Patents

Literature

86 results about "Sodium product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Milk, beets, and celery also naturally contain sodium, as does drinking water, although the amount varies depending on the source. Sodium is also added to various food products. Some of these added forms are monosodium glutamate, sodium nitrite, sodium saccharin, baking soda (sodium bicarbonate), and sodium benzoate.

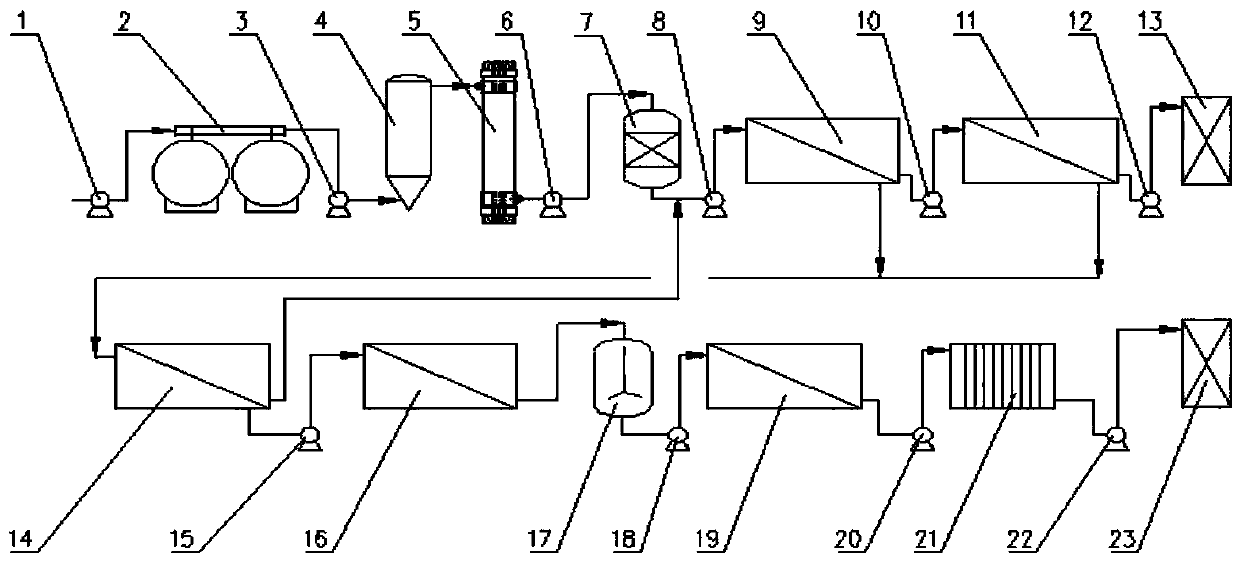

