A Z-shaped strip working face mining method

A mining method and technology of working face, which are applied in surface mining, mining equipment, underground mining and other directions, can solve the problems of high roadway excavation rate and low cost of roadway retention, and achieve the advantages of reduced support cost, simple construction and reduced labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

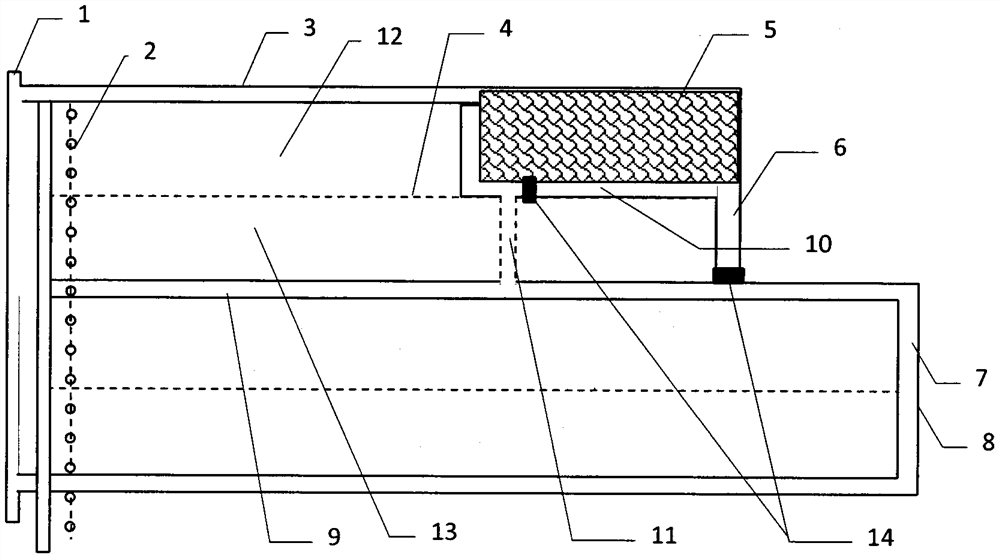

[0022] Such as figure 1 As shown, in a mining area, the front end is the system roadway 1 and the roadway coal pillar 2, and the mining area is divided into several strip groups, and each strip group includes a strip working face 12 and its adjacent strip coal Column 13, strip working face boundary line 4 is arranged between strip working face 12 and strip coal pillar 13, and strip working face 12 rear end is goaf 5; Strip group roadway includes strip Yunshun 3, strip The belt return line 9 and the return air lane 6 at the boundary of a strip group, the strip transport route 3 of the next strip group coincides or partially overlaps with the strip return line 9 of the previous strip group.

[0023] Strip mining: the return airway 6 at the boundary of the strip group from the strip Yunshun 3 to the boundary line 4 of the strip working face is used as the opening position of the strip working face to form a Z-shaped mining layout. The reserved roadway 10 at the boundary position...

