Method for catalytic oxidation degradation of wood chips by novel polyoxometallate

A polyoxometalate, catalytic oxidation technology, applied in chemical instruments and methods, catalyst activation/preparation, preparation of organic compounds, etc., can solve the problems of low reaction selectivity and difficult catalyst separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

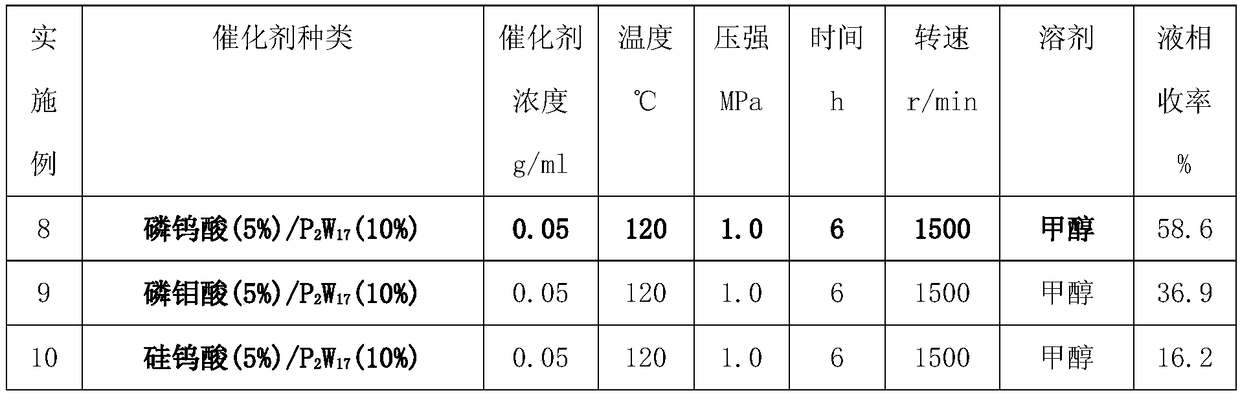

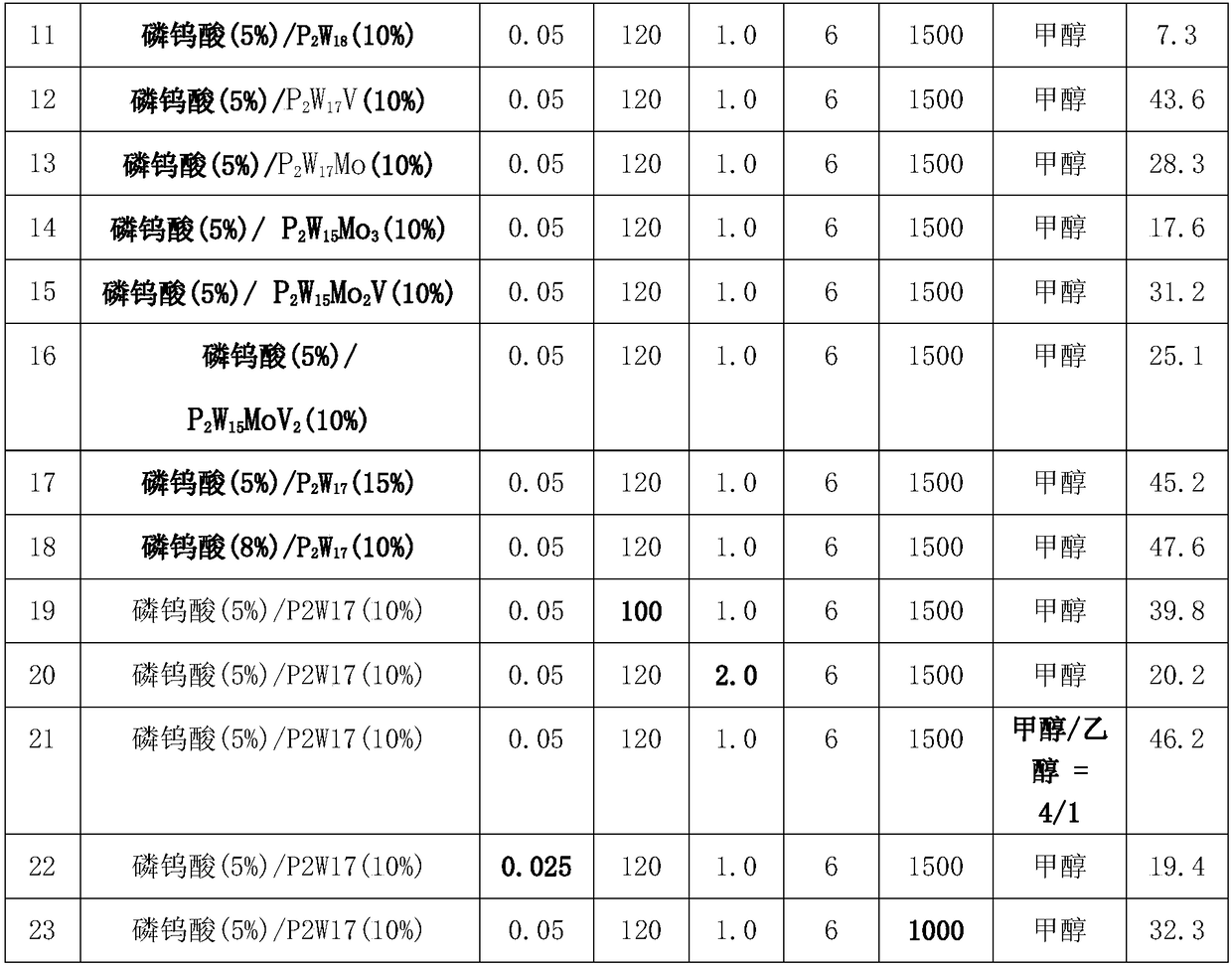

Examples

Embodiment 1

[0028] Preparation of Keggin-type polyoxometalates: Taking silicotungstic acid as an example, dissolve 198g of sodium tungstate in 250ml of water at 50°C, add 240ml of 3M HCl, and add 100ml of an aqueous solution containing 11g of sodium silicate under vigorous stirring. Adjust the pH to 1 with HCl, concentrate the solution down to 400ml at 80°C, then adjust the solution to pH 2 with KOH, add a large amount of KCl, filter, dry the filter cake, and recrystallize to obtain the silicotungstic acid catalyst. Phosphomolybdic acid, silicomolybdic acid, and phosphotungstic acid are obtained by the same method.

Embodiment 2

[0030] Dawson-type polyoxometalates P 2 W 18 Preparation: mix 62.5g sodium tungstate with 52.5ml phosphoric acid, reflux for 1 hour, gradually add hydrogen peroxide dropwise to the mixed solution, react for 0.5h, cool to room temperature, add 25g NH 4 Cl, filter, dissolve the filter cake in 150ml water, add 25g KCl, let stand overnight, filter with Buchner funnel and wash with water three times, the solid is recrystallized under water at 65°C to obtain Dawson type polyoxometalate P2W18.

Embodiment 3

[0032] Notched Dawson-type polyoxometalates P 2 W 17 Preparation of: 40g P 2 W 18 Dissolve in water, add dropwise to the solution containing 10g KHCO 3After stirring vigorously at room temperature for 2 hours, filter, and the filter cake was recrystallized twice in hot water to obtain an angled Dawson type heteropolyacid P 2 W 17 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com