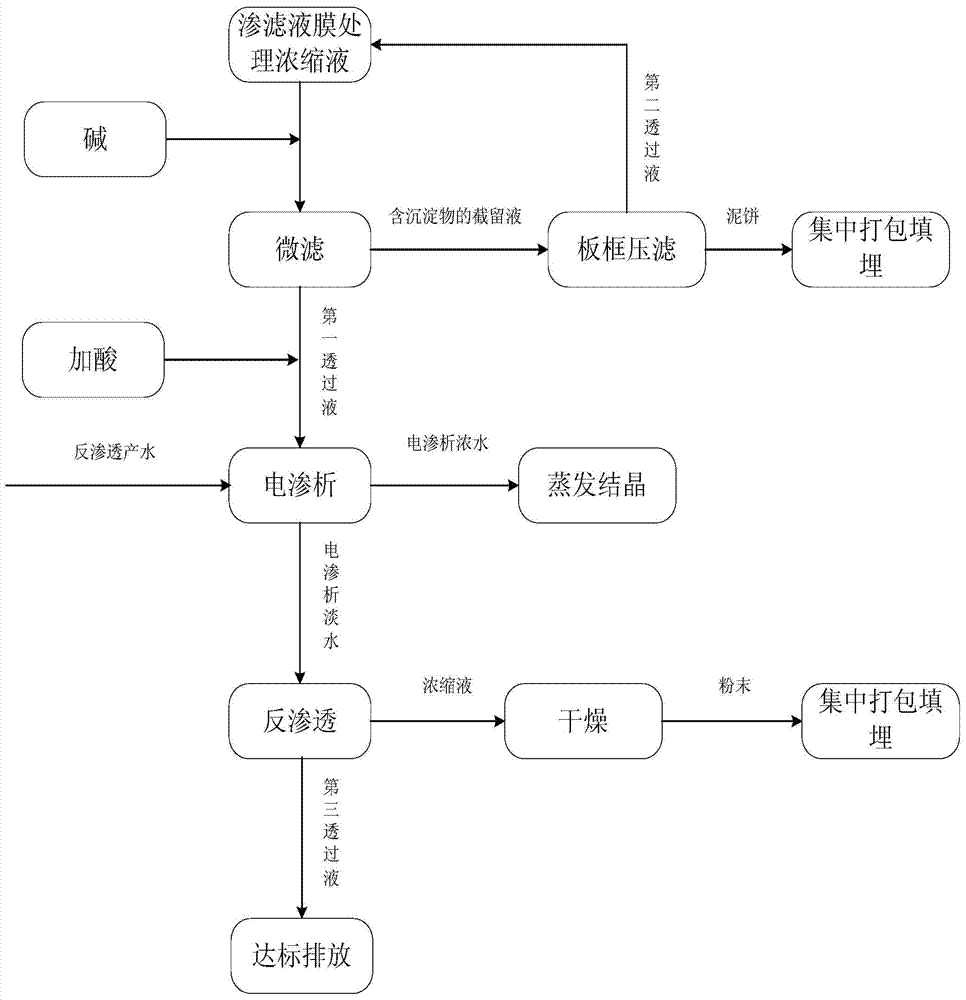

Method for processing percolate membrane treatment concentrated solution of waste incineration plant

A technology of waste incineration and leachate, applied in separation methods, chemical instruments and methods, neutralized water/sewage treatment, etc., can solve the problem of evaporator and spray dryer hardening, ineffective treatment of concentrated liquid, serious equipment loss, etc. problems, to achieve the effect of reducing the amount of concentrated water, reasonable process settings, and reducing equipment loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The combined process disclosed by the invention is used to treat the leachate membrane treatment concentrate of a waste incineration plant.

[0034] The CODcr concentration of the concentrated liquid after membrane treatment in the incineration plant is 3000mg / L, the total hardness content is 8000mg / L, the conductivity is 15600μs / cm, and the pH is 7.2.

[0035] (1) Take 5 tons of membrane treatment concentrate, add industrial grade caustic soda to the membrane treatment concentrate to adjust the pH to 11.5, at this time, the heavy metal ions, calcium and magnesium ions in the membrane treatment concentrate react with caustic soda to form a large amount of precipitation;

[0036] (2) Filter the above-mentioned mixed solution containing sediment through a tubular microfiltration membrane. The pore size of the microfiltration membrane is 0.1 μm, and the operating pressure is 0.35 MPa. After filtration, 4.5 tons of the first permeate and 500 L of the retained solution conta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com