Patents

Literature

1291 results about "Alkyl sodium sulfates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium alkyl sulfate is the singular of a group of generic salts called sodium alkyl sulfates, which is a mixture of different alkyls as the term implies, e.g. sodium lauryl sulfate. They are pale yellow solids/ powders or thick liquids, which smell of detergent.

Completely fused paper soap and its making process

InactiveCN1357613AImprove solubilityImprove decontamination abilityDetergent materialsPhenolFatty alcohol

The component of the paper soap include carboxymethyl cellulose sodium, fatty alcohol polyioxymethyl ethyleneethere sodium sulfate, sodium dodecyl benzene sulfonate, lauryl sodium sulfate, cocinin diethanolamide, nonly phenol polyoxyethyleneether, glycerine, quaternary ammonium salt and citric acid. Its preparation includes preparing carboxymethyl cellulose sodium mother liquor, adding the mixed solution of other components to prepare solution through stirring, spraying the prepared solution of PVC plate and drying in a sealed room and moisture extract at 35-40 deg.c to form film.

Owner:成都洁利康实业发展有限公司

Expendable pattern casting (EPC) molding shell paint for casting steel and preparation method thereof

InactiveCN102407275AHigh strengthImprove breathabilityFoundry mouldsFoundry coresFiberPolyvinyl alcohol

The invention relates to an expendable pattern casting (EPC) molding shell paint for casting steel, and the EPC molding shell paint comprises surface a layer fireproof paint and a back layer reinforcing paint, wherein the surface layer fireproof paint comprises the following components in parts by weight: 80-90 parts of high-chromium alundum powder, 10-20 parts of calcined kaolinite, 6-8 parts ofcalcium rectorite powder, 1-3 parts of sodium tripolyphosphate, 3-5 parts of polyvinyl formal solution, 0.3-0.5 part of ethoxylated alkyl sodium sulfate, 0.6-1.0 part of polyether type modified polydimethylsiloxane and 60-75 parts of water; and the back layer reinforcing paint comprises the following components in parts by weight: 75-85 parts of coal gangue sand, 15-25 parts of kaolinite, 3-6 parts of feldspar powder, 8-13 parts of calcium rectorite powder, 8-10 parts of sodium tripolyphosphate, 1.5-2.0 parts of wood fiber and 30-45 parts of water. A molding shell manufactured by the surface layer fireproof paint and the back layer reinforcing paint has the characteristics of high strength and refractoriness, good air permeability and the like.

Owner:HUBEI UNIV OF TECH

Hair-blackening and hair-growing liquid shampoo and preparation method thereof

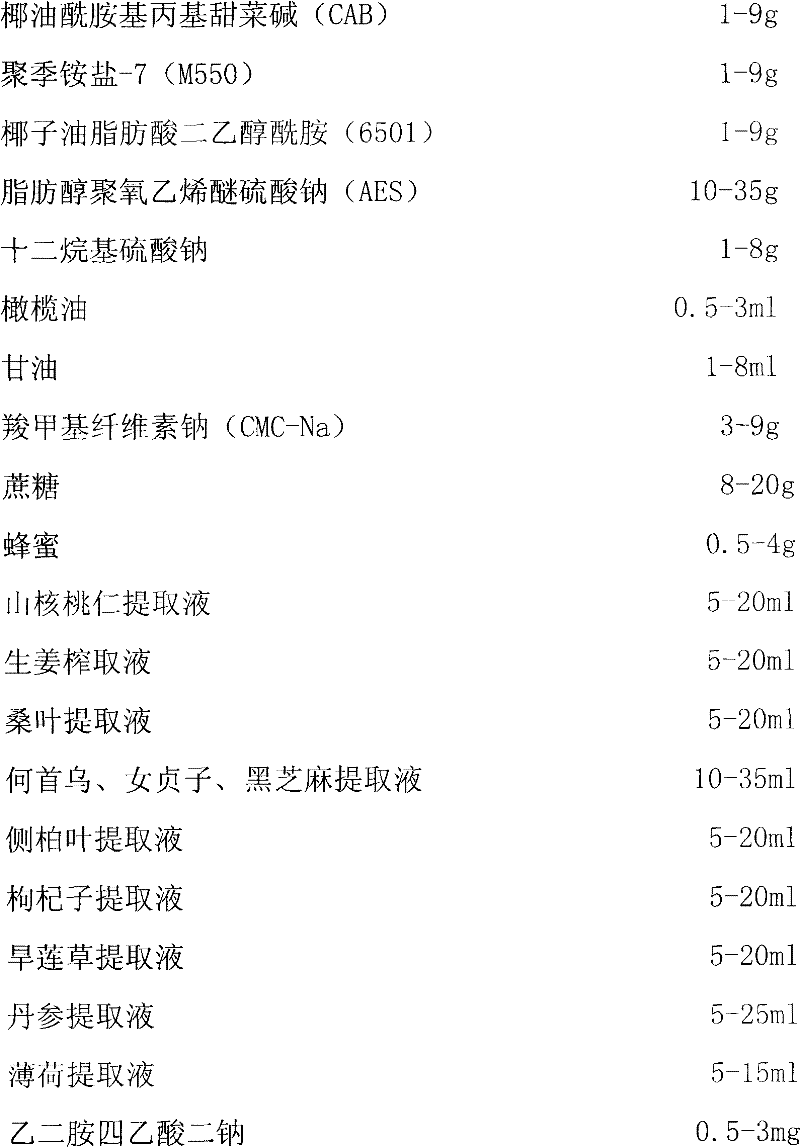

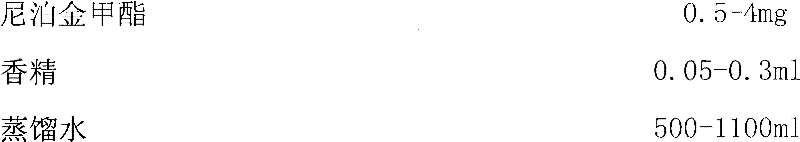

The invention discloses a hair-blackening and hair-growing liquid shampoo and a preparation method thereof. Every 770g of the liquid shampoo comprises the following substances by weight: 1-9g of cocoamidopropyl betaine (CAB), 1-9g of polyquaternium-7 (M550), 1-9g of coconut fatty acid diethanolamide (6501), 10-35g of fatty alcohol-polyoxyethylene ether sodium sulfate (AES), 1-8g of lauryl sodium sulfate, 0.5-3ml of olive oil, 1-8ml of glycerol, 3-9g of sodium carboxymethylcellulose (CMC-Na), 8-20g of cane sugar, 0.5-4g of honey, 5-20ml of a pecan nut extracting solution, 5-20ml of a ginger extracting solution, 5-20ml of a mulberry leaf extracting solution, 10-35ml of a polygonum multiflorum, glossy privet fruit and black sesame extracting solution, 5-20ml of a cacumen biotae extracting solution, 5-20ml of a barbary wolfberry fruit extracting solution, 5-20ml of a yerbadetajo herb extracting solution, 5-25ml of a red-rooted salvia root extracting solution, 5-15ml of a mint extracting solution, 0.5-3mg of ethylene diamine tetraacetic acid, 0.5-4mg of methyl-p-hydroxy benzoate, 0.05-0.3ml of essences and 500-1,100ml of distilled water. The hair-blackening and hair-growing liquid shampoo prepared with the method has the advantages of light yellow color, transparency, glittering, proper viscosity and consistency, high stability, aromatic smell, and capabilities of supplying nutrients to scalp, nourishing deep scalp, and making hairs become black, smooth and elastic.