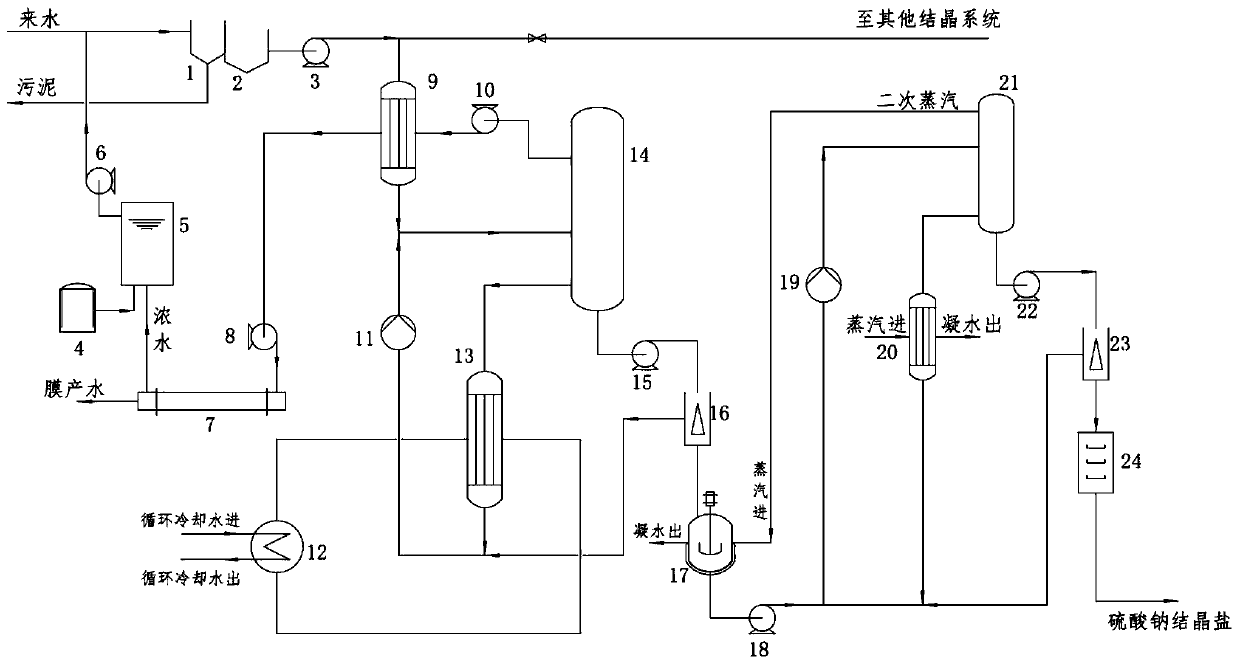

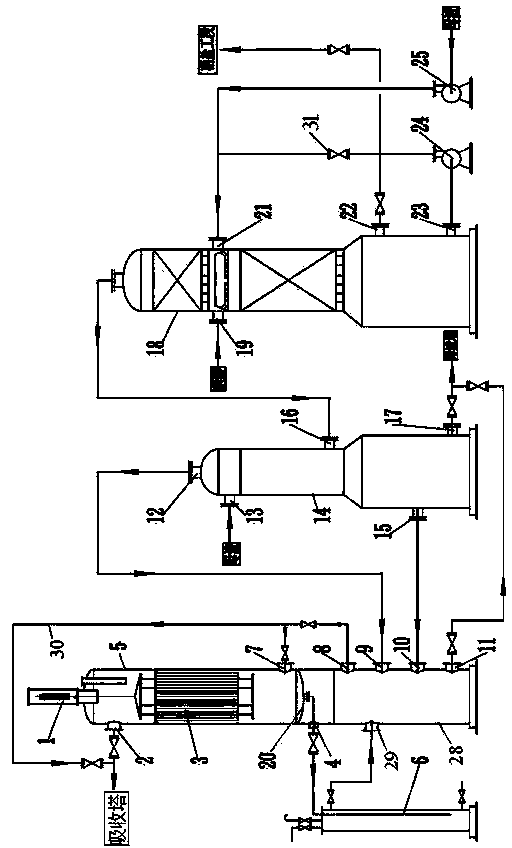

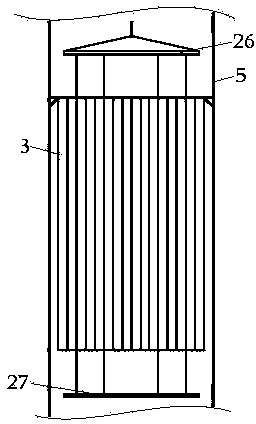

Coking wastewater membrane concentration salt separation zero-emission treatment system and coking wastewater membrane concentration salt separation zero-emission treatment method

InactiveCN110734178AAvoid foulingGuaranteed uptimeSpecific water treatment objectivesChemical industryFiltrationReverse osmosis

