Method for rapidly determining content of phenol in wastewater through purge and trap-gas chromatography-mass spectrometry

A purge-and-trap and gas-mass spectrometry technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of complex pretreatment process, cumbersome steps, and large consumption of organic solvents, so as to avoid sample purity and anhydrous state , improve detection efficiency, and simplify the experimental process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

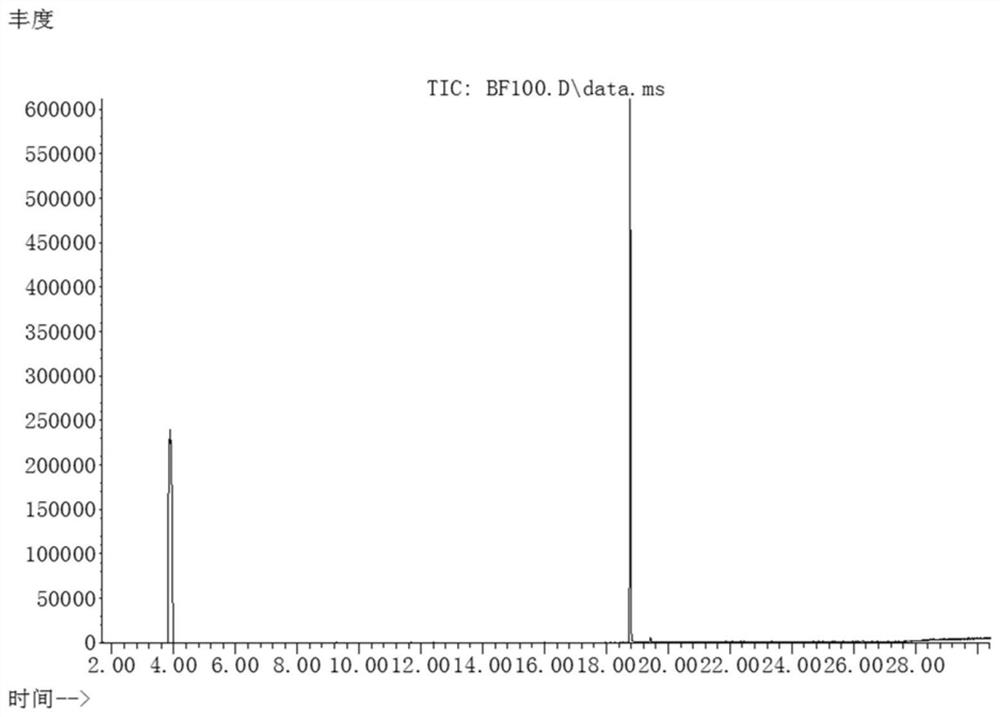

[0040] The specific determination steps of the phenol content in the wastewater discharged from the production of a chemical plant are as follows:

[0041] 1. Collect water samples in a brown glass bottle, add 0.08mol / L phosphoric acid after collection, adjust the pH to 5, take 10mL water sample into the sample bottle, add a magnetic stirrer and seal the cap. Place the vial in the purge and trap injector.

[0042] 2. Set the analysis conditions of purge and trap as follows: transfer line temperature 140°C, purge flow rate 40mL / min, purge time 11min, purge temperature 20°C, sample volume 10ml, sample bottle temperature 40°C, dry purge time 2min , Dry purge flow rate 100mL / min, dry purge temperature 20°C.

[0043]3. The collected and extracted phenol was analyzed by gas chromatography-mass spectrometry. The gas chromatography conditions were: chromatographic column 60m×250μm×1.4μm, constant flow mode with a flow rate of 1mL / min, and an inlet temperature of 270°C. In the split ...

Embodiment 2

[0049] The specific determination steps of phenol content in the effluent water of an aerobic pool in a pharmaceutical factory are as follows:

[0050] 1. Collect water samples in a brown glass bottle, add 0.12mol / L phosphoric acid after collection, adjust the pH to 6, take 15mL water samples into the sample bottle, add a magnet and seal the cap. Place the vial in the purge and trap injector.

