Low temperature removal method for COS with relatively high concentration in gas

A low-temperature removal and high-level technology, which is applied in separation methods, gas treatment, chemical instruments and methods, etc., can solve the problems of poor regeneration, difficult to maintain above 95%, short breakthrough time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] The crude gas originates from the gas-making workshop and is produced from coke, carbon dioxide and oxygen in the gas-making furnace. The temperature of the control point of the gasification furnace is 1100-1200°C. The by-product steam of the waste boiler is cooled down, and then further cooled to 30-40°C by the circulating water heat exchanger, and the tar and dust impurities are removed by the electric tar remover, with a gas volume of 5000-6000Nm 3 / h, gauge pressure 10-15kPa; the basic composition (volume content) of crude gas is CO 68%, CO 2 29%, O 2 0.20%, H 2 1.2%, H 2 S0.07%, COS0.16%, CS 2 0.003%, H 2 O 0.8%, and trace amounts of HCl, HCN, NOx, SO 3 and AsH 3 、PH 3 .

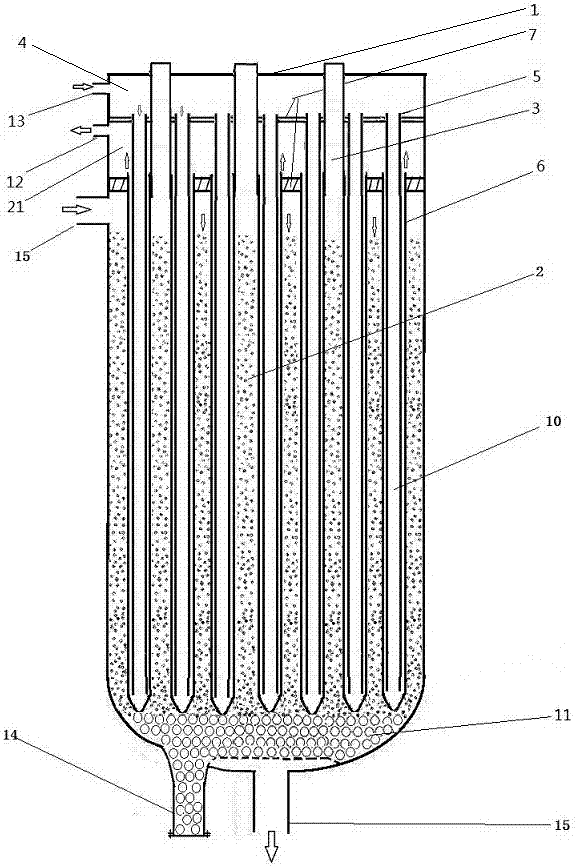

[0032] The sideline test device mainly includes a 50L protective agent tank, a heater, a 100L hydrolysis desulfurization tower, and a 50L regenerative condenser (water-cooled, with a coil area of 3m2) connected in sequence along the airflow direction. 2 ), the protective agent tank is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com