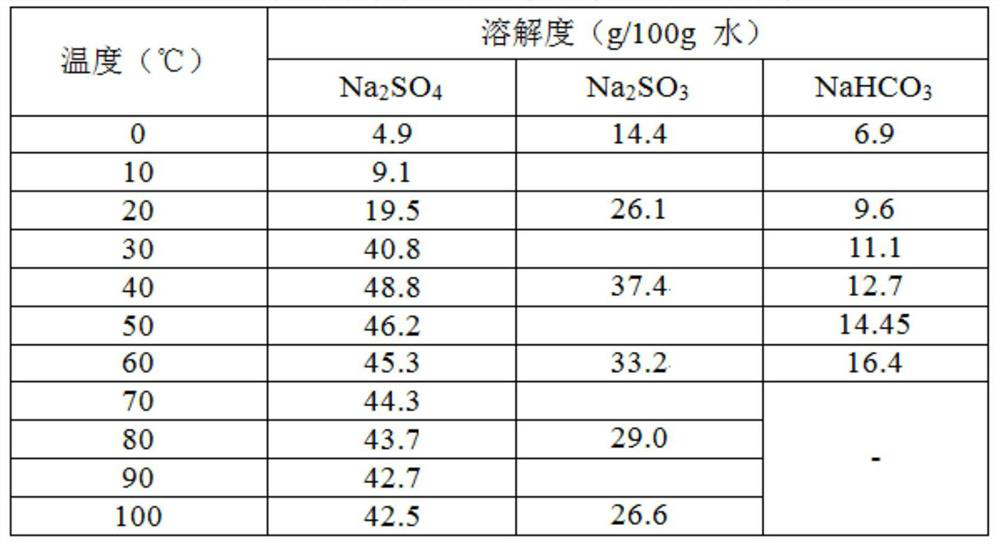

The invention belongs to the technical field of water treatment, and particularly relates to a coking wastewater membrane concentration salt separation zero-emission treatment system and a coking wastewater membrane concentration salt separation zero-emission treatment method. The method comprises: coking wastewater pretreatment, wherein the coking wastewater pretreatment comprises full-automaticsand filtration, active carbon adsorption regeneration, ultra-filtration and softening; membrane salt separation and concentration treatment, wherein the membrane salt separation and concentration treatment comprises low-pressure nano-filtration, high-pressure nano-filtration, purification nano-filtration and reverse osmosis treatment; and concentration treatment, fluorine and silicon removal, electrodialysis concentration and evaporative crystallization, wherein an industrial-grade sodium chloride product with a purity of more than 92% is obtained, a sodium sulfate concentrated solution enters a freezing crystallization device to generate mirabilite, the mirabilite is heated and melted and then enters an evaporation crystallization, centrifugation and drying system, and an industrial-grade sodium sulfate product with a purity of more than 95% is obtained. According to the invention, with the system and the method, the zero discharge of coking wastewater is achieved, and the process technology is an innovative coking wastewater zero discharge process at home and abroad.

