Extractive organic phase and application thereof

An organic phase and extraction technology, applied in the direction of improving process efficiency, etc., can solve the problems of low selectivity and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

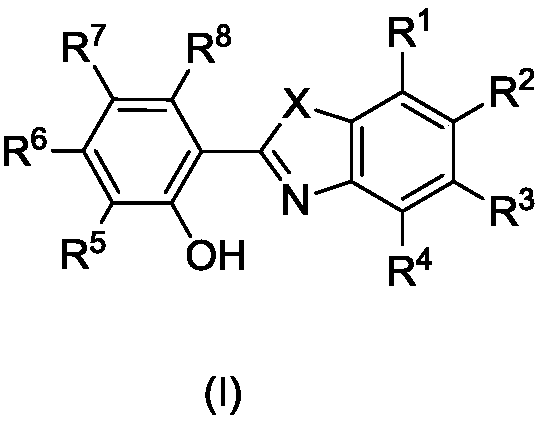

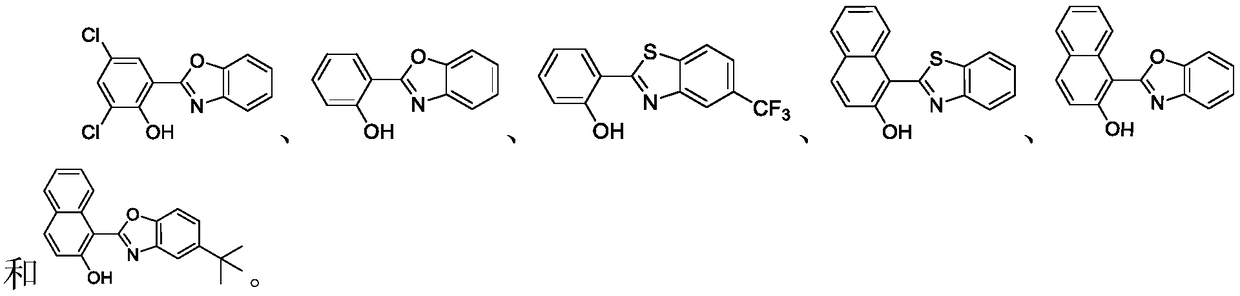

Method used

Image

Examples

Embodiment 1

[0070] Preparation of extraction organic phase, compound: The concentration is 0.11mol / L; modifier: trioctylmethylammonium chloride, the concentration is 0.11mol / L; diluent: chloroform. In the lithium-containing aqueous phase, the concentration of lithium ions is 0.05 mol / L, and the concentration of chloride ions is 0.05 mol / L.

[0071] Extraction method: Add a certain amount of NaOH to the lithium-containing aqueous phase to adjust the pH value to 12-13. The organic phase of the extractant is compared with the aqueous phase at a ratio of 1:1, and fully exposed to single-stage extraction. After static phase separation, 2mol / L hydrochloric acid was used as the stripping solution, and the organic phase system was recycled after stripping to obtain the stripped lithium product. The lithium ion concentration in the extracted organic phase was measured to be 0.042mol / L, and the single-stage extraction rate of lithium was 84%.

Embodiment 2

[0073] Preparation of extraction organic phase, compound: The concentration is 0.50mol / L; modifier: trioctyl ammonium methyl sulfate, the concentration is 0.30mol / L; diluent: 2-octanone. In the lithium-containing aqueous phase, the concentration of lithium ions is 0.20 mol / L, and the concentration of sulfate ions is 0.10 mol / L.

[0074] Extraction method: Add a certain amount of NaOH to the lithium-containing aqueous phase to adjust the pH value to 13-14, and the organic phase of the extractant is compared with the aqueous phase at a ratio of 1:1, fully exposed to single-stage extraction. After static phase separation, 2mol / L hydrochloric acid was used as the stripping solution, and the organic phase system was recycled after stripping to obtain the stripped lithium product. The lithium ion concentration in the extracted organic phase was measured to be 0.17mol / L, and the single-stage extraction rate of lithium was 85%.

Embodiment 3

[0076] Preparation of extraction organic phase, compound: The concentration is 0.60mol / L; modifier: butyl phosphonate dibutyl ester, the concentration is 0.60mol / L; diluent: sulfonated kerosene. In the lithium-containing aqueous phase, the concentration of lithium ions is 0.15 mol / L, the concentration of sulfate ions is 0.05 mol / L, and the concentration of hydroxide ions is 0.05 mol / L.

[0077] Extraction method: Add a certain amount of NaOH to the lithium-containing aqueous phase to adjust the pH value to 14. The organic phase of the extractant is compared with the aqueous phase at a ratio of 1:1, and fully exposed to single-stage extraction. After standing still for phase separation, 2mol / L sulfuric acid was used as the stripping solution, and the organic phase system was recovered and recycled after stripping to obtain the stripped lithium product. The lithium ion concentration in the organic phase of the extractant was measured to be 0.096mol / L, and the single-stage extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com