Patents

Literature

40results about How to "Process setting is reasonable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultrasonic process of preparing theasaponin

The present invention is ultrasonic process of preparing theasaponin and belongs to the field of agricultural side product processing technology. The technological scheme is that tea seed cake residue after extracting oil is processed through crushing, mixing with organic solvent, ultrasonic leaching, separating, recovering solvent, ultrafiltering to purify and to obtain theasaponin concentrate, decolorizing and drying to obtain theasaponin product. The present invention has the beneficial effects of physical extraction process caused high theasaponin extracting rate, high product purity and quality, simple technological process with low power consumption and low production cost, less pollution, etc.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

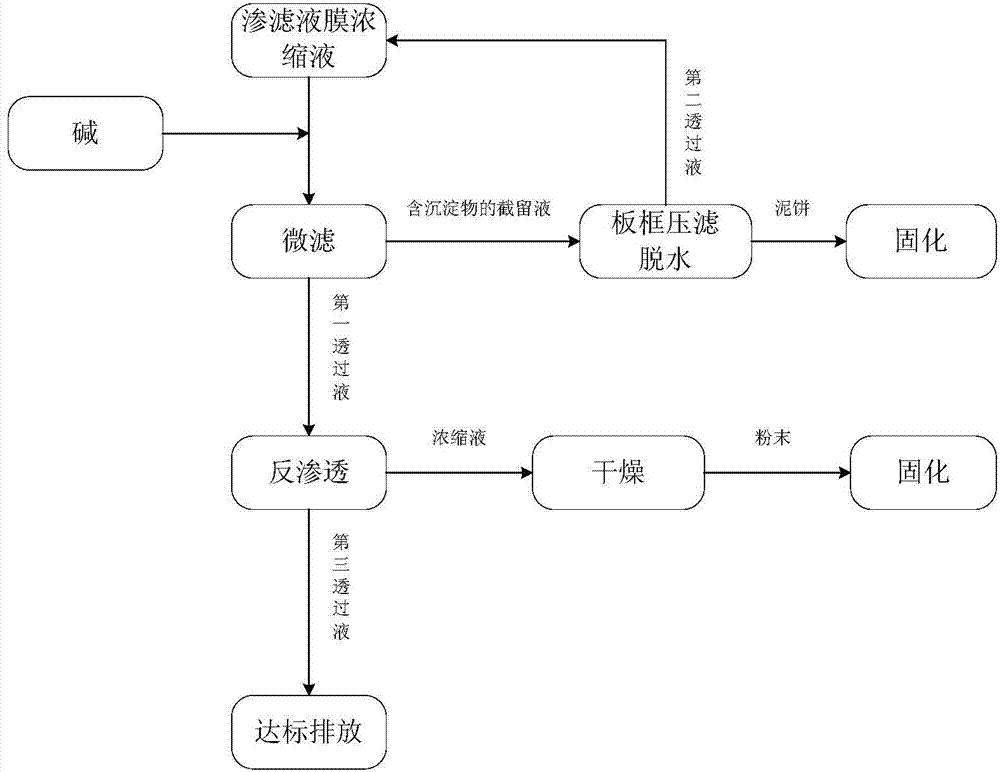

Method for processing percolate membrane treatment concentrated solution of refuse landfill

ActiveCN103570157AReduce hardnessSimple processSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentSludgeReverse osmosis

The invention discloses a method for processing a percolate membrane treatment concentrated solution of a refuse landfill. The method comprises steps of adding an alkali into the percolate membrane treatment concentrated solution of a refuse landfill, and reacting to obtain a mixed liquor containing precipitate; micro-filtering the mixed liquor to obtain a first permeating liquor and a closure liquor; press-filtering for dehydrating the closure liquor through a plate frame so as to obtain a second permeating liquor and mud cakes, returning the second permeating liquor to the alkali adding step for recycling, and solidifying the mud cakes; adding an acid into the first permeating liquor, regulating the pH to be 6-9, and then concentrating the first permeating liquor through reverse osmosis to obtain a third permeating liquor and a concentrated liquor; discharging the third permeating liquor directly, and drying and solidifying the concentrated liquor. The method is simple, can improve the recovery rate of the percolate membrane treatment concentrated solution, and reduces damage to the reverse osmosis membranes; the quality of the effluent is stable and reaches the standard.

Owner:浙江博世华环保科技有限公司 +1

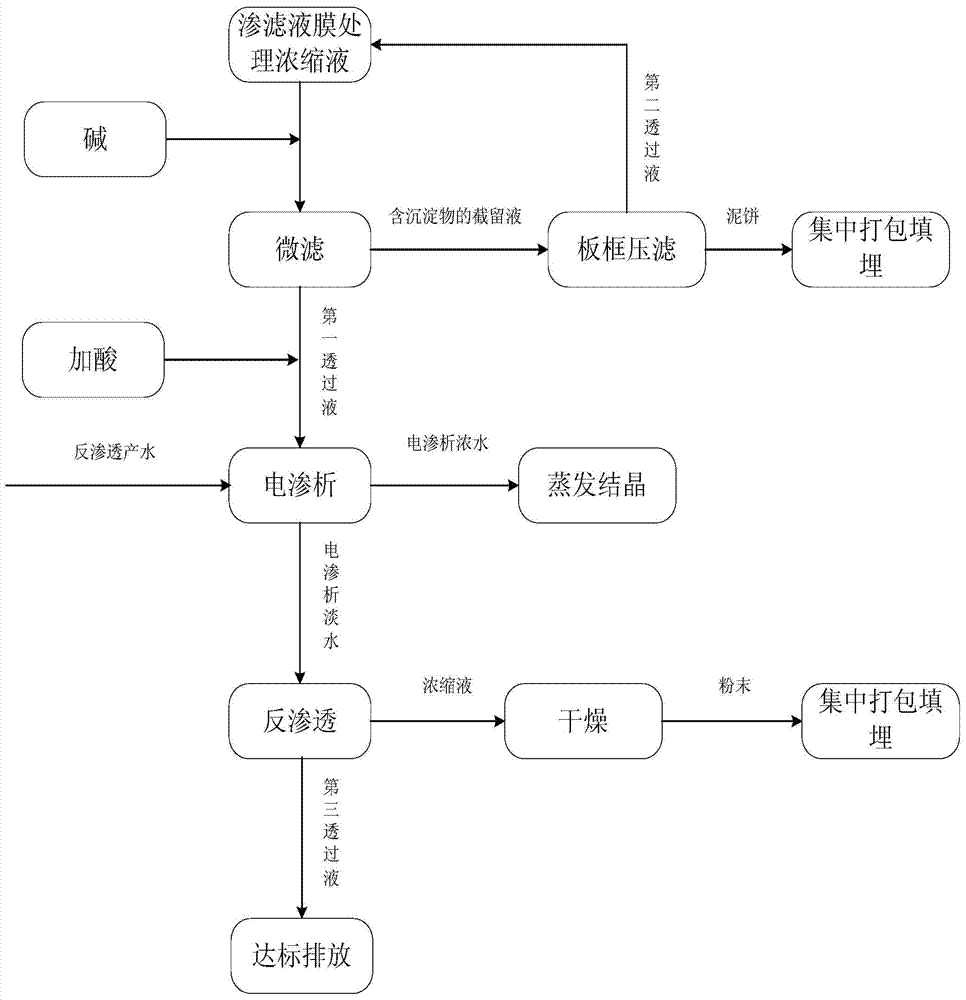

Method for processing percolate membrane treatment concentrated solution of waste incineration plant

ActiveCN103570175AReduce hardnessReduce contentDispersed particle separationWater/sewage treatment bu osmosis/dialysisReverse osmosisFresh water

The invention discloses a method for processing a percolate membrane treatment concentrated solution of a waste incineration plant. The method comprises steps of adding an alkali into the percolate membrane treatment concentrated solution of the waste incineration plant, and reacting to obtain a mixed liquor containing precipitate; micro-filtering the mixed liquor to obtain a first permeating liquor and a closure liquor; press-filtering for dehydrating the closure liquor through a plate frame to obtain a second permeating liquor and mud cakes, returning the second permeating liquor to the alkali adding step for recycling, and solidifying the mud cakes; adding an acid into the first permeating liquor, regulating pH to be 6-9, and then desalting the first permeating liquor through electrodialysis to obtain electrodialysis fresh water and electrodialysis thick water; carrying out evaporative crystallizing on the electrodialysis thick water, and concentrating the electrodialysis fresh water through reverse osmosis to obtain a third permeating liquor and a concentrated liquor; directly discharging the third permeating liquor, and drying and solidifying the concentrated liquor. The method is simple, has good processing effect, and high recovery rate of the percolate membrane concentrated solution of the waste.

Owner:浙江博世华环保科技有限公司 +1

High efficiency continuously producing method for natto functional active components

The invention relates to a method in producing functional active constituent contained in natto. Said method for effective continuous production of functional active constituent in natto is characterized by consisting of steps as follows: 1) fermenting : take weighted bean to be immersed, sterilizing at high temperature and receive natto bacterial strain to be put in the incubator at constant temperature of 35-40deg.C to ferment and cultivate for 20-24 hours; 2) grinding ;3)leaching: adopting means of mixing or ultrasonic; 4) centrifugal separation : the fermented liquid that has been processed by ultrasonic to be cooled for the centrifugal, after said centrifugal the clear liquid to be filtered through filter of 0.22-0.45mum and get extracting solution of functional active constituent from natto; 5)ultrafiltration: to ultrafiltrate said extracting solution and get different component such as natto kinase, poly glutamic acid and natto peptide; 6) drying: to get said product after been ultrafiltrated and through spray drying .

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

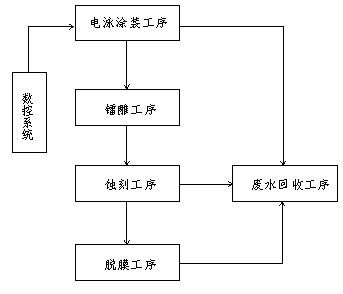

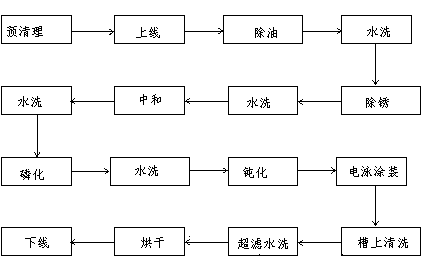

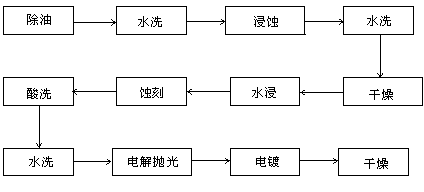

A novel etching process for coating and etching a metal workpiece

InactiveCN104342709AResidue reductionProcess setting is reasonableElectrophoretic coatingsLaser beam welding apparatusLaser etchingElectrophoresis

A novel etching process for coating and etching a metal workpiece relates to the etching of a metal part. The process comprises an electrophoretic coating procedure for coating an electrical part, a laser etching procedure for carving the electrical part, an etching procedure for graphic processing of the coating of the electrical part, and a film removing procedure for removing the coating of the electrical part. The process further comprises a wastewater recycling procedure for recycling wastewater generated in the electrophoretic coating procedure, the etching procedure, and the film removing procedure. The above described electrophoretic coating procedure is connected with and is automatically controlled by a numerical control system. The novel etching process has beneficial effects that the process setup is reasonable, multiple times of washing reduce solution residual in different procedures, the resulting product has no out-of-shape decoration and has high precision.

Owner:天津祥和兴金属制品有限公司

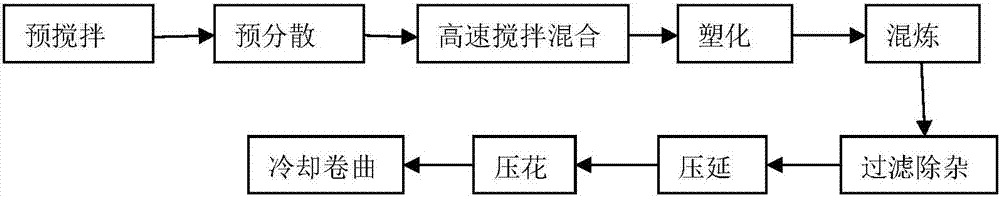

Preparation method of PVC (Polyvinyl Chloride) film for flex banner

The invention discloses a preparation method of a PVC film for light box cloth, wherein the PVC film comprises the following raw materials in parts by weight: 60-80 parts of polyvinyl chloride resin, 40-60 parts of active nano-calcium carbonate, 8-12 parts of talcum powder, 25-40 parts of plasticizer, 3-6 parts of epoxidized soybean oil, 3-5 parts of stabilizer, 1-3 parts of active additive, 5-8 parts of auxiliary agent, 2-4 parts of coloring material, the preparation method of PVC film It includes the following steps: pre-stirring, pre-dispersing, high-speed stirring and mixing, plasticizing, kneading, filtering to remove impurities, calendering, embossing and cooling and curling. The product obtained in the present invention has high structural strength, uniform color and good tensile strength High performance, anti-fouling performance and anti-aging performance are conducive to industrial production and application.

