Construction method of pile precast slab retaining wall with drainage ditch

A construction method and drainage ditch technology, applied in the field of retaining walls, can solve the problems of damage to the ecological environment of the mountain, mining of large rubble, slow construction speed, etc., and achieve the effect of reducing excavation, less material, and small working surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

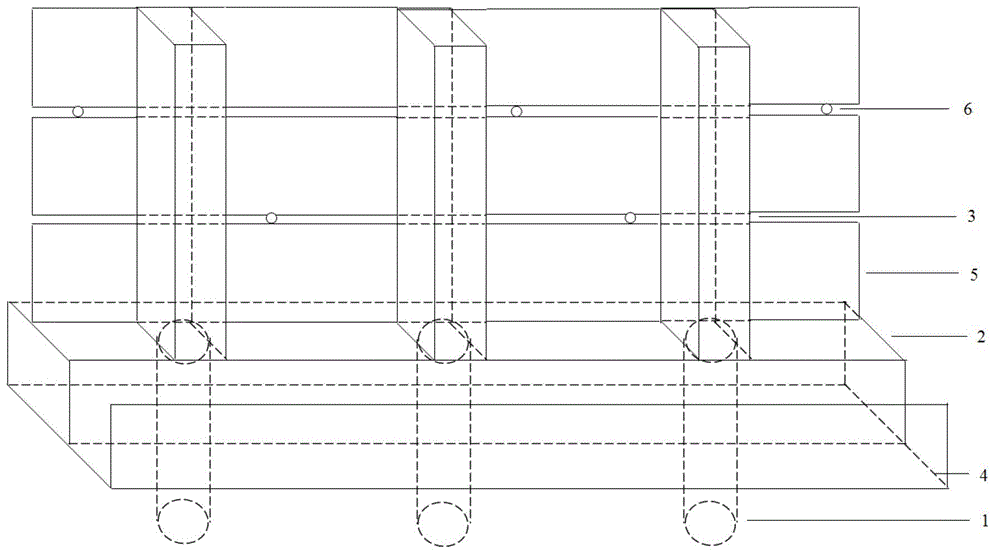

[0038] Such as figure 1 Shown, a kind of construction method of the pile prefabricated slab retaining wall with drainage ditches, comprises the following steps:

[0039] A. Clean the foot of the wall, lay out the wires and lay out the points, and excavate the pile holes.

[0040] Clean up the slope foundation with slope protection soil, clean and level the base belt with a width of 0.8-1 meters and a preset length, remove plants, litter and fallen leaves and other debris on the base belt, and loose soil, and compact the base belt , lay out the line along the foundation belt (or lay out the line according to the design drawings), use lime as marking points every 1.4-1.6 meters on the foundation belt along the line, and dig out a diameter of 340-360 mm at each marking point with a Luoyang shovel. , The pile hole with a depth of 2-6 meters. The depth of the pile hole is mainly determined according to the thickness of the filling soil, the depth of the solid layer and the height ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com