Owner:广州市昌盛化妆品技术有限公司

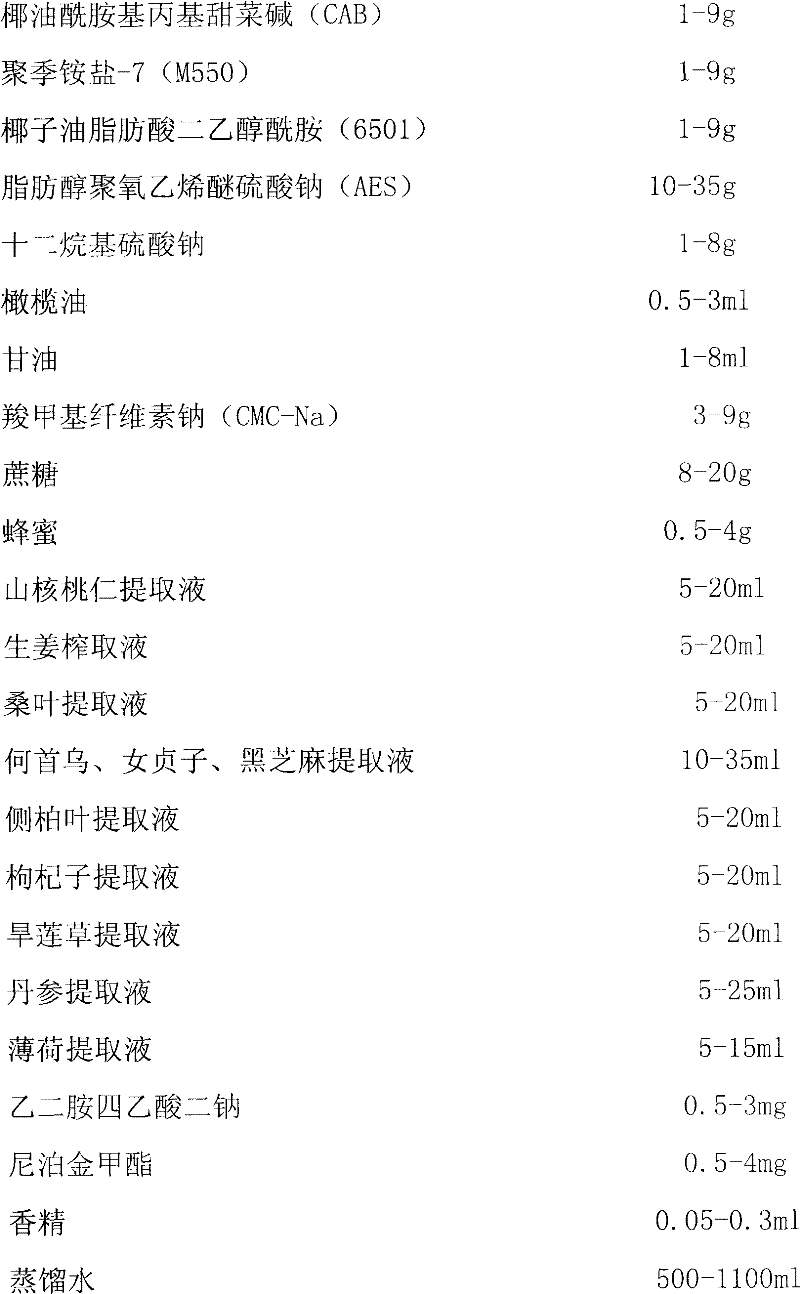

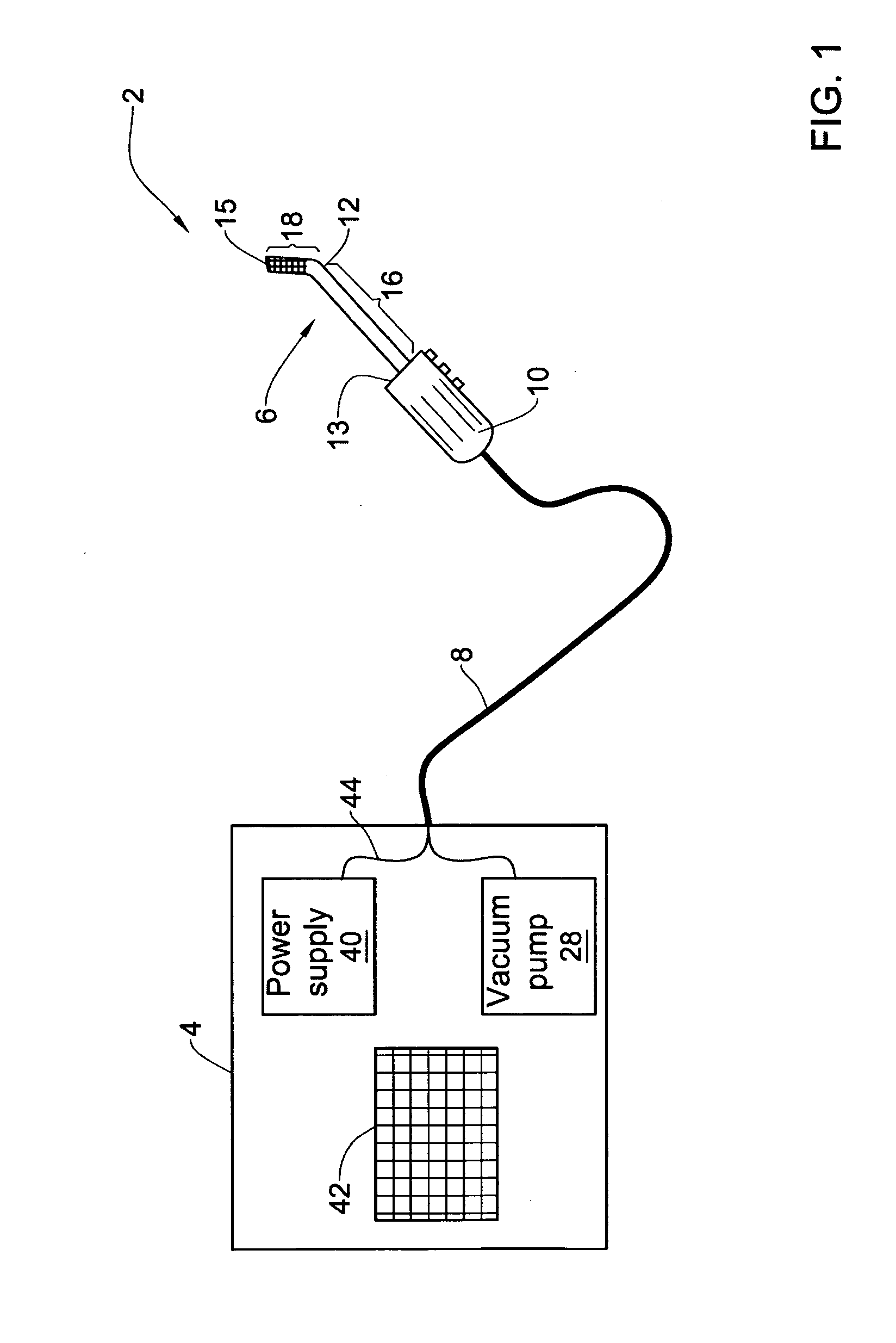

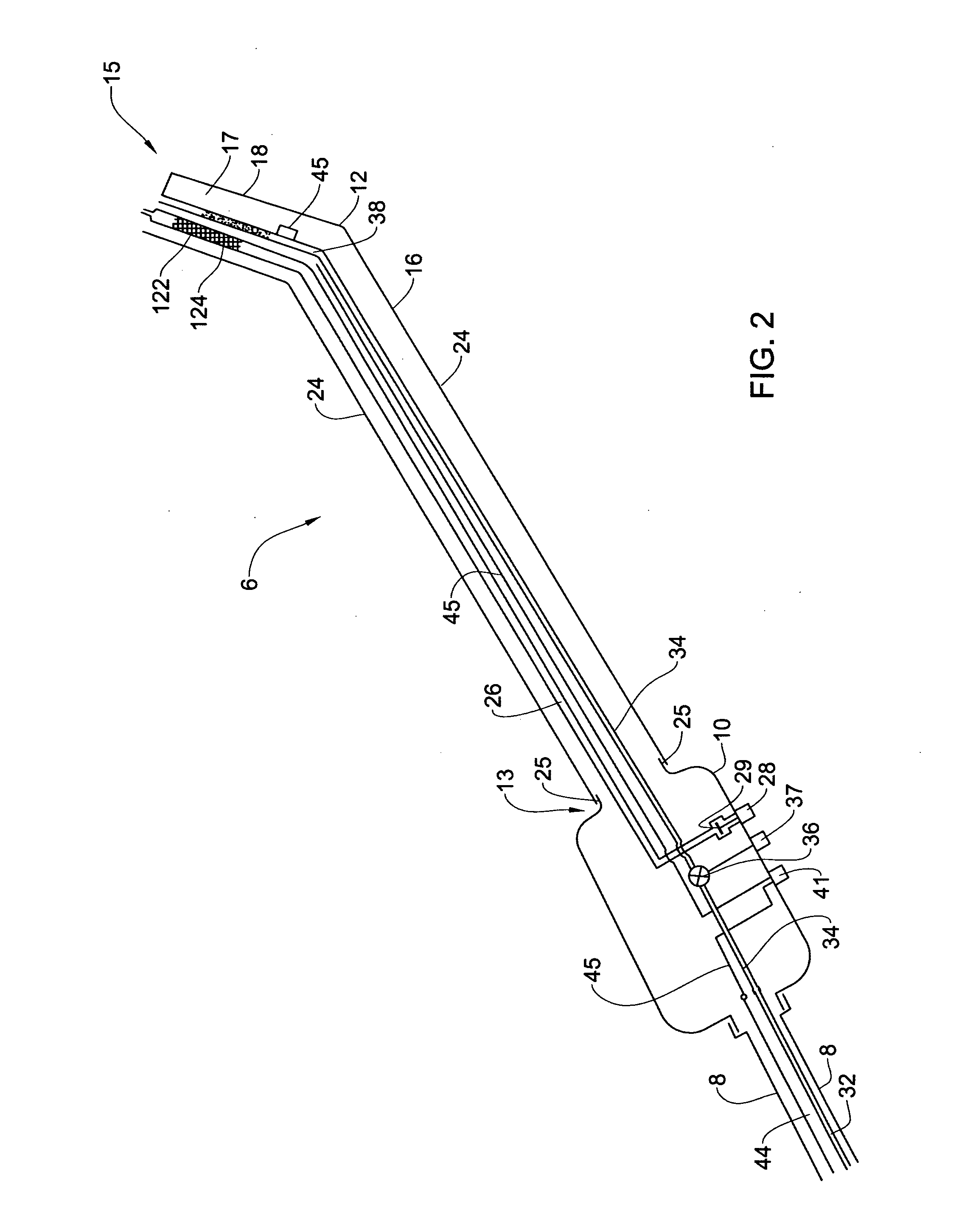

Pharmaceutical composition and system for permeabilizing fetal membranes

Provided is a pharmaceutical composition for permeabilizing fetal membranes including an active ingredient having a log K in the range of 2 to 4, where K is the octanol / water partition coefficient. The active ingredient may be, for example, bupivacaine, sodium lauryl sulfate or oleic acid. Further provided is a system for transfetal membrane transport. The system includes a probe unit adapted for insertion into a female reproductive tract and releasing a substance onto fetal membranes that permeabilizes the membranes. The system is also configured to apply ultrasound radiation to the fetal membranes to further increase the membrane permeability.

Owner:B G NEGEV TECH & APPL LTD

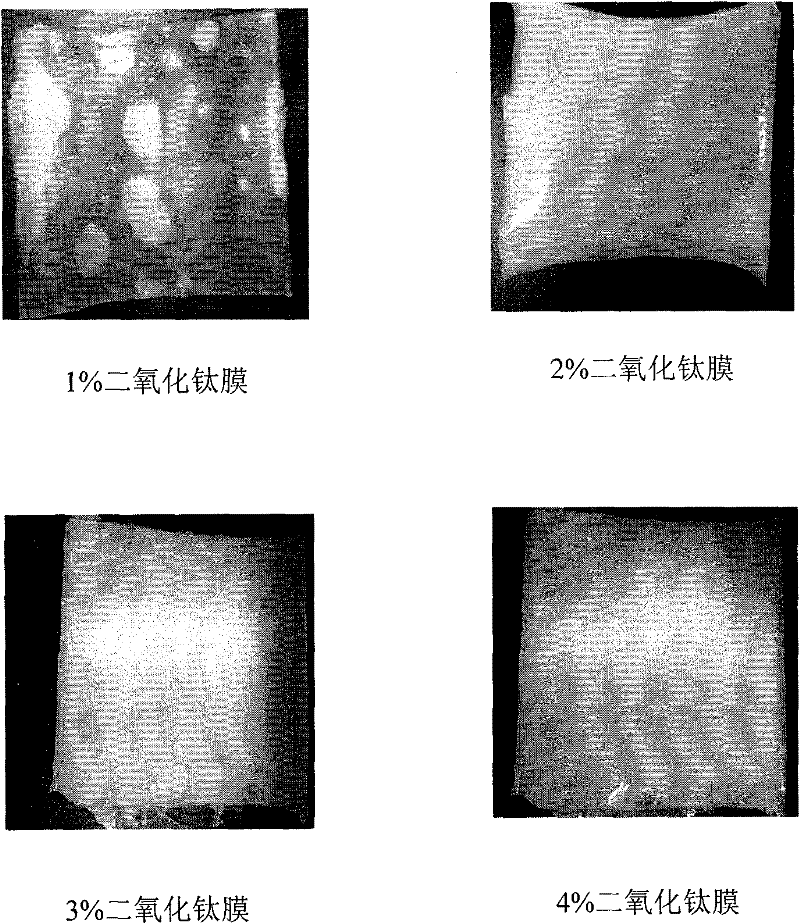

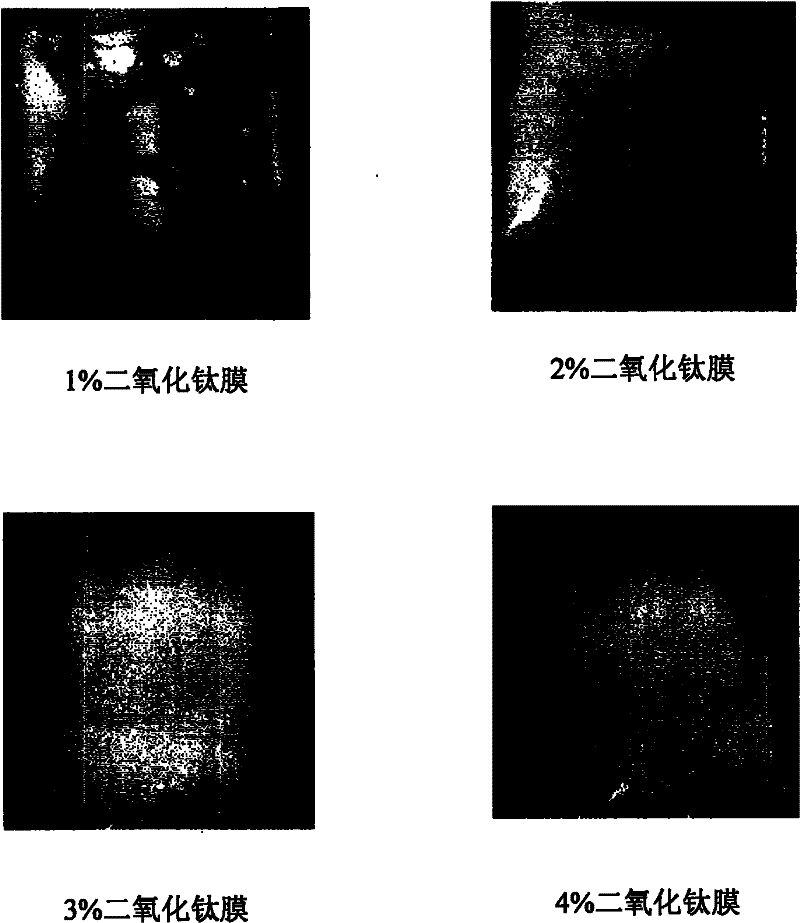

Preparation method of nano tio2 modified pvdf ultrafiltration membrane

InactiveCN102294180AImprove hydrophilicityExtended service lifeSemi-permeable membranesHydrophilic monomerUltrafiltration

The invention relates to a preparation method of a nano TiO2-modified PVDF (Polyvinylidene Fluoride) ultrafiltration membrane. The preparation method comprises the following steps of: preparing a membrane making liquid from 15-20 percent by mass of PVDF, 1-3 percent of pore-foaming agent, 1-4 percent of nano TiO2, 3-5 percent of surfactant and 70-80 percent of solvent, ultrasonically oscillating the membrane making liquid for 5-10 minutes, leaching and defoaming; scraping with a membrane scraping machine to form a liquid membrane, standing in the air for 20-60 seconds, soaking into a coagulation bath and coagulating the liquid membrane into an ultrafiltration membrane; and after the ultrafiltration membrane falls off, taking the ultrafiltration membrane out, soaking into distilled water and cutting according to required size for later use. A nano TiO2 hydrophilic monomer is arranged on the surface of the PVDF ultrafiltration membrane, sodium dodecyl sulfate serving as a surfactant is used simultaneously, and dispersion is performed by ultrasonically oscillating, so that agglomeration of nano TiO2 is reduced, nano TiO2 is quickly and uniformly distributed into the membrane making liquid, the hydrophilicity of the PVDF ultrafiltration membrane is enhanced effectively, the energy consumption is enhanced greatly, the anti-pollution capacity and pollutant intercepting performance of the membrane are enhanced, and the service life of the membrane is prolonged.

Owner:ZHEJIANG OCEAN UNIV

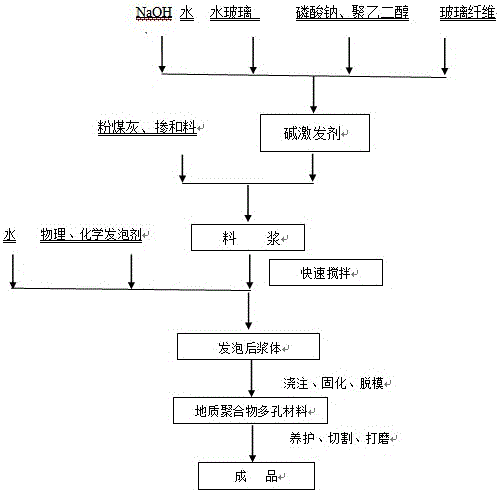

Flyash geopolymer based porous material and preparation process thereof

InactiveCN105800972APracticalSimple production processCement productionSodium phosphatesPolyethylene glycol

The invention provides a flyash geopolymer based porous material and a preparation process thereof. The porous material comprises the following components in parts by weight: 60-100 parts of flyash, 40-70 parts of alkali activator, 0-40 parts of admixtures, 0-5 parts of glass fibers, 2-8 parts of physical foaming agents and 0-0.8 part of chemical activators, wherein the alkali activator is alkaline mixed liquor containing various ions and comprises industrial water glass, sodium hydroxide, water, polyethylene glycol and sodium phosphate; the admixtures refer to levigated metakaolin, silicon micropowder and calcined coal gangue; the physical foaming agents include expired shampoo, an anionic surfactant sodium dodecyl sulfate (SDS), fatty alcohol polyoxyethylene ether sodium sulfate (AES) and disodium fatty alcohol polyoxyethylene ether monosulfosuccinate (AESS); the chemical foaming agents include aluminium powder, hydrogen peroxide, and the like. The porous material has adjustable volume density, fine and uniform pore diameter, low heat conductivity, high strength, the same life as buildings and good fireproof performance.

