[0008] The

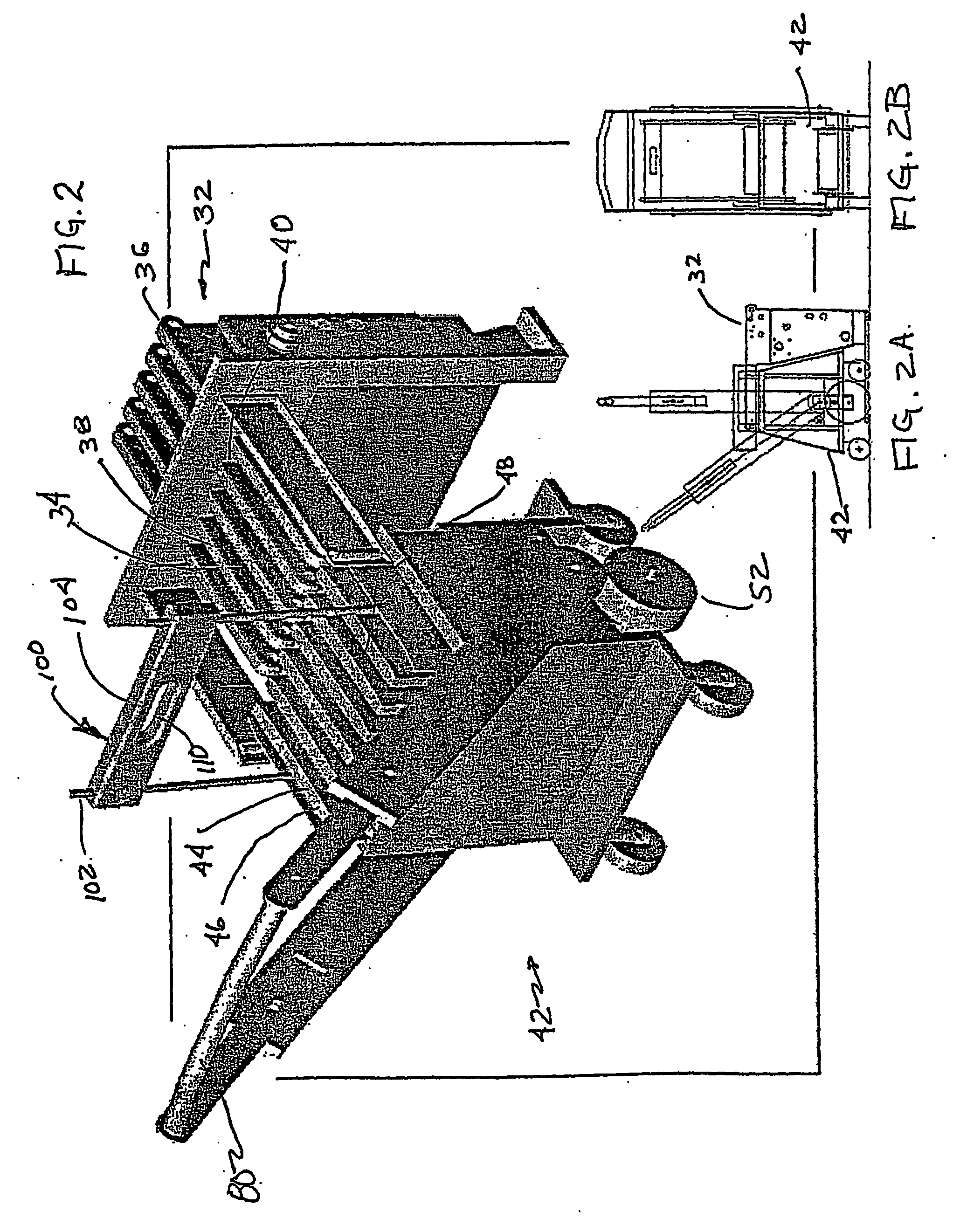

transfer station includes a platform comprising a series of driven surfaces in the form of, for example, driven rollers or flat rotary belts, which are spaced to engage with a number of different structures. The transfer station may be a separate station or the transfer station components may be incorporated into a modular processing station. For ease of understanding, this application will refer to belts. It will be appreciated, however, that alternate designs, such as those utilizing a plurality of in-line driven rollers, are likewise form appropriate driven plurality of elongated support surfaces, and are to be considered to fall within the purview of the term “belt” as utilized herein. The spaced belts can intermesh with the slotted surface of a

