Epoxy sealant with high water resistance

A technology of water resistance and beautifying joint agent, which is applied in the direction of epoxy resin glue, non-polymer adhesive additives, adhesives, etc., can solve the problems of high frequency of action, easy damage, etc., and achieve good moisture resistance and environmental protection. , process setting reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

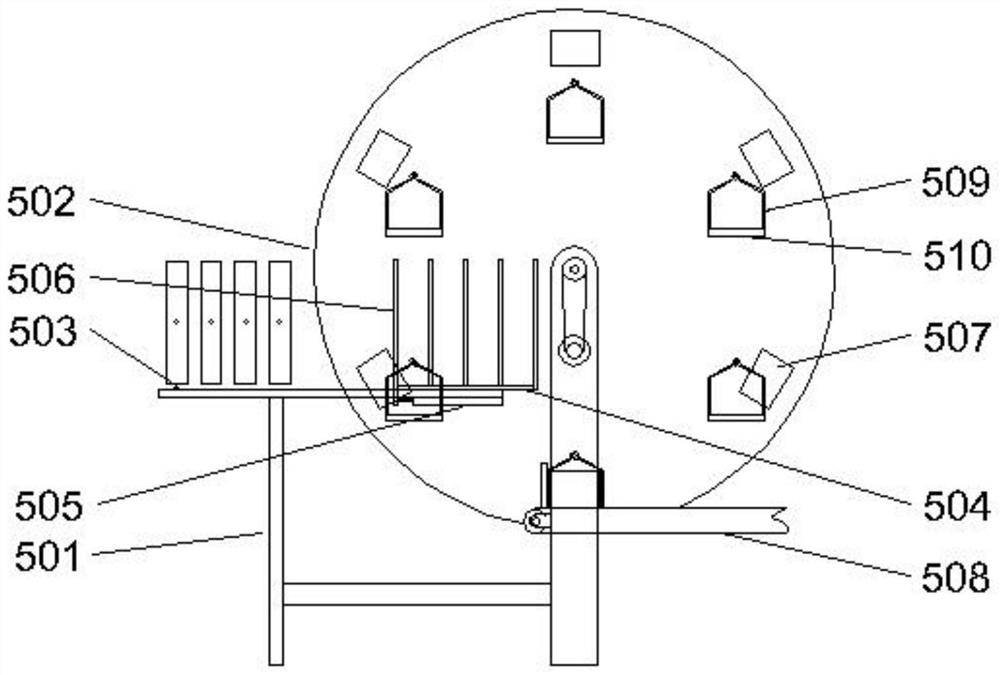

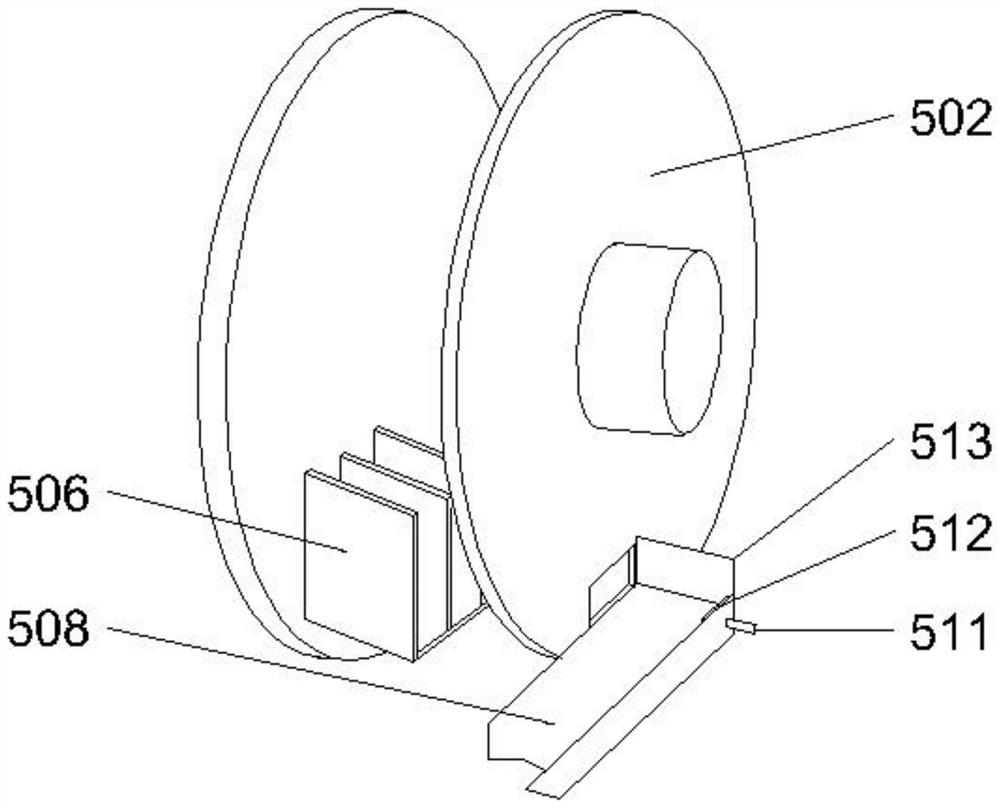

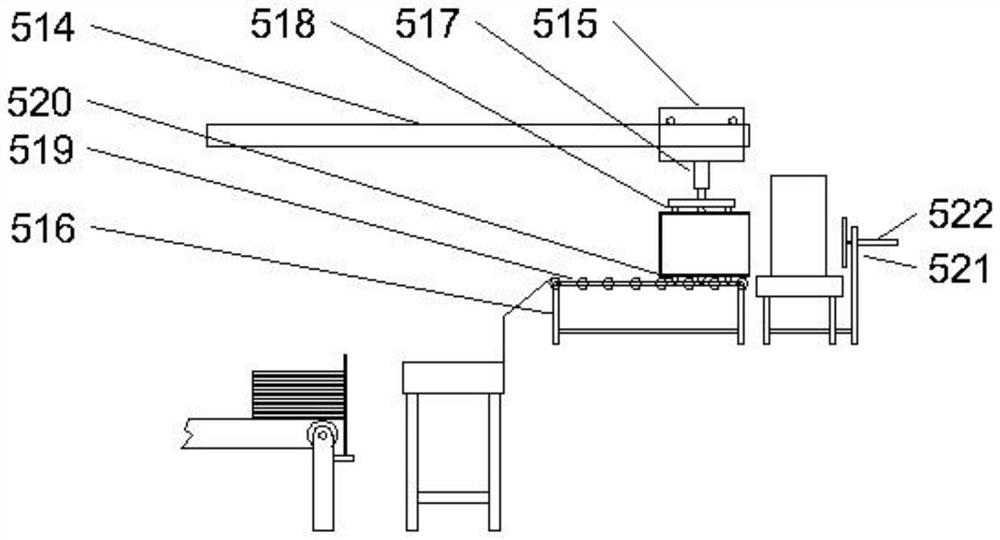

[0033] The present invention will be further described below in conjunction with all the accompanying drawings, and the preferred embodiment of the present invention is: figure 1 to the attached Image 6 , a kind of high water-resistant epoxy beauty joint agent described in this embodiment includes A component and B component;

[0034] The A component includes the following raw materials in parts by mass: 85-92 parts of epoxy resin, 6-10 parts of diluent, 0.01-0.03 part of defoamer, and 3-9 parts of thixotropic agent;

[0035] The B component includes the following raw materials in parts by mass: 15-22 parts of modified alicyclic amine curing agent, 15-20 parts of aliphatic amine, 32-42 parts of diluent, 0.01-0.03 part of defoamer, thixotropic agent 5-9 parts, 1-2 parts of dispersant;

[0036] The point mass ratio of the A component to the B component is 1:1-1.19.

[0037] The preparation method of described modified alicyclic amine comprises:

[0038] Control the vacuum d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com