Owner:QINGHAI UNIVERSITY +1

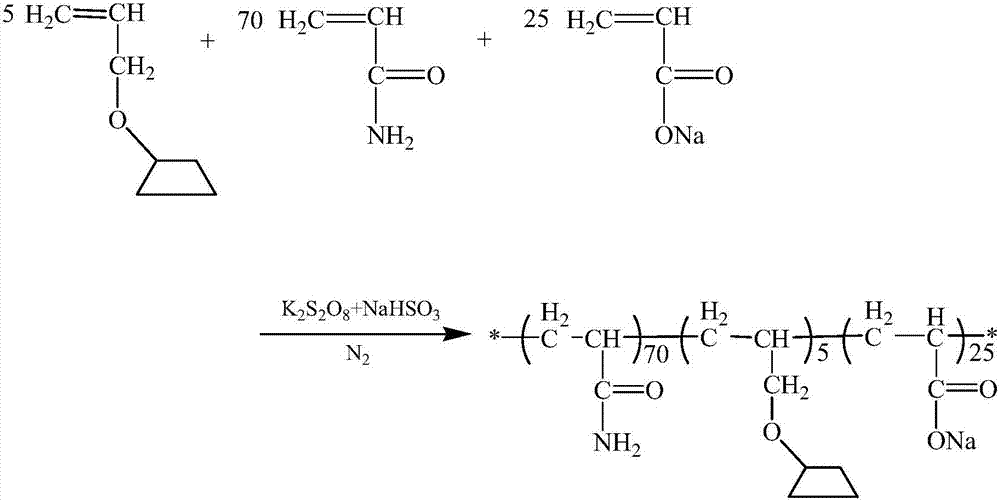

Textile water-based pigment printing binding agent and preparation method

ActiveCN102605648AMeet printing requirementsHigh fastnessEster polymer adhesivesDyeing processTextile printerPolymer science

The invention relates to a textile water-based pigment printing binding agent and a preparation method. The textile water-based pigment printing binding agent is prepared in a way that acrylonitrile, ethyl acrylate, butyl acrylate, crylic acid, hydroxyethyl methacrylate, acrylamide, sodium dodecyl sulfate, alcohol dodecyl polyoxyethylene (10) ether, deionized water, ammonium persulfate and sodiumhydrogen sulfite are subjected to emulsion polymerization and then are mixed with pyrolysis closed polyurethane crosslinking agent according to proportion. The product is cured in low temperature condition, has remarkable advantages in the aspects of dry rubbing fastness, wet rubbing fastness, soaping fastness and the like, is simple and easily-controllable in production operation, and is energy-saving and environment-friendly.

Owner:LIAONING FIXED STAR FINE CHEM

PE (polyurethane) protective film glue and preparation method thereof

InactiveCN102206476AStrong adhesionHigh bonding strengthFilm/foil adhesivesEster polymer adhesivesIsooctyl acrylateWater based

The invention discloses PE (polyurethane) protective film glue and a preparation method thereof. The PE protective film glue consists of the following components in parts by weight: monomers: 20-60 parts of butyl acrylate, 25-45 parts of methyl methacrylate, 12-32 parts of methyl acrylate, 5-15 parts of acrylic acid, 10-24 parts of hydroxyethyl acrylate, 120-140 parts of enthyl hexyl acrylate; emulsifying agents: 0.5-1.5 parts of polyoxyethylene octyl phenyl ether, 0.5-1.5 parts of sodium dodecyl sulphate, 0.5-1.5 parts of sodium dodecyl benzene sulfonate; a solvent: 280-350 parts of deionized water; and an initiating agent: 0.6-1.5 parts of ammonium persulfate. The PE protective film glue provided by the invention is the water-based adhesive and has the advantages of environment friendliness, no pollution, strong adhesive force and adhesive strength, and short drying time. A PE protective film coated with the PE protective film glue provided by the invention can be used for a vehicleprotective film, the protective films of all home appliances and so on. The effects of non-degumming and no residue glue can be realized.

Owner:BOLEX SHENZHEN ADHESIVE PROD

Non-methanal environment-friendly type plant protein modified adhesion agent

InactiveCN101319131AMeet emission testing standardsSolve the hazardProtein adhesivesGlue/gelatin preparationFiberRapeseed

The invention relates to a formaldehyde-free environment-friendly vegetable protein modified adhesive, which aims to solve the problem that the prior urea-formaldehyde adhesive, phenolic aldehyde adhesive and melamine aldehyde adhesive release formaldehyde and cause environmental hazard and pollution, etc. The compositions in portion by weight of the modified adhesive are: 30 to 50 portions of natural plant dregs, 5 to 12 portions of basic material, 5 to 10 portions of calcium hydroxide emulsion, 6 to 15 portions of urea, 4 to 10 portions of alkyl sodium sulfate, 2 to 5 portions of 10 to 20 percent of inorganic acid and 90 to 120 portions of deionized water. The invention takes macromolecular proteins in natural plant soybean dregs, peanut dregs, rapeseed dregs, cottonseed dregs, linseed dregs and sunflower seed dregs as raw materials so as to synthesize a new-generation formaldehyde-free environment-friendly vegetable protein modified adhesive through chemical modification. The formaldehyde-free environment-friendly vegetable protein modified adhesive has the characteristics of uniform and stable product, high adhesion strength, hydrolysis resistance and nontoxicity, etc.; moreover, the performance and the price of the modified adhesive are suitable for wood adhesion and for making artificial fiber boards such as plywood, shaving board and fiber board.

Owner:上海世鹏聚氨酯科技发展有限公司

Recycled aggregate concrete and preparation method thereof

InactiveCN105174852AImproves microscopic stress-strain performanceWide variety of sourcesSolid waste managementEpoxySodium sulfate

The invention discloses recycled aggregate concrete and a preparation method thereof. The recycled aggregate concrete comprises the following raw materials by weight percent: 15 to 20 percent of cement, 5 to 15 percent of water, 15 to 25 percent of third mixed additive, 38 to 63 percent of coarse aggregate, 0.3 to 1 percent of modified wood fiber-containing polyurethane modified epoxy resin flexibilizing emulsion, 0.1 to 0.5 percent of lauryl sodium sulfate, 0.1 to 0.5 percent of sodium gluconate, 0.1 to 0.5 percent of water glass, 0.5 to 1 percent of polyacrylate, and the sum of weight percent of the raw materials is 100 percent; and the coarse aggregate is the waste concrete renewable coarse aggregate or a mixture of waste concrete renewable coarse aggregate and natural coarse aggregate. The renewable aggregate concrete has good impact resistance, earthquake resistance and crack resistance, the pressure resisting strength of the recycled aggregate concrete in 28 days can reach 80 to 100 MPa, and the recycled aggregate concrete is applicable to a load-bearing structure.

Owner:FUJIAN JIANGXIA UNIV

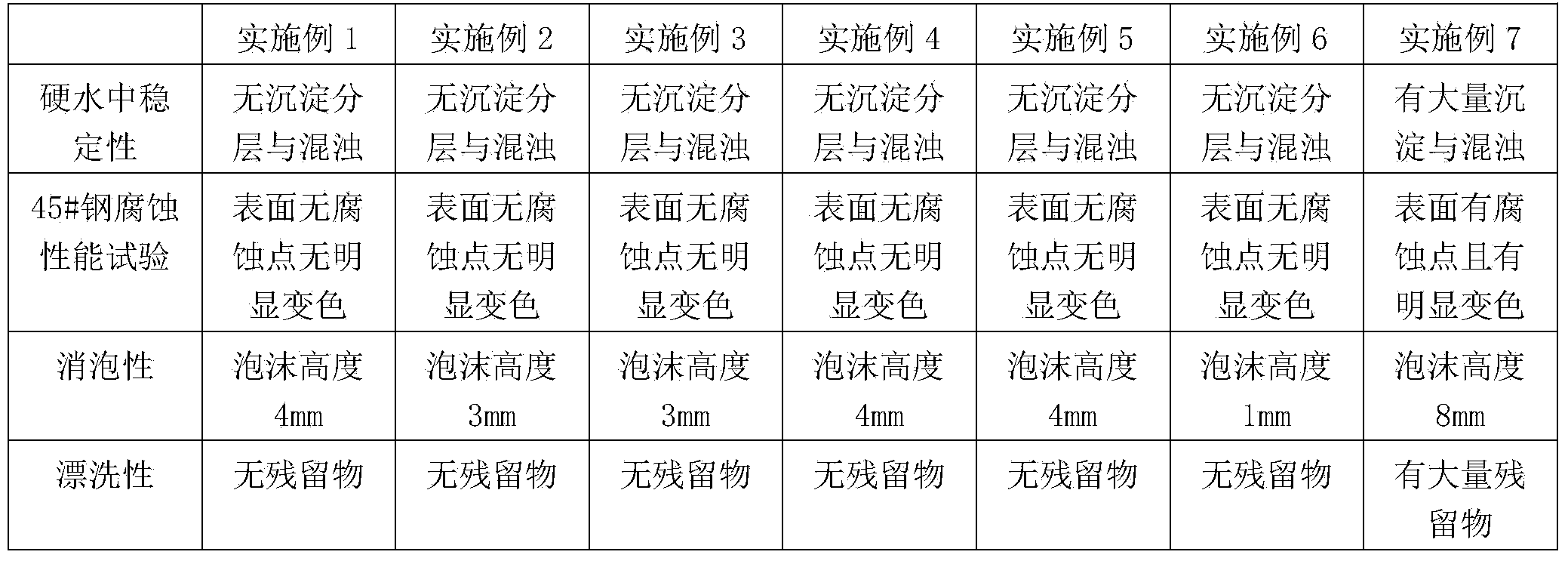

Water-based metal cleaner and preparation method thereof

The invention discloses a water-based metal cleaner and a preparation method thereof. The water-based metal cleaner is prepared from sodium dodecylbenzene sulfonate, fatty alcohol-polyoxyethylene ether, alkylphenol polyoxyethylene, triethanolamine oleate, triethanolamine, 3-methyl-3-methoxy-1-butanol, polyphosphate, silicate, glycerol, primary sodium alkyl sulfate, isooctyl phosphate, benzotriazole, polyethylene glycol, dimethylaminoethyl methacrylate, 2-hydroyl-3-sulfopropyl starch ether and deionized water; the preparation method of the water-based metal cleaner comprises the following steps: firstly, adding a surfactant and the triethanolamine oleate to the glycerol, heating and stirring, next, adding the triethanolamine, the 3-methyl-3-methoxy-1-butanol, the polyphosphate and the silicate, adding the primary sodium alkyl sulfate, the isooctyl phosphate, the benzotriazole and the polyethylene glycol under the conditions of stirring and preserving heating, and finally adding the rest components under the conditions of stirring and preserving heating, and heating and stirring to obtain the cleaner. The water-based metal cleaner has excellent cleaning performance and relatively high corrosion inhibition period.