Owner:BAOWU CHARCOAL MATERIAL TECH CO LTD

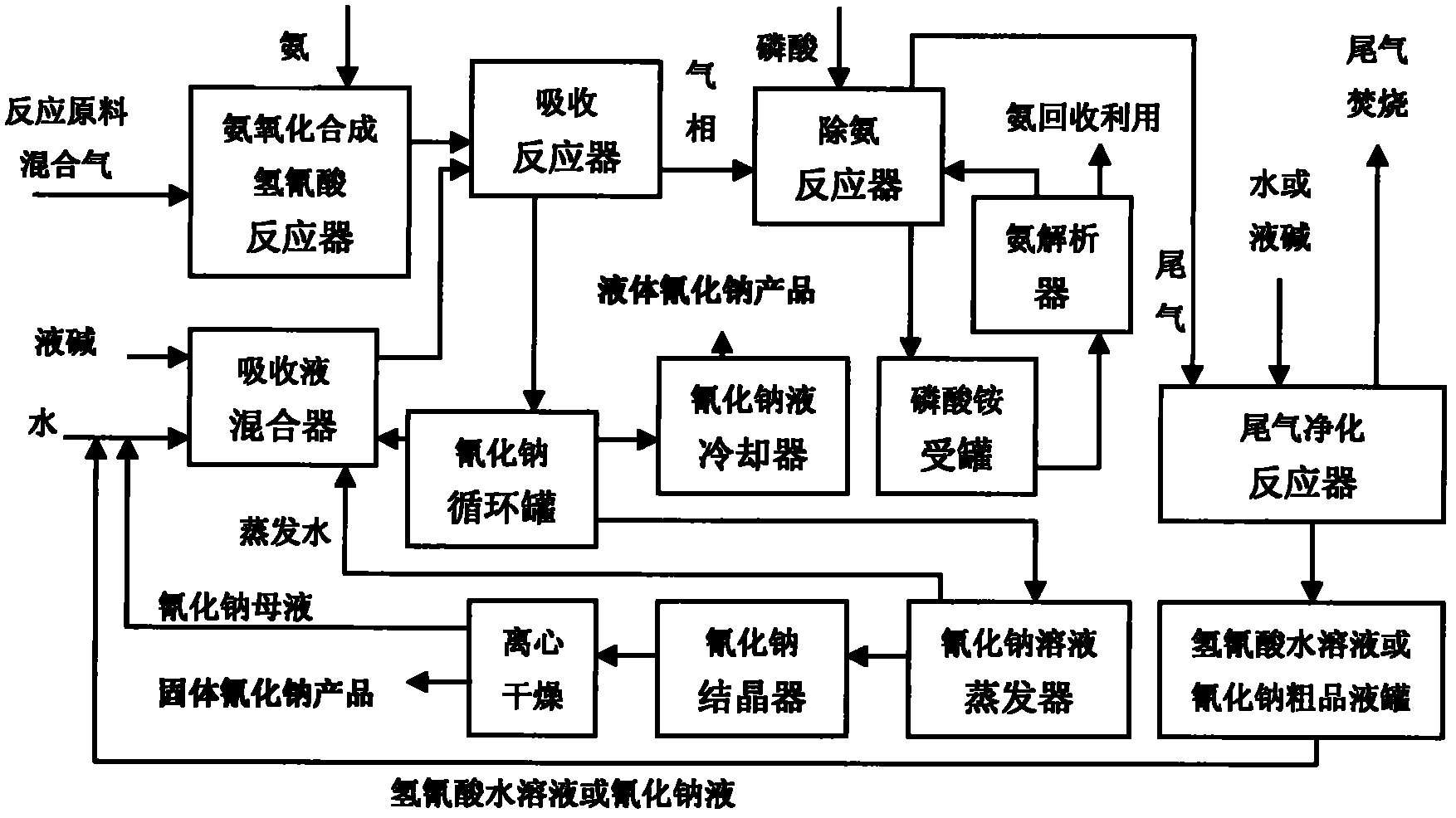

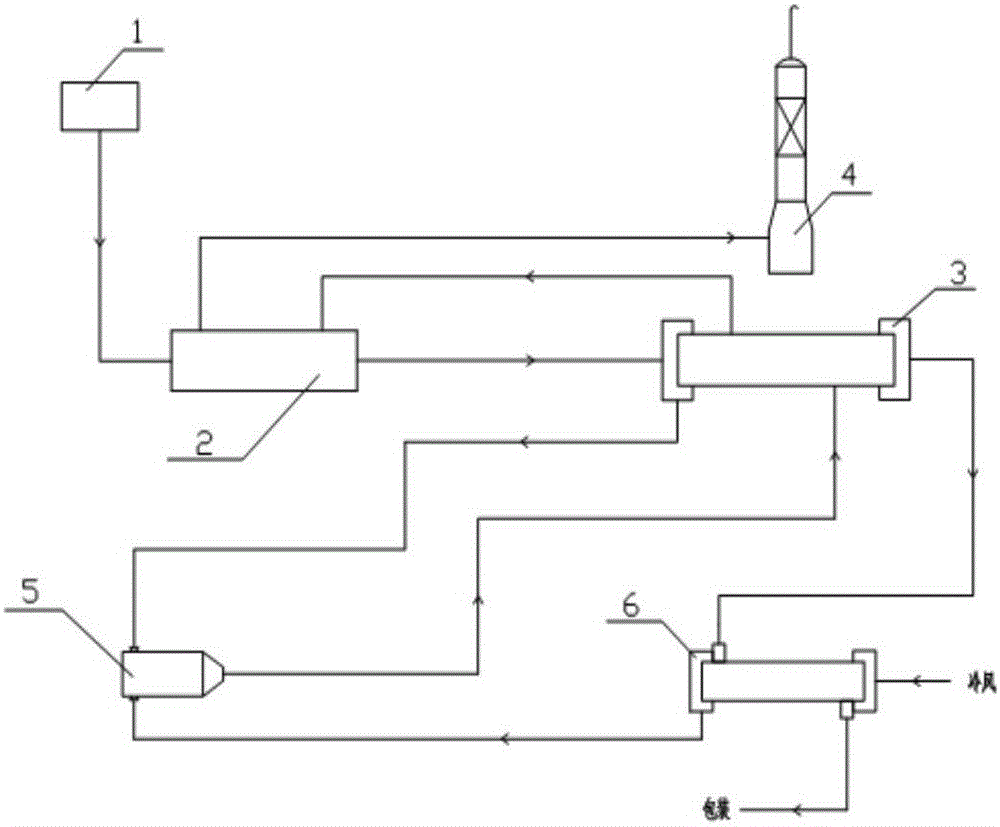

Environment-friendly clean production method for high purity sodium cyanide

InactiveCN103073027ARealize recyclingAchieving a circular economy modelAlkali metal cyanidesPhosphoric acidSodium cyanide

The invention provides an environment-friendly clean production method for high purity sodium cyanide. The production method comprises the following steps that: without removal of ammonia, hydrocyanic acid synthetic gas synthesized through ammoxidation is directly absorbed by and reacts with an aqueous sodium hydroxide solution to obtain a high purity aqueous sodium cyanide solution, and free ammonia remains in tail gas; the aqueous sodium cyanide solution is cooled and blended to obtain a high purity liquid sodium cyanide product, the high purity liquid sodium cyanide product undergoes condensation, crystallization and centrifugation to obtain a high purity solid sodium cyanide product, and mother liquor is indiscriminately used in liquid alkali absorption liquor; phosphoric acid or ammonium biphosphate is employed as a carrier for repeated cyclic indiscriminate application of ammonia so as to recover ammonia in the tail gas; and after recovery of ammonia, the tail gas is purified and absorbed with water or the aqueous sodium hydroxide solution, a small amount of the aqueous hydrocyanic acid solution or a crude aqueous sodium cyanide solution product is obtained while the tail gas is purified, the purified tail gas is burned with a tail gas boiler, and the aqueous hydrocyanic acid solution or the crude aqueous sodium cyanide solution product is indiscriminately used in the liquid alkali absorption liquor.

