Stage division and fault detection method based on correlation analysis

A technology of correlation analysis and fault detection, applied in electrical testing/monitoring, testing/monitoring control systems, instruments, etc., can solve problems such as the reduction of the accuracy of the representative model of the stage, the inability of the clustering algorithm to consider the sequence sequence of stages, and the intersection of time sequences.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

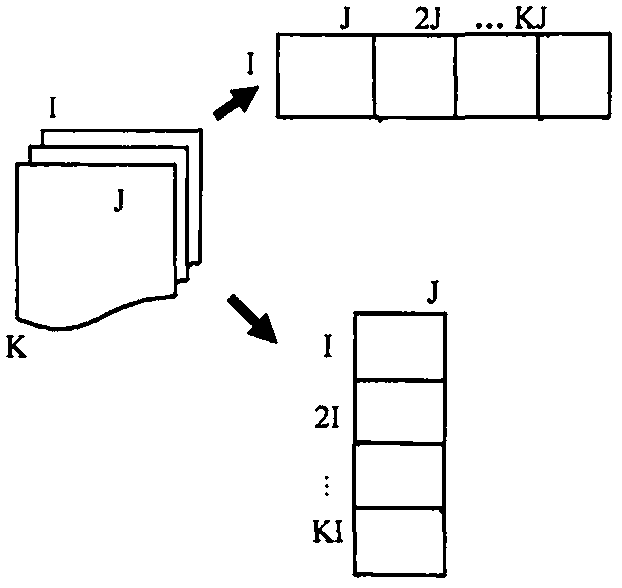

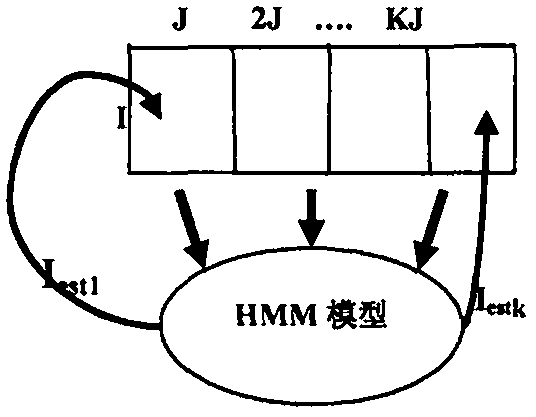

[0042] In the present invention, partial least squares (PLS) is an important method in multivariate statistical analysis, which mainly focuses on finding the relationship between the multidimensional matrix X and Y, and extracting the optimal low-dimensional feature interpretation direction. is built in the sense of predictive power from the input space to the output space. Multidirectional Partial Least Squares (MPLS) is an extension of PLS, by combining multiple batches of historical industrial process data matrix X(I×J×K) and quality data matrix Y(I×M×K) with variables Or batch-wise expanded into two-dimensional matrices X(IK×J) and Y(IK×M), and extract low-dimensional latent features. The above expansion method not only preserves the nonlinear time-varying trajectory between variables, but also preserves the average trajectory between batches. Among them, the monitoring method based on the variable expansion method neither needs forecast data nor requires batches of equal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com