Owner:SUZHOU CHANGSHENG ELECTROMECHANICAL

Core-shell type paint dyeing and printing adhesive agent emulsion and preparation method thereof

InactiveCN101368342AImprove bonding fastnessImprove stabilityDyeing processPotassium persulfatePolymer science

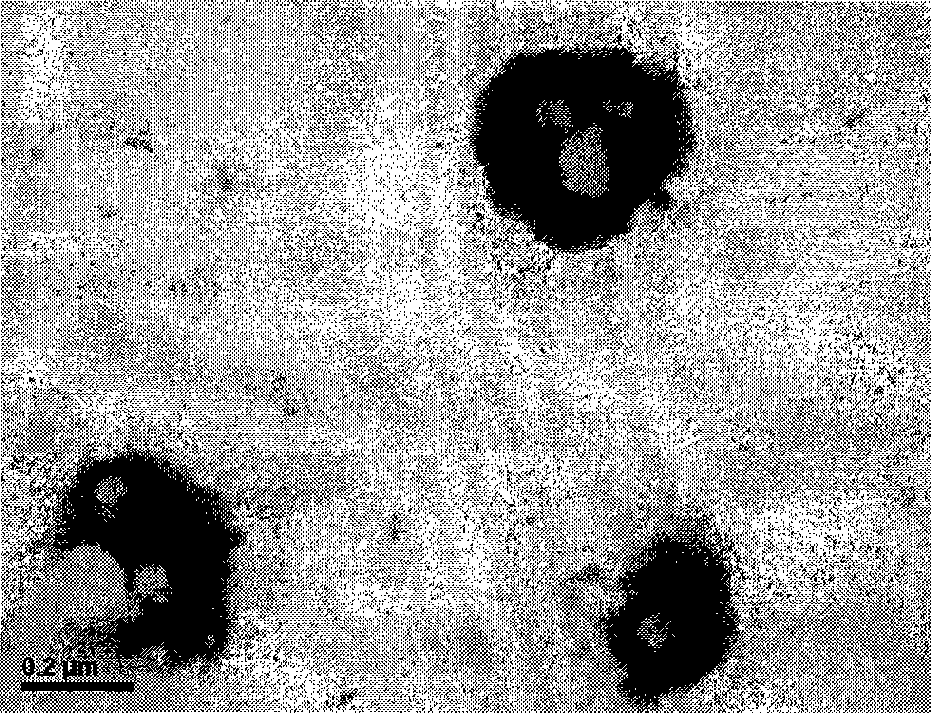

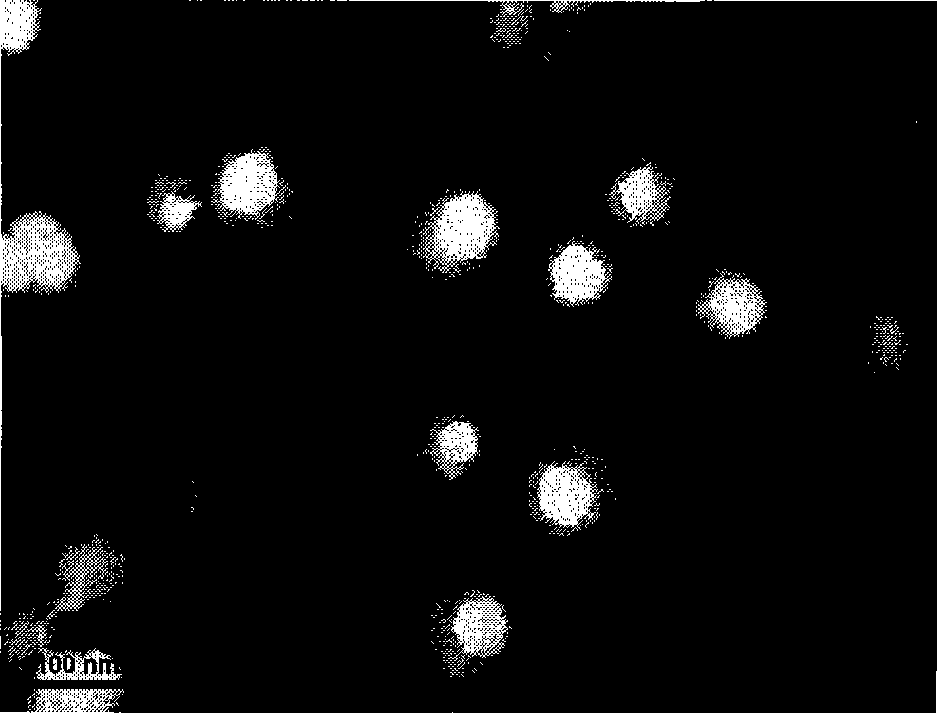

The invention discloses a method for preparing core-shell emulsion type adhesive which is modified by hydroxyl-terminated acrylic ester and is used in fabric printing and dyeing processes. The adhesive is prepared through the following steps: soft monomers copolymerize with crosslinking monomers and portions of hard monomers to produce core-shell particles; then a small portion of soft monomers and a large portion of crosslinking monomers copolymerize with hard monomers to coat the surface of the core layer, thus obtaining a shell layer and forming stable core-shell type emulsion. One or the mixture of two or more from 2-hydroxyethyl acrylate, hydroxypropyl acrylate, hydrobutyl acrylate and hydrohexyl acrylate is taken as a portion of soft monomers and crosslinking monomers; one or the mixture of two or more from hydroxylmethyl methacrylic acid, 2-hydroxyethyl acrylate methacrylic acid and hydroxypropyl methacrylic acid is taken as a portion of hard monomers and crosslinking monomers; one from butyl acrylate, ethyl acrylate and 2 ethylhexyl acrylate is taken as main soft monomers; one or the mixture of two or more from methyl methacrylate, crylic acid, cinnamene, acrylonitrile and methacrylic acid is taken as the hard monomers; surfactant sodium dodecyl sulfate, sodium dodecyl benzene sulfonate and octyl phenol polyethylene glycol are taken as emulsifying agent; potassium persulfate or ammonium persulfate is taken as initiator; and the copolymer emulsion is produced through emulsion copolymerization. Observed by transmission electron microscopy, the particles of the emulsion have visible core-shell structure and are even in distribution; the emulsion is stable, absolutely has no formaldehyde release both during the machining and using processes; the emulsion can be used both for pigment printing and for pigment dyeing.

Owner:JIANGNAN UNIV

Capsule preparation containing tegafur, gimeracil and potassium oxonate

ActiveCN102302499AAdvantages and Notable ImprovementsReduce dosageCapsule deliveryAntineoplastic agentsPotassium oxonateActive component

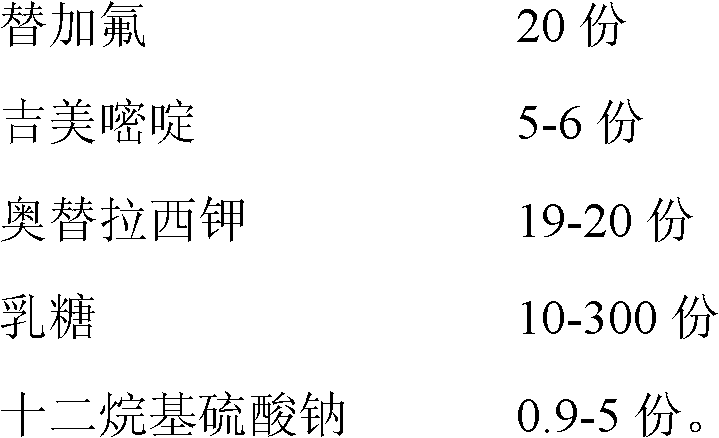

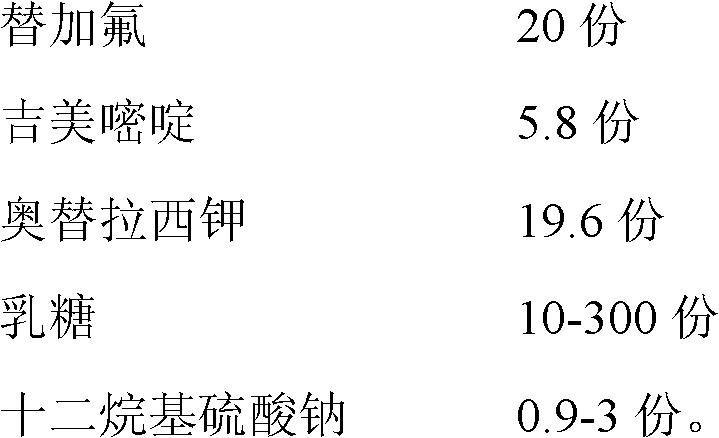

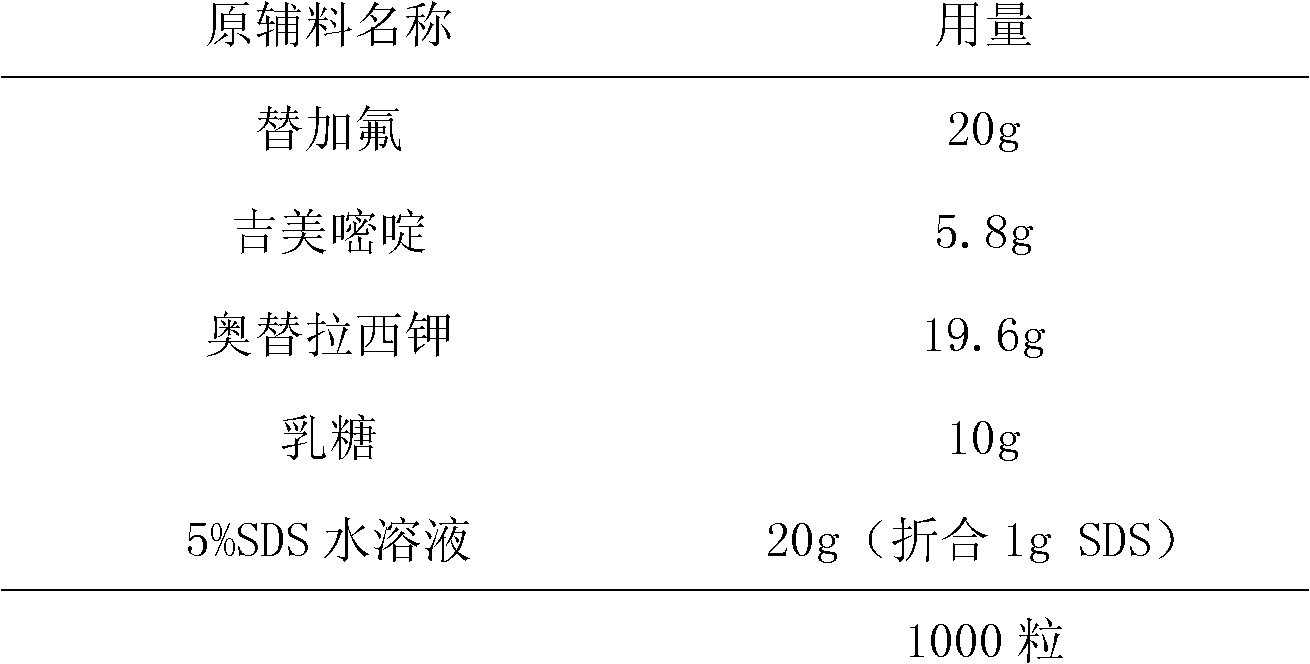

The invention refers to a capsule preparation containing tegafur, gimeracil and potassium oxonate. The capsule preparation comprises the following components by weight parts: 20 parts of tegafur, 5-6 parts of gimeracil, 19-20 parts of potassium oxonate, 10-300 parts of lactose, and 0.9-5 parts of sodium dodecyl sulfate. According to the invention, the use level of the surfactant of sodium dodecylsulfate is greatly reduced on the premise of guaranteeing rapid dissolving-out of active components in the preparation, so that the irritation of the capsule preparation to the human gastrointestinaltract is decreased and the medicine compliance of a patient is increased.

Owner:鲁南新时代生物技术有限公司

Plugging agent with double plugging function and filling method thereof

InactiveCN101798500AReduce resistanceImprove stabilityDrilling compositionSealing/packingCross-linkPolymer science

The invention provides a plugging agent with a double plugging function and a filling method thereof. The plugging agent comprises a foaming agent, a foam stabilizer, a cross-linking agent, gas and water, wherein the foaming agent is sodium dodecyl sulfate as an anionic surfactant, the foam stabilizer is water-soluble polyacrylamide with relative molecular mass of 11.6*106, and the cross-linking agent is a chromium cross-linking agent and comprises Na2Cr2O7 and Na2SO3. The filling method comprises the following steps: sequentially filling a far-well foaming liquid comprising the foaming agent, the foam stabilizer and the cross-linking agent, transition-area foaming liquid and near-wall foaming liquid; then, filling HPAM (hydrolyzed polyacryamide) over-top replacing liquid and nitrogen; and finally, filling clear water as the over-top replacing liquid for completely replacing the nitrogen into a layer of the earth. The gel foam plugging agent not only has Jamin effect of nitrogen foam, but also has a selective plugging function of polymer gels, improving foam stability by using the gel as an outer phase and increasing the effect and the effective period of a plugging measure.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Anti-flaming antisepsis leather coating and preparation method thereof

InactiveCN105925099AImprove water resistancePrevent penetrationFireproof paintsAntifouling/underwater paintsDecabromodiphenyl etherTriterpenoid saponin

The invention discloses an anti-flaming antisepsis leather coating which is composed of, by weight, 2-3 parts of hydrous zinc borate, 1-1.5 parts of linoleic acid calcium soap, 0.1-0.2 part of triterpenoid saponin, 0.7-1 part of calcium naphthenate, 1.7-2 parts of polyvinylpyrrolidone, 0.8-1 part of polyacrylamide, 1.6-2 parts of stannous chloride, 0.1-0.13 part of triethanolamine, 190-200 parts of methyl methacrylate, 3-4 parts of lauryl sodium sulfate, 0.1-0.2 part of urotropine, 0.2-0.3 part of ammonium persulfate, 6-7 parts of a 20%-25% formaldehyde solution, 16-20 parts of zinc acetate, 4-7 parts of silver nitrate, 1-2 part of decabromodiphenyl ether and 0.4-1 part of sodium lauryl sulfate. The anti-flaming antisepsis leather coating has a good antibacterial property and excellent moisture permeability and water resistance. Leather coated with the obtained emulsion is good in antibacterial property and excellent in hygiene property.

