Two-ridge four-row hydraulic automatic row-aligning harvesting device

A harvesting device and hydraulic technology, applied in the direction of excavator harvesters, harvesters, agricultural machinery and implements, etc., can solve the problems such as the inability to adjust the distance, the error of the ridge spacing, and the inability to adjust the row spacing of the harvesting device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

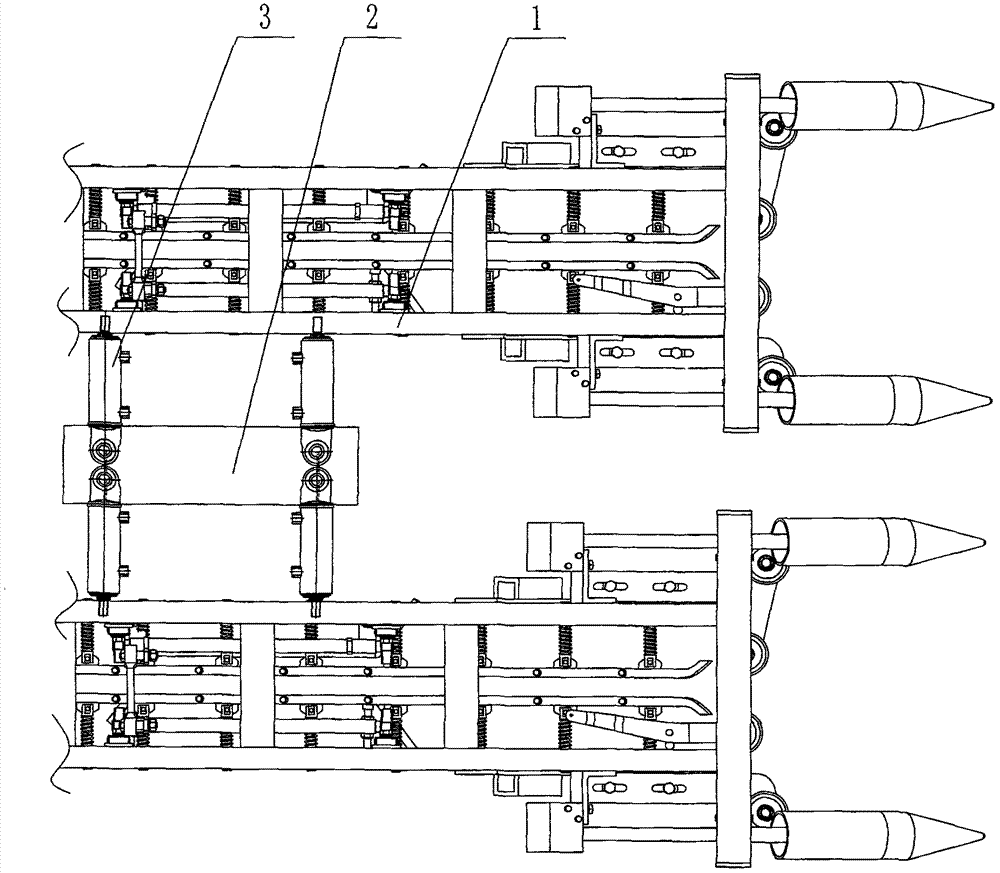

[0011] As shown in the figure, a two-ridge four-row hydraulic automatic harvesting device includes two sets of harvesting devices 1, a hydraulic manifold 2, and a hydraulic cylinder 3. The two sets of harvesting devices 1 are installed on the peanut combine harvester through a chute. On the rack, it is characterized in that a hydraulic manifold block 2 is arranged between the two sets of harvesting devices 1, and two sets of 4 hydraulic cylinders 3 are symmetrically arranged on the hydraulic manifold 2, and each harvesting device 1 Connect with a group of hydraulic cylinders 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com