Liquid-liquid-liquid three phase continuous extraction vibrating sieve plate tower

A sieve tray and three-phase technology, applied in the direction of liquid solution solvent extraction, etc., can solve the problems of not being able to adapt to continuous production, and achieve the effects of simple structure, low power consumption, and great practical significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

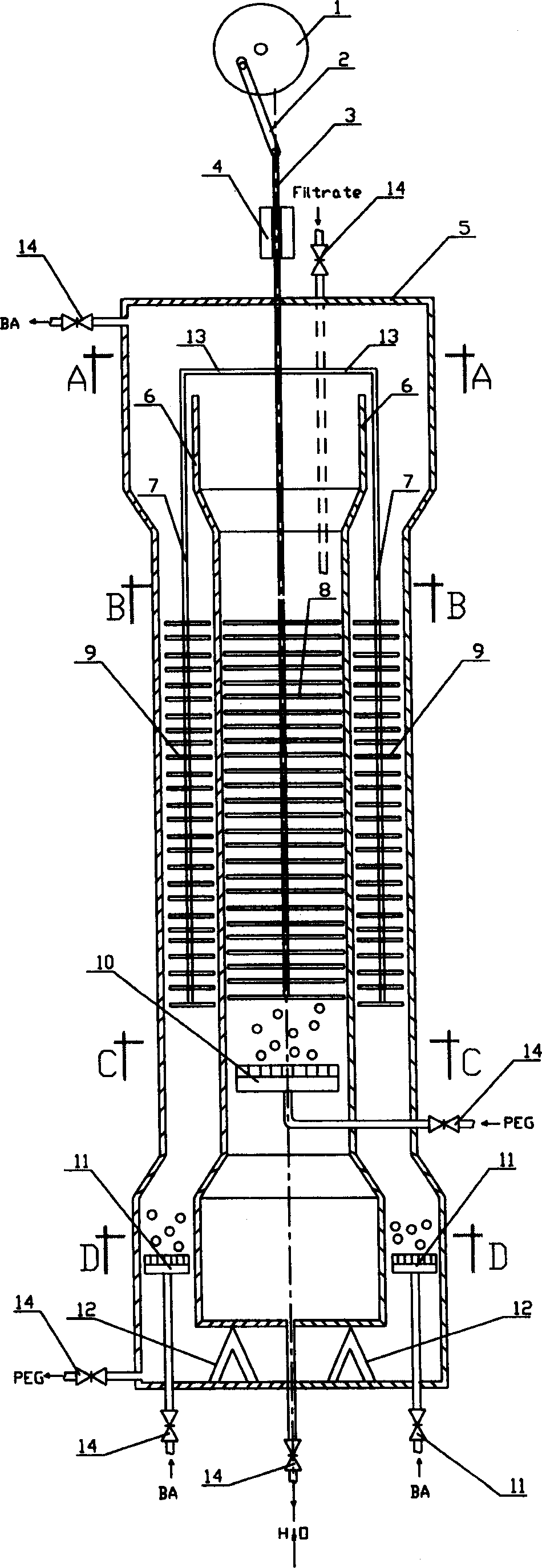

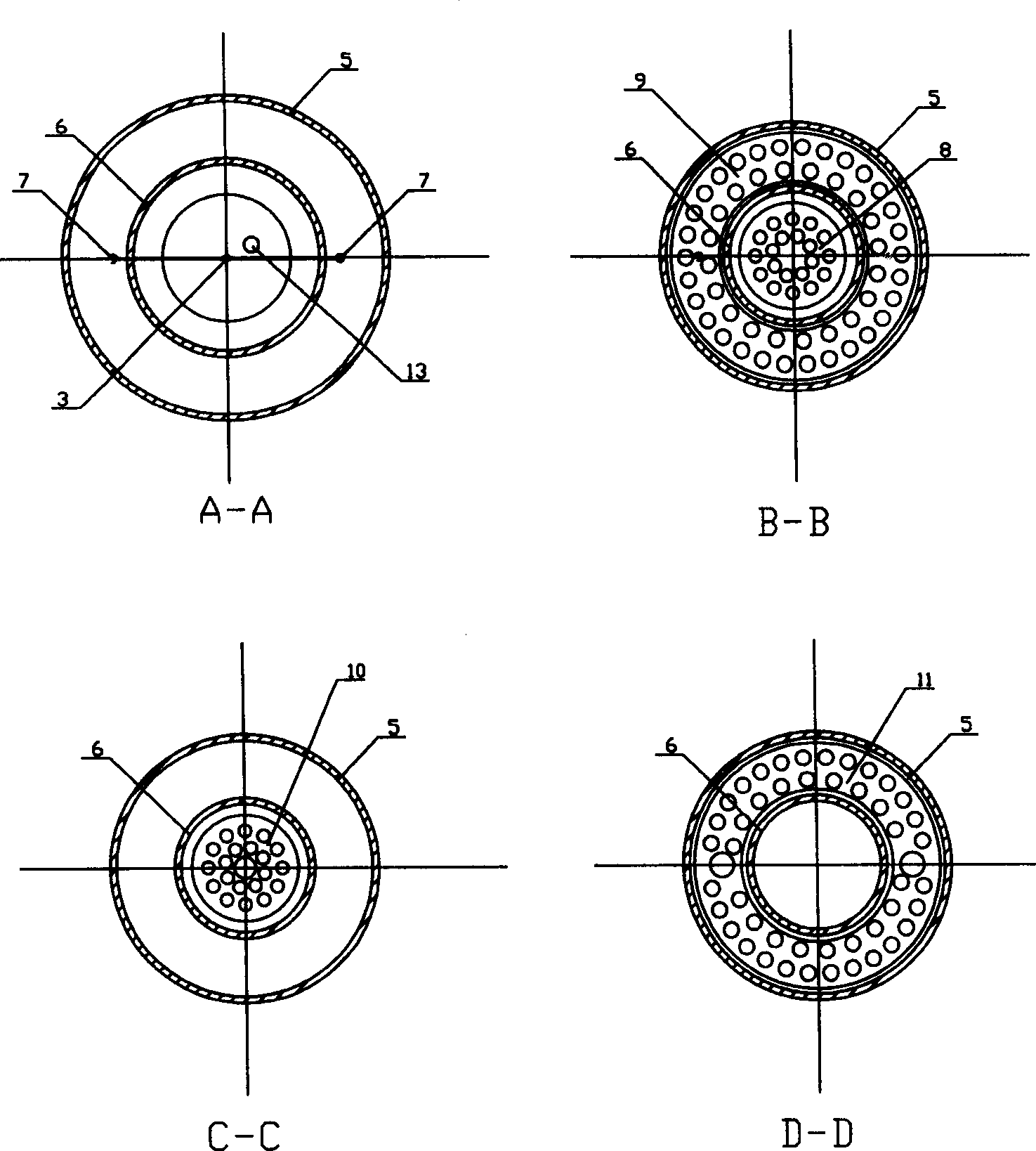

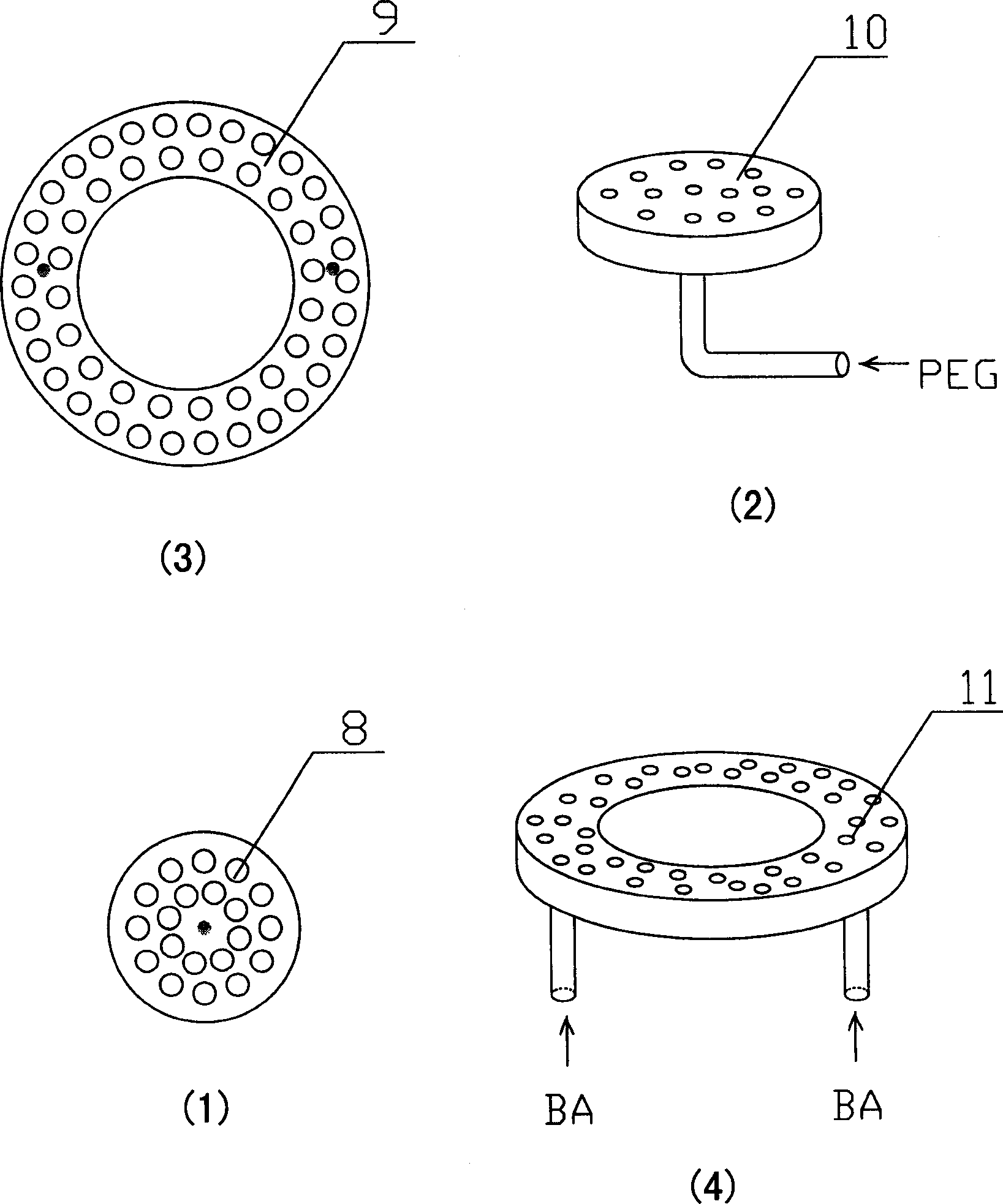

[0029] Please refer to Figure 1 to Figure 3 , the present invention is mainly composed of mechanical transmission part, tower body, sieve plate, liquid phase disperser and auxiliary facilities. in:

[0030] The mechanical transmission part includes:

[0031] The eccentric wheel 1 connected with the motor, one end of the main shaft 3 is connected with the eccentric wheel 1 by the connecting rod 2, and the other end is connected to the inner tower circular sieve plate 8 and a main and secondary shaft connecting rod 13 through the slider 4. , The secondary shaft connecting rod 13 is connected with the secondary shaft 7 connecting the outer tower annular sieve plate 9 . When the motor rotates, the circular sieve plate 8 of the inner tower and the annular sieve plate 9 of the outer tower vibrate accordingly.

[0032] The tower part includes:

[0033] The outer tower body 5 and the concentric inner tower body 6 inside it; the top of the inner tower body is open, so that the mes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com