[0051] 2. Set the analysis conditions of purge and trap as follows: transfer line temperature 140°C, purge flow rate 40mL / min, purge time 11min, purge temperature 20°C, sample volume 10mL, sample bottle temperature 40°C, dry purge time 2min , the dry purge flow rate is 100ml / min, and the dry purge temperature is 20°C.

[0052] 3. The collected and extracted phenol was analyzed by gas chromatography-mass spectrometry. The gas chromatography conditions were: chromatographic column 60m×250μm×1.4μm, constant flow mode with a flow rate of 1mL / min, and an inlet temperature of 270°C. In the ...

Embodiment 3

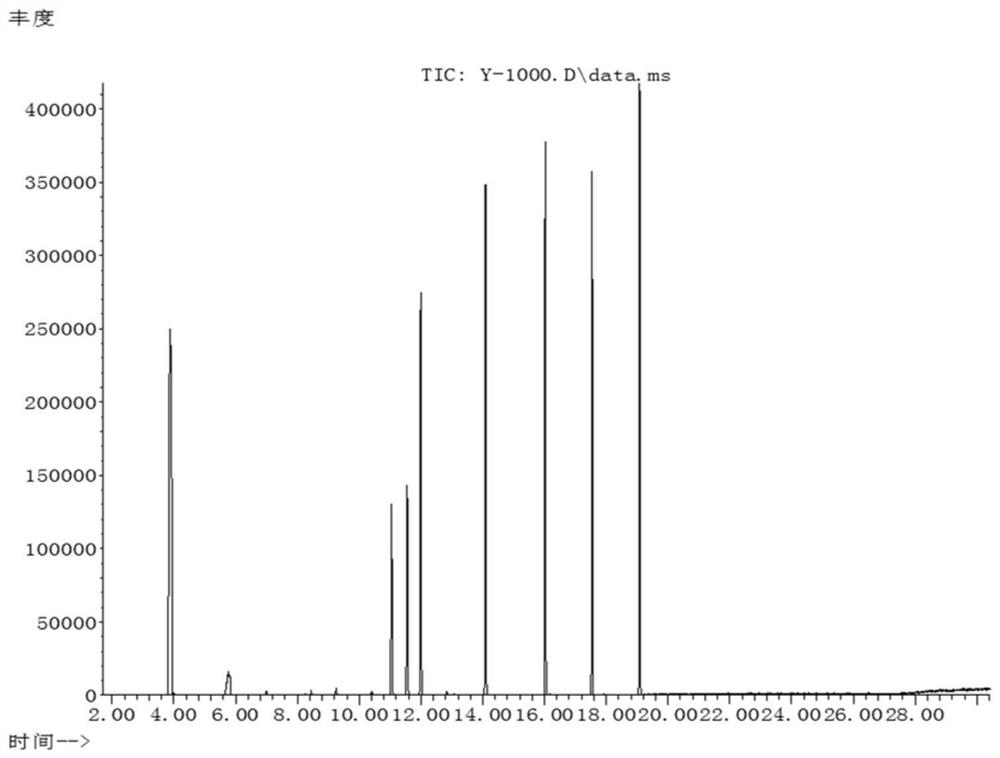

[0062] The specific determination steps of phenol content in the water quality of the sewage treatment plant inlet are as follows:

[0063] 1. Collect water samples in a brown glass bottle, add 0.1mol / L phosphoric acid after collection, adjust the pH to 5, take 15mL water sample into the sample bottle, add a magnet and seal the cap. Place the vial in the purge and trap injector.

[0064] 2. The analysis conditions for setting the purge and trap device are: transfer line temperature 130°C, purge flow rate 40mL / min, purge time 11min, purge temperature 20°C, sample volume 10mL, sample bottle temperature 50°C, drying purge time 2min, dry purge flow rate 100mL / min, dry purge temperature 20°C.

[0065] 3. The collected and extracted phenol was analyzed by gas chromatography-mass spectrometry. The gas chromatography conditions were: chromatographic column 60m×250μm×1.4μm, constant flow mode with a flow rate of 1mL / min, and an inlet temperature of 270°C. In the split injection mode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com