Efficient precision machining process for showing stand

A technology of precision machining and display racks, which is applied in application, display hangers, display shelves, etc., can solve the problems of reduced production efficiency and pass rate, failure to improve the processing precision of display racks, and easy scratches on pipes and sheets, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] The high-efficiency precision machining process for display racks includes the following steps:

[0044] (1) Correction: Measure the blanks of display racks with a height gauge, and correct the blanks of display racks that do not meet the requirements through tooling;

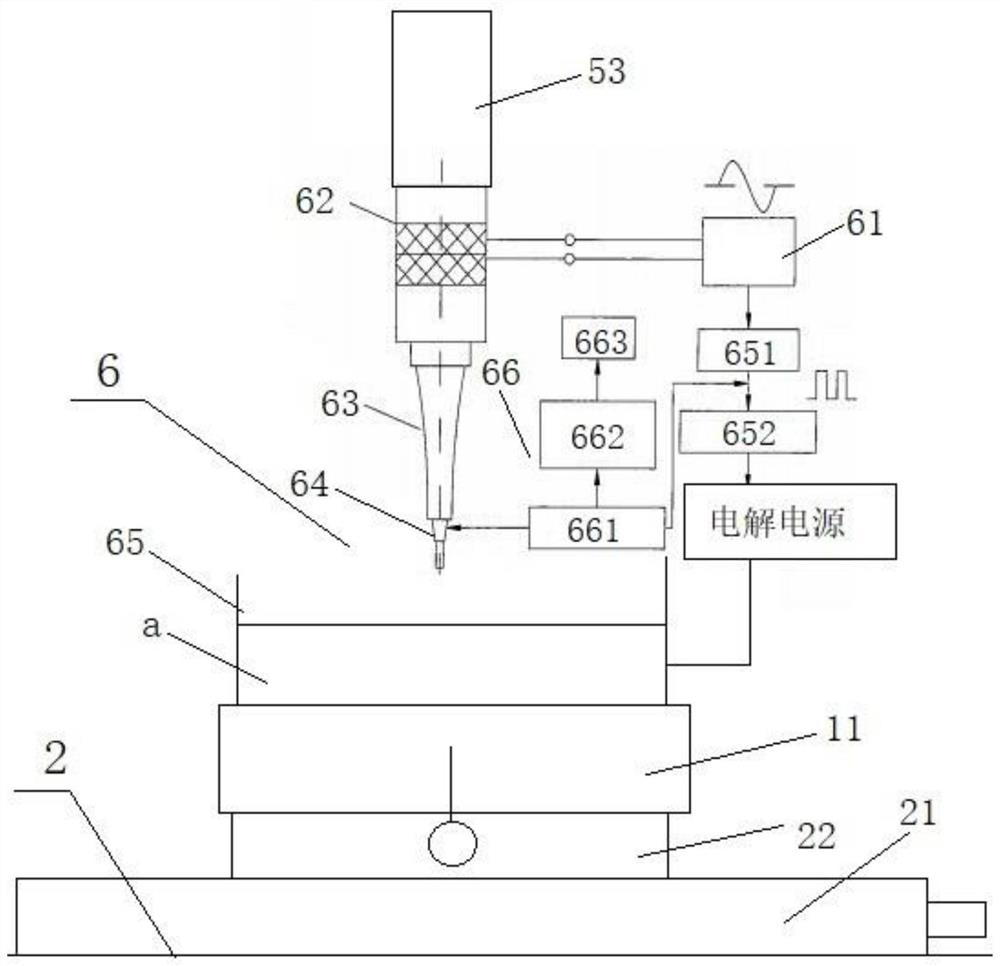

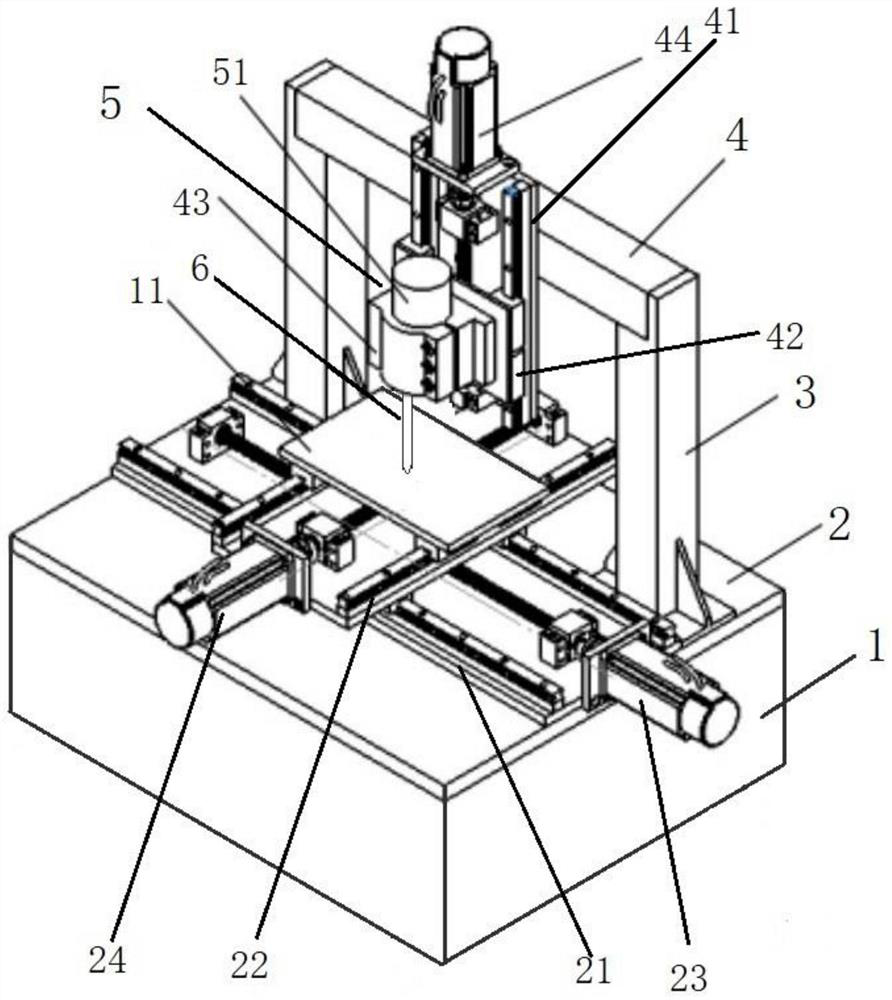