Owner:浙江铭龙新材料科技有限公司

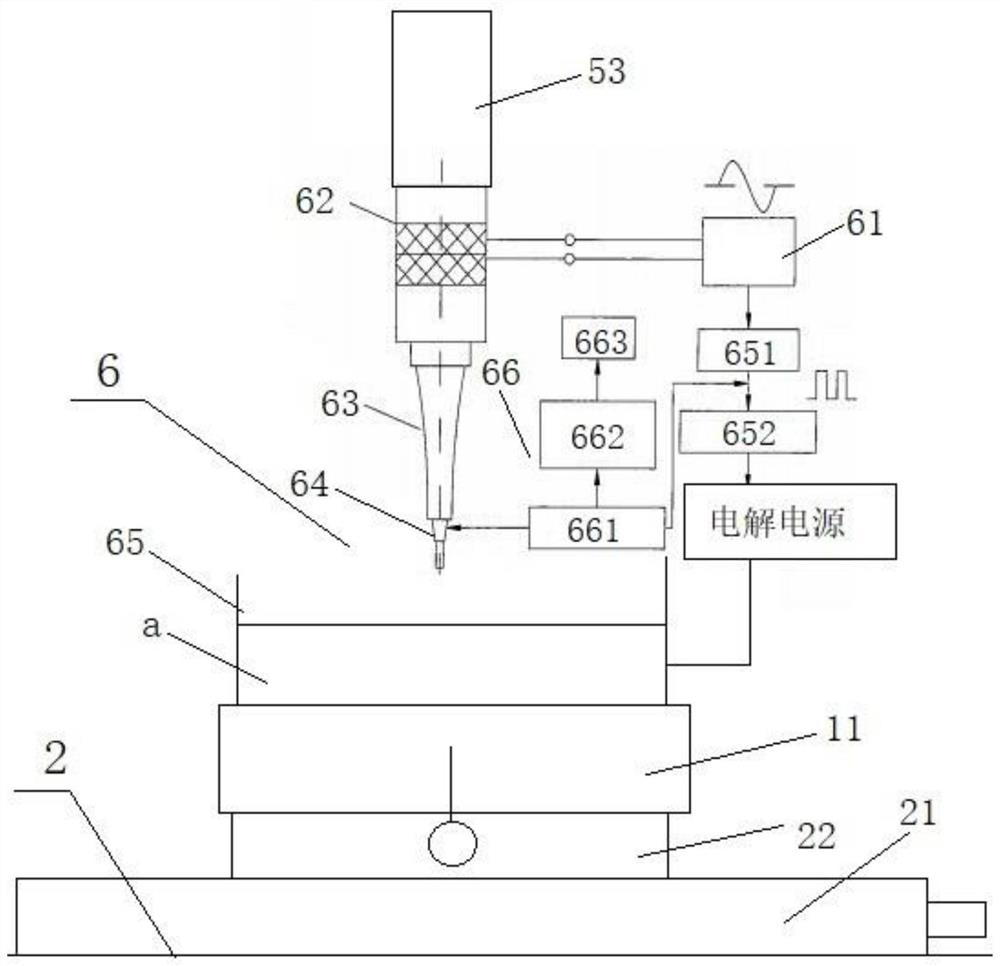

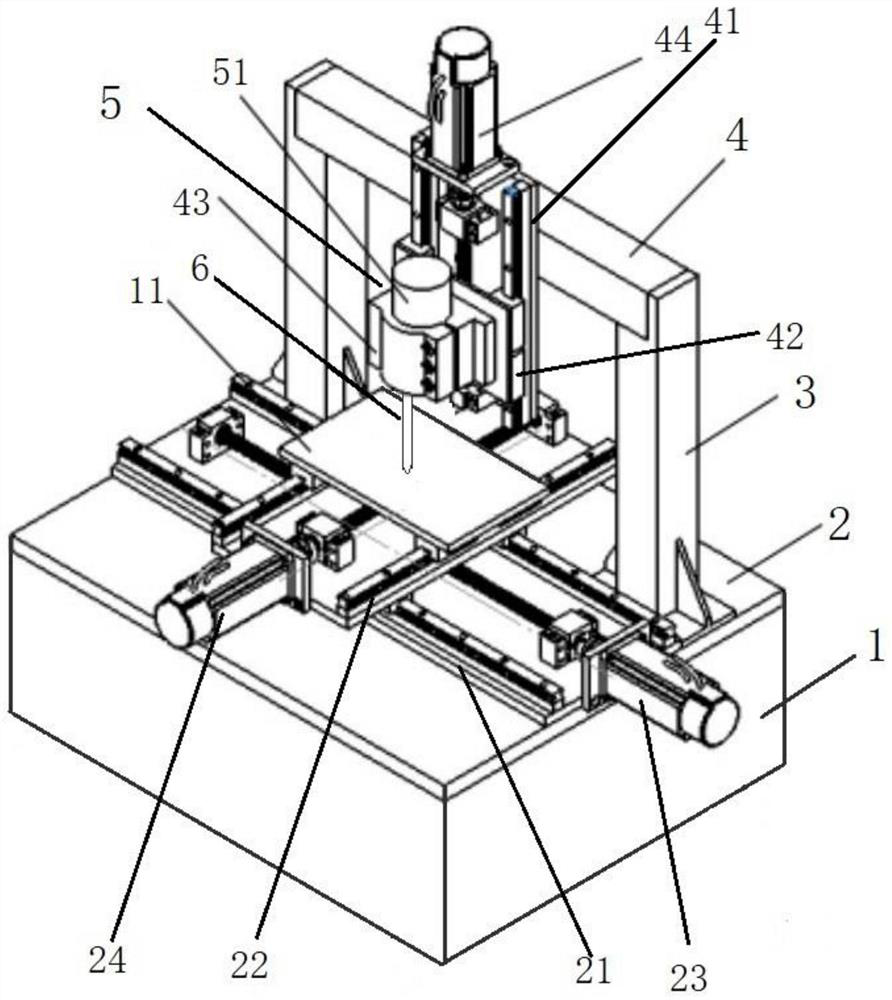

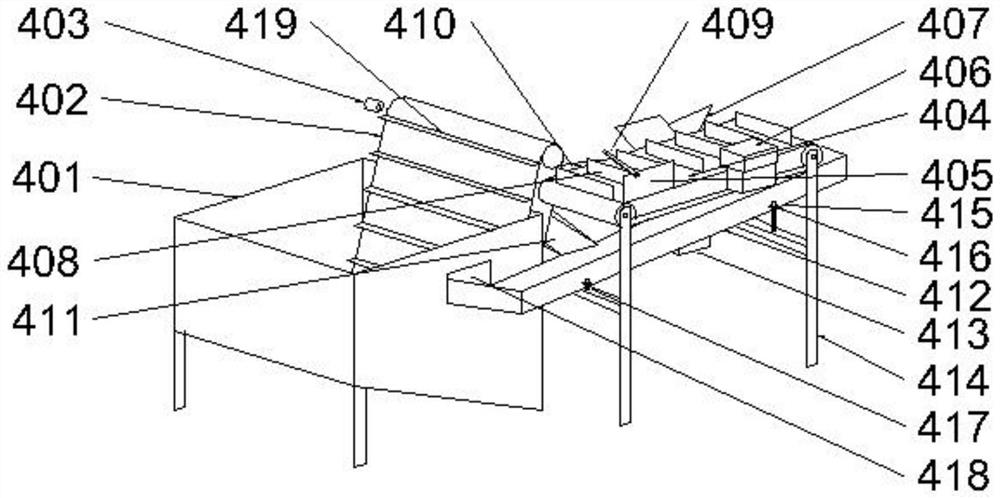

Efficient precision machining process for showing stand

InactiveCN112775623AIncrease flexibilityImprove processing efficiencyShow shelvesShow hangersUltrasonic vibrationMachining process

An efficient precision machining process for a showing stand comprises the following steps that (1) correction is conducted, specifically, a showing stand blank is measured through a height gauge, and the showing stand blank which does not meet the requirement is corrected through a tool; (2) a reference surface is milled, specifically, the reference surface of the showing stand blank is milled by adopting precision machining equipment, the precision machining equipment comprises a rack, a bottom plate, gantry stand columns, a gantry cross beam, a main shaft mechanism and an ultrasonic vibration machining mechanism; (3) a vertical machining center is used for machining; (4) drilling is conducted; (5) correction is conducted; and (6) surface treatment is conducted, specifically, the surface of the corrected showing stand blank is sprayed, and the showing stand is obtained. The efficient precision machining process for the showing stand is reasonable in process setting, simple, controllable, high in flexibility and machining efficiency, high in machining precision, capable of being used for large-scale production, good in economical efficiency and wide in application prospect.

Owner:TAICANG U UP DISPLAY FIXTURES CO LTD

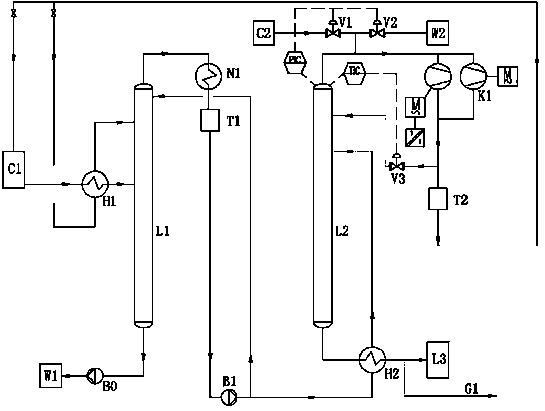

Low temperature removal method for COS with relatively high concentration in gas

InactiveCN106975340ALow running costSolve the problems existing in desulfurizationGas treatmentDispersed particle separationHigh concentrationSulfur

The invention provides a low temperature removal method for COS with a relatively high concentration in gas. The low temperature removal method mainly comprises the following steps: process gas is maintained or heated to 30-80 DEG C and is introduced into hydrolysis desulfuration towers to be treated; the hydrolysis desulfuration towers are filled with a COS hydrolysis agent and an H2S oxidation desulfuration agent in a stacking or laminating manner; the H2S oxidation desulfuration agent can be subjected to sulfur-blowing thermal regeneration at 200-300 DEG C, and the performance of the COS hydrolysis agent is less or barely reduced after a thermal regeneration process; two or more hydrolysis desulfuration towers are arranged, can be connected in series or parallel for use and comprise vertical heating sleeves, and hydrolysis agent-desulfuration agent bed layers are arranged among the sleeves; and captured elemental sulfur is melted, gasified and blown out by the hydrolysis desulfuration towers during the thermal regeneration at 200-300 DEG C and is collected as sulfur by virtue of a regeneration condenser. The low temperature removal method has the beneficial effects that the desulfuration process is simple and reliable, the COS removal rate is easily maintained above 90% or even above 95%, the control is easy, the elasticity of processing quantity is high, and the method has strong adaptability to the degrees and fluctuation of contents of H2S and COS, and is safe and environment-friendly and low in operation cost.

Owner:淄博赢信达知识产权咨询服务有限公司

Danger removing and strengthening seepage control method for barrier lake natural rock-fill dam

ActiveCN111119128AImprove anti-seepage effectImprove stabilityFoundation engineeringEarth-fill damsLandslide damSlurry

The invention belongs to the technical field of seepage control in hydraulic engineering, and particularly relates to a danger removing and strengthening seepage control method for a barrier lake natural rock-fill dam. The method comprises the steps of pouring a concrete cap weight layer of the rock-fill dam; installing a borehole orifice-pipe; performing boring construction; and performing grouting construction. According to the danger removing and strengthening seepage control method for the barrier lake natural rock-fill dam, consistence of grouting slurry is adjusted at any time during thegrouting construction, so that a better seepage control effect can be achieved and stability is improved; the pipe fixation problem is solved by an employed small diameter boring and grouting technology; and construction cost is effectively reduced by the employed grouting slurry material.

Owner:CHINA HYDROPOWER ELEVENTH ENG BUREAU ZHENGZHOU CO LTD +1

Preparation method of antibacterial waterproofing moisture-permeable polyurethane thin film

InactiveCN109280366AGood broad-spectrum antibacterial propertiesImprove mechanical propertiesComposite filmMoisture

The invention discloses a preparation method of an antibacterial waterproofing moisture-permeable polyurethane thin film. The method includes: 1) preparing a modified composition; 2) performing surface modification on antibacterial composite filler; 3) preparing antibacterial enhancing modified polyurethane resin; 4) preparing the polyurethane composite thin film. In the invention, molybdenum tailings, bamboo charcoal powder and nano TiO2 are subjected to the surface modification and then are added to the waterborne polyurethane resin during synthesis, thus preparing the inherent-antibacterialenhanced polyurethane resin; then the polyurethane resin is physically blended with a beta-cyclodextrin / tetrahydrofuran composite in the presence of nano silver antibacterial solution to prepare thethin film. The composite thin film has excellent broad-spectrum antibacterial property, mechanical performance, water resistance and breathability and waterproofing function, is excellent in comprehensive performance and has extensive market prospect.