Owner:龙智

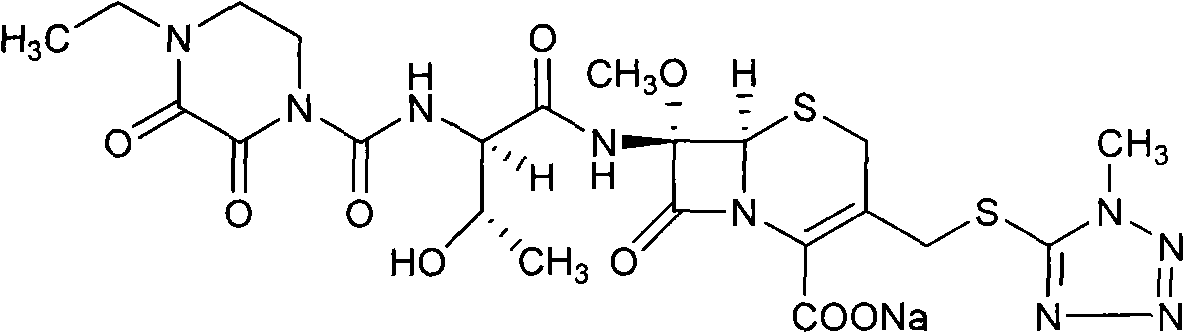

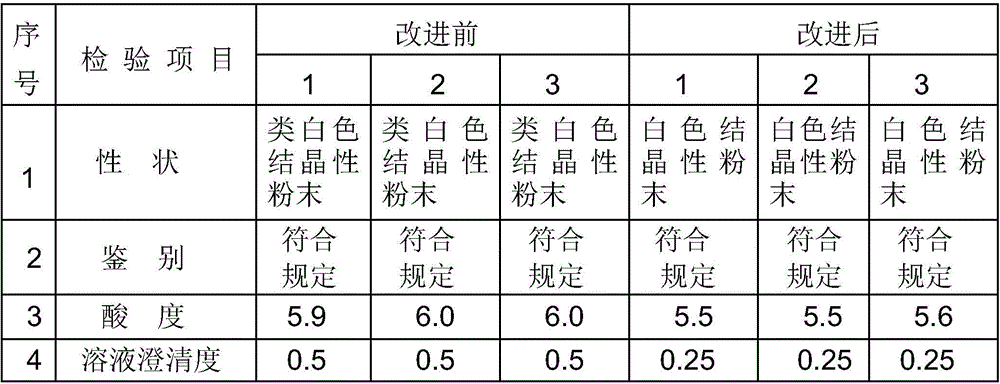

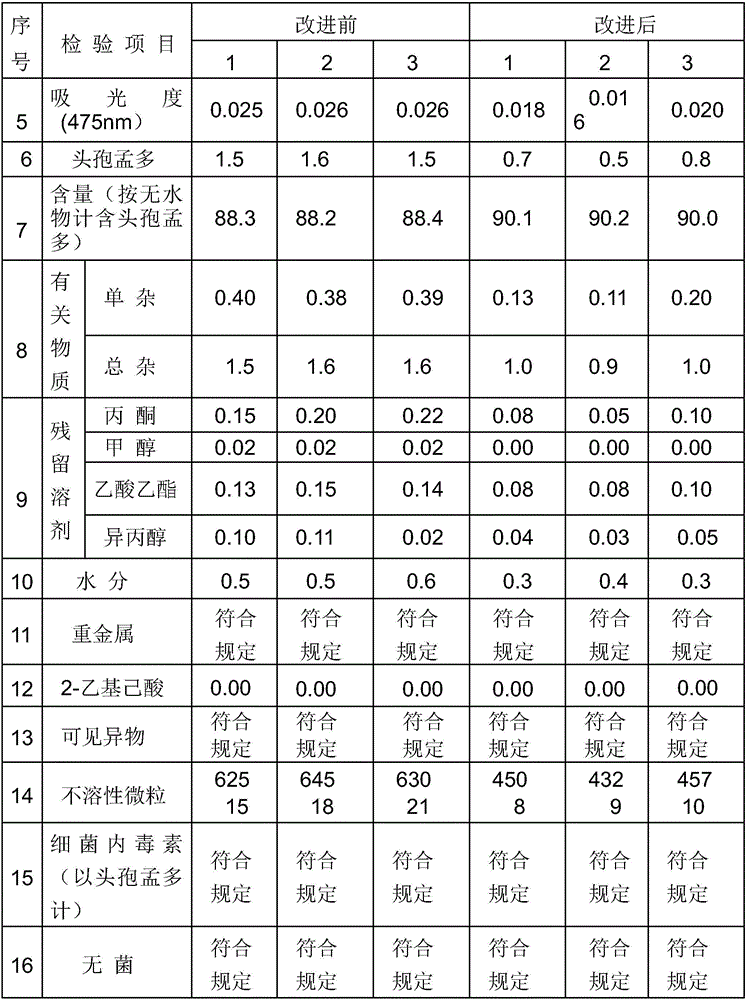

Preparation technology of high-purity flomoxef sodium

The invention discloses a preparation technology of high-purity flomoxef sodium. The preparation technology includes following steps: on the basis of a flomoxef intermediate, performing an acidifying reaction to obtain a reaction liquid; performing a water washing process, an extraction process, an aseptic filtration process and the like to the reaction liquid; and performing a solventing-out crystallization step through a one-step crystallization process to obtain a flomoxef sodium product with a purity being higher than 99.90%, wherein key points in the solventing-out crystallization step are selection and proportion of a solventing agent and dropwise addition of a salifying agent and the solventing agent at the same time with crystal growing. The preparation technology overcomes problems which are difficult to control during the solventing-out crystallization step of the flomoxef sodium. The flomoxef sodium is prepared in one step with the flomoxef intermediate as a raw material and the purity of the product of the flomoxef sodium reaches higher than 99.90% just through one crystallization step, which is cannot be achieved through a freeze-drying method or a common solventing-out crystallization process in the prior art. Quality of the product is in conformity with or even exceeds a standard in japanese pharmacopoeia JP16. The preparation technology has a more wide application prospect.

