Liquid-liquid-liquid triphase horizontal continuous lifting stirring extraction device

A technology of extraction device and liquid phase, which is applied in the field of liquid-liquid-liquid three-phase horizontal continuous lifting stirring extraction device, can solve the problems of low mass transfer efficiency and extraction efficiency, and achieves improved space utilization, reduced volume, Reduce the effect of backmixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

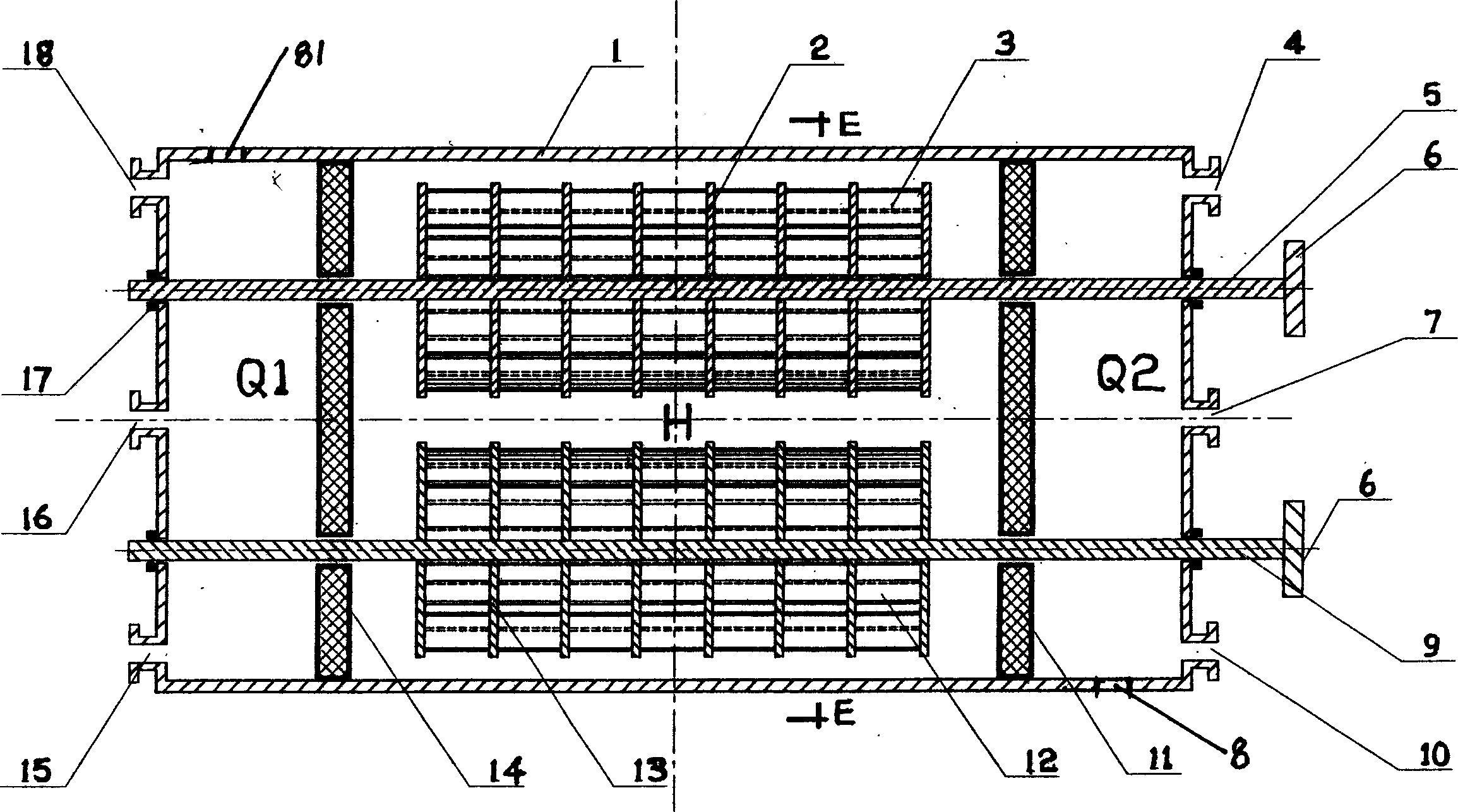

[0037] As can be seen from the figure, the liquid-liquid-liquid three-phase horizontal continuous lifting and stirring extraction device provided by the present invention is characterized in that the device includes:

