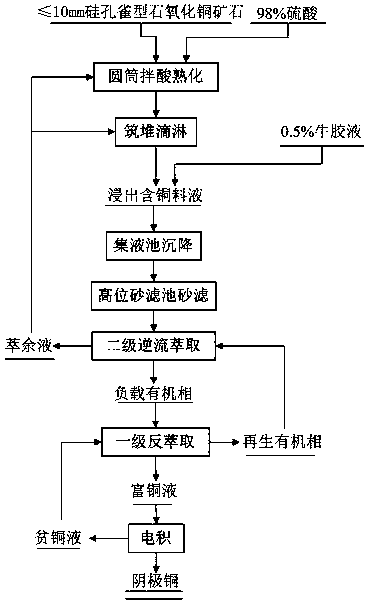

Method for extracting copper from chrysocolla type copper oxide ores through wet process

A technology for sillimanite and copper oxide ore, which is applied in the direction of improving process efficiency, can solve the problems of chaotic extraction production, difficult phase separation of extraction and stripping, and high production cost, and achieves the effect of shortening leaching time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] (1) Ore sampling and acid slaking

[0031] The chrysocolla-type copper oxide ore is crushed to a particle size of ≤10mm, and one analysis sample is taken per 100t of ore before acid mixing, and the average analysis result of 50 samples is: Cu3.41%, acid-soluble SiO 2 1.32%, continuously add 98% sulfuric acid at the feed end of the mixing cylinder lined with anti-corrosion rubber pads, and continuously add raffinate at the rear end of the mixing cylinder, control the amount of sulfuric acid added to 3t / t.Cu, and control the raffinate The amount of liquid added is 6-10% of the moisture content of the ore.

[0032] (2) Heap drip leaching out of copper

[0033] The ore after acid mixing is transported to the heap leaching site, and the heap height is 2m, the heap height is 2m, the heap volume is 10,000t, and the aging time is 15 days. h 2 SO 4 3-5g / L, the amount of dripping is controlled according to the acid content of the leaching material; after 50-60 days of leachin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com