stacker, feeder, or other

elevator mechanism such that the stack processing module can deposit or remove sheet stacks from the transfer station. Additionally, the spaced belts of the transfer station platform may intermesh with the slotted

deck of the

cart, such that the sheet stacks can be moved from one transfer station to another using the cart, without connecting the two transfer stations physically. Finally, the spaced flat belts of the transfer station platform can intermesh with the spaced flat belts of another transfer station or an intermediate station. Under these circumstances, the belts of the second transfer station are spaced at one-half

pitch off that of its mate. In this way, transfer stations can be connected to form a conveyor between processing modules to transfer sheets or stacks of sheets, eliminating the need for manual intervention to move sheets or sheet stacks between processing modules during processing. The transfer station may be provided with an

elevator mechanism that moves a stack of sheets supported thereon in a vertical elevation to provide the stack for further transfer or for further processing operation. It is further envisioned that preexisting processing stations may be retrofit with such transfer or elevator transfer stations to allow their integration into the

document handling system.

[0009] The moveable cart would likewise have a slotted

deck that could intermesh between the individual belts of the transfer station to form a joint sheet

support surface. Preferably, the cart may be manually, electrically, hydraulically, or otherwise powered, and includes a mechanism whereby the cart

deck can be raised or lowered by

cam, lever, electrical power, hydraulics or other mechanism such that the cart may deposit a stack of sheets on the transfer station platform or raise a stack of sheets from the transfer station platform to remove the stack from the transfer station. Preferably, the cart includes a quick clamp release system to secure the sheet stack for transport. Additionally, the cart is preferably symmetrical such that a stack may be picked up or deposited from either side of the cart to readily provide phasing of the edges of the stack. The transfer station or elevator transfer station, as well as the processing modules themselves may provide for alternate movement of the support surfaces into or out of the sheet

handling system to facilitate access by the cart. For example, the

support surface or deck may move in a substantially

perpendicular direction from the system to allow intermediate access to a stack of sheets. In this way, the cart may readily be utilized to access and remove a stack from the deck. The deck may then be retracted back into the system.

[0010] Finally, the storage station includes a slotted stationary platform where the slots are spaced to receive and intermesh with the slotted deck of the cart. In this way, the cart may be used to deposit the sheet stack on the storage station when the stack is not transferred directly to the elevator transfer station. The storage station may include upright stacking guides which may be adjustable or permanently spaced or installed. The stacking guide may also be removable for storage and to provide a tidy appearance. As with the elevator transfer station, the cart may be used to place a sheet stack on the storage station and the cart then lowered, leaving the stack on the storage station. Similarly, an empty cart may be intermeshed with the slotted platform of the storage station and the cart slotted deck raised to lift the sheet stack from the storage station for removal to an elevator transfer station.

[0012] The aforementioned document

transport system facilitates an improved and novel

document processing system. In particular, a modular transfer station mates with both processing module elevators and other transfer stations to allow a new version of “in-line” processing in which sheet stacks or individual sheets are passed automatically between processing modules with a relatively large buffer. The buffer allows large and numerous stacks to be placed between the modules allowing for considerable pauses in one module without a concurrent pause in the other modules in the inline process, and allows considerable mismatches in processing speeds between machines without forcing human intervention or modification of the modules to synchronize their processing speeds. Further, this movement between modules during in-line processing can take place without intervention by an operator and the incumbent risk of error.

[0013] Additionally, the cart that mates with the transfer station can be docked in one of two directions with the transfer station, allowing the operator to choose to reverse the processing orientation of the stack desired. The cart also includes a quick clamping system which allows the stack to be quickly secured without extended operator involvement.

Login to View More

Login to View More