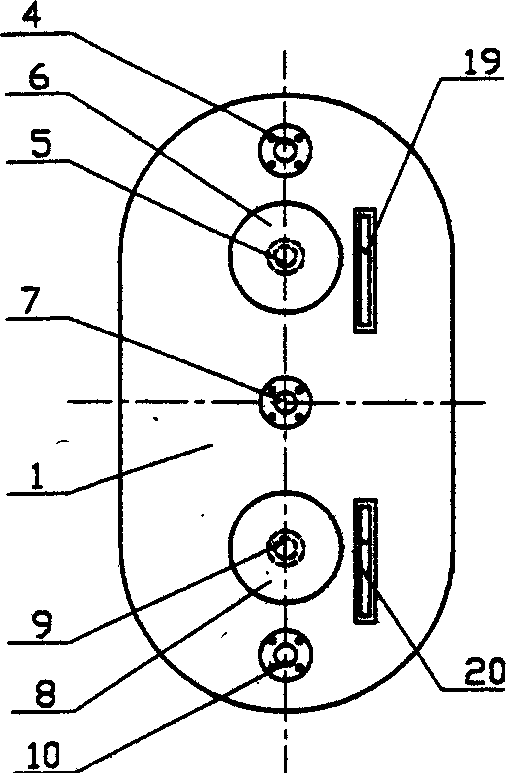

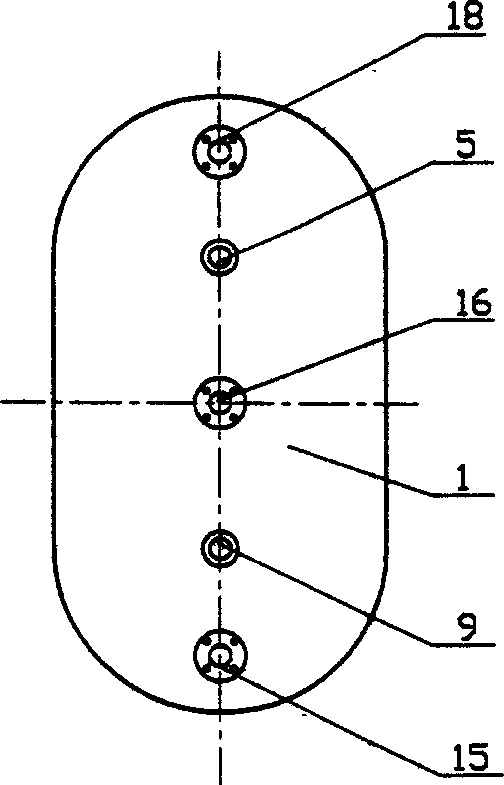

[0038] A horizontal reactor 1, the longitudinal section of the horizontal reactor 1 is a semicircle in the upper and lower parts, and the middle part is a straight line racetrack cross-section; the top of the horizontal reactor 1 is provided with an exhaust hole 81, A drain hole 8 is provided at the bottom; a vertical hollow isolation panel box 14 is respectively installed at both ends of the horizontal reactor 1, and the vertical porous isolation panel box 14 is in contact with the inner wall of the horizontal reactor 1. Packing 11 is housed in the crate 14, and a through hole is provided on the crate wall; an upper shaft 5 and a lower shaft 9 are installed in parallel across the end walls on both sides of the horizontal reactor 1 and the two vertical hollow iso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com