulation of an ammonia nitrogen index. In the fermentation process of vitamin B12, stage-by-stage batch feeding is carried out; in the earlier stage of fermentation, a yeast extract juice is refilled, so a certain content of ammonia nitrogen is maintained at a certain stage, so as to ensure the nitrogen source needed for growthand metabolism of bacteria. The stage-by-stage batch feeding is carried out in the fermentation process, the yeast extract juice is refilled in the earlier stage of fermentation, the concentration ofammonia nitrogen is controlled, the contradiction between the growth of the bacteria and biosynthesis of high-concentration ammonia nitrogen in the fermentation of vitamin B12 is solved, the nutritional components required for the growth and metabolism of the bacteria are ensured in the early stage of fermentation, the growth of bacteria is promoted, the phenomena of premature senescence and metabolic stagnation in the later period are avoided, and the fermentation unit of vitamin B12 is increased.

Owner:HEBEI HUARONG PHARMA

Method for industrially producing L-hydroxyproline through fermentation method

InactiveCN105506019ARaise the fermentation unitHigh yieldOrganic chemistryMicroorganism based processesFermentationPollution

Provided is a method for industrially producing L-hydroxyproline through a fermentation method. The method comprises the steps of strain solid culture, fermentation culture, fermentation liquor extraction and purification. According to the method for industrially producing the L-hydroxyproline through the fermentation method, the L-hydroxyproline is industrially produced through a direct glucose fermentation method, the fermentation unit, yield and quality of the L-hydroxyproline is improved, the production cost is reduced, and three-waste pollution is avoided.

Owner:TIANJIN JINGYE FINE CHEM

Mutant strain for producing sisomicin

InactiveCN102618473ARaise the fermentation unitStable production processBacteriaMicroorganism based processesMutant strainMicromonospora sp.

The invention relates to a mutant strain for producing sisomicin, which is applied to antibiotic manufacture and belongs to the field of antibiotic pharmacy. The mutant strain is micromonosporainyoensis HP388 registered and preserved in a general microorganism center of the Chinese microscobial preservation management committee on March 19, 2012, and the preservation number is CGMCCNo.5921. The mutant strain HP388 has the most remarkable advantages of high fermentation unit, stable production process, convenience in control, low oxygen consumption, low cost, low pollution and fine product quality.

Owner:FUZHOU UNIVERSITY +1

Fermenting method for increasing pleocidin output

ActiveCN107523598APromote growthIncrease productionMicroorganism based processesFermentationCompound organicNitrogen source

The invention relates to a fermenting method for increasing pleocidin output. The method comprises the following steps: putting saccharopolyspora spinosa in a fermenting culture medium to ferment; after fermentation in 72-120hr, supplementing a compound organic nitrogen source for the first time, wherein the adding amount is the amount, by which the final concentration of the compound organic nitrogen source in a fermenting liquid is 5-20g / L; and after fermentation in 120-160hr, supplementing the compound organic nitrogen source for the first time, wherein the adding amount is the amount, by which the final concentration of the compound organic nitrogen source in the fermenting liquid is 5-20g / L. Continuous production of thalli and product synthesis are facilitated, so that the pleocidin output can be further increased.

