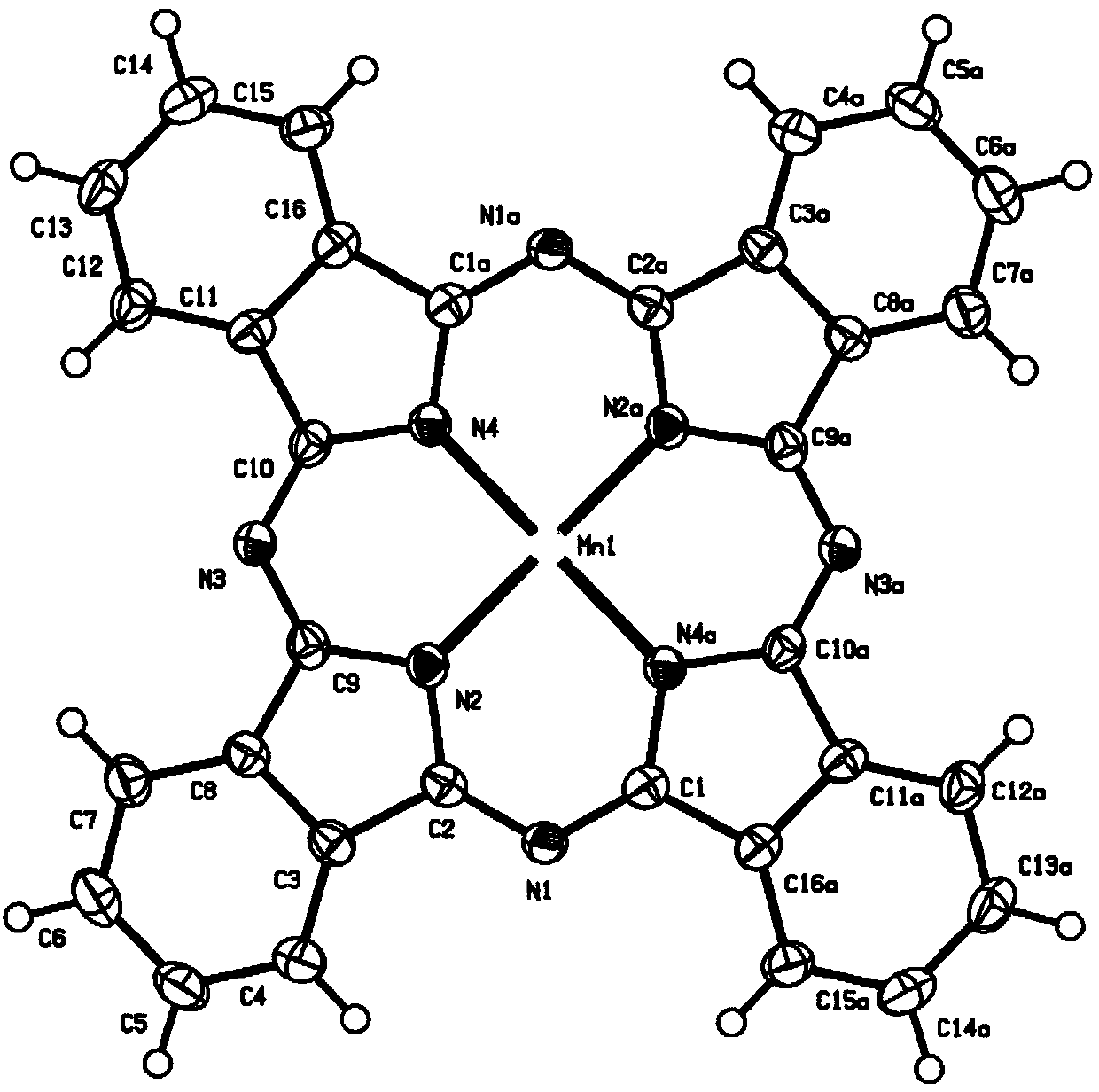

Method for one-step preparation of manganese phthalocyanine crystal through solvothermal reaction

A solvothermal reaction and manganese phthalocyanine technology is applied in the field of preparation of metal phthalocyanine crystals, which can solve the problems of complex operations such as synthesis and purification of manganese phthalocyanine, high viscosity, etc., and achieves easy control of the reaction process, low energy consumption and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

