New purpose of foam killer

A defoamer and bacteria-producing technology, which is applied in the direction of foam dispersion/prevention, fermentation, etc., can solve the problems of affecting the oxygen mass transfer rate, causing serious consequences in the fermentation process, and affecting the physiological metabolism of antibiotic-producing bacteria.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

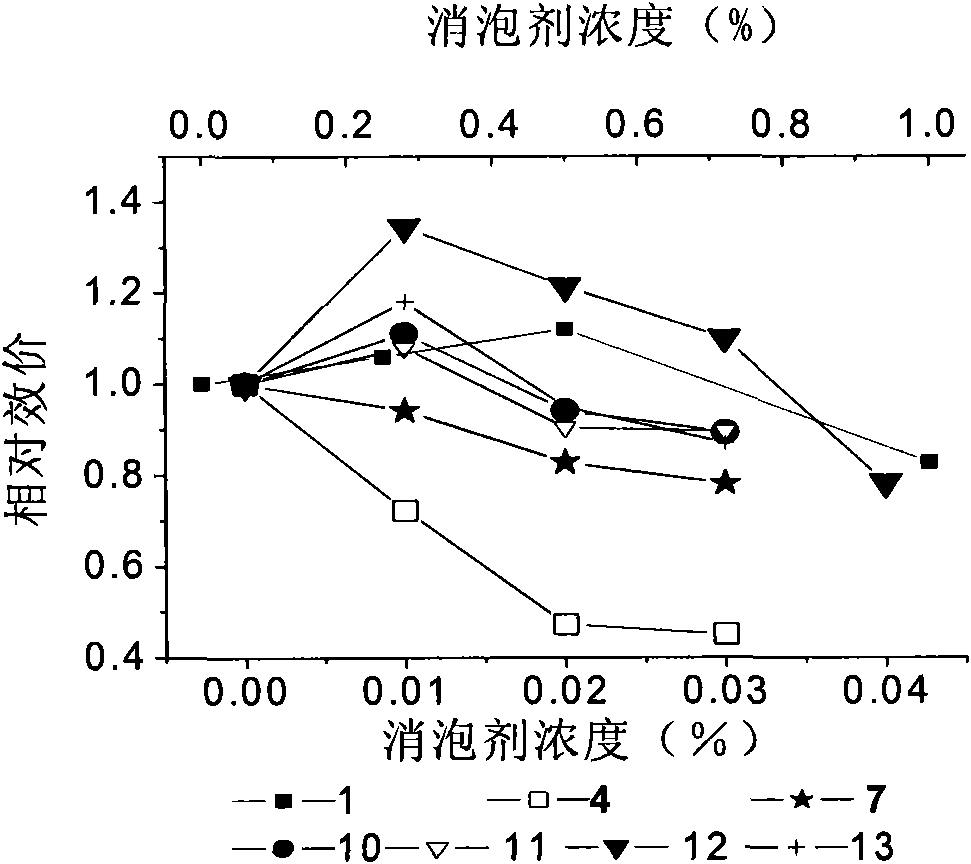

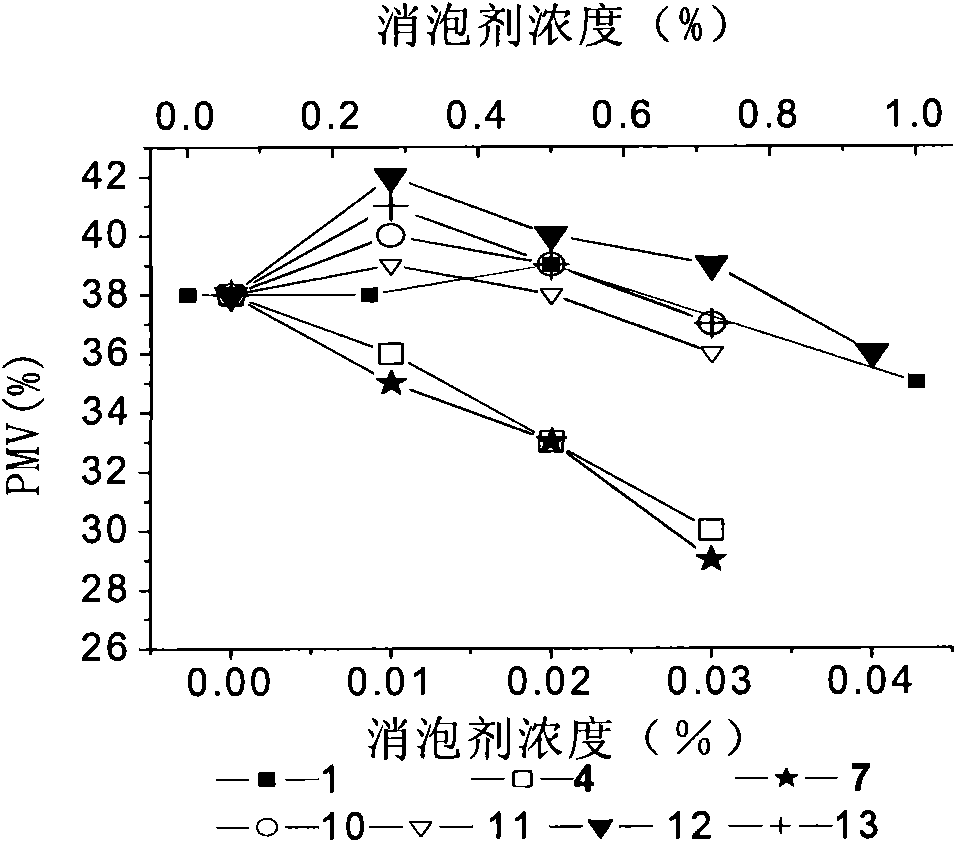

Examples

Embodiment 1

[0052] 1 Materials and methods

[0053] 1.1 Strains

[0054] Bitespiramycin genetic engineering strain WSJ-1-195 was provided by Shenyang Tonglian Pharmaceutical Group Shanghai Research Institute.

[0055] 1.2 Culture medium formula (see Wang Yiguang, Jinlianfang, Jinwenzao, etc. Cloning of 4'acylase gene and expression in spiramycin-producing bacteria [J]. Acta Biological Engineering, 1992, 8(1): 1)

[0056] 1.2.1 Incline medium starch, soybean meal, NaCl, CaCO 3 , KH 2 PO 4 , peptone, etc.

[0057] 1.2.2 Seed medium starch, soybean meal, NaCl, CaCO 3 , KH 2 PO 4 , peptone, etc.

[0058] 1.2.3 Fermentation Shake Flask Medium Glucose, starch, fish meal, NH 4 NO 3 , CaCO 3 , KH 2 PO 4 , MgSO 4 ·7H 2 O, NaCl, etc.

[0059] 1.2.4 Medium for the determination of biological potency beef extract, peptone, glucose, yeast extract, agar, etc.

[0060] 1.3 Culture method

[0061] 1.3.1 Incline cultivation method

[0062] Add 40ml of slant medium to the eggplant bottle...

Embodiment 2

[0098] Physiological Effects in Fermentation of Erythromycin

[0099] The No. 12 defoamer in Example 1 verified the same effect in the fermentation of another macrolide antibiotic—erythromycin.

[0100] Operating conditions: Dig fresh slant (1cm×1cm) into a 500mL shake flask with 80mL seed medium, temperature 34°C, rotation speed 220r / min, after 44-48h of cultivation, transfer to a fermentation bottle for cultivation, inoculum size 5%, the temperature is 34°C, the rotation speed is 240r / min, and cultivated for 144h.

[0101] In the test group, different concentrations of No. 12 defoamer were added to the medium, and no defoamer was used as a control, and the biological potency was measured after the fermentation.

[0102] Image 6 It shows that adding 0.02% of the preferred antifoaming agent group increases the fermentation unit of erythromycin by 30.9%.

[0103] The results show that the No. 12 defoamer has a good effect on the defoaming and antifoaming of the bitspiramyci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com