Owner:NORTH CHINA PHARMA HEBEI HUAMIN PHARMA

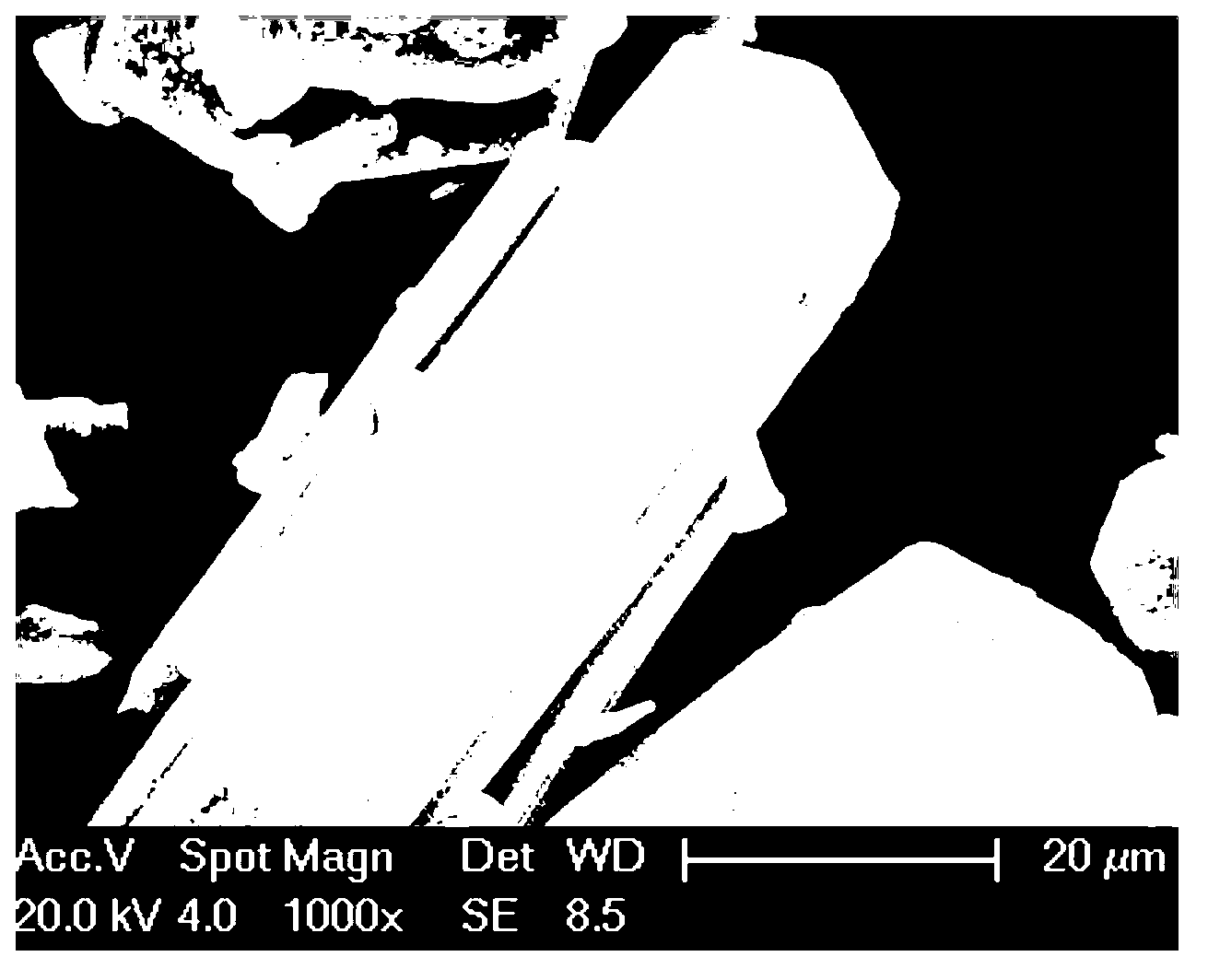

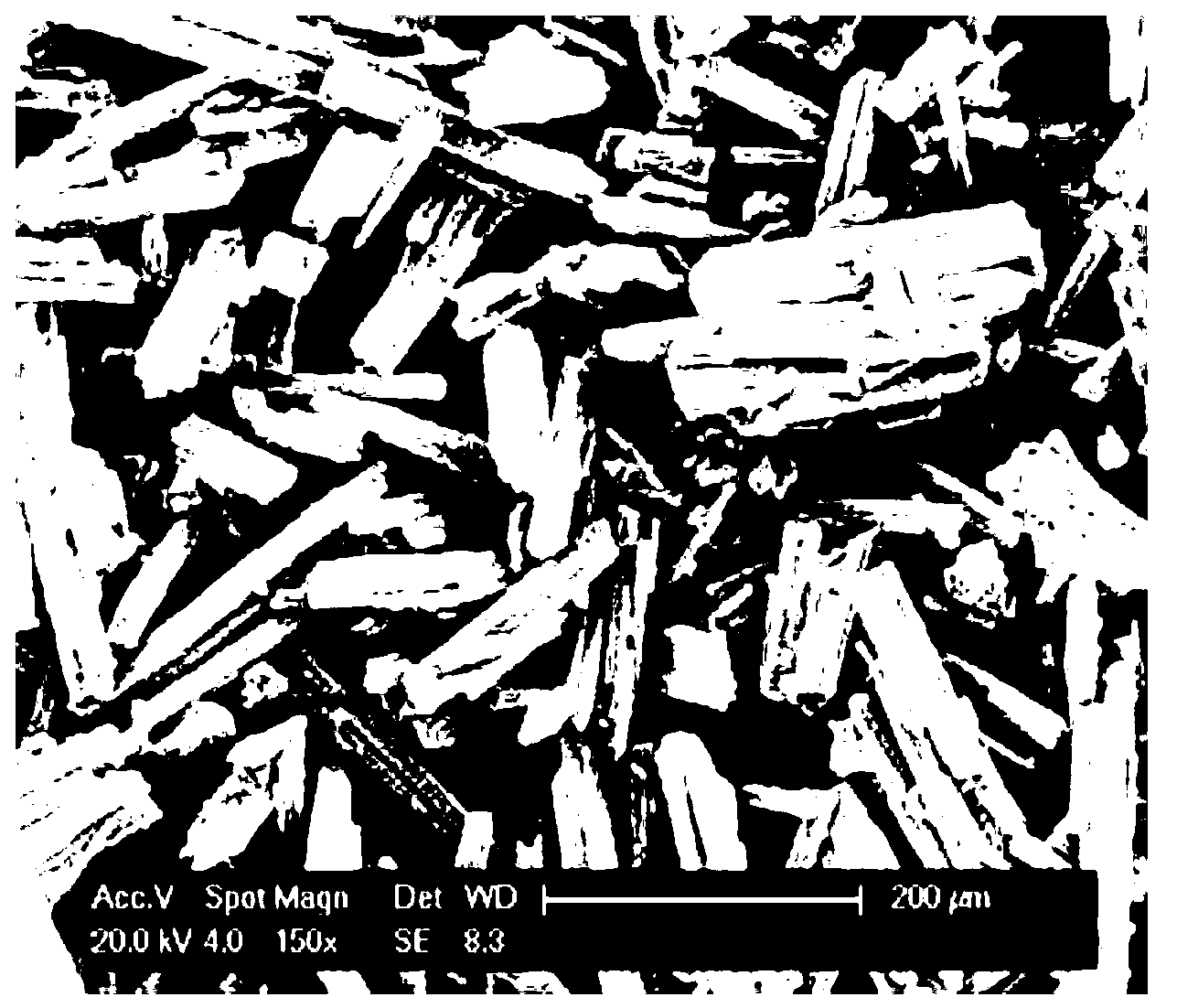

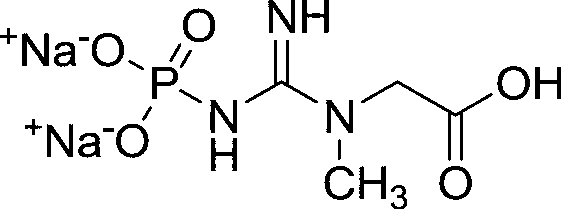

Crystal preparation method of creatine phosphate sodium

ActiveCN103012472AHigh crystallinityCrystal habit completeGroup 5/15 element organic compoundsPhosphateKetone

The invention discloses a crystallizing method for preparing high-purity creatine phosphate sodium. The crystallizing method comprises the following steps of: dissolving a creatine phosphate sodium crude product in water to prepare a 0.5-1.1 g / ml creatine phosphate sodium aqueous solution, continuously stirring for 30-60 minutes to decolor; after filtering, transferring a filtrate into a crystallizer, controlling a system temperature to be within 5-45 DEG C, and adding an alcohol or ketone organic solvent to perform solvent-out crystallization; after crystallizing, and separating through filtering, washing with a solvent and drying to obtain a creatine phosphate sodium product. The creatine phosphate sodium crystal provided by the invention is high in crystallinity degree, complete in product crystal habit, and uniform in particle size distribution; and a primary particle size is 67.1-70.2 mu m. The