Owner:JIANGSU HONGYUAN NEW MATERIAL TECH

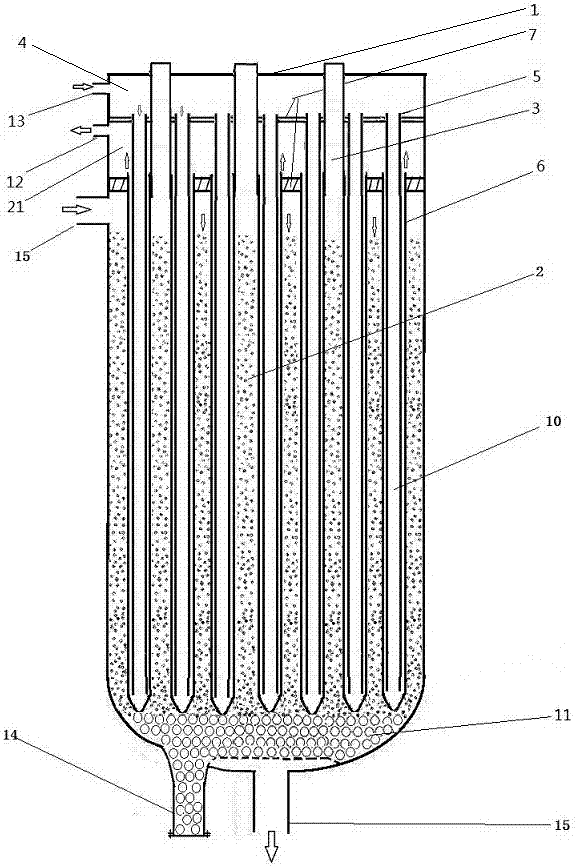

Ship flue gas desulfurization and denitration device and technology

PendingCN107583429AEfficient removalProcess setting is reasonableDispersed particle separationAir quality improvementEngineeringSmall footprint

The invention provides a ship flue gas desulfurization and denitration device and technology. The device provided by the invention comprises a spraying tower and a flue connected with the spraying tower, wherein the flue is provided with a flue gas inlet, an ozone injector and a first spraying nozzle in sequence along the movement direction of flue gas; a rectification porous plate, a second spraying nozzle, a third spraying nozzle, a flue gas cooler, a defogging layer and a gas outlet of the spraying tower are arranged in a main body space of the spraying tower in the axial direction along the movement direction of the flue gas; the bottom of the spraying tower is a reversed cone, and a wastewater outlet of the spraying tower is arranged at the center of the reversed cone. According to the device provided by the invention, an ozone oxidization technology and a spraying and absorption technology are combined to treat ship flue gas; low-valence nitrogen oxide and sulfur dioxide are oxidized by utilizing ozone, so that pollutants are efficiently removed by subsequent three times of circulating spraying and absorption. The technology is reasonable and the device occupies a small area;the ship flue gas desulfurization and denitration device and technology are very convenient in the aspect of construction or reconstruction on ships, and the construction cost is low.

Owner:GUANGDONG J TECH ENVIRONMENT SCI CO LTD

Ultrasonic process of preparing theasaponin

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

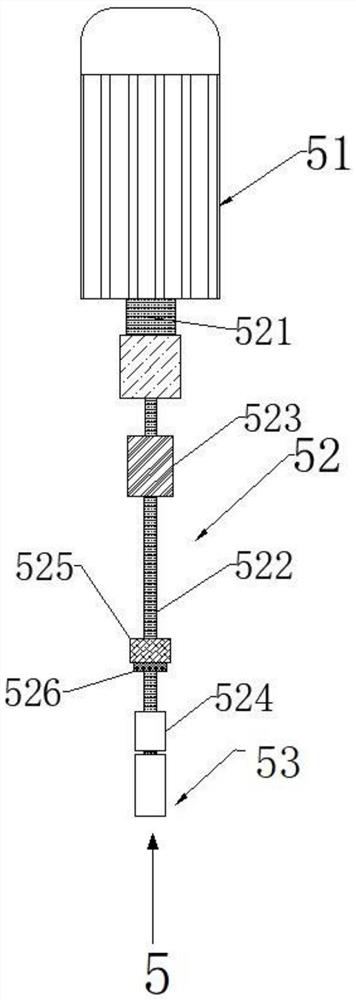

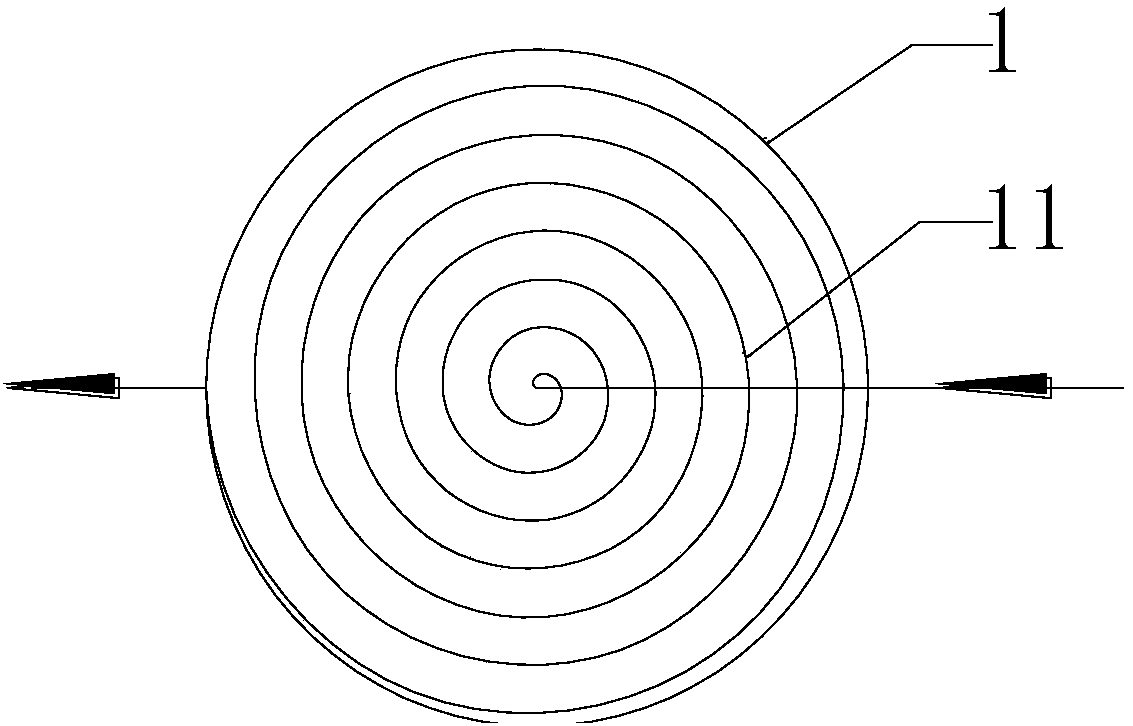

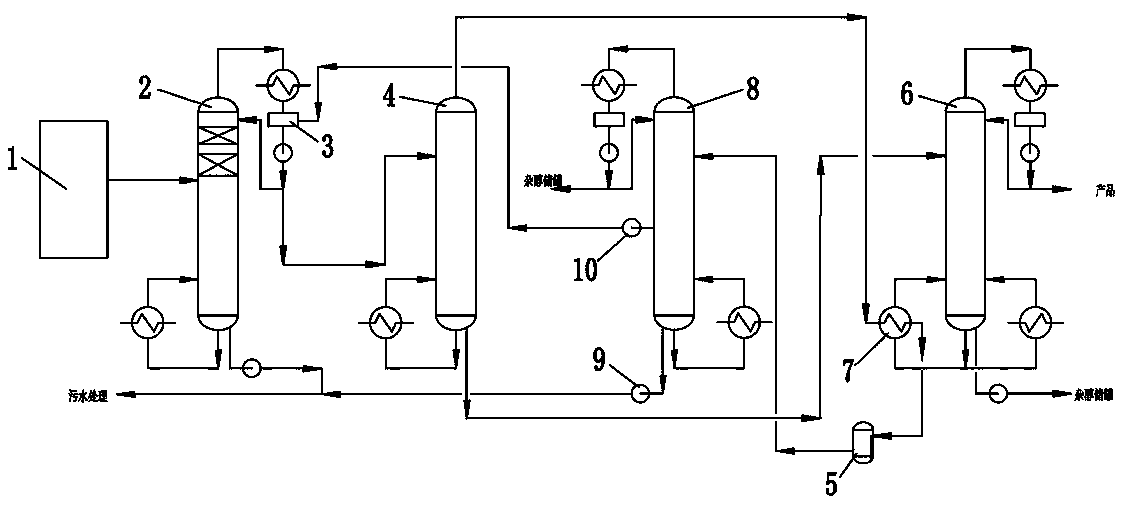

THF rectification equipment for PBT production

PendingCN110975316AHigh yieldTake advantage ofEnergy recuperation in distillationFractional distillationReboilerWastewater

The invention relates to THF rectification equipment for PBT production, which includes a first rectification column, a second rectification column, a third rectification column and a fourth rectification column. The first rectification column is connected to a THF wastewater device. A top outlet of the first rectification column is connected to the middle upper part of the second rectification column. A gas phase outlet of the second rectification column is connected to an auxiliary reboiler shell inlet of the third rectification column. An auxiliary reboiler shell outlet of the third rectification column is connected to a recovery liquid tank and the middle upper part of the fourth rectification column in order. A side-draw outlet of the fourth rectification column is connected to a reflux tank of the first column through a side-draw pump, and a bottom product of the fourth rectification column is combined with the product of the first rectification column and then conveyed to a sewage treatment system. The bottom of the second rectification column is connected to the third rectification column through a pipeline, a heavy component is discharged from the bottom of the third rectification column and a THF product is produced from the column top. The equipment can effectively improve the THF yield, reduce energy consumption and effectively save the operation cost.

Owner:查都(海南)科技有限公司

Two-stage citric acid fermentation process with whole wheat flour as raw material

InactiveCN1336438ASimple processProcess setting is reasonableFermentationTwo stage fermentationEnergy consumption

The two stage fermentation technology of citric acid using whole wheat flour as raw material is characterized in that whole wheat flour is directly mixed with water in wt. ratio of 1:5-1:8 to prepare paste, raise temp. to 85 deg.c, adding high temp. amylase, raising paste temp. to 90 deg.C until completely liquified; quick filtration to obtain liquified liquid, fill liquified liquid into fermentation tank, heat and sterilized, than quickly lower temp. to 35 deg.C, inocculate first stage culture into fermentation tank and ferment until fermentation is complete. Advantages include: simple and ratioal technology, low cost on raw material, equipment and energy consumption, can raise saccharification rate of row material and fermentation conversion rate etc.