Owner:CHUZHOU VOCATIONAL & TECHN COLLEGE

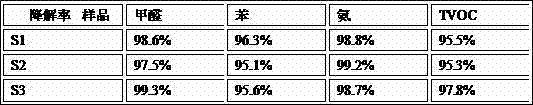

Nano air purifying catalytic agent and preparation method thereof

InactiveCN104722297AImprove adsorption capacityEfficient degradationBiocideOther chemical processesPlatinumGraphene

The invention discloses a nano air purifying catalytic agent and a preparation method thereof. The nano air purifying catalytic agent comprises the following components in percentage by mass: 1%-10% of titanium dioxide, 0.5%-5% of nano platinum, 1%-3% of methylcellulose, 0.5%-1.5% of sodium dodecyl benzene sulfonate, 1%-20% of graphene, 1%-10% of sodium alkyl sulfate, 1%-5% of carboxymethylcellulose, 0.5%-5% of nano negative-ion powder, 0.05%-2% of nano silver and the balance of deionized water. The nano air purifying catalytic agent can continuously purify indoor air for 24 hours in the whole day under the condition of light or no light.

Owner:广东星帮尼科技股份有限公司

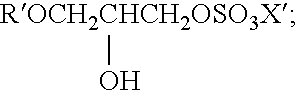

Compositions with suspended particles

InactiveUS20060189495A1Cosmetic preparationsHair cosmeticsSuspended particlesSODIUM TRIDECETH SULFATE

Provided are compositions comprising a hydrophobically-modified acrylic polymer, sodium trideceth sulfate, and one or more particles suspended therein having unexpectedly high stability. Also provided are methods of suspending at least one particle comprising combining at least one particle with a hydrophobically-modified acrylic polymer and sodium trideceth sulfate to produce a composition comprising the hydrophobically-modified acrylic polymer and sodium trideceth sulfate in which the at least one particle is suspended.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

Cement base soil-solidified-agent and preparation and application thereof

InactiveCN101597496AImprove adhesionReduce consumptionBuilding constructionsOrganic fertilisersPotassium hydroxideSodium sulfate

The invention discloses a cement base soil-solidified-agent and preparation and application thereof. The soil-solidified-agent is prepared by the following raw materials by weight percent: 10-40% of sodium sulfate, 2-6% of sodium tripolyphosphate, 2-5% of carbamide, 2-8% of polyacrylamide, 1-5% of lauryl sodium sulfate emulsifier, 2-10% of triethanolamine, 10-60% of sodium silicate, 4-12% of sodium hydroxide, 2-15% of sodium carbonate,2-6% of potassium hydroxide and 2-8% of methyl sodium silicate; and the sum of the percentage is 100%. The soil-solidified-agent can be prepared into powder or liquid, can fully activate various physical, chemical and physical chemistry reactions of cement and soil, so as to greatly improve engineering performance of cement soil, improve strength, reduce dry shrinkage and improve durability. The invention can be widely applied to projects such as road foundation, embankment reinforcement, channel seepage prevention, water and soil conservation, side slope protection, pile foundation processing and the like.

Owner:NORTHWEST A & F UNIV

Micronized tanaproget and compositions containing same

The present invention provides compositions, desirably pharmaceutical compositions, containing micronized tanaproget. The compositions can also contain microcrystalline cellulose, croscarmellose sodium, anhydrous lactose, and magnesium stearate; or can contain microcrystalline cellulose, croscarmellose sodium, sodium lauryl sulfate, povidone, and magnesium stearate. The compositions are useful in contraception and hormone replacement therapy and in the treatment and / or prevention of uterine myometrial fibroids, benign prostatic hypertrophy, benign and malignant neoplastic disease, dysfunctional bleeding, uterine leiomyomata, endometriosis, polycystic ovary syndrome, and carcinomas and adenocarcinomas of the pituitary, endometrium, kidney, ovary, breast, colon, and prostate and other hormone-dependent tumors, and in the preparation of medicaments useful therefore Additional uses include stimulation of food intake.

Owner:WYETH LLC

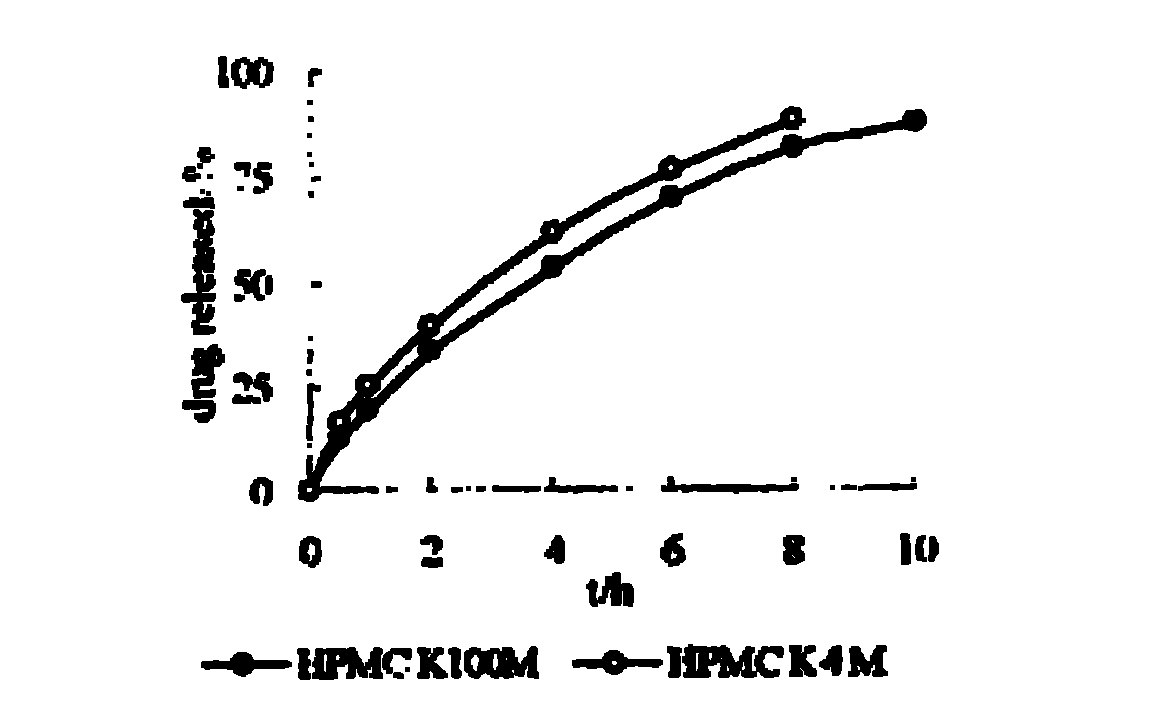

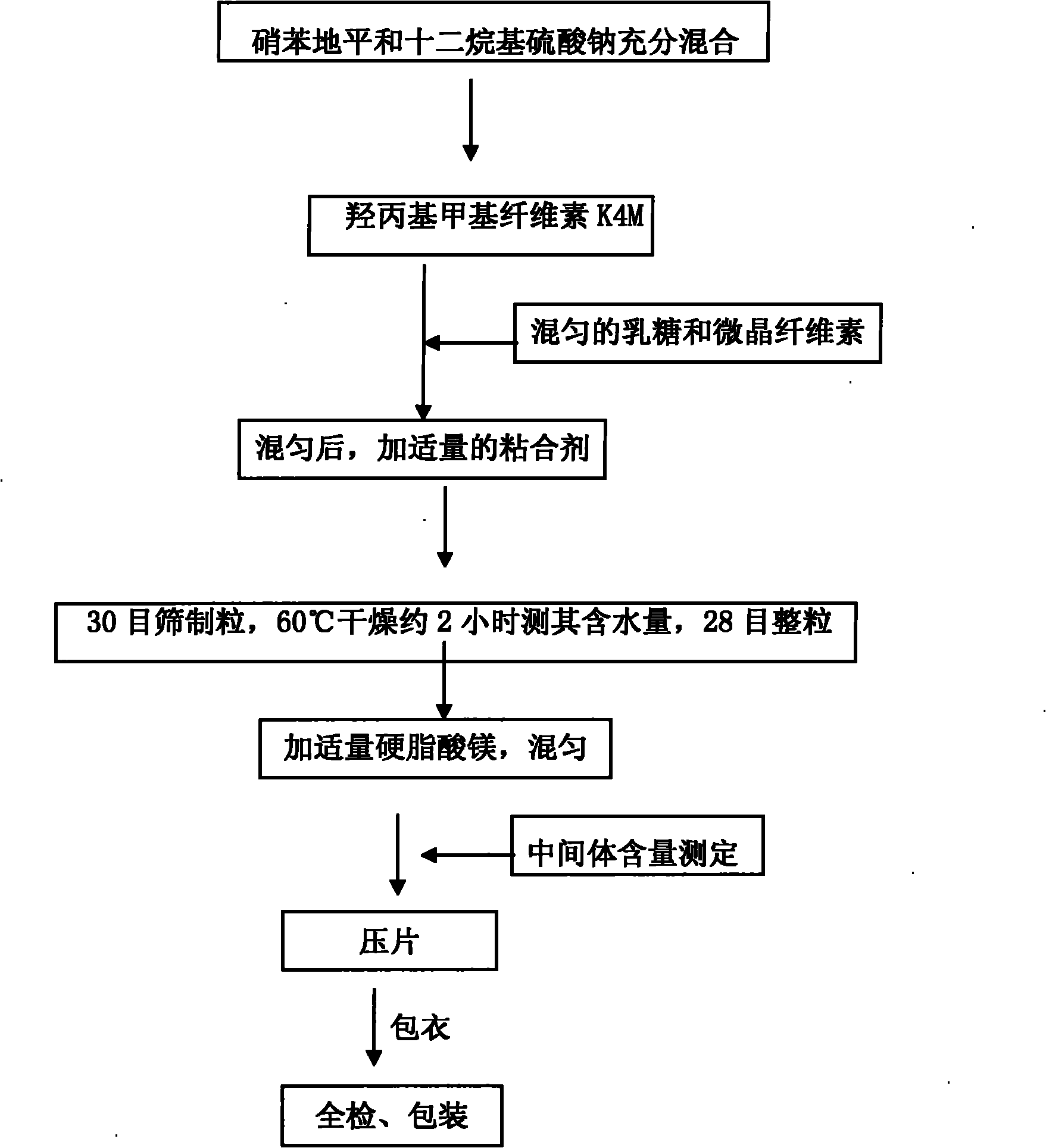

Nifedipine sustained release tablet

InactiveCN101966164AOrganic active ingredientsPharmaceutical delivery mechanismProlonged-release tabletMagnesium stearate

The invention relates to a nifedipine sustained release tablet and a preparation method thereof. The nifedipine sustained release tablet is characterized by comprising a tablet core and film coating liquid, wherein the tablet core comprises the following components in percentage by mass: 10 to 12 percent of nifedipine (Nif), 6.5 to 7.5 percent of hydroxypropyl methyl cellulose K4M, 45 to 47 percent of lactose, 34 to 35 percent of microcrystalline cellulose, 0.48 to 0.55 percent of lauryl sodium sulfate, a proper amount of 95 percent ethanol and a proper amount of magnesium stearate; and the film coating liquid comprises the following component in percentage by mass: 5.85 to 6.55 percent of Opadry II and 92.86 to 93.82 percent of distilled water. The preparation method comprises the following step of: mixing the nifedipine and polymer by utilizing the imported polymer and dispersion technology to form a hydrophilic matrix tablet so as to fulfill the aim of sustained release. Compared with an ordinary tablet, the sustained release tablet can continuously act for 12 hours relaxatively, is released in a sustained way and has less and slighter adverse reaction.