Embodiment 2

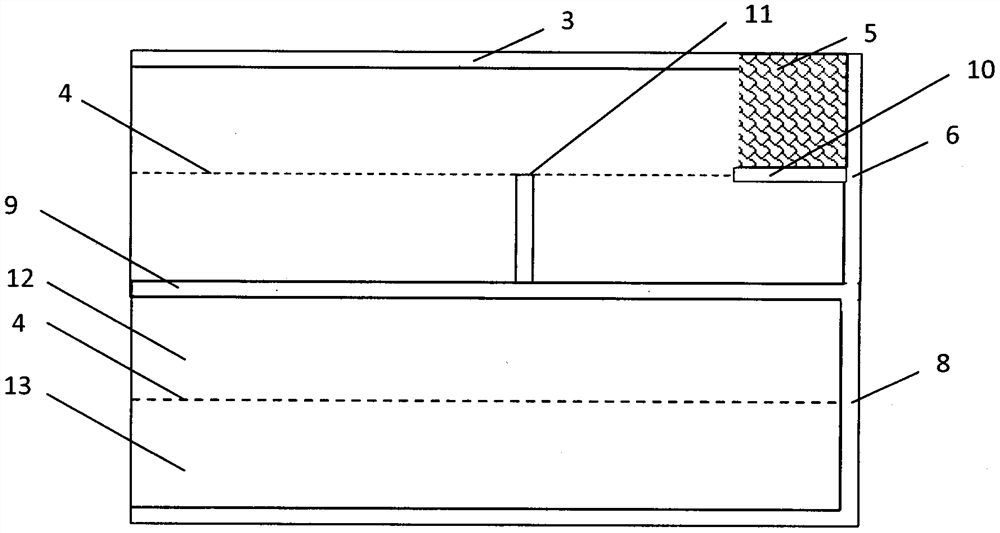

[0033] Such as figure 2 As shown, in a mining area, the front end is the system roadway 1 and the roadway coal pillar 2, and the mining area is divided into several strip groups, and each strip group includes a strip working face 12 and its adjacent strip coal Column 13, strip working face boundary line 4 is arranged between strip working face 12 and strip coal pillar 13, and strip working face 12 rear end is goaf 5; Strip group roadway includes strip Yunshun 3, strip The belt backshun 9 and the return air lane 6 at the boundary of a strip group, the strip transportation 3 of the next strip group coincides with the strip backshun 9 of the previous strip group.

[0034] Strip mining: the return airway 6 at the boundary of the strip group from the strip Yunshun 3 to the boundary line 4 of the strip working face is used as the opening position of the strip working face to form a Z-shaped mining layout. The reserved lane 10 at the boundary position of the head strip coal pillar ...

Embodiment 3

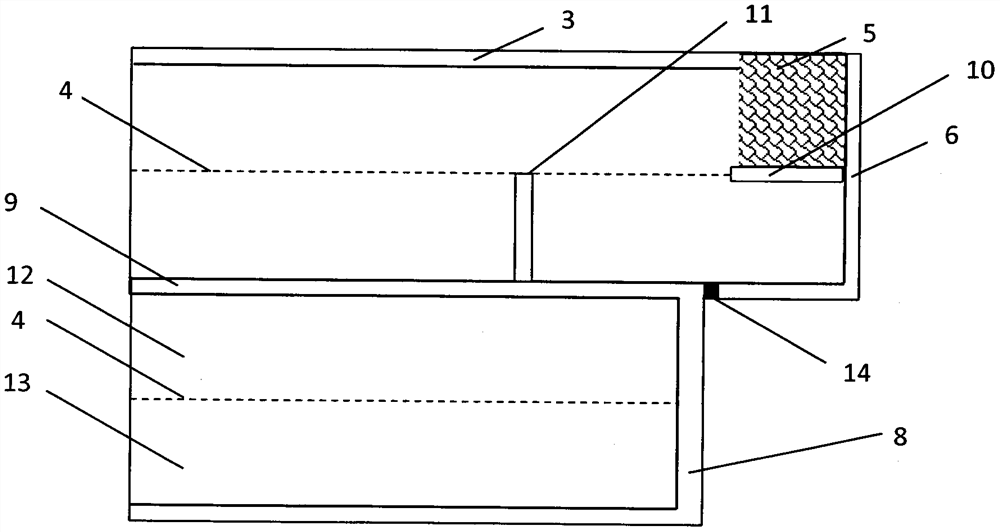

[0042] Such as image 3 As shown, in a mining area, the front end is the system roadway 1 and the roadway coal pillar 2, and the mining area is divided into several strip groups, and each strip group includes a strip working face 12 and its adjacent strip coal Column 13, strip working face boundary line 4 is arranged between strip working face 12 and strip coal pillar 13, and strip working face 12 rear end is goaf 5; Strip group roadway includes strip Yunshun 3, strip The belt backshun 9 and the return air lane 6 at the boundary of one strip group, the strip transportation 3 of the next strip group partially overlaps with the strip backshun 9 of the previous strip group.

[0043]Take the return airway 6 at the boundary of the strip group from Yunshun 3 of the strip to the boundary line of the coal pillar of the strip as the opening position of the strip working face to form a Z-shaped mining layout, and the coal pillar at the end of the working face during the mining process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com