Method for pressurized ethanol/water extraction of diosgenin

A technology for extracting diosgenin and water, which is applied in the production of steroids, organic chemistry, bulk chemicals, etc., can solve the problems of polluting the environment, large amount of acid, etc., achieve less impurity content, reduce emissions, and avoid acid pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

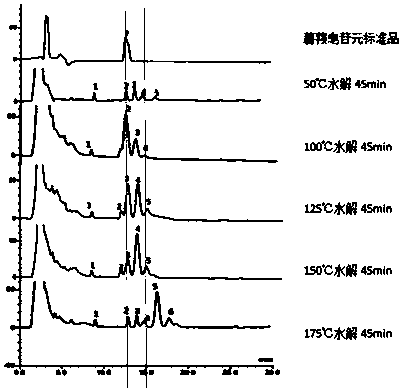

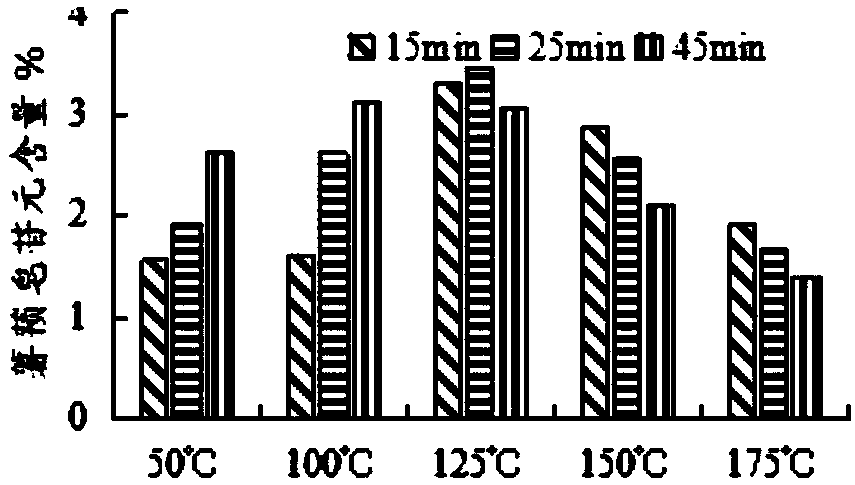

Method used

Image

Examples

Embodiment 1

[0018] A method for extracting diosgenin with pressurized ethanol / water, which is carried out according to the following steps: (1) take dried rhizomes of pangolin or other Dioscoreaceae plants, and grind them through a 24-60 mesh sieve according to a conventional method. (2) According to the solid-liquid ratio of 1: 10 (g / mL) ratio, adding volume ratio is 50% ethanol, then adding acidic ionic liquid, finally making the pH of the solvent in the extraction tank be 2, then at the extraction temperature of 100 ° C, the extraction pressure Extract for 25min under the condition of 0.2MPa. (3) After the extraction, let the extract cool to 50-60°C, filter, put the filtrate on a macroporous resin column, first elute the acidic ionic liquid with water, then gradually increase the ethanol concentration, elute diosgenin, and concentrate the eluent , after drying or crystallization, diosgenin can be obtained.

Embodiment 2

[0020] A method for extracting diosgenin with pressurized ethanol / water, which is carried out according to the following steps: (1) take dried rhizomes of pangolin or other Dioscoreaceae plants, and grind them through a 24-60 mesh sieve according to a conventional method. (2) According to the solid-liquid ratio of 1: 15 (g / mL), it is 60% ethanol to add the volume ratio, then add the acidic ionic liquid, finally make the pH of the solvent in the extraction tank be 3, then at the extraction temperature of 125 ° C, the extraction pressure It is extracted for 45min under the condition of 0.3MPa. (3) After the extraction, let the extract cool to 50-60°C, filter, put the filtrate on a macroporous resin column, first elute the acidic ionic liquid with water, then gradually increase the ethanol concentration, elute diosgenin, and concentrate the eluent , after drying or crystallization, diosgenin can be obtained.

Embodiment 3

[0022] A method for extracting diosgenin with pressurized ethanol / water, which is carried out according to the following steps: (1) take dried rhizomes of pangolin or other Dioscoreaceae plants, and grind them through a 24-60 mesh sieve according to a conventional method. (2) According to the solid-liquid ratio of 1:20 (g / mL), it is 80% ethanol to add the volume ratio, then add the acidic ionic liquid, finally make the pH of the solvent in the extraction tank be 4, then at the extraction temperature of 150 ° C, the extraction pressure Extract for 25min under the condition of 0.5MPa. (3) After the extraction, let the extract cool to 50-60°C, filter, put the filtrate on a macroporous resin column, first elute the acidic ionic liquid with water, then gradually increase the ethanol concentration, elute diosgenin, and concentrate the eluent , after drying or crystallization, diosgenin can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com