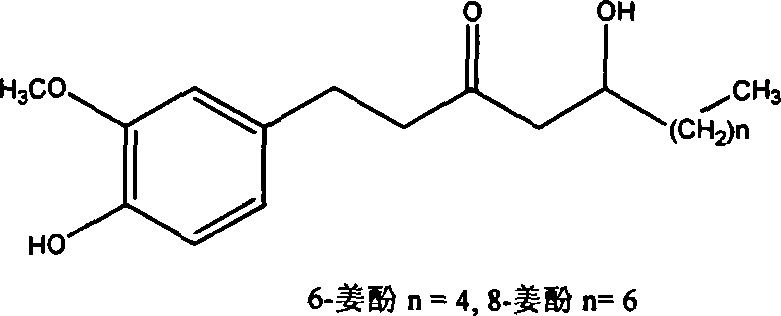

Method for preparing 6-gingerol and 8-gingerol from ginger

A technology of gingerol and ginger, which is applied in the field of natural active product preparation, can solve the problems of less preparation amount, lower yield, and low product yield, and achieve low requirements for instruments and equipment, avoid solvent extraction, and high product yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Wash 5kg of fresh ginger, cut into thin slices, dry below 60°C, pulverize in a grinder, and pass through a 100-mesh sieve. Put the above-mentioned gingerol in a 2L round-bottomed flask, add ethyl acetate according to the ratio of ginger powder:ethyl acetate (1:2-3, V / V), heat and reflux for extraction 3 times, each time for 2 hours, and combine the extraction Liquid, under 40°C, use a rotary evaporator to depressurize and return to the extract, and the pressure is 0.08-0.1Mpa to obtain 250g of extract extract;

[0021] Dissolve the above extract with 400mL ethyl acetate, add 750g 200-300 mesh silica gel for column chromatography to mix the sample, heat in a water bath to evaporate the ethyl acetate, then add 5.0kg blank silica gel (200-300 mesh ) column, first elute with 10 BV petroleum ether (60-90°C), then 8 BV petroleum ether: ethyl acetate (20:1, V / V), and finally use petroleum ether: ethyl acetate (10:1, V / V) elution, TLC detection elution progress (silica gel GF ...

Embodiment 2

[0026] Wash 2kg of fresh ginger, cut into thin slices, and dry below 60°C. Pulverize in a pulverizer, pass through a 100-mesh sieve, and put it into a 1000mL Erlenmeyer flask. According to the ratio of ginger powder: acetone (1:2-3, V / V), add acetone, airtight soak for 24 hours, shake once every 4 hours during soaking; repeat soaking 3 times, combine extracts, below 40°C The solvent was recovered under reduced pressure to obtain 80 g of extract extract.

[0027]Dissolve the above extract with 200mL of ethyl acetate, add 250g of 200-300 mesh silica gel for column chromatography to mix the sample, heat in a water bath to evaporate the ethyl acetate, then add 2kg of blank silica gel (200-300 In the column of the purpose), first use 10 BV petroleum ether (60 ~ 90 ℃) to elute, then use 8 BV petroleum ether: ethyl acetate (20:1, V / V) to elute, and finally use petroleum ether: ethyl acetate Ester (10:1, V / V) was eluted, and the elution progress was detected by TLC. The relatively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com