Owner:ANHUI HUAYUAN BIOLOGICAL PHARMA IND

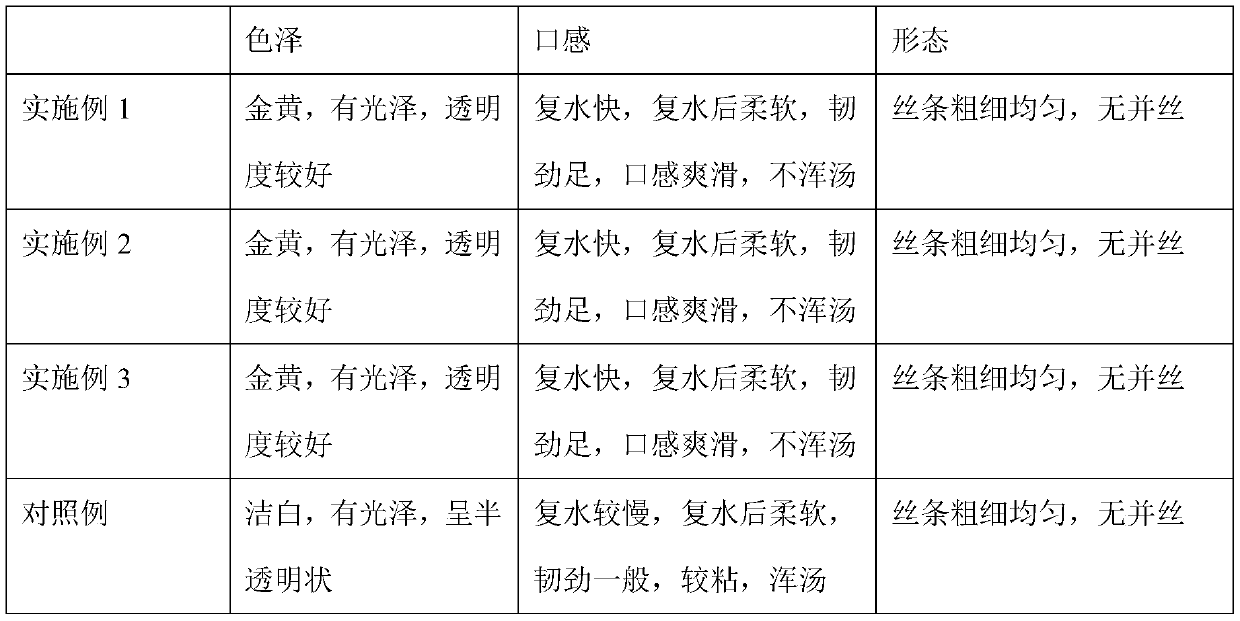

Pumpkin vermicelli and preparation method thereof

InactiveCN110367519AHigh in proteinNutritious and comprehensiveFood ingredientsPotato starchWheat gluten

The invention provides pumpkin vermicelli which is prepared from mixed starch, soybean, pumpkin and auxiliary materials. The auxiliary materials include glutamine transaminase accounting for 0.05-0.1%of mass of the soybean, and the mixed starch comprises one or multiple of sweet potato starch, potato starch, cassava starch, pea starch, corn starch and other similar starch and further comprises wheat gluten accounting for 0.1-10% of mass of the mixed starch. The pumpkin vermicelli prepared by the method is high in protein content, balanced in nutrient, golden and attractive in color, chewy andsmooth in taste and quick in rehydration, and is ready for eating by only adding seasoning after being brewed in water of 85 DEG C, thereby being convenient and quick.

Owner:武冈市卤卤香食品有限责任公司

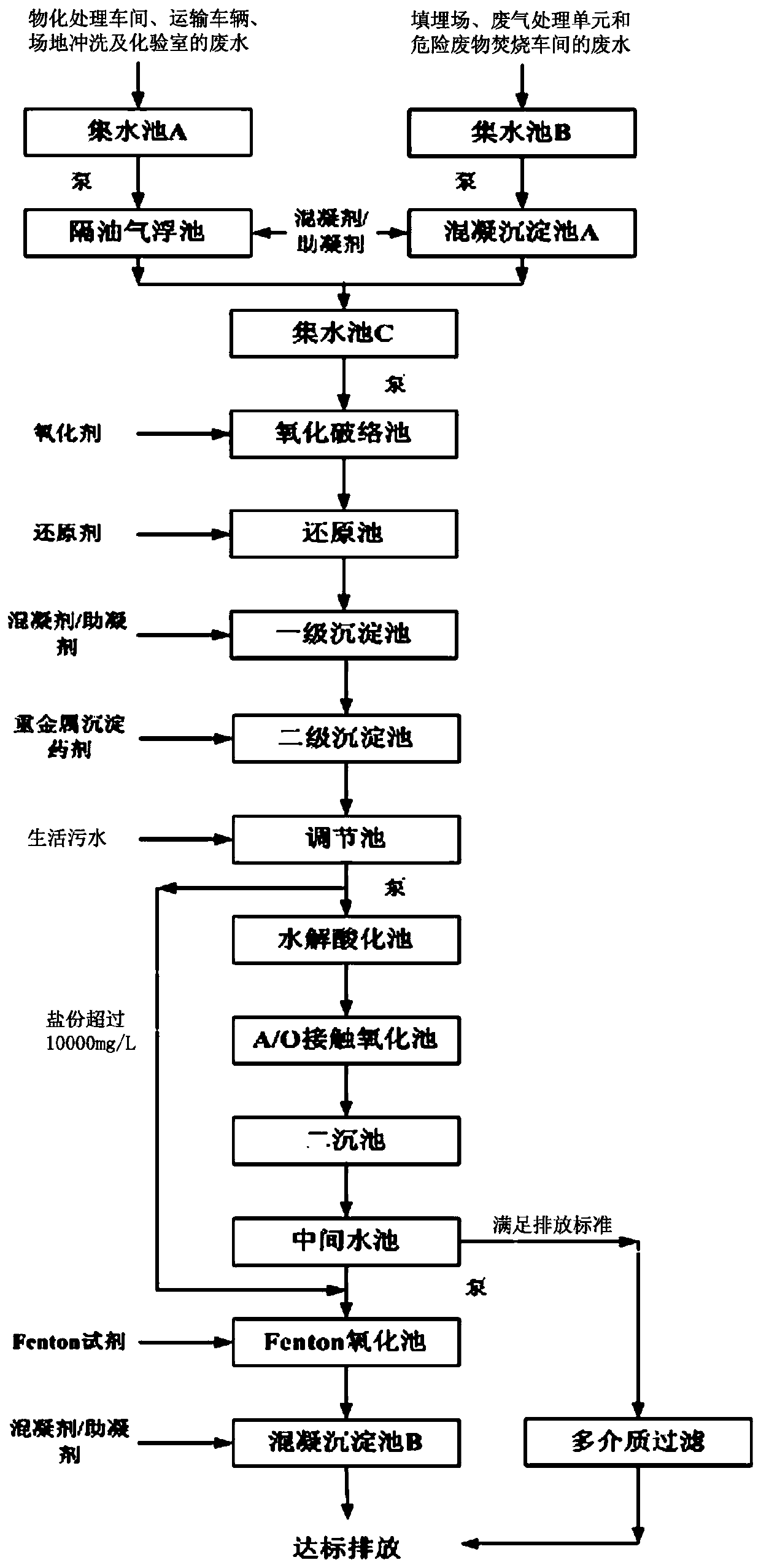

Method for treating wastewater from comprehensive disposal center for hazardous waste

InactiveCN110386718AGreat water qualityLarge changes in water volumeWater treatment compoundsWater contaminantsWastewaterHydrolysis

The invention discloses a method for treating wastewater from a comprehensive disposal center for hazardous waste. The method comprises the following steps: 1) classified collection and treatment according to different qualities; 2) oxidative decomplexation; 3) reduction of heavy metals; 4) two-stage precipitation; 5) hydrolysis acidification and A / O contact oxidation; and 6) Fenton oxidation andcoagulation sedimentation, thereby allowing effluent to reach the standard. The method of the invention realizes the maximal harmless treatment of the wastewater from the comprehensive disposal centerfor hazardous waste, has the advantages of strong adaptability, high reliability, small land occupation, economical rationality, etc., and is a good way for realizing efficient and low-carbon treatment and stable standard-reaching discharge of wastewater in the comprehensive disposal center for hazardous waste.