Owner:ANHUI YONSENT PHARMA

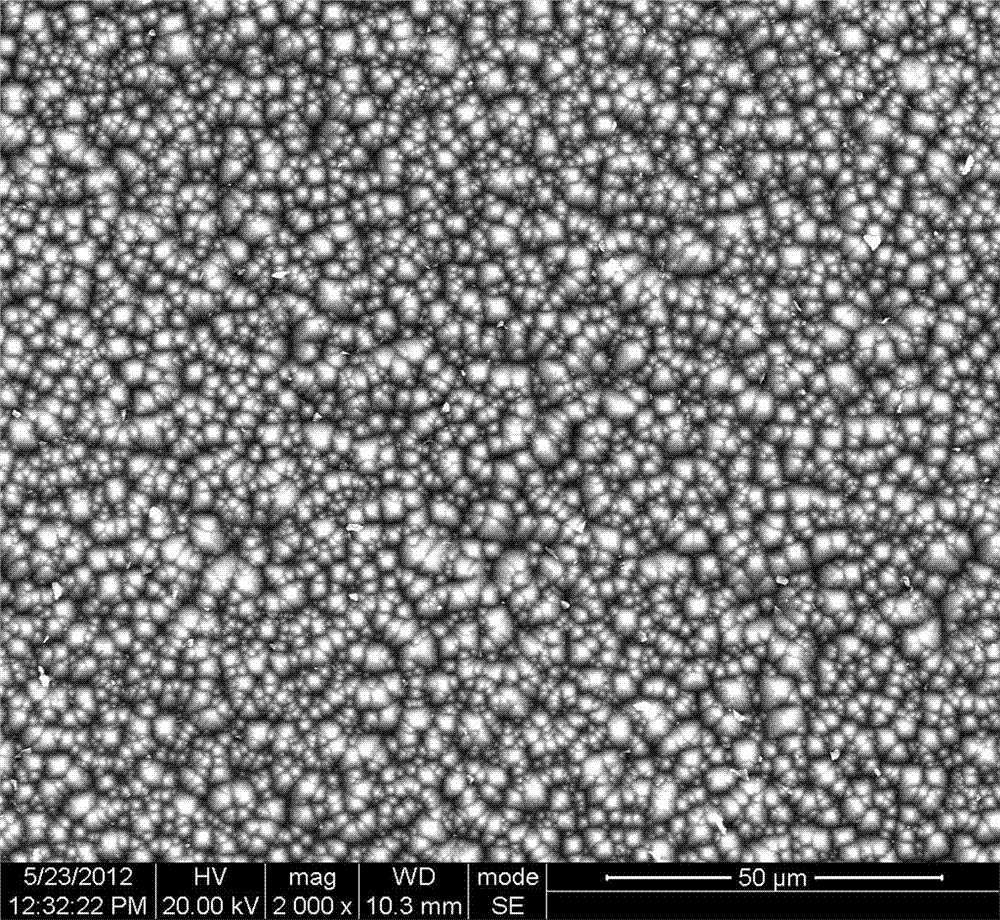

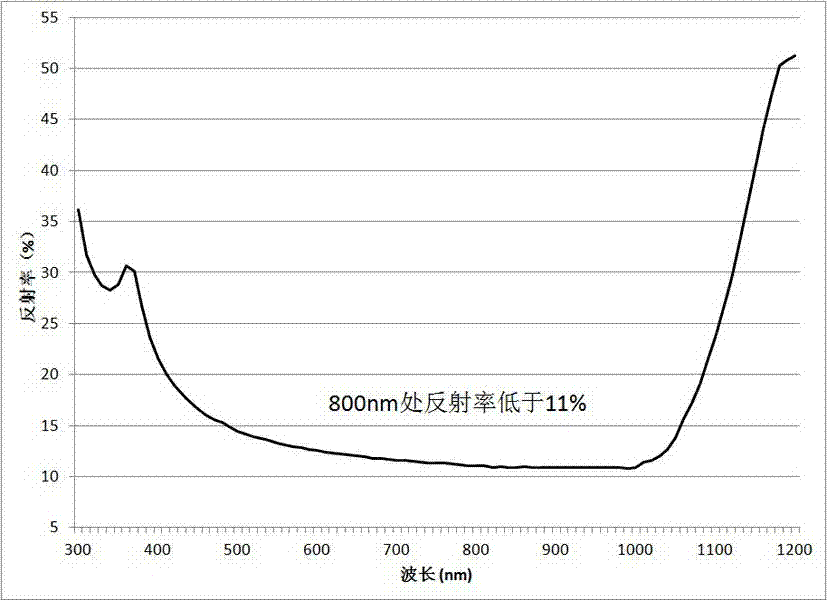

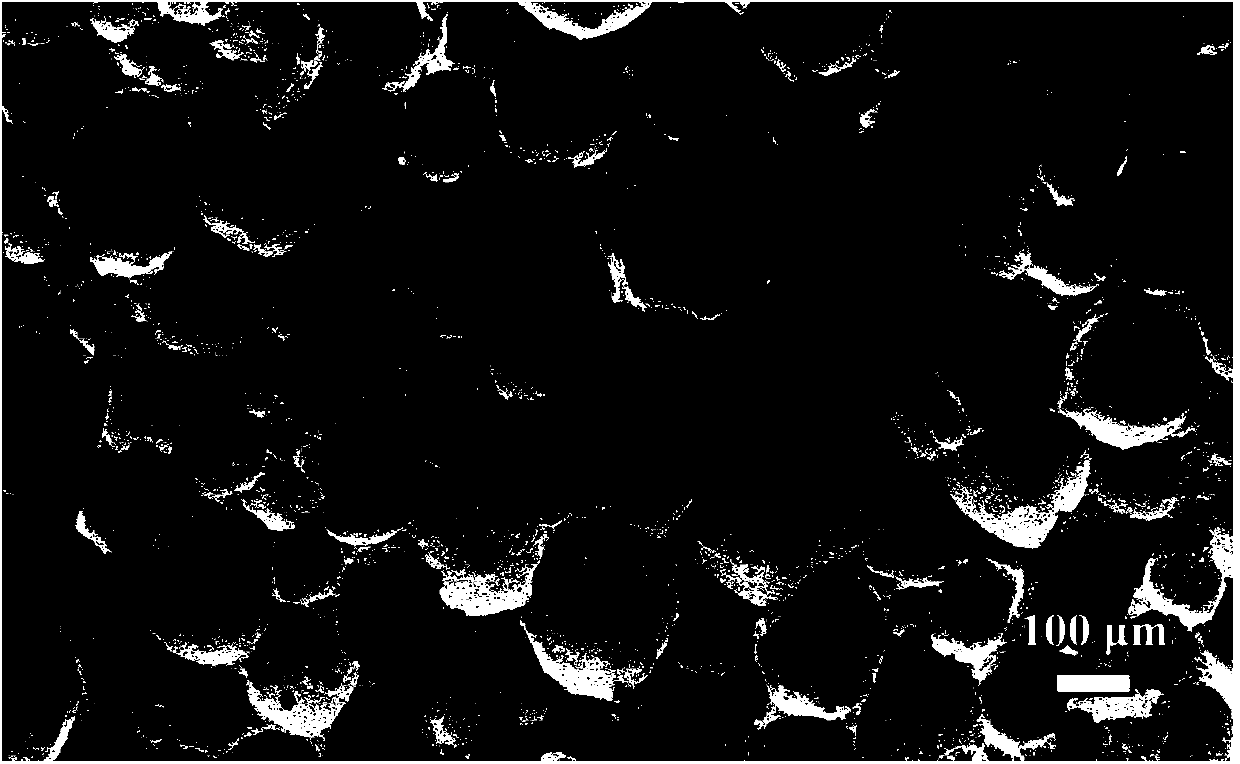

High-boiling point monocrystalline silicon wafer surface texturing additive and using method thereof

The invention relates to a high-boiling point monocrystalline silicon wafer surface texturing additive and a using method thereof and belongs to the technical field of production of solar cells. The additive is prepared from the following raw materials in percentage by weight: 0.01 to 3 percent of sodium alginate, 0.01 to 3 percent of trisodium phosphate, 0.001 to 1 percent of lauryl sodium sulfate, 0.1 to 2 percent of vitamin, 0.1 to 5 percent of propylene carbonate and the balance of deionized water; when the additive is used, a sodium oxide solution is needed to be added into the additive so as to obtain a texturing solution; the volume percentage ratio of the additive to the sodium oxide solution is (0.1-5):100; the temperature of the texturing solution is 70 to 90 DEG C; and the texturing time of the monocrystalline silicon is 600 to 1,500s. The reaction speed is controlled by using high viscosity of the sodium alginate, and the concentration of sodium hydroxide is increased simultaneously, so that a pyramid texture which is uniform in size is obtained; and the sodium alginate has the chelation function on metal and the function of cleaning the silicon wafer, and is low in cost.

Owner:绍兴拓邦新能源股份有限公司

Manufacture method of high porosity and high strength yttrium-silicon-oxygen porous ceramics

The invention relates to the porous ceramics material field, and concretely relates to a method for manufacturing high porosity and high strength yttrium-silicon-oxygen porous ceramics material through a foaming injection coagution process. According to the method, yttrium oxide and silicon oxide mixed power can be taken as a raw material, water is taken as a disperse medium, polyethyleneimine or ammonium citrate is selected as a dispersant, acrylamide or N-methylolacrylamide is taken as a monomer, a cross-linking agent N,N'-methylene bisacrylamide is added, a foaming agent sodium dodecyl sulfate, a peeling inhibitor polyoxyethylene, a catalyst N, N, N',N'-tetramethyl ethylenediamine and an initiator ammonium persulfate are added after stirring, and then injection mold solidification is carried out, drying is carried out for 24-48 hours at room temperature after demoulding, and then drying is carried out for 24-36 hours under the temperature of 60-90 DEG C, high temperature reaction sintering is carried out for 1.5-2.5 hours under the temperature of 1500-1550 DEG C finally, and the gamma-Y2Si2O7 porous ceramics can be finally manufactured. The manufactured gamma-Y2Si2O7 porous ceramics material having a multi-layer pore structure has controllable porosity with high porosity (75-85%) and high strength (3-8MPa).

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

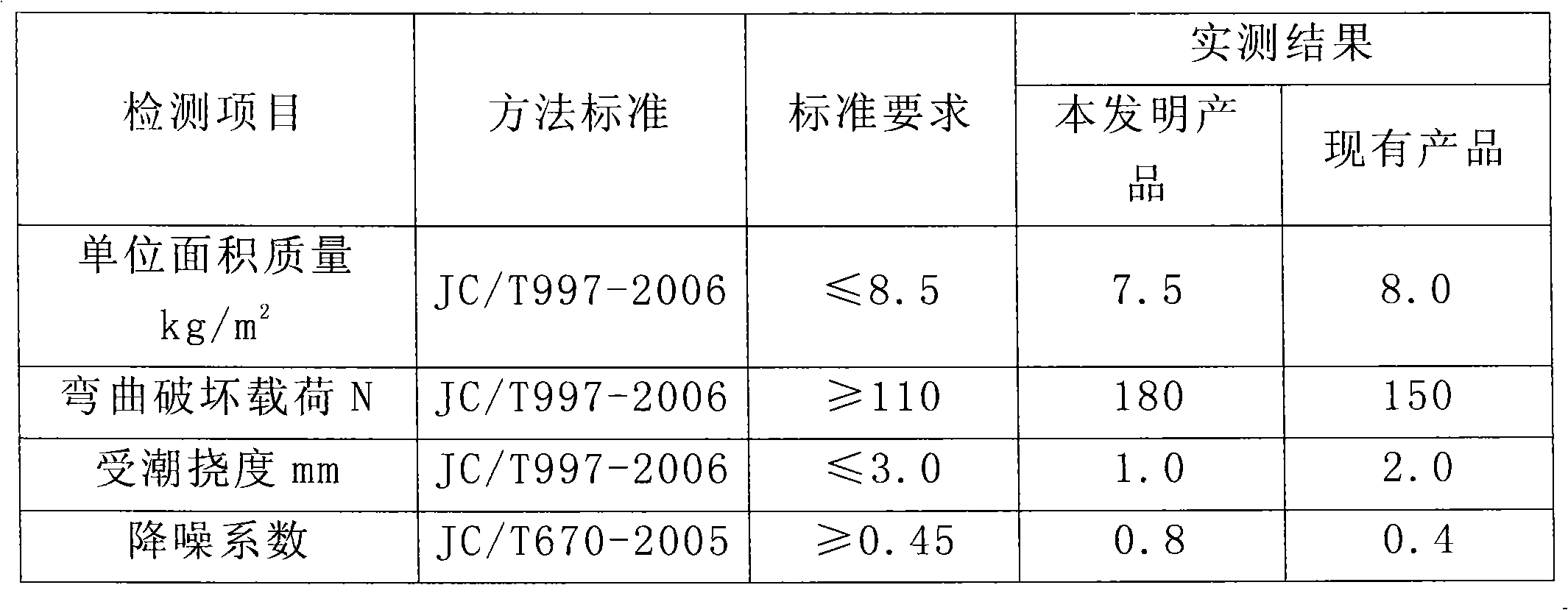

Sound absorbing decorative gypsum board and production method thereof

ActiveCN101649669ASolve the shortcomings of sagging deformation after decorationLow costCovering/liningsLamination ancillary operationsFiberNoise reduction

The invention provides a sound absorbing decorative gypsum board and a production method thereof, and relates to a decorative panel. The sound absorbing decorative gypsum board comprises an aluminiumfoil (1), a paper-faced gypsum board (2), and an embossing relief (3). The paper-faced gypsum board (2) is prepared by the following raw materials according to the proportioning rate: 60 parts of desulfurization gypsum, 4 parts of modified starch, 1 part of foaming agent, namely lauryl sodium sulfate, 1 part of glass fiber and 34 parts of water. The product is manufactured by the following steps:rotary drum embossing, film adhering of coating and drying. Compared with the existing sound absorbing board with the material quality, such as sound absorbing fiber or mineral wool and the like, thesound absorbing decorative gypsum board has the advantages of simple manufacturing process, high strength, dampproof performance, long service life and good effect of noise reduction and sound absorption.

Owner:TAISHAN GYPSUM CO LTD

Formula of flame-retardant polyvinyl chloride (PVC) plastics

InactiveCN103554787AImprove heat resistanceImprove antistatic performancePolymer sciencePolyvinyl chloride

The invention discloses a formula of flame-retardant polyvinyl chloride (PVC) plastics. The formula is characterized by comprising PVC and supplementary additives, wherein the supplementary additives include a flame retardant, a mildew preventive, an antistatic agent, a heat-resisting agent, a crosslink agent and a coupling agent, the flame retardant is triphenyl phosphate and ammonium polyphosphate, the mildew preventive is 8-hydroxyquinoline copper, the antistatic agent is sodium alkyl sulfate, the heat-resistant agent is 2-ethylhexyl thioglycolate, the crosslink agent is 2,5-dimethyl-2,5 bis(tert-butyl peroxy hexane and the coupling agent is aminopropyltriethoxysilane. The flame retardant is used for improving the flame-retardant property of the PVC plastics; by adding multiple assistants in the flame-retardant PVC plastics, the heat resistance and the antistatic property of the flame-retardant PVC plastics can be improved, the stability of the flame-retardant PVC plastics also can be improved, and the production cost can be reduced by accelerating the reaction speed and reducing the consumption of raw materials.

