Automatic assembly method and assembly line for gas meter movement

A gas metering and automatic assembly technology, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve problems such as poor assembly consistency, low efficiency, and error-prone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

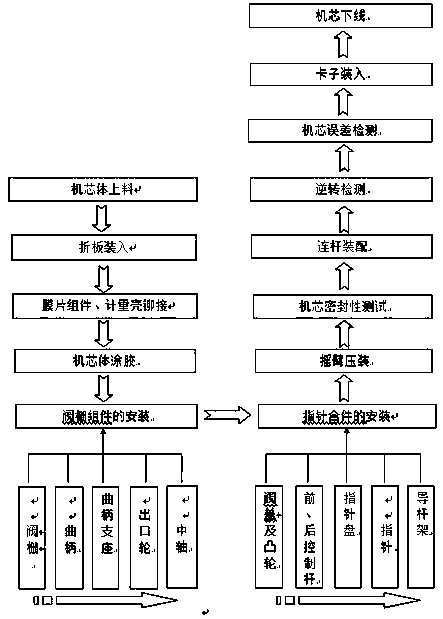

[0063] Such as figure 1 Shown, a kind of gas meter core automatic assembly method comprises the following steps:

[0064] 1) Core body loading: put the core body of the gas meter to be assembled on the accompanying tooling with RFID chips, and the accompanying tooling is placed on the conveyor line;

[0065] 2) Folding plate loading: put the folding plate into the machine body, and at the same time apply grease to both ends of the vertical shaft and the inside and outside of the sealing cap, assemble the vertical shaft and sealing cap into the vertical shaft assembly, insert the vertical shaft assembly through the machine body into the folding plate In the hole, when pressing, detect the pressing height of the vertical shaft and the damage of the folding plate, and write the detection information into the RFID chip;

[0066] 3) Dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com