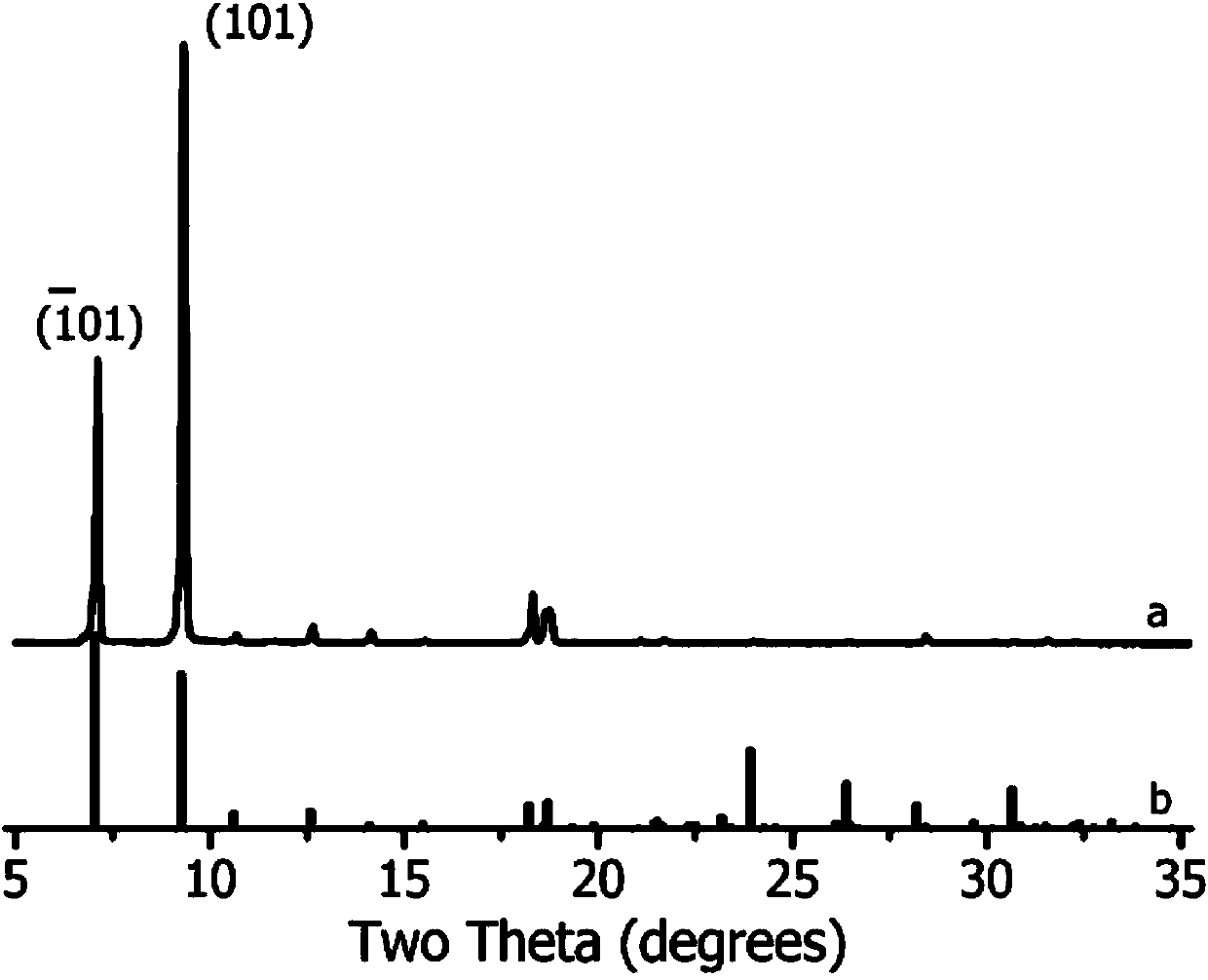

[0030] Add 6 millimoles of phthalonitrile (769 mg), 1.5 millimoles of manganese acetate tetrahydrate (368 mg) into a 50 milliliter polytetrafluoroethylene material reactor liner, add 37.5 milliliters of absolute ethanol (The filling degree of the system is 75%). After stirring the reactants evenly with a glass rod, put the reaction kettle into a stainless steel jacket and close it tightly. The reaction kettle was placed in an oven at 190° C., and a solvothermal reaction was carried out at this temperature for a reaction time of 1 hour. After the reaction was completed, the heating was stopped, and the reaction was naturally cooled to room temperature. Use a small key to carefully take the black needle-shaped manganese phthalocyanine crystals out of the reactor, use hot water and hot ethanol to repeatedly rinse the remaining reactants adsorbed on the surface of the manganese phthalocyanine crystals, and vacuum dry at 100°C for 4 hours to obtain manganese phthalocyanine crystals ...

