Aqueous two-phase extraction system of mixed surfactant

A surfactant and two-phase technology, applied in the field of separation, can solve the problems of difficult formation of two-phase and limited effect, and achieve the effect of low cost, easy control and wide phase range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

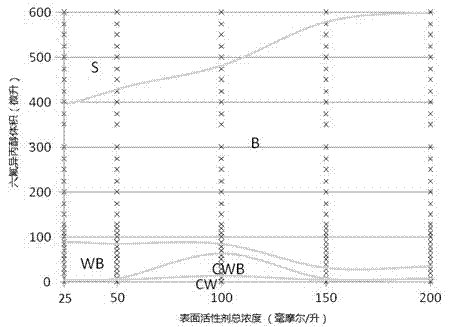

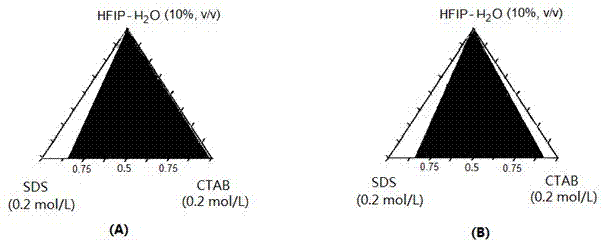

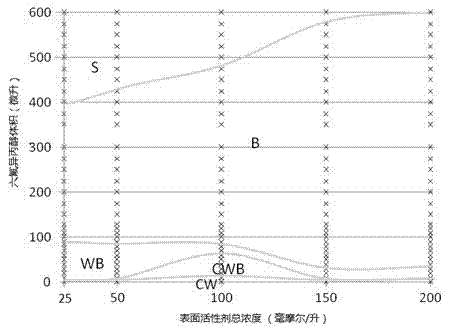

[0032] Take sodium dodecyl sulfate solution with a concentration of 100 mmol / L and mix equimolarly with cetyltrimethylammonium bromide solution at room temperature (2.5 mL SDS, 2.5 mL CTAB), add 10% of the total volume of the mixed system (v / v) hexafluoroisopropanol (0.5 mL), mix well, centrifuge at 2000 rpm and stand at room temperature to obtain a two-phase system with clear interface and two phases. The material composition of the two phases is detected, and the percentage of the material is shown in Table 1. The upper layer has a small viscosity and a large water content, and the lower layer has a large viscosity and a large content of surfactant and hexafluoroisopropanol.

[0033] Table 1 Substance composition and content of HFIP-induced SDS / CTAB (1:1, mol / mol) aqueous two-phase system

[0034]

Embodiment 2

[0036]Take sodium dodecyl sulfate solution with a concentration of 200 mmol / L at room temperature and mix with cetyl trimethyl ammonium bromide solution in a molar ratio of 86:14, and add 10% of the total volume of the mixed system (v / v) hexafluoroisopropanol, mixed well, centrifuged at 2000 rpm and allowed to stand at room temperature to obtain a two-phase aqueous system with a clear interface and both phases.

Embodiment 3

[0038] Take sodium dodecyl sulfate solution with a concentration of 200 mmol / L at room temperature and mix with cetyl trimethyl ammonium bromide solution in a molar ratio of 85:15, and add 10% of the total volume of the mixed system (v / v) hexafluoroisopropanol, mixed well, centrifuged at 2000 rpm and allowed to stand at room temperature to obtain a two-phase aqueous system with a clear interface and both phases.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com