Owner:江苏省环境工程技术有限公司

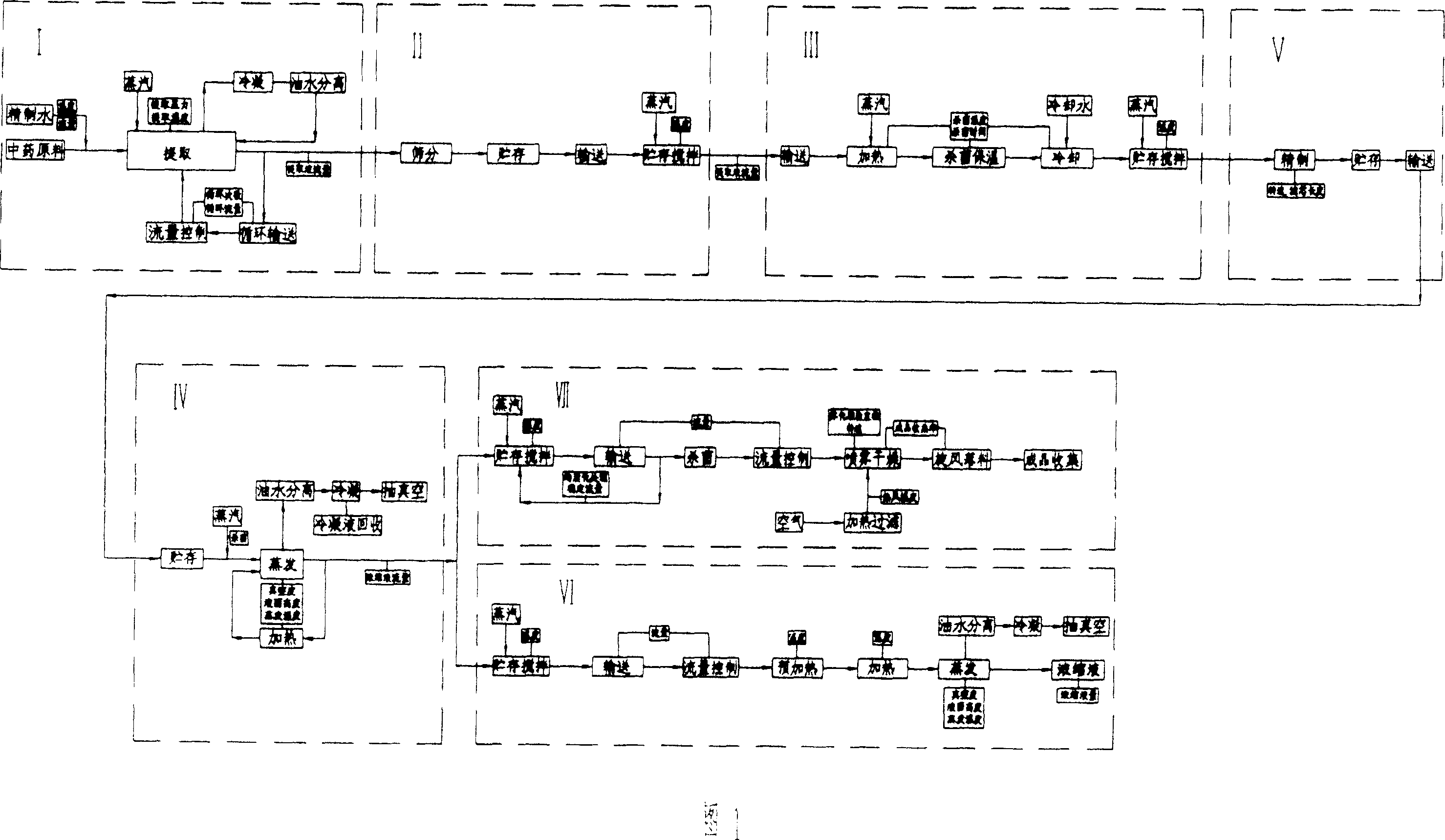

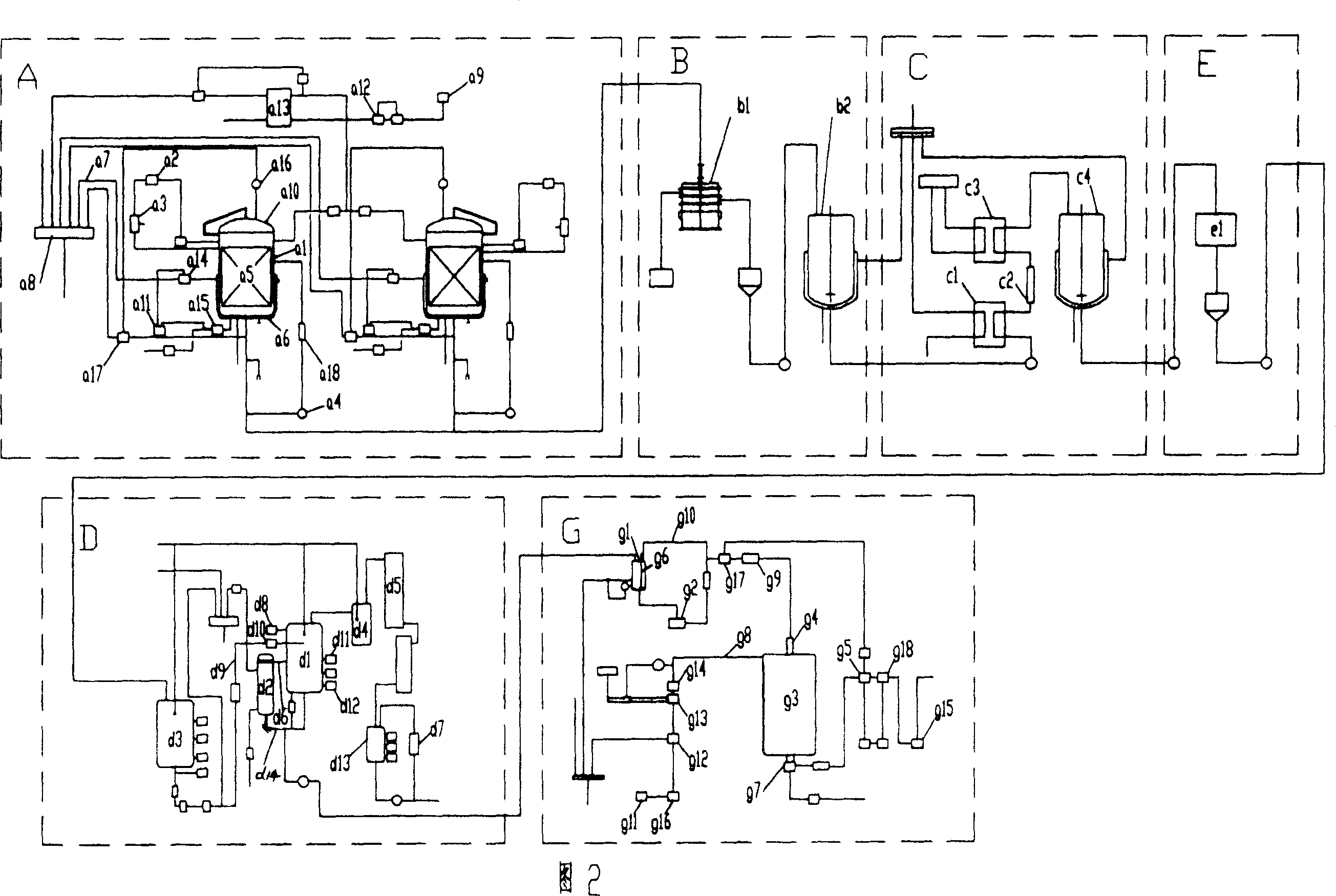

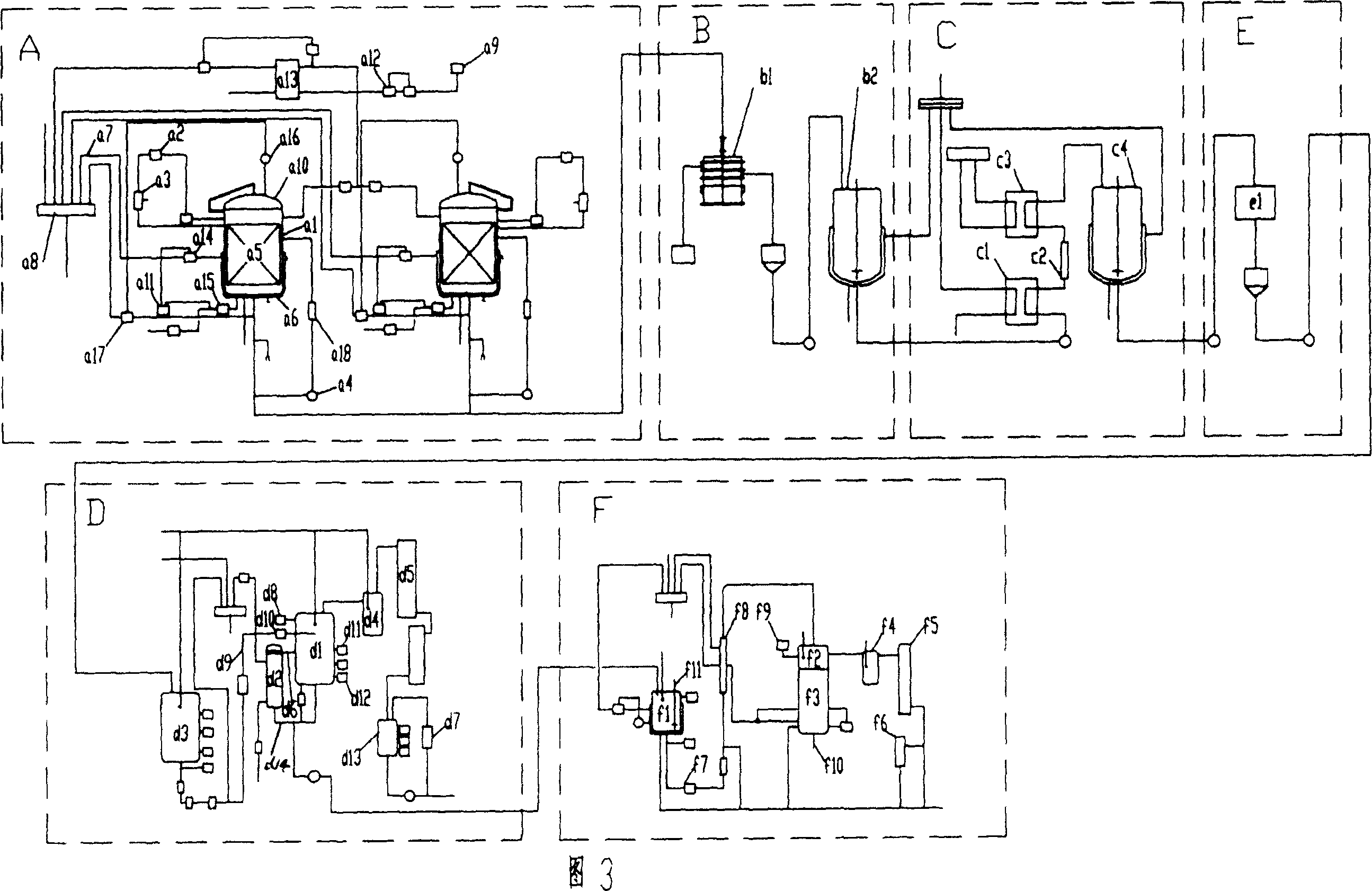

Chinese medicine preparation and set of apparatuses thereof

ActiveCN100342839CReduce heat gainSolve the blockageVapor condensationPharmaceutical product form changeProcess engineeringChinese drug

Owner:云南昆船电子设备有限公司

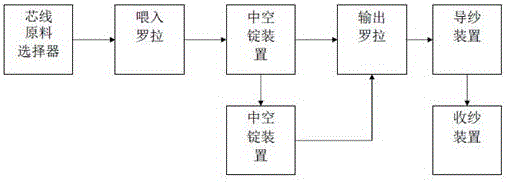

Production process of dot wrapped yarn

InactiveCN106120065AAdd automatic control systemProcess setting is reasonableDrafting machinesYarnYarnAutomatic control

The invention discloses a production process of a dot wrapped yarn. A driving way with combination of a stepping motor and a synchronous belt is adopted, a computer automatic control system is added, and the effects of freely adjusting the process and obtaining the wrapped yarn with any preset patterns are achieved by controlling the rotating speed of a hollow spindle and the speed of a roller. A traditional production process of a wrapped yarn is changed, the structure of the yarn is changed, the layering sense of the appearance effect of the yarn can be increased while the yield is ensured, and the effects of gradual change, multiple changes and dot forms are achieved.

Owner:JIANGSU HAITE GARMENTS CO LTD

Heat treatment process of electric power pole

InactiveCN107012300AReasonable collocationEfficient removalSolid state diffusion coatingFurnace typesElectric power systemElectric power

The invention relates to a heat treatment process of an electric power pole. The heat treatment process comprises the following steps of carrying out acid pickling and phosphating, water washing, grinding treatment, first heat treatment, first cooling, secondary heat treatment and secondary cooling on the electric power pole. The heat treatment process is reasonable in process, rigorous in parameter setting and high in product quality.

Owner:江苏银河钢杆有限公司

Electroplating energy-saving method

The invention belongs to the field of metal electroplating, and particularly relates to an electroplating energy-saving method. The electroplating energy-saving method comprises the following technological process of racking, cathode degreasing, anode degreasing, washing, washing, washing, activation, washing, washing, antipole operation, electroplating, recycling washing, recycling washing, washing, draining and taking down. According to the washing process, a circulating water treatment system is included, and recycling of water resources in the production process can be achieved; according to the electroplating process, an automatic dosing machine, a filtering machine, an electric control ampere meter and a temperature alarm device are added into the electroplating process. The time in the electroplating process is controlled to 30 minutes to 60 minutes. The electroplating energy-saving method has the beneficial effects of being reasonable in process setting and ideal in electroplating effect, achieving recycling and reutilizing of energy resources, saving production cost and reducing the pollution to the environment.

