Genetic engineering strain Streptomyces tsukubaensis L21 and application thereof

A technology of genetically engineered strains, Streptomyces tsukuba, applied in the field of bioengineering, can solve the problem of low fermentation units of strains, and achieve the effects of stable fermentation units, high fermentation units, and stable genetic traits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The acquisition of embodiment 1 Streptomyces tsukuba L21

[0025] The DNA sequence of SEQ ID NO.1 was amplified by polymerase chain reaction (PCR), and the amplified DNA fragment was digested with a restriction endonuclease and inserted into the plasmid pIJ8660, and then the plasmid containing the above DNA sequence was transformed into the large intestine Bacillus ET12567 (which already contains plasmid pUZ8002).

[0026] Inoculate Escherichia coli ET12567 (already containing plasmid pUZ8002) containing the above recombinant plasmid into 50mL LB liquid medium (containing corresponding antibiotics), and cultivate to OD at 37°C 600 was 0.4, the cells were collected by centrifugation, washed once with 20 mL LB liquid medium, and then washed once with 10 mL LB. Then centrifuge the supernatant and resuspend with 0.5mL LB liquid medium; add 20μL of the screened Streptomyces tsukuba spores to resuspend in 0.5mL 2×YT liquid medium, heat shock at 45°C for 10min, and then cool ...

Embodiment 2

[0027] The thalline morphology characteristic of embodiment 2 Streptomyces tsukuba L21

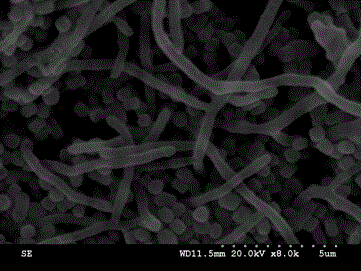

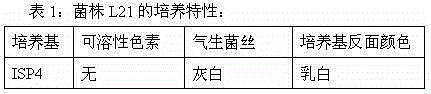

[0028] Streptomyces tsukuba L21 was cultured in ISP4 solid medium for 7 days, observed under the electron microscope, it can be seen that the hyphae and aerial hyphae in the base are well developed, the spore filaments are flexible or curved, and the number of mature spore chainspores is less than 10 Above, the spores are short rod-shaped (see figure 1 ). The apparent characteristics in ISP4 solid medium, the results are shown in Table 1.

[0029]

Embodiment 3

[0030] The fermentation verification of embodiment 3 Streptomyces tsukuba L21

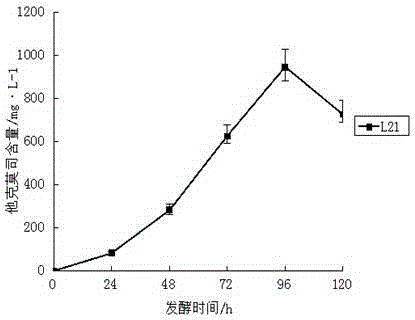

[0031] Inoculate 20 μL of Streptomyces tsukuba L21 spores into the seed medium at a rotational speed of 250 rpm and incubate at 28°C for 24 hours; inoculate the mycelium in the seed medium into the fermentation medium at a rotational speed of 250 rpm at 28°C at 10% of the inoculum amount At 120 hours, samples were taken after 24, 48, 72, 96, and 120 hours of culture to measure the production of tacrolimus.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com