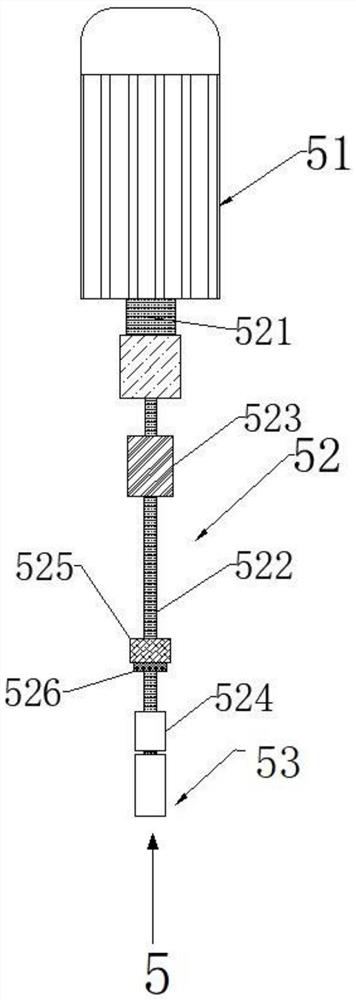

[0045] (2) Milling datum plane: use precision machining equipment to mill the datum plane of the display stand blank; the precision machining equipment includes frame 1, bottom plate 2, gantry column 3, gantry beam 4, spindle mechanism 5, ultrasonic vibration processing Mechanism 6, the bottom plate 2 is installed on the frame 1, the X-axis component 21 is installed horizontally and the Y-axis component 22 is installed vertically on the bottom plate 2, and the cross slide composed of the X-axis component 21 and the Y-axis component 22 The table structure and the workbench 11 are fixedly installed on the top, and the X-axis component 21 and the Y-axis component 22 respectively drive the screw nuts corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com