Owner:TIANJIN DAGANG GALVANIZED FACTORY

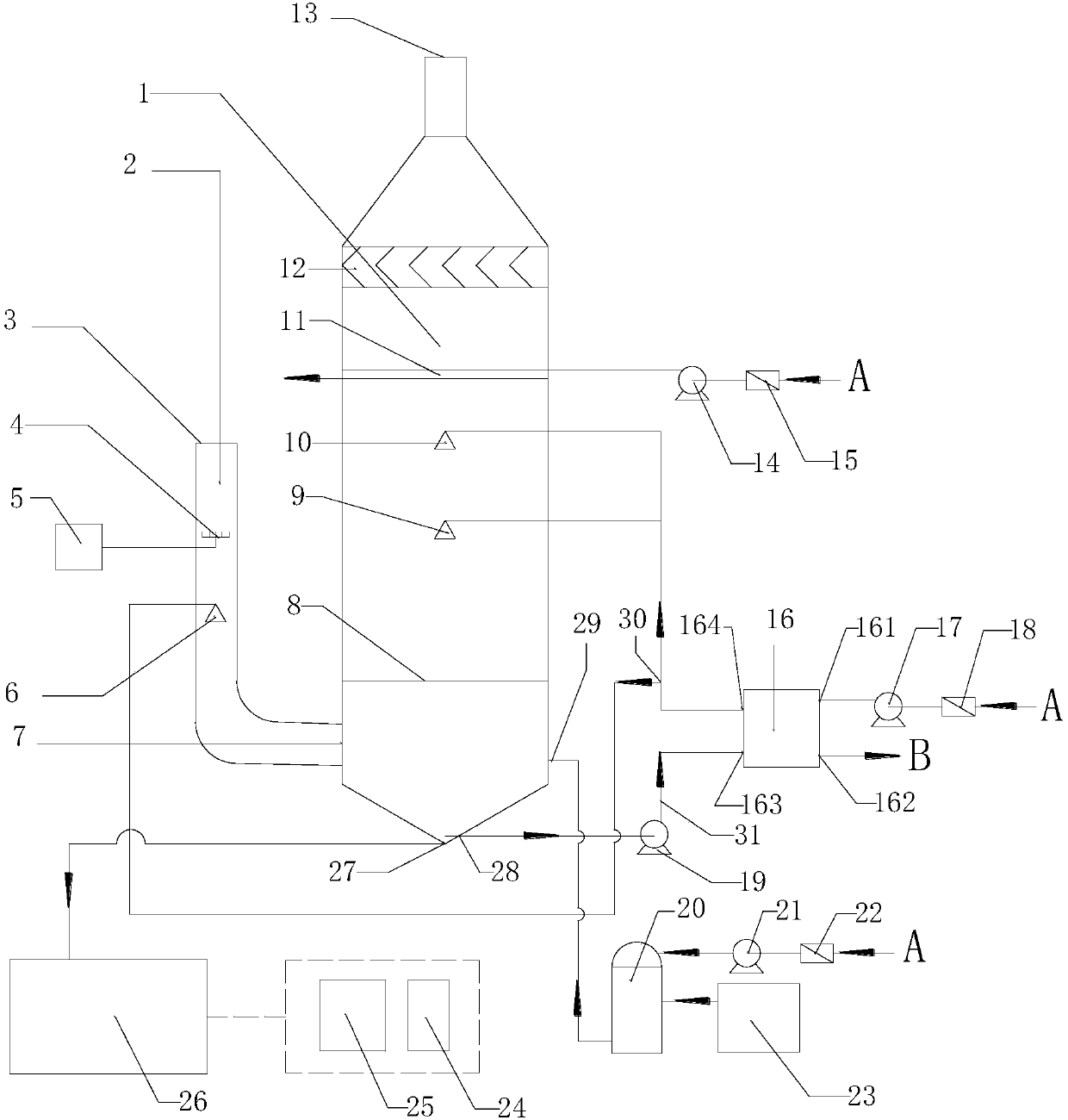

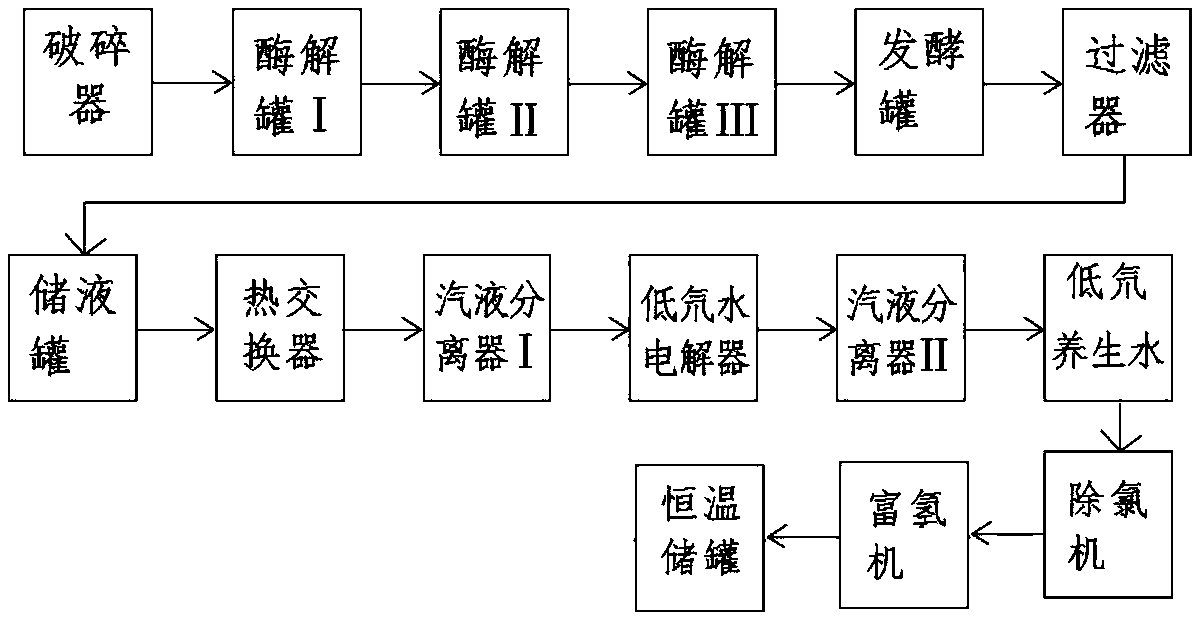

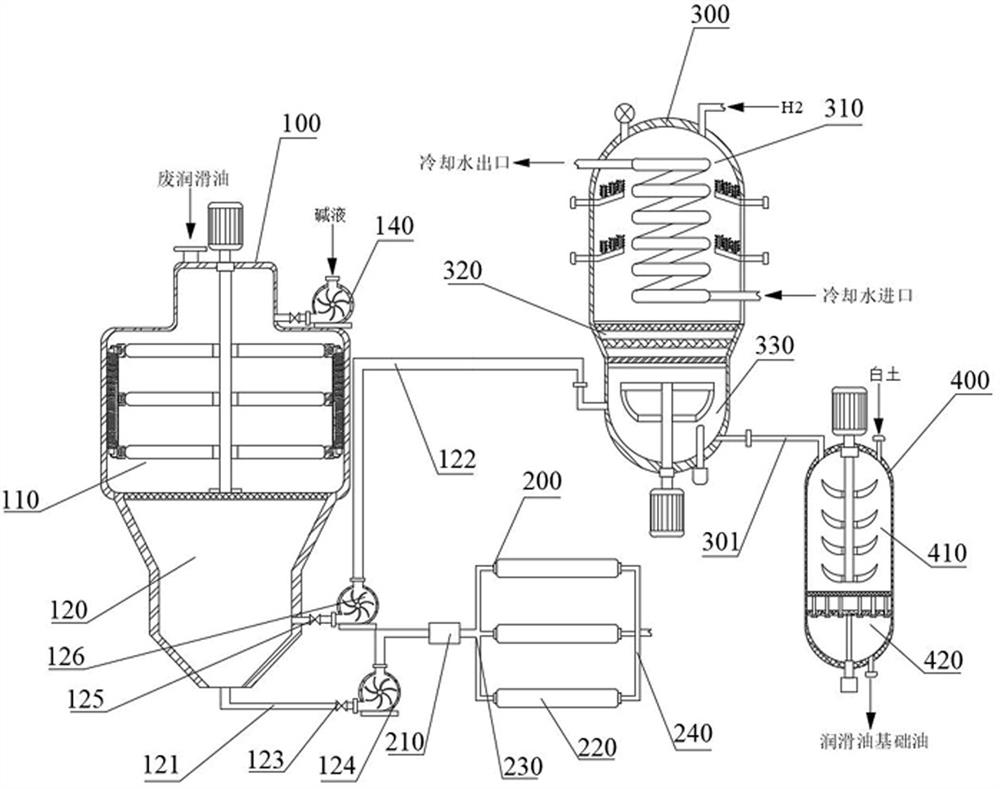

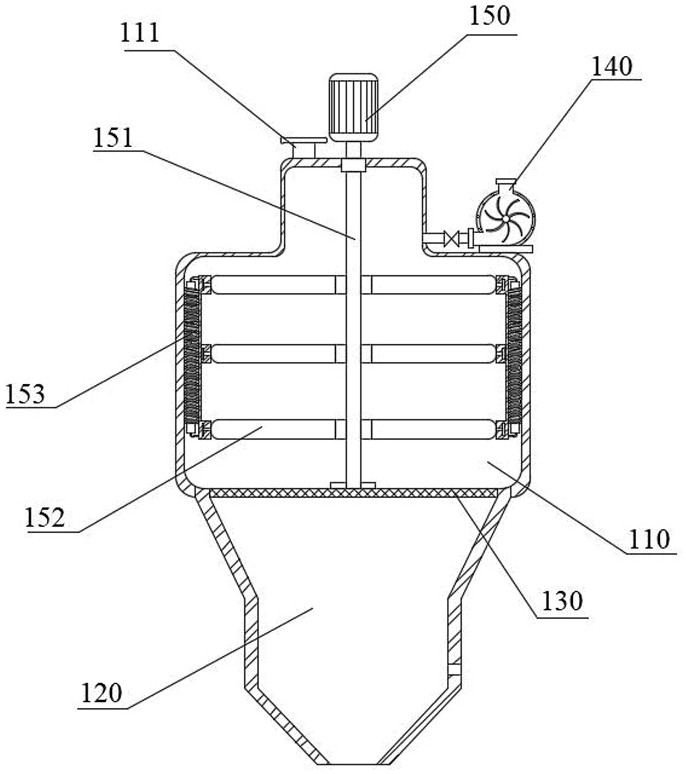

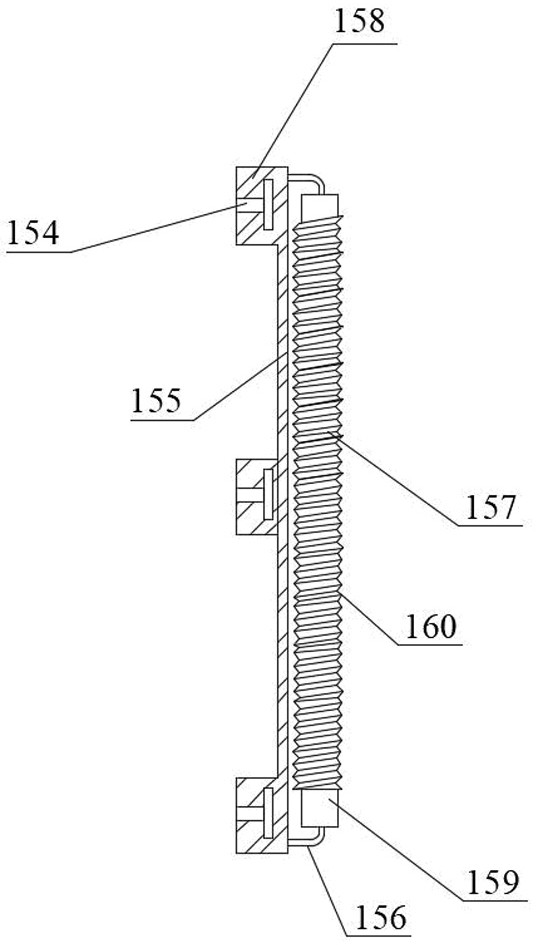

Preparation system of chlorine-removing hydrogen-enriched electrolytic low-deuterium health-preserving water

InactiveCN109052824AReasonable designImprove production efficiencyWater contaminantsMultistage water/sewage treatmentProduction lineElectrolysis

The invention discloses a preparation system of chlorine-removing hydrogen-enriched electrolytic low-deuterium health-preserving water. The preparation system of the chlorine-removing hydrogen-enriched electrolytic low-deuterium health-preserving water comprises a crusher, an enzymolysis tank, a fermentation tank, a liquid storage tank, a heat exchanger, a low-deuterium water electrolyzer, a chlorine remover, a hydrogen-enriching machine and a health-preserving water storage tank which are connected with one another sequentially. The preparation system of the chlorine-removing hydrogen-enriched electrolytic low-deuterium health-preserving water is reasonable in design; the whole preparation system adopts production line setting and is reasonable in process setting; the preparation efficiency of the hydrogen-enriched low-deuterium health-preserving water is greatly improved; furthermore, the preparation system is simple and convenient to operate.

Owner:ANHUI GUOKE BIOTECH CO LTD

Epoxy sealant with high water resistance

PendingCN114736639APromote environmental protectionImprove moisture resistanceNon-macromolecular adhesive additivesPackaging bottlesPolymer scienceAliphatic amine

The invention provides a high-water-resistance epoxy sealant. The high-water-resistance epoxy sealant comprises a component A and a component B, the component A comprises the following raw materials in parts by mass: 88 parts of epoxy resin, 8 parts of a diluent, 0.02 part of a defoaming agent and 6 parts of a thixotropic agent; the component B comprises the following raw materials in parts by mass: 18 parts of a modified alicyclic amine curing agent, 17 parts of aliphatic amine, 37 parts of a diluent, 0.02 part of a defoaming agent, 7 parts of a thixotropic agent and 1-2 parts of a dispersing agent; the mass ratio of the component A to the component B is 1: (1-1.19). After the scheme is adopted, intelligent automatic production is effectively realized, the process setting is reasonable, the use effect is good, and the production speed is high.

