Production of granular dodecyl-sodium sulfate

A technology of sodium lauryl sulfate and production process, which is applied in sulfate preparation, organic chemistry and other directions, can solve problems such as damage to employee health, harsh operating environment, and difficulty in dissolving operations, so as to improve subsequent use conditions and reduce dust pollution. , The effect of the process setting is reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

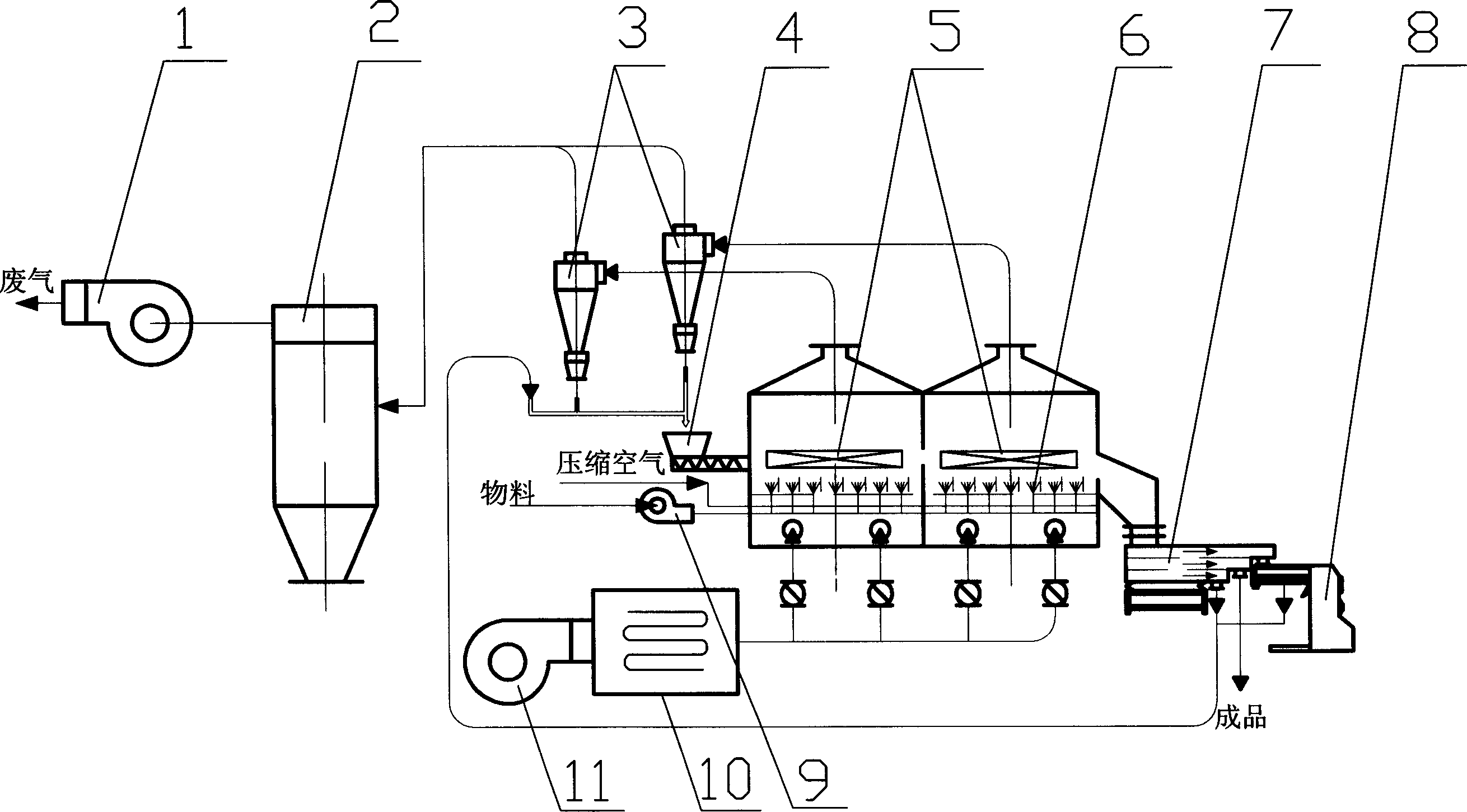

Method used

Image

Examples

Embodiment 1

[0019] Sodium lauryl sulfate slurry with a water content of 60% is 50Kg / hr for fluidized bed spray granulation, and the material is sent to the airflow atomizer with a pressure pump, and the air inlet temperature is controlled at 145°C, and the dryer temperature is 70°C , dried for two hours, and screened by a sieving machine, spherical sodium lauryl sulfate with a particle size of φ0.8-1.2mm can be obtained. The target product has a water content of 3%, and the active substance can be produced per hour. Spherical sodium lauryl sulfate product 16Kg, water evaporation is 29Kg / hr. The sieved fine powder is recovered by the cyclone separator and sent to the screw feeder, then added to the fluidized bed, and re-enters the fluidized bed as a seed crystal for spray granulation. After the coarse particles are sized by the granulator, the fine powder and fine particle material are returned to the screw feeder, and re-enter the fluidized bed as crystal seeds for spray granulation. Aft...

Embodiment 2

[0021] Sodium lauryl sulfate slurry with a moisture content of 70% is 50Kg / hr for fluidized bed spray granulation, and the material is sent to the air-flow atomizer with a pressure pump, and the air inlet temperature is controlled at 145°C, and the dryer temperature is 70°C After two hours of drying, spherical sodium lauryl sulfate with a particle size of φ0.8-1.2mm can be obtained. The target product has a water content of 3%, and spherical sodium lauryl sulfate with an active substance of 96% can be produced per hour. The sodium product is 12Kg, and the water evaporation is 35Kg / hr. The sieved fine powder is recovered by the cyclone separator and sent to the screw feeder, then added to the fluidized bed, and re-enters the fluidized bed as a seed crystal for spray granulation. After the coarse particles are sized by the granulator, the fine powder and fine particle material are returned to the screw feeder, and re-enter the fluidized bed as crystal seeds for spray granulation...

Embodiment 3

[0023] Sodium lauryl sulfate slurry with a water content of 60% is 40Kg / hr for fluidized bed spray granulation, and the material is sent to the air-flow atomizer with a pressure pump, and the temperature of the air inlet is controlled at 120°C, and the temperature of the dryer is 60°C After two hours of drying, spherical sodium lauryl sulfate with a particle size of φ0.8-1.2mm can be obtained. The target product has a water content of 3%, and spherical sodium lauryl sulfate with an active substance of 96% can be produced per hour. The sodium product is 13Kg, and the water evaporation is 24Kg / hr. The sieved fine powder is recovered by the cyclone separator and sent to the screw feeder, then added to the fluidized bed, and re-enters the fluidized bed as a seed crystal for spray granulation. After the coarse particles are sized by the granulator, the fine powder and fine particle material are returned to the screw feeder, and re-enter the fluidized bed as crystal seeds for spray ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com