Owner:SHANGHAI NONGLE BIOLOGICAL PROD

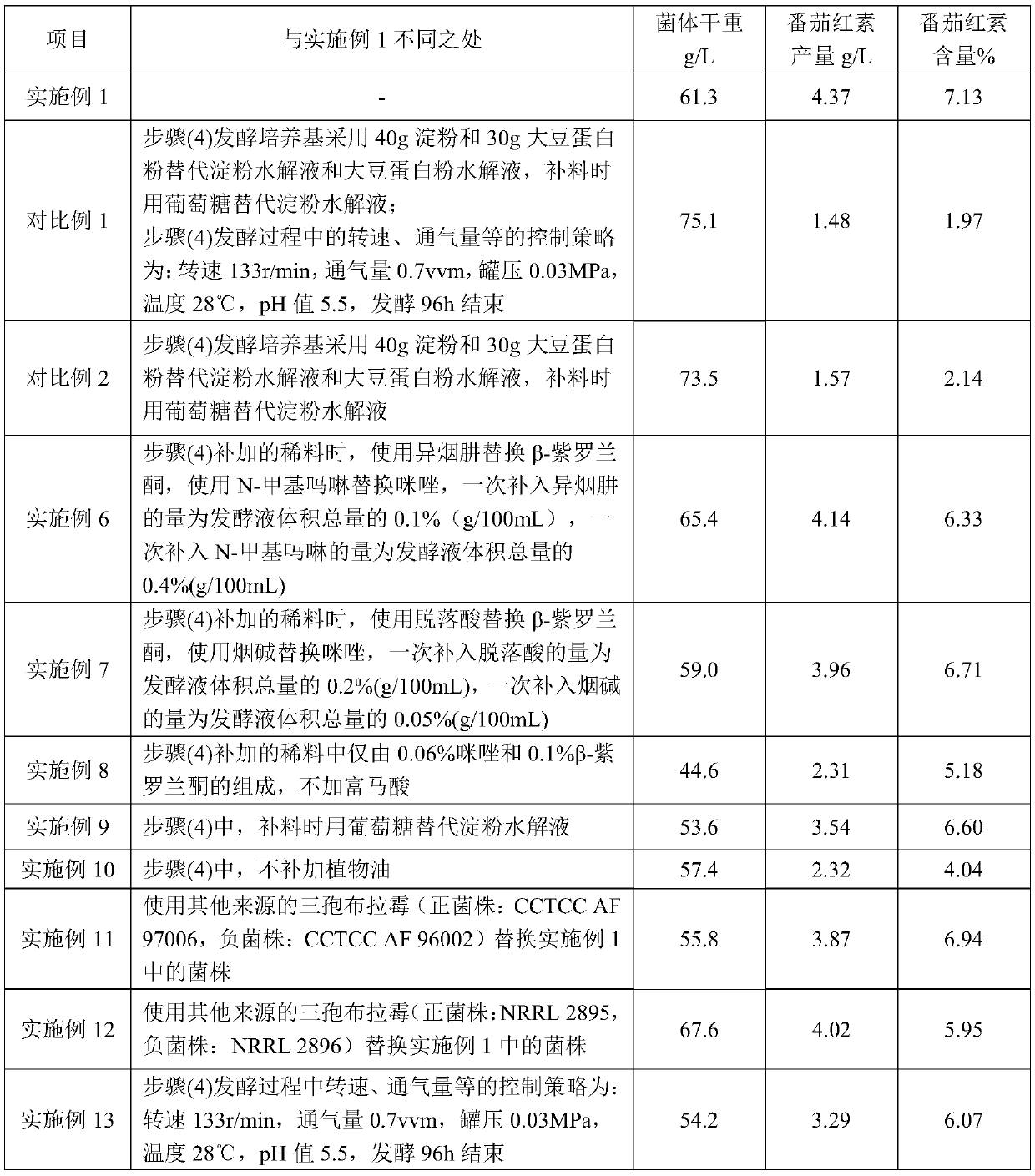

Fermentation medium, application thereof and method for preparing lycopene through fermentation of Blakeslea trispora

ActiveCN110283854AIncrease productionSatisfy consumptionMicroorganism based processesFermentationVegetable oilHydrolysate

The invention belongs to the field of production of lycopene and discloses a fermentation medium, the application thereof and a method for preparing lycopene through fermentation of Blakeslea trispora. The fermentation medium comprises the following ingredients: a starch component, a bean flour component, fish meal, vegetable oil, copper sulfate, magnesium sulfate, monopotassium phosphate, vitamin E and an emulsifying agent, wherein the starch component comprises starch and / or starch hydrolysate; the bean flour component comprises bean flour and / or bean flour hydrolysate; and at least one of the starch component and the bean flour component is the hydrolysate of the starch or bean flour. With the adoption of the fermentation medium provided by the invention, the concentration of dissolved oxygen can be improved, and the dissolved oxygen can be reasonably and efficiently utilized. Therefore, the yield of lycopene is improved.

Owner:KINGDOMWAY BIOTECH (JIANGSU) CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com