Owner:湖南浩森胶业有限公司

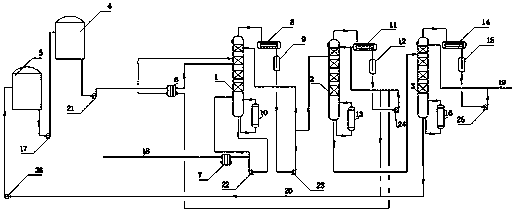

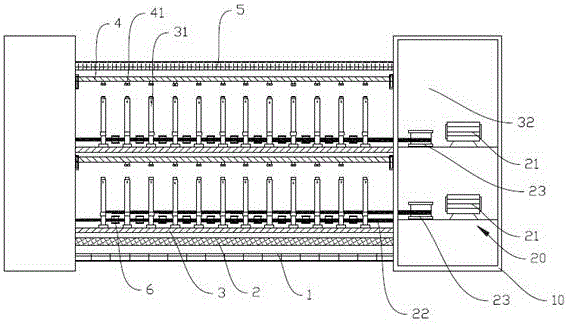

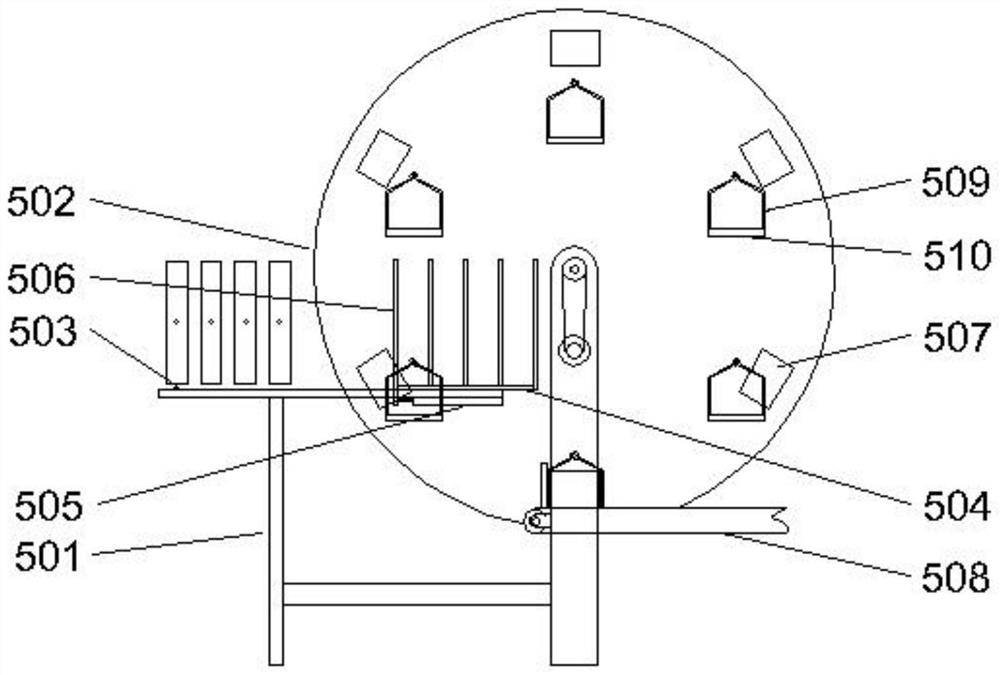

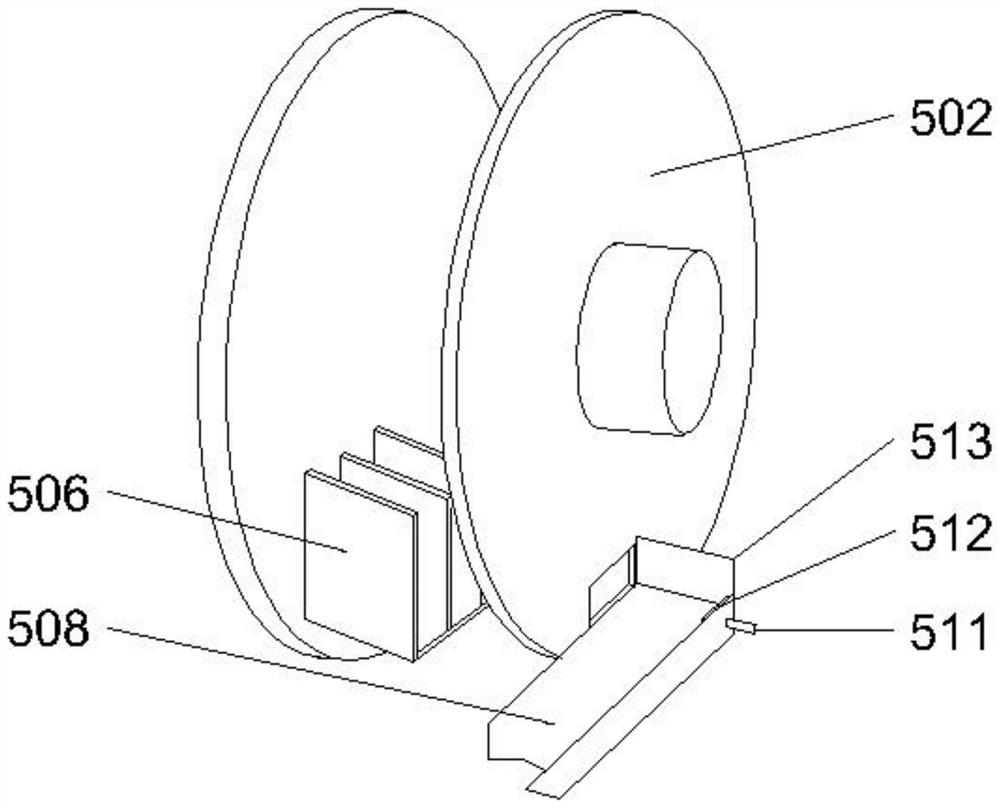

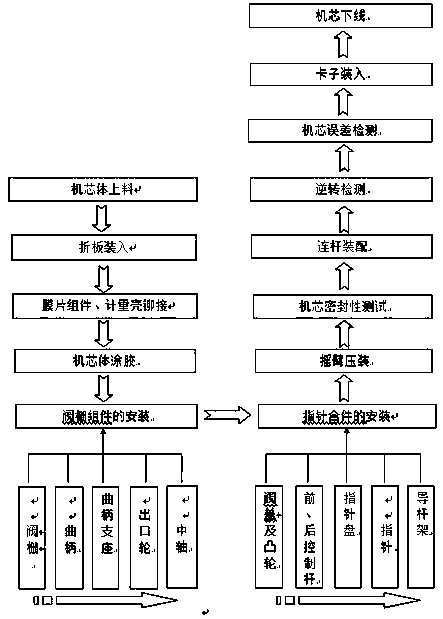

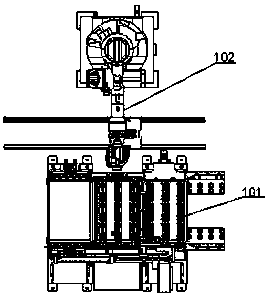

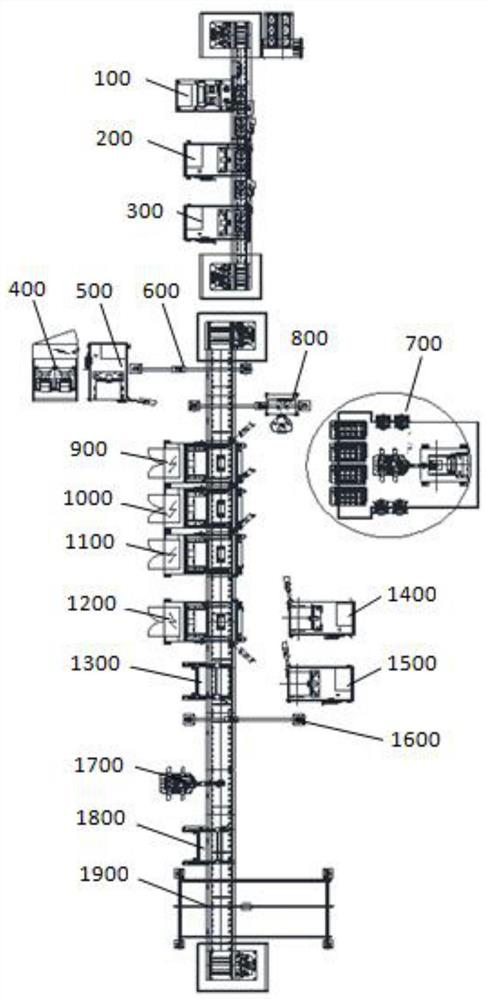

Automatic assembly method and assembly line for gas meter movement

ActiveCN106944823BProcess setting is reasonableSimplify the assembly processAssembly machinesProduction lineAssembly line

The invention discloses an automatic assembling method and assembly line for a fuel gas meter movement. The assembly method comprises the steps of (1) movement body feeding; (2) folding plate mounting; (3) membrane assembly and measurement shell riveting; (4) movement body gelatinizing; (5) mounting of a valve gate assembly; (6) mounting of a pointer assembly; (7) rocker arm pressing mounting; (8) airtightness test of the movement; (9) connecting rod assembling; (10) reversion detection; (11) movement error detection; (12) clamp mounting; and (13) movement offline. The assembly line comprises a movement body feeding device, a folding plate pressing mounting device, a riveting device, a gelatinizing device, a valve gate assembly mounting device, a pointer assembly mounting device, a rocker arm pressing mounting device, an airtightness test device, a connecting rod assembling device, a reversion detecting device, a movement error detecting device, a clamp mounting device and a movement offline stacking device. The serial-parallel mixed automatic assembling method and assembly line are adopted, key information in the assembly process can be traced, the production efficiency is improved, and the product quality is guaranteed.

