Fermentation process fault monitoring method based on multiple contraction automatic encoders

A technology of automatic encoder and fermentation process, which is applied in the direction of instrumentation, program control, electrical test/monitoring, etc., and can solve problems such as limiting AE fault monitoring performance, poor robustness of hidden layer features, and noise interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

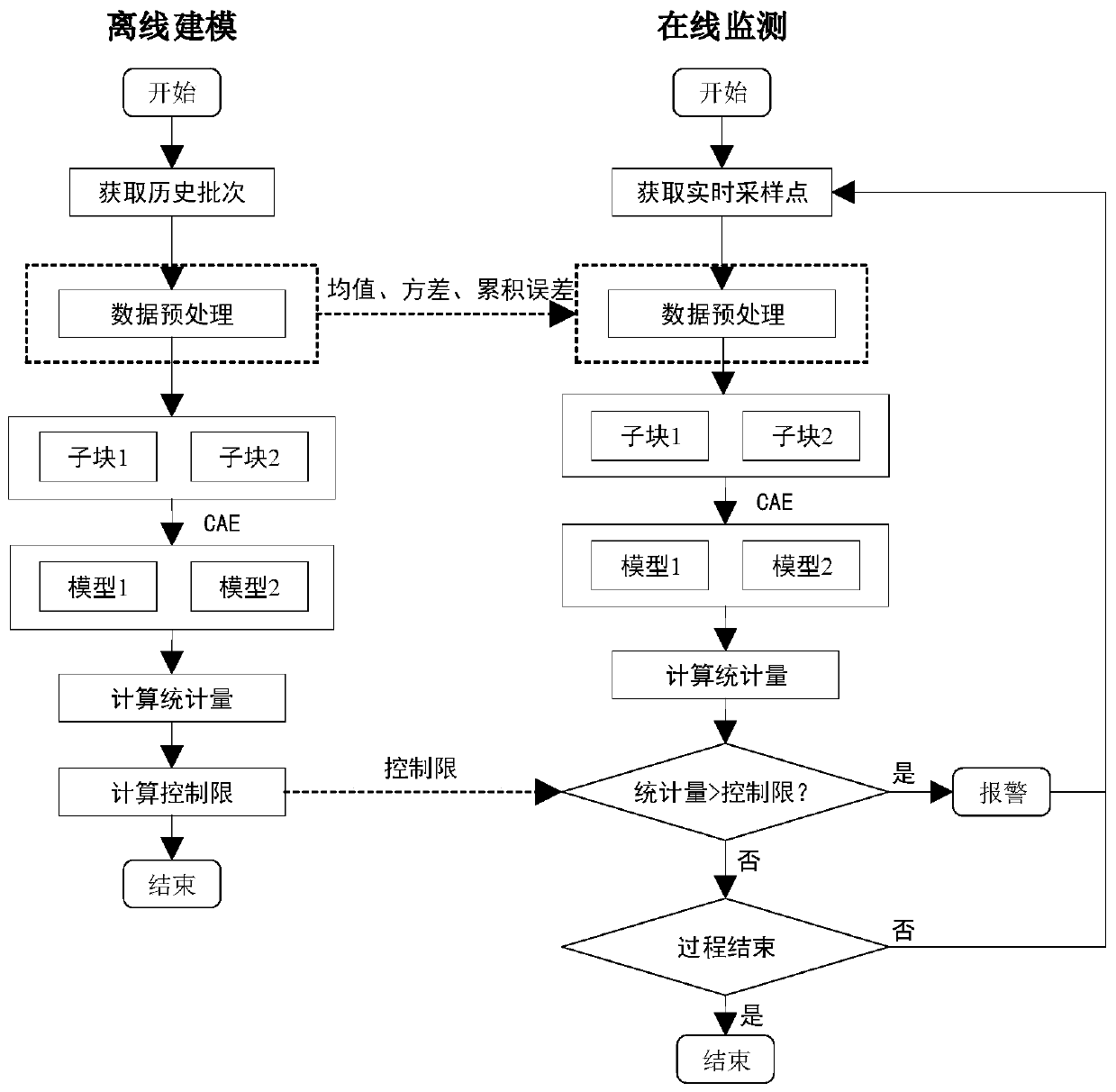

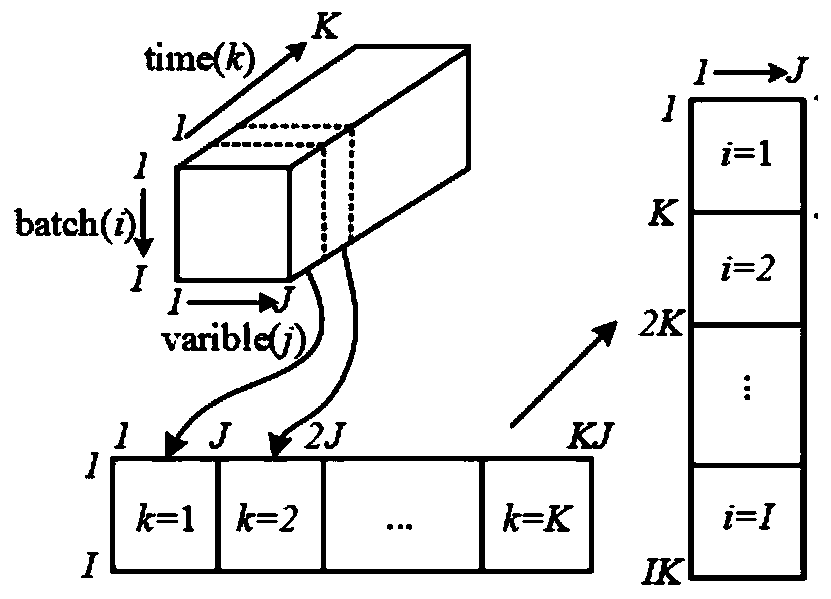

Method used

Image

Examples

Embodiment Construction

[0056] Penicillin is an important antibiotic with high efficiency, low toxicity and wide clinical application. Its production process is a typical dynamic, nonlinear, multi-stage batch production process. PenSim2.0, a penicillin simulation platform developed by the process monitoring and technology group of Illinois State Institute of Technology in the United States, provides a standard platform for the monitoring, fault diagnosis and control of penicillin intermittent production process. A series of simulations of the fermentation process of penicillin can be realized on this platform, and relevant research has shown the practicability and effectiveness of this simulation platform.

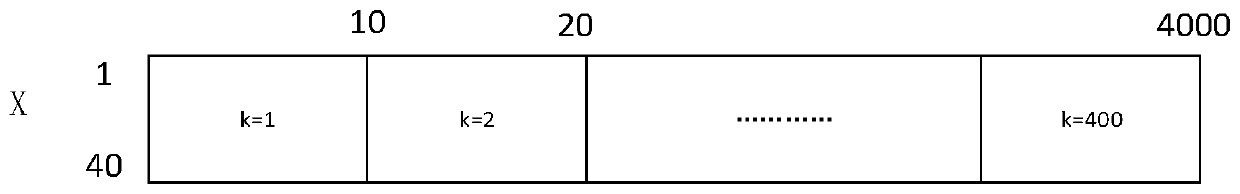

[0057] This experiment takes PenSim2.0 as the simulation research object, sets the sampling interval as 1h, and selects 10 process variables to monitor the process operation status, as shown in Table 1. 41 batches of normal data and 2 batches of fault data were simulated, each batch lasted 400 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com