A method for regenerating waste lithium nickel cobalt manganate ternary cathode material

A technology of nickel-cobalt-lithium-manganese-manganese oxide and positive electrode materials, which is applied in chemical instruments and methods, solid waste removal, electrical components, etc., and can solve problems such as failure to realize closed-loop circulation of metal components, complex recycling process, and serious secondary pollution , to achieve the effect of promoting leaching efficiency, simple operation and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

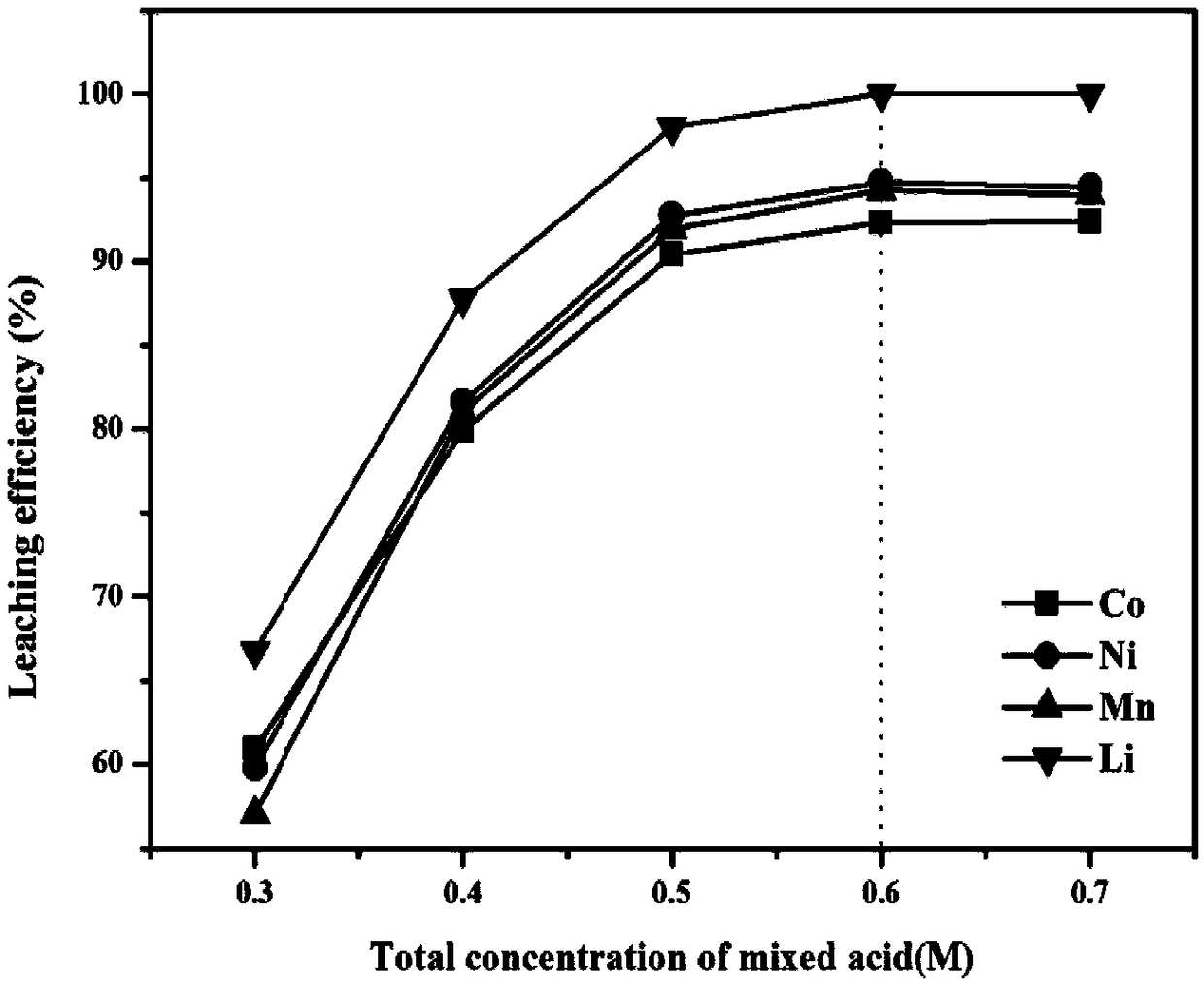

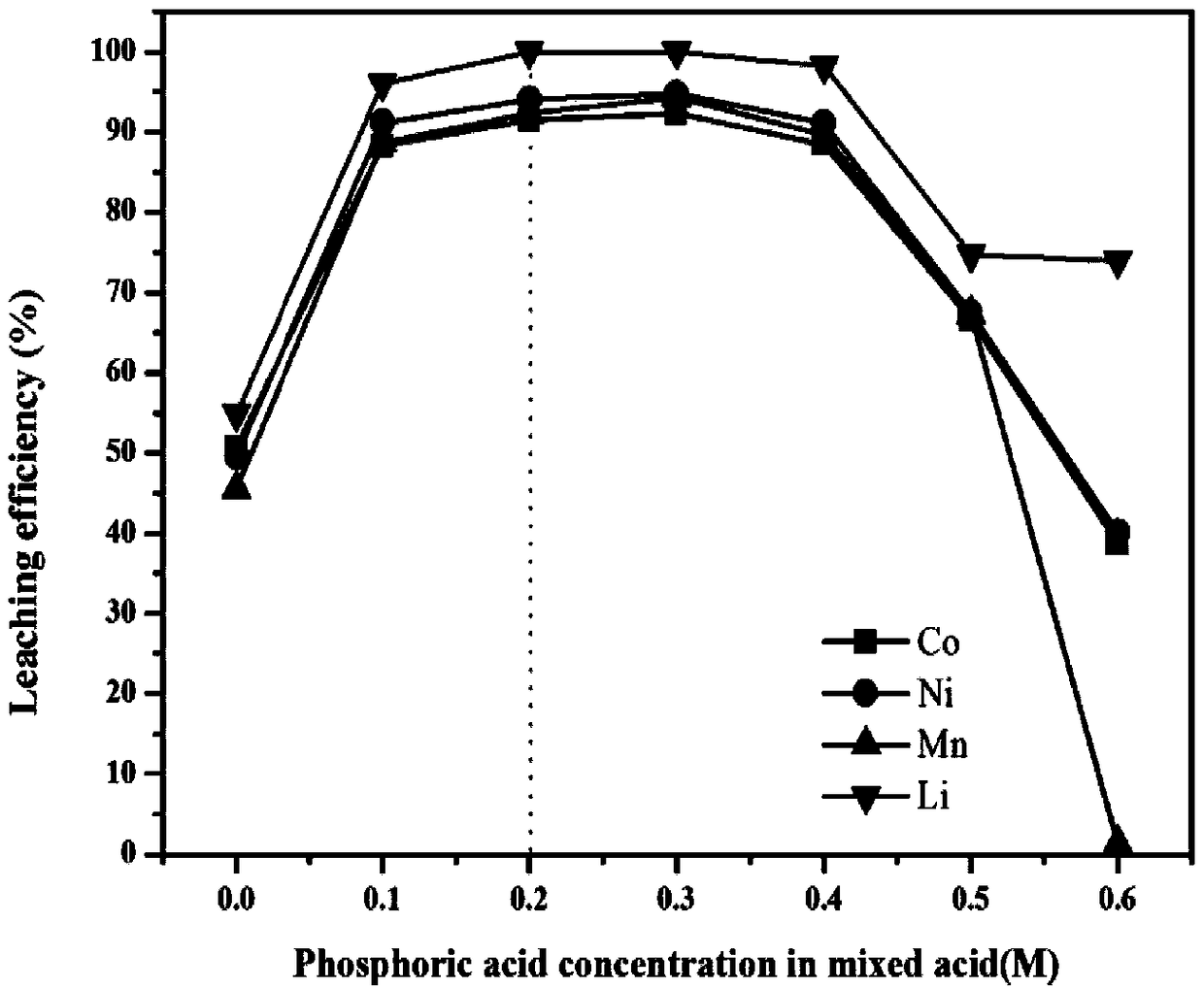

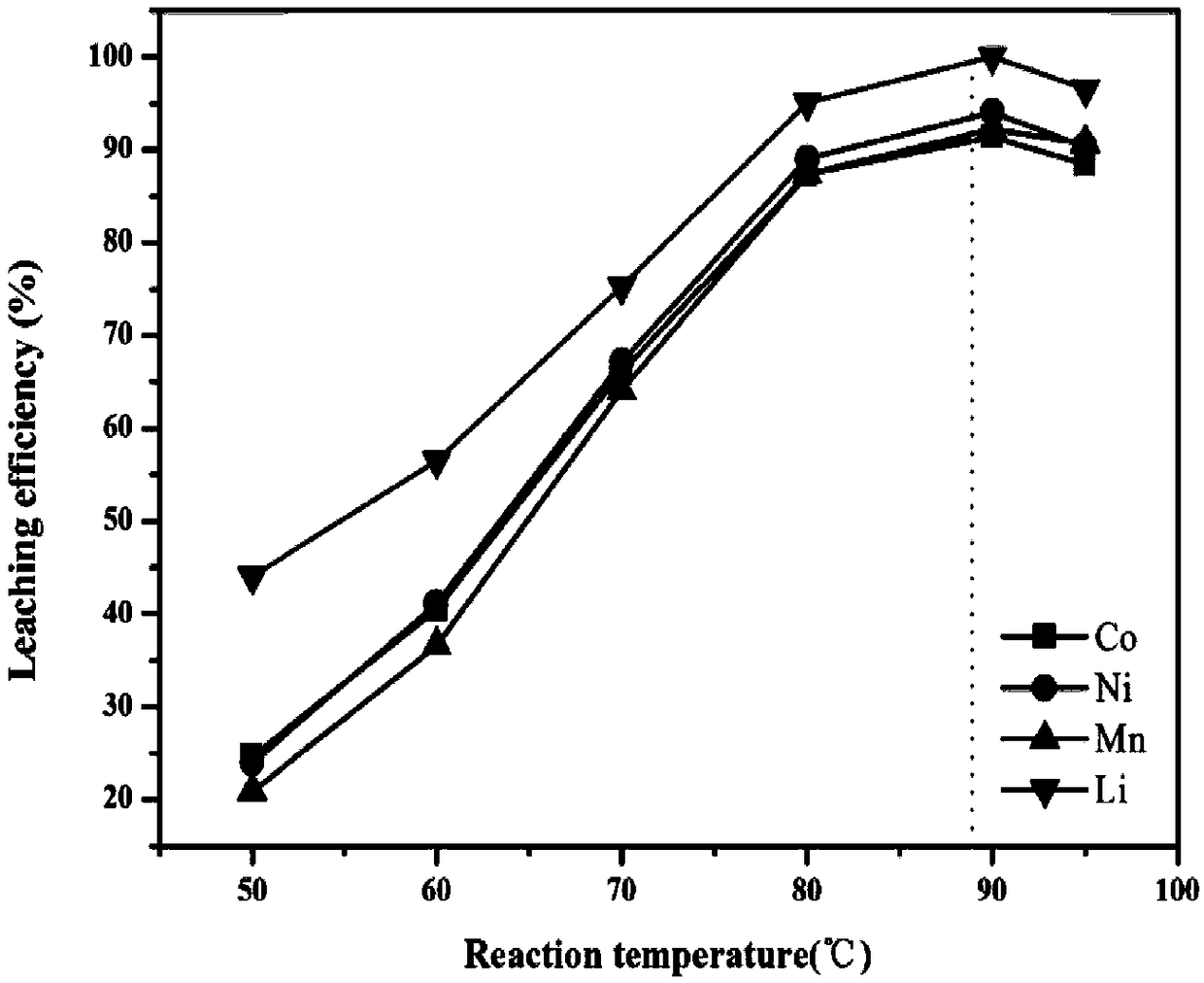

[0068] (1) Prepare a mixed acid solution in which the total concentration of mixed acids is 0.6M, wherein the concentration of phosphoric acid is 0.2M, and the concentration of citric acid is 0.4M. Take 100ml and put it into a 250ml flask, and adjust the speed to 500r / min. When the solution is heated to 90°C, add 2g LiNi 0.5 co 0.2 mn 0.3 o 2 Ternary cathode waste, stirred and reacted for 30min, then suction filtered to obtain + 、Ni 2+ 、Co 2+ , Mn 2+ The solution.

[0069] (2) Take 50ml (1) step gained solution, add (CH 3 COO) 2 Ni·4H 2 O,(CH 3 COO) 2 Co 4H 2 O and (CH 3 COO) 2 Mn 4H 2 O, regulate Ni 2+ ,Co 2+ and Mn 2+ The molar ratio of ions is 5:2:3, and the total metal ion concentration of the solution is 0.4M. At a stirring speed of 600rpm, the nickel-cobalt-manganese mixed solution was added dropwise into an appropriate amount of H by adopting a forward feeding method. 2 C 2 o 4 In the solution, the dropping rate was 9mL / min. During the reaction, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com