Fermentation process stage division method based on scoring matrices

A scoring matrix and fermentation process technology, applied in the direction of program control, electrical program control, comprehensive factory control, etc., can solve the problems of "increasing false positives and false negatives, misclassification" and cannot reflect the characteristics of the transition stage well, to achieve The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

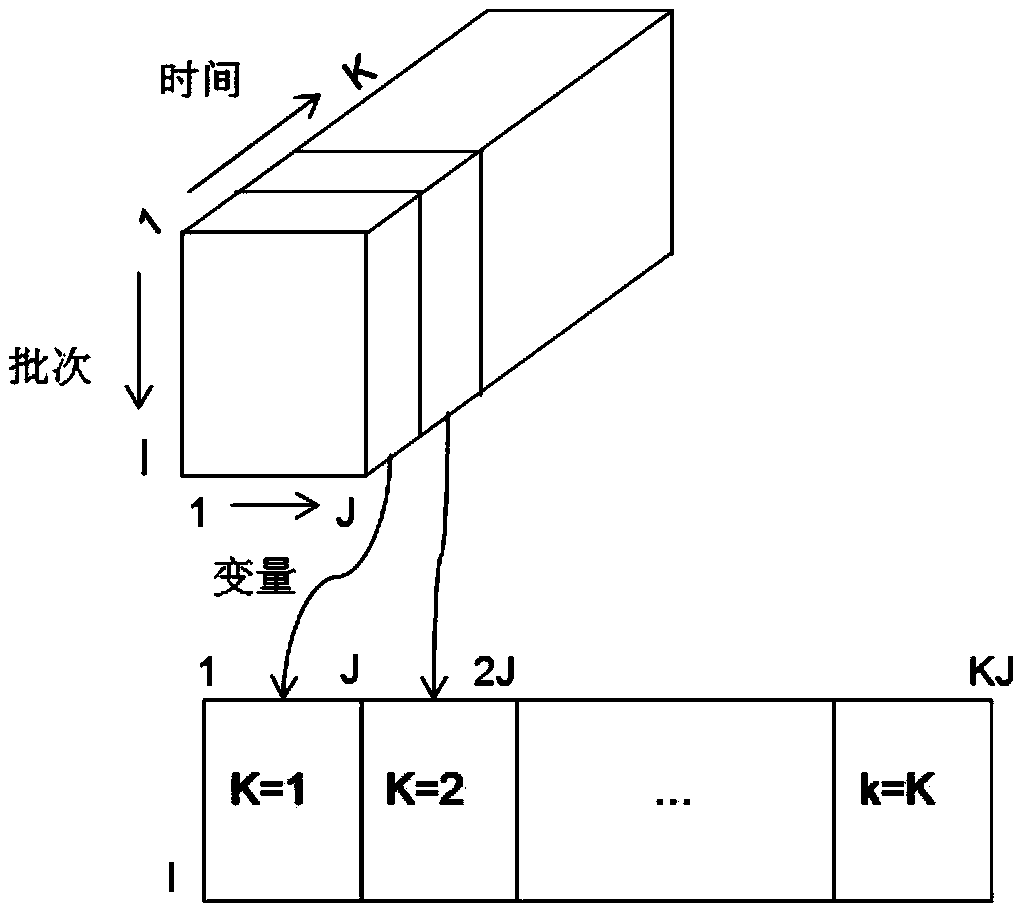

[0025] Penicillin (Penicillin, or transliteration Penicillin) is a relatively common clinical antibacterial drug in life, and its production and preparation process is a typical batch process. The Pensim simulation platform developed by Professor Cinar of Illinois State Institute of Technology in the United States can analyze the microbial concentration and CO in the production process of penicillin under different operating conditions. 2 Concentration, pH value, penicillin concentration, oxygen concentration and heat generated etc. are simulated. The duration of each batch of penicillin fermentation was 400h, and the sampling interval was 1 hour. Select 10 main process variables as shown in Table 1, and select a quality variable (product concentration). In this paper, 60 batches of penicillin fermentation process are selected for training and modeling, and 20 batches are used for prediction.

[0026] Table 1 Penicillin Fermentation Process Variables

[0027] Table 1Process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com