Embodiment 2

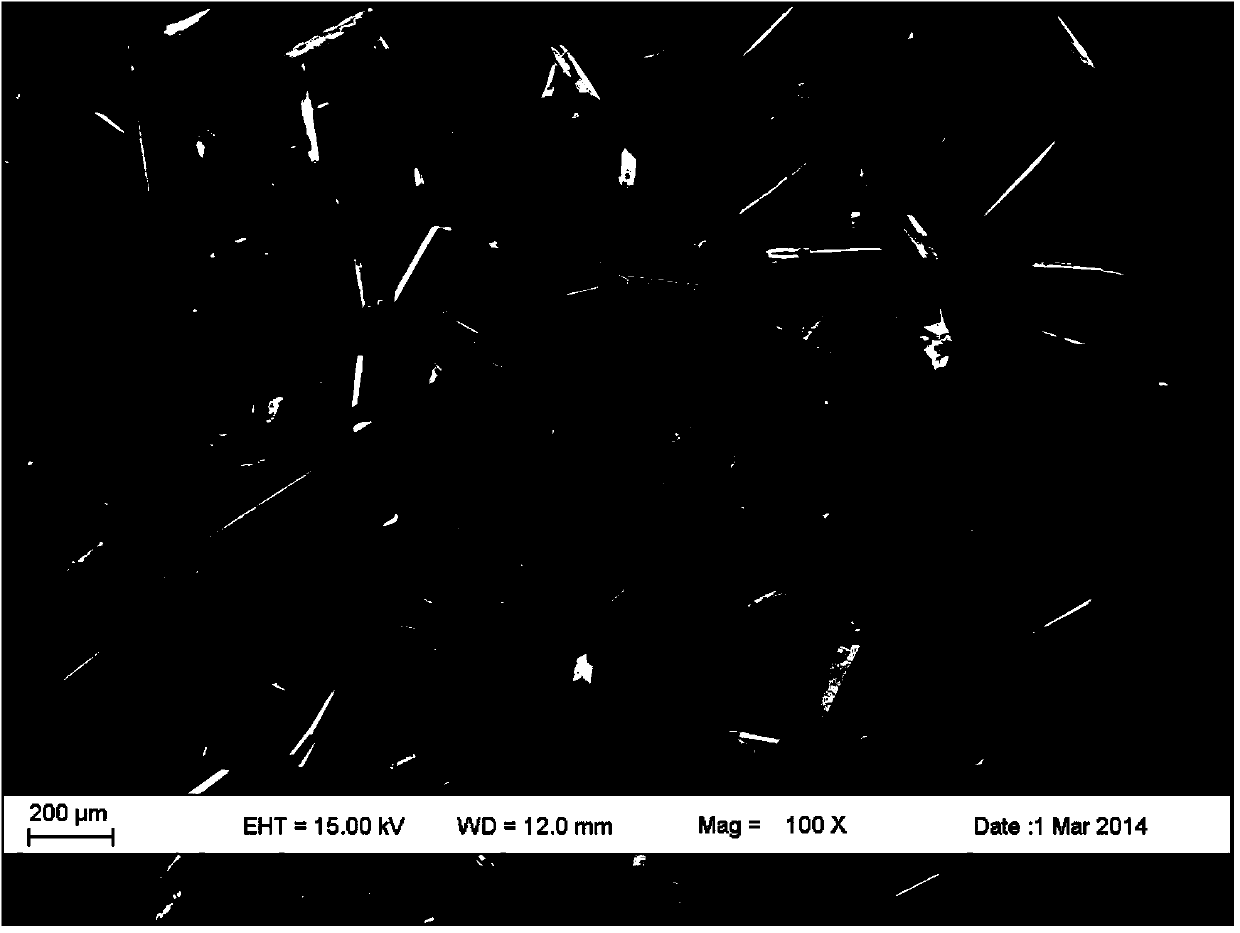

[0032] The preparation process and purification method are the same as in Example 1, only the solvothermal reaction time is 3 hours. SEM such as Image 6 shown by Image 6 It can be seen that the length of manganese phthalocyanine crystals has reached the order of millimeters.

Embodiment 3

[0034] The preparation process and purification method are the same as in Example 1, only the solvothermal reaction time is 6 hours. SEM such as Figure 7 shown by Figure 7 It can be seen that the manganese phthalocyanine quadrangular prism crystal is smooth and even.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com