Owner:苏州市双赢包装材料有限公司

Method for enhancing restoration of soil nitrobenzene contamination by anion-nonionic surfactant

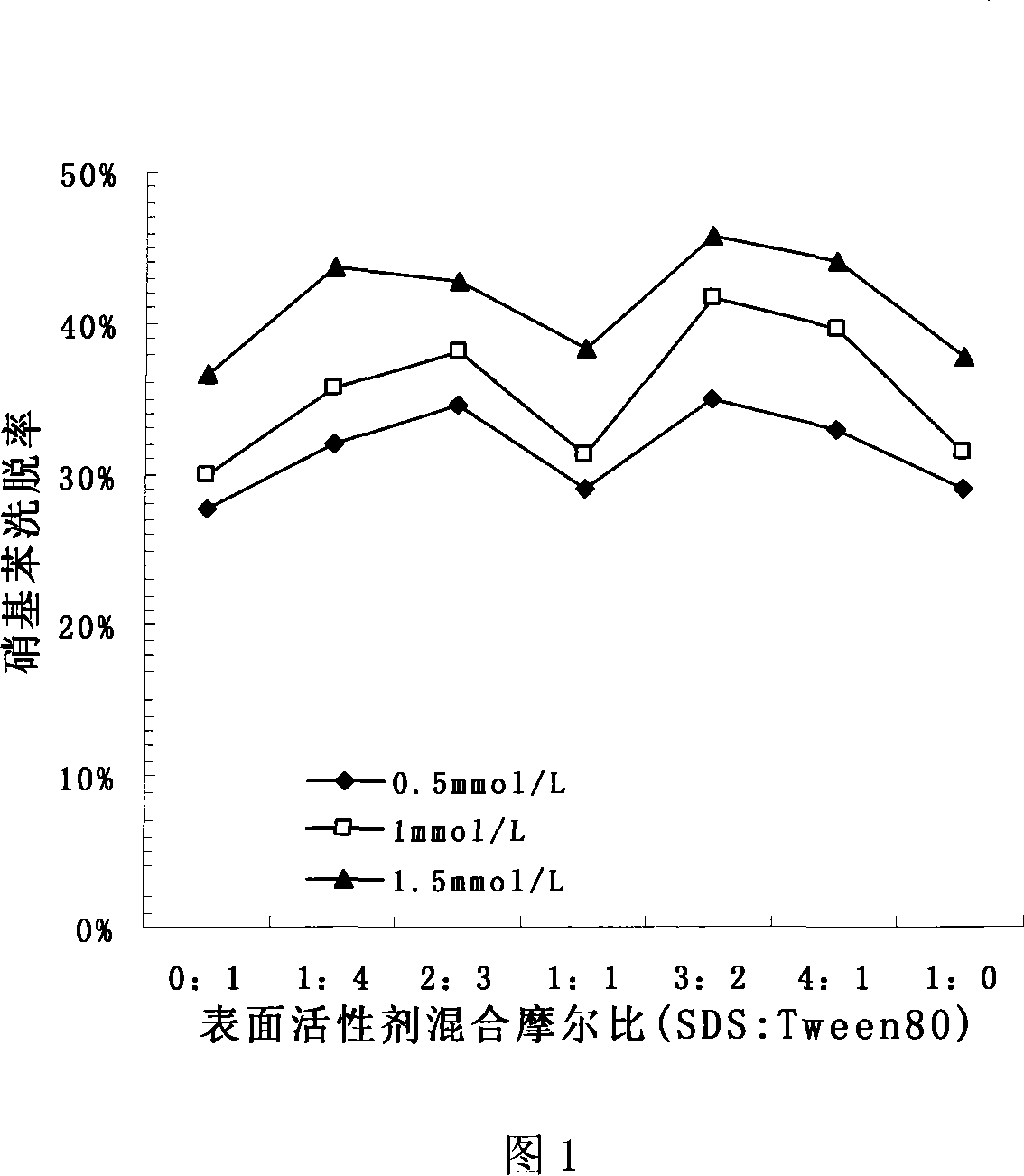

InactiveCN101181716ARepair efficient purificationLow costContaminated soil reclamationOrganic fertilisersDecompositionWastewater

The invention discloses a remediation method for soil nitrobenzene contamination with anionic-nonionic mixed surfactants synergism, pertaining to agricultural technical field. The steps of the invention are that: firstly, anionic surfactant, lauryl sodium sulfate and nonionic surfactant, poly-oxyethylenesorbitan monooleate are mixed and prepared into anionic-nonionic mixed surfactants solution; secondly, the obtained anionic-nonionic mixed surfactants solution is injected into nitrobenzene contaminated soil through a pump, and nitrobenzene in soil is solubilized and eluted by the anionic-nonionic mixed surfactants solution; thirdly, mixed surfactants eluent injected into nitrobenzene contaminated soil is drawn out through a pump, and anaerobic bio-decomposed via nitrobenzene decomposition bacteria to remove the nitrobenzene, thus purifying soil contamination caused by nitrobenzene. The eluting rate of the invention is as high as 90.7%, and the domestic sewage and industrial wastewater containing surfactants can be secondarily utilized at the same time.

Owner:SHANGHAI JIAO TONG UNIV

Soil modifier for earth pressure balance shield

InactiveCN105295933AImprove stabilitySimple preparation processBuilding constructionsOrganic fertilisersSulfonateSoil science

The invention relates to a soil modifier for earth pressure balance shield. The soil modifier is a foaming agent mixed from a foaming agent, a foam stabilizing agent and water. The foaming agent comprises of sodium alkyl sulfate, alkylbenzene sulfonate, alpha-alkenyl sodium sulfonate and fatty alcohol-polyoxyethylene ether. Each group is in the following weight percentage: 1-13% of sodium alkyl sulfate, 0.3-18% of alkylbenzene sulfonate, 0.5-15% of alpha-alkenyl sodium sulfonate, 0.5-3% of fatty alcohol-polyoxyethylene ether, 0.1-2% of foam stabilizing agent and the balance of water. The soil modifier can be used for earth pressure balance shield construction, has good stabilizing effect on excavation faces of different geological structures. Compared with other foaming agents, the soil modifier has higher foaming expansion rate and better stability, and can better improve the plastic flow property and permeability of soil body.

Owner:SHANGHAI SUNRISE POLYMER MATERIAL CO LTD

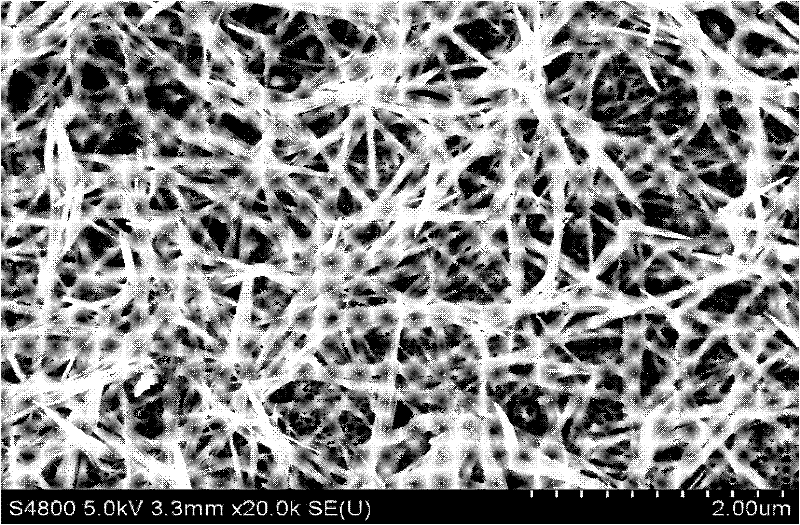

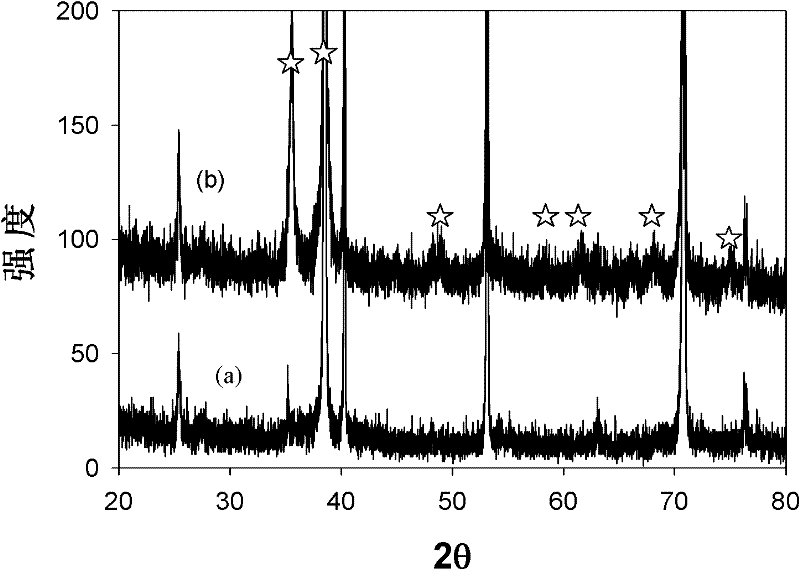

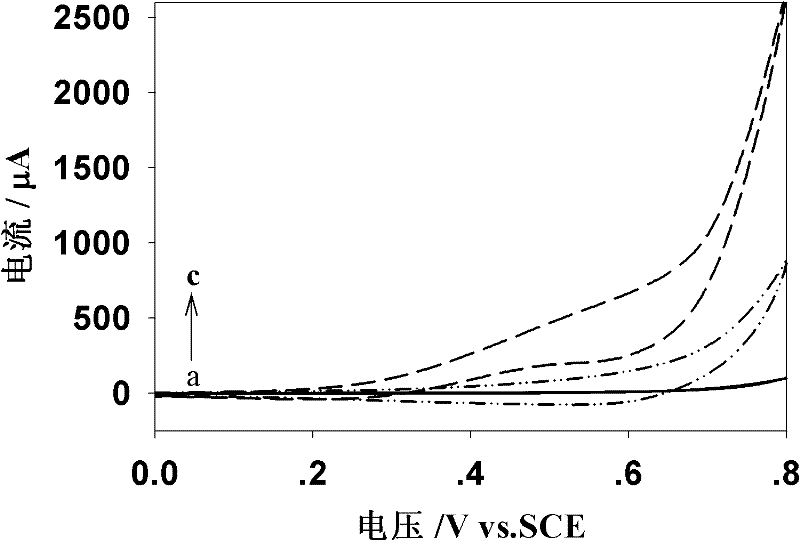

CuO/TiO2 nanotube array and preparation method and application method thereof

InactiveCN102249183ALarge specific surface areaAperture adjustableDecorative surface effectsNanotechnologyTio2 nanotubeHigh electron

The invention relates to a CuO / TiO2 nanotube array and a preparation method and an application method thereof. The preparation method comprises the following steps of: depositing elementary Cu nanoparticles on a TiO2 nanotube array in a standard three-electrode system by using aqueous solution containing 0.005 to 2mol / L CuSO4.5H2O as plating solution; putting the CuO / TiO2 nanotube array into mixed solution of 0.25 to 0.5mol / L NaOH, 5 to 15mmol / L K2S2O8 and 10 to 25mmol / L sodium lauryl sulfate, and oxidizing; and calcining the modified TiO2 nanotube array under the aerobic condition. The CuO / TiO2 nanomaterial with a novel structure has high specific surface area, a high electron transport rate, and a wide application prospect in the aspects of solar cells, photocatalysts, sensors and the like.