Owner:CSIC PRIDENANJINGINTELLIGENT EQUIP SYST CO LTD

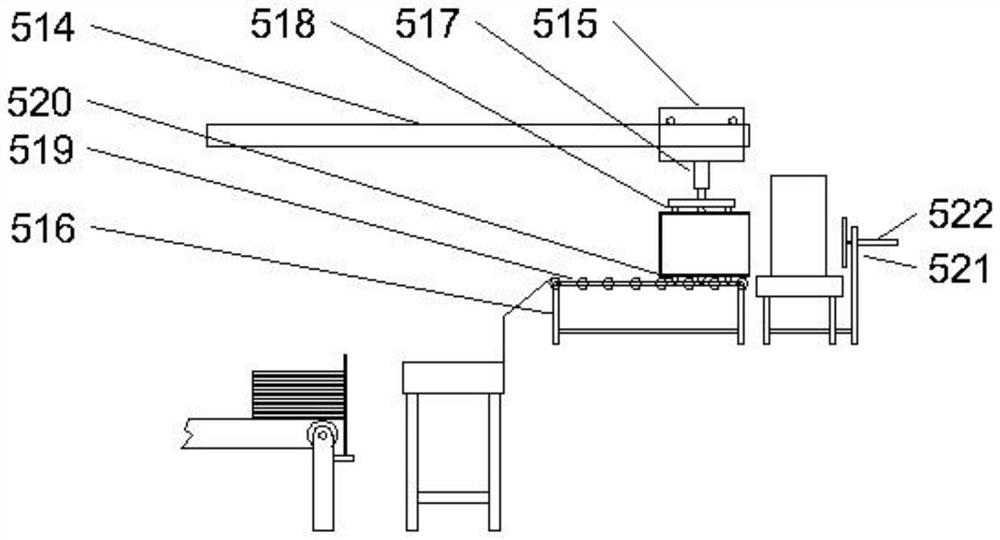

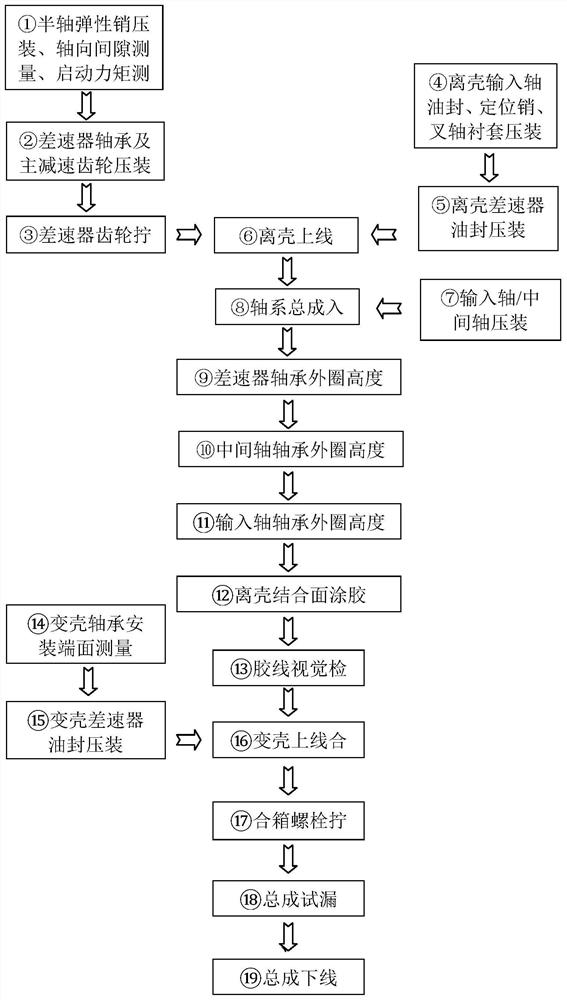

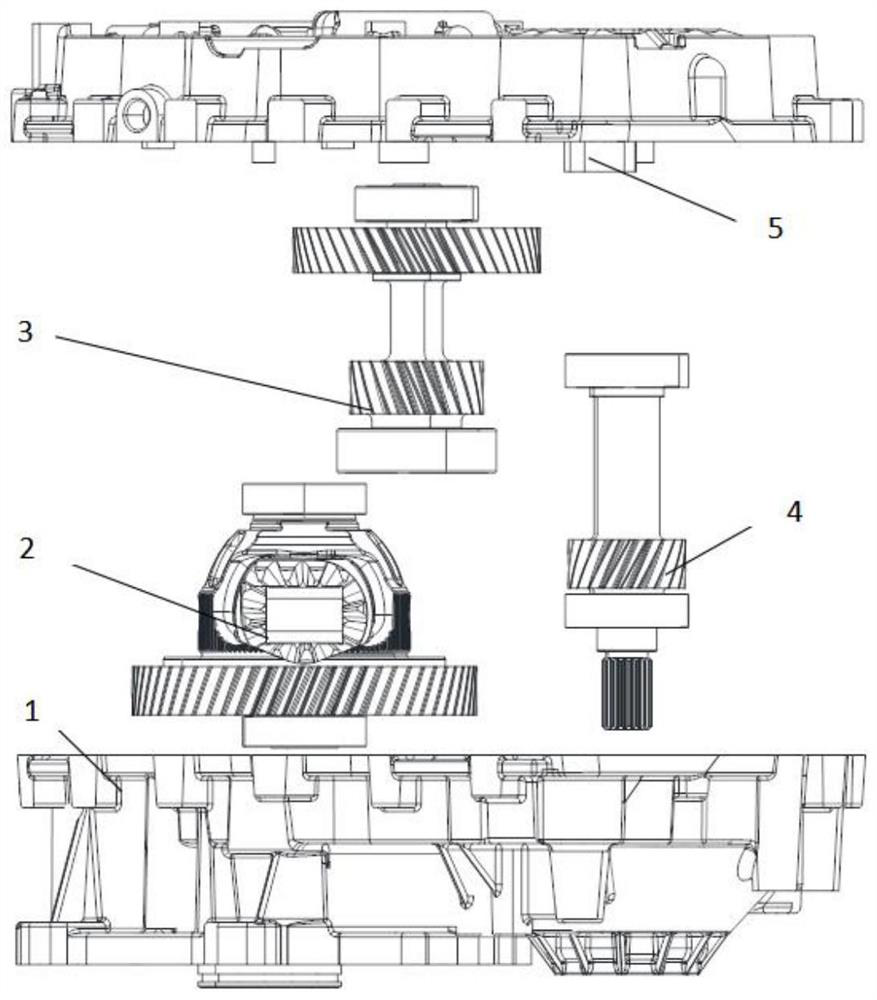

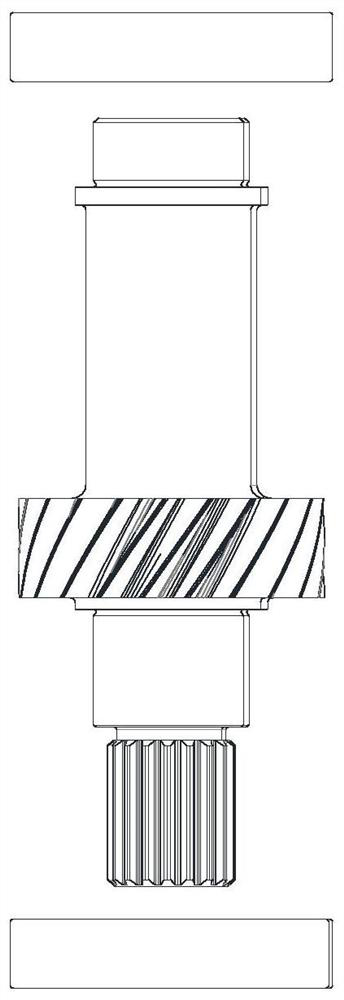

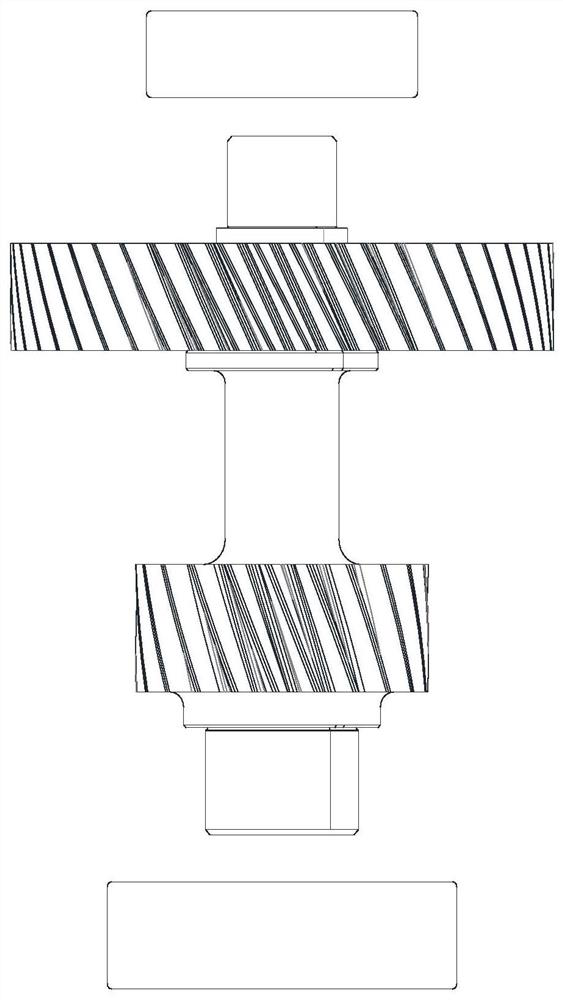

A gearbox assembly method and assembly system

ActiveCN111975346BProcess setting is reasonableSimplify the assembly processMaterial gluingAssembly machinesStructural engineeringAssembly line

The invention discloses a gearbox assembly method and an assembly system. The method comprises the following steps: (1) assembling a differential; (2) assembling a separation case, and installing a differential oil seal into the separation case; (3) Assemble the input shaft assembly and the intermediate shaft assembly, and install them into the casing; (4) Apply glue to the surface of the casing; (5) Install the differential oil seal into the casing; (6) Install the The variable case is installed on the separated case and locked with bolts. After the assembly is completed, the finished gearbox is moved off the assembly line; Assembling line and changing case sub-assembly line, the assembly assembly line assembles the differential, the separation case, the input shaft assembly, the intermediate shaft assembly, and the changing case into a finished gearbox. The method adopts a series and parallel mixed process scheme, the process setting is reasonable, the assembly process is optimized, and the production efficiency is improved; the assembly system is automatically produced, which can effectively control product quality and trace information.

Owner:CSIC PRIDENANJINGINTELLIGENT EQUIP SYST CO LTD

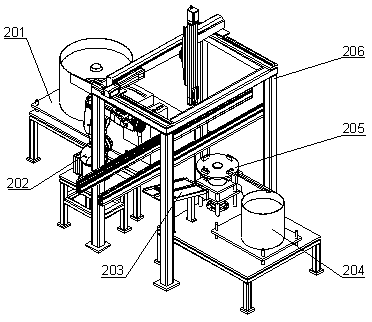

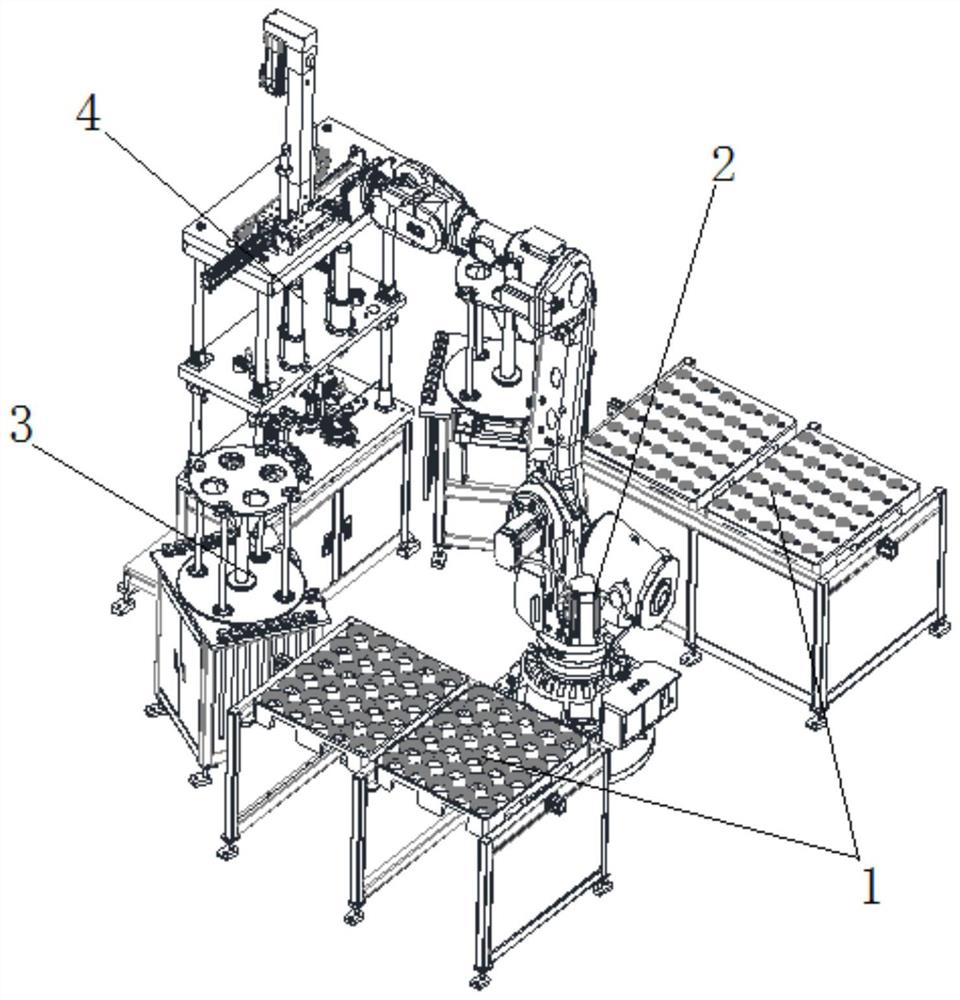

Automatic assembling system and method for intermediate shaft of input shaft of gearbox

InactiveCN111941036AHigh degree of automationHighly integratedMetal working apparatusControl engineeringAutomation

The invention discloses an automatic assembling system and method for an intermediate shaft of an input shaft of a gearbox. The system comprises a material rack, a feeding robot, a bearing feeding device, a press-fitting device, and a controller. The controller is electrically connected with the feeding robot, the bearing feeding device, and the press-fitting device. During assembly, the controller controls the feeding robot to clamp a shaft on the material rack and place the shaft into a shaft fixing device of the press-fitting device, the controller controls a bearing material pipe of the bearing feeding device to discharge, the feeding robot places a clamped bearing into a bearing fixing device of the press-fitting device after the bearing falls onto a bearing discharging table, and thecontroller controls the press-fitting device to act to assembly the bearing to the shaft. According to the system and the method, the degree of automation is high, the degree of integration is high,and the process arrangement is reasonable, the assembling process is effectively optimized, the assembling time is saved, and the production efficiency is improved.

Owner:CSIC PRIDENANJINGINTELLIGENT EQUIP SYST CO LTD

Formula and production process of traditional Chinese medicine preparation for treating acne

PendingCN112656858ADefinite curative effectSimple recipeDermatological disorderPlant ingredientsFormularyModern medicine

The invention relates to a formula and a production process of a traditional Chinese medicine preparation for treating acne, and belongs to the technical field of traditional Chinese medicines. 10-300 parts of honeysuckle, 10-300 parts of angelica sinensis, 15-150 parts of ligusticum wallichii, 15-150 parts of divaricate saposhnikovia root, 10-100 parts of schizonepeta, 10-150 parts of fructus forsythiae, 10-100 parts of cape jasmine, 10-100 parts of coptis chinensis, 10-150 parts of scutellaria baicalensis, 10-100 parts of mint, 10-150 parts of radix angelicae, 15-300 parts of platycodon grandiflorum, 3-60 parts of fructus aurantii, 3-15 parts of licorice and 3-12 parts of rhubarb. The traditional Chinese medicine composition is derived from a Gansu red-eared folk Chinese herbal medicine medical clinical proved recipe, and long-term clinical treatment observation proves that the curative effect is exact. The traditional decoction medicine is developed into the granular preparation convenient to carry and take according to the modern medicine preparation theory, the quality standard is formulated, the modern medicine approval requirement is met, and the traditional Chinese medicine composition can be clinically applied and popularized.

Owner:罗宗明

Improved galvanization process of power pole

PendingCN112063946AInhibitionReduce manufacturing costHot-dipping/immersion processesCooling powerElectric power

The invention relates to an improved galvanization process for a power pole. The improved galvanization process for the electric pole comprises the following steps of (1) carrying out acid pickling and phosphating on the power pole; (2) firing the power pole; (3) polishing the power pole; (4) soaking the power pole in a plating assistant agent; (5) carrying out hot galvanizing on the power pole; (6) carrying out air blowing on the galvanized power pole; (7) putting the power pole subjected to air blowing into a clear water cooling pool for cooling; (8) passivating the cooled power pole; and (9) carrying out anti-friction treatment on the passivated power pole by using an anti-friction treatment agent. According to the the improved galvanization process for the electric pole provided by theinvention, the process is reasonable, the manufacturing cost is low, the product quality is high, and the friction coefficient is effectively increased.

Owner:江苏银河钢杆有限公司

A method for reinforcement and anti-seepage of a natural rockfill dam in a barrier lake

ActiveCN111119128BImprove anti-seepage effectImprove stabilityFoundation engineeringEarth-fill damsLandslide damSlurry

Owner:CHINA HYDROPOWER ELEVENTH ENG BUREAU ZHENGZHOU CO LTD +1

Water-resistant epoxy sealant based on low cost

PendingCN114752331ALow costImprove water resistanceLiquid fillingBottle-handling machinesPolymer scienceFirming agent

The invention provides a low-cost water-resistant epoxy sealant. The low-cost water-resistant epoxy sealant comprises a component A and a component B, the component A comprises the following raw materials in parts by mass: 90-95 parts of epoxy resin, 8-12 parts of a diluent, 0.01-0.03 part of a defoaming agent and 3-9 parts of a thixotropic agent; the component B comprises the following raw materials in parts by mass: 10-16 parts of a modified alicyclic amine curing agent, 15-20 parts of aliphatic amine, 35-42 parts of a diluent, 0.01-0.03 part of a defoaming agent, 3-8 parts of a thixotropic agent, 1-3 parts of a dispersing agent and 2-5 parts of an accelerant; the mass ratio of the component A to the component B is 1: (1-1.16). After the scheme is adopted, intelligent automatic production is effectively realized, the process setting is reasonable, the use effect is good, and the production speed is high.

Owner:湖南浩森胶业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com