Owner:HUNAN UNIV

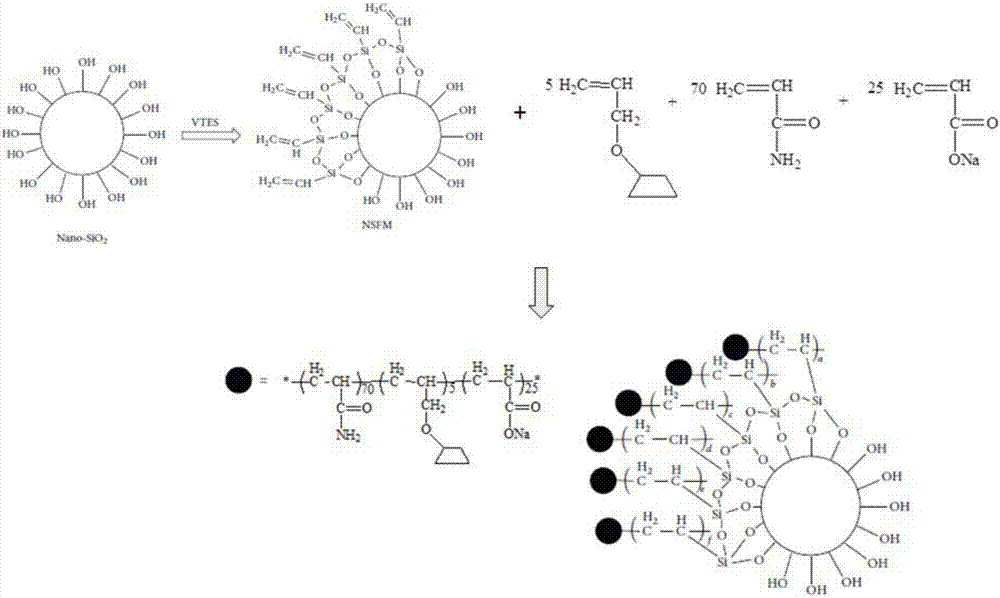

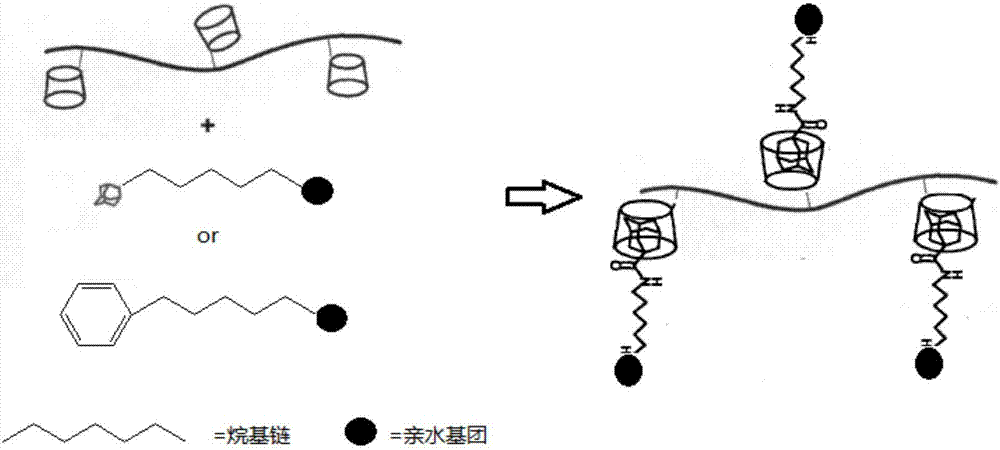

Polymer system in controllable association strength

The invention discloses a polymer system in controllable association strength. The polymer system comprises a subject cyclodextrin polymer and an object surfactant; the subject cyclodextrin polymer is selected from linear cyclodextrin polymer and modified Nano-SiO2 star-shaped macromolecule cyclodextrin polymer; the object surfactant is selected from adamantine-sodium octadecyl sulfate, adamantine-lauryl sodium sulfate, adamantine-cetyl sodium sulfate, benzyl-sodium octadecyl sulfate, benzyl-lauryl sodium sulfate and benzyl-cetyl sodium sulfate. In an application, the cyclodextrin polymer is prepared into an aqueous solution in the concentration of 0.1-0.5g / ml and then is mixed with the surfactant, the cyclodextrin advantage is utilized to wrap adamantine or benzene ring while the alkyl hydrophobic chain is exposed on the exterior of the cyclodextrin hydrophobic chamber, so that the polymer system in controllable association strength can be realized, the system viscosity is changed and the purpose of dynamically regulating the system viscosity can be achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

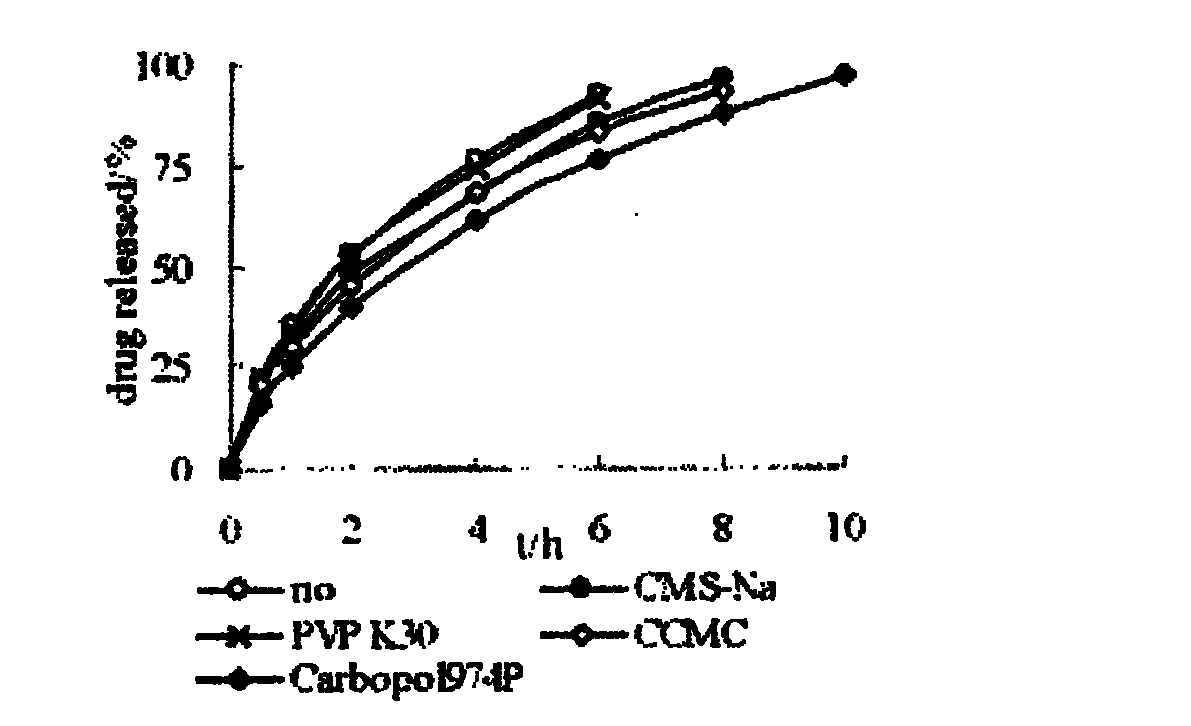

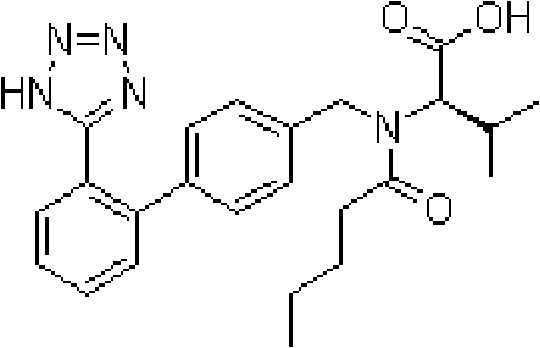

A kind of valsartan capsule and preparation method thereof

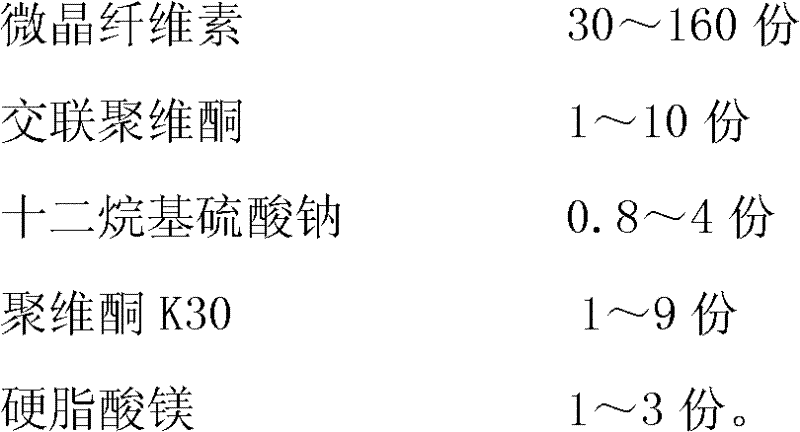

The invention relates to valsartan capsules and a preparation method thereof. The valsartan capsules comprise the following components in parts by weight: valsartan 50-200 parts, microcrystalline cellulose 30-160 parts, crosslinked povidone 1-10 parts, sodium dodecyl sulfate 0.8-4 parts, povidone K30 1-9 parts, and magnesium stearate 1-3 parts. The valsartan capsules provided by the invention canbe used for treating mild and moderate primary hypertension. The valsartan capsules have the advantages of reasonable formula, feasible process, stable and reliable quality, and good stability, dissolution and bioavailability. The valsartan capsules are prepared by using a wet granulation process, the addition method of solubilizer sodium dodecyl sulfate is proper, the concentration of the bonding agent is proper, and the granules have angle of repose smaller than 40 degrees, belong to powders with good fluidity and can meet the need of capsule filling. The valsartan capsules have short production process and low production costs, and are easy for industrial production.

Owner:HAINAN JINRUI PHARMA

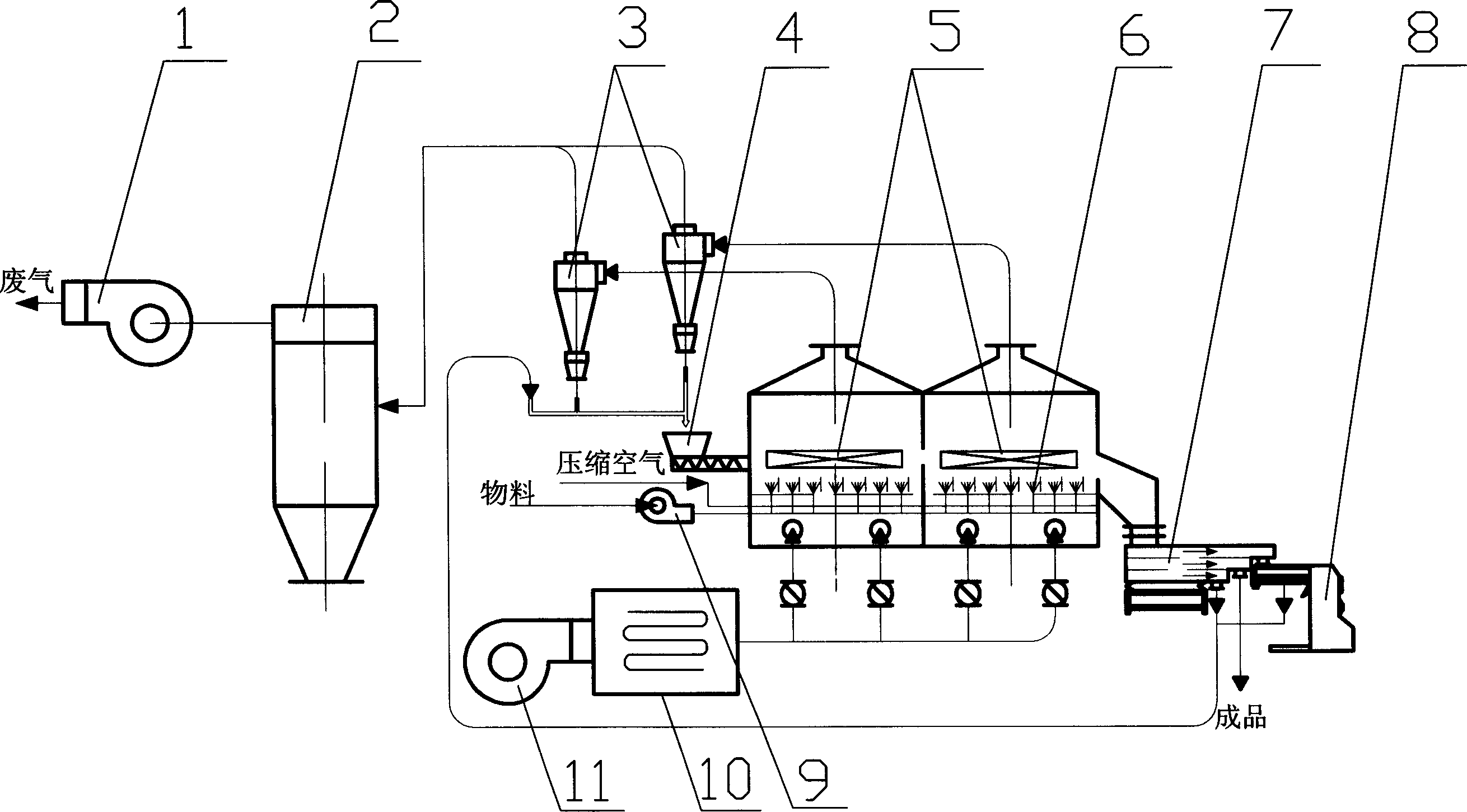

Production of granular dodecyl-sodium sulfate

ActiveCN1680303ARealize continuous productionProcess setting is reasonableSulfuric acid esters preparationFluidized bedEngineering

Production of particle lauryl sodium sulfate is carried out by delivering liquid or cream lauryl sodium sulfate feed liquid into atomizer in bottom of atomizing granulating fluidized bed by pressure pump, heating air by heat exchanger, entering into bottom of fluidized bed, contacting with material by distributing board on fluidized bed, fluidizing material, continuously atomizing feed liquid by atomizing nozzle of atomizer, coating onto fluidized particle surface, particle growing, contacting with hot air, drying, fluidizing, coating, drying, particle growing to required particle size, lowering temperature of discharging section, discharging from fluidized bed, screening, and packing. Its advantages include low cost, reasonable process, no environmental pollution, and good fluidity and dissolubility.

Owner:SINOLIGHT CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com