product purity reaches more than 99.5%, and a single molar yield during the crystallizing process is more than 98.0%; and the method is simple in process, low in cost and suitable for industrial production.

Owner:TIANJIN UNIV

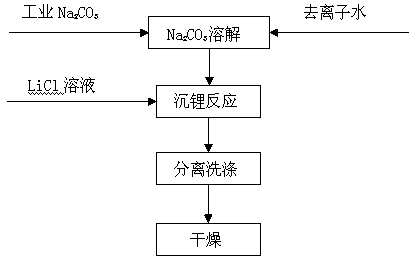

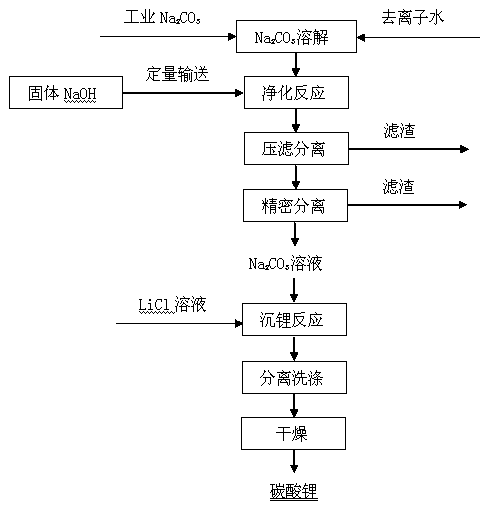

Purification method of sodium carbonate solution in lithium carbonate production

InactiveCN103508469AImprove qualityReduce contentAlkali metal carbonatesLithium carbonates/bicarbonatesPurification methodsLithium chloride

The invention discloses a purification method of a sodium carbonate solution in lithium carbonate production. The method comprises the following steps: 1, preparing a sodium carbonate solution with sodium carbonate mass percentage concentration of 25%; 2, adding solid sodium hydroxide, reacting Ca and Mg ions in the sodium carbonate solution with NaOH and precipitating completely to obtain a mixture liquid; 3, carrying out primary filtration on the mixture to obtain a primary filtration liquid; 4, carrying out depth filtration on the primary filtration liquid to realize the content of Ca and Mg no more than 10ppm in a filtrate, so as to obtain a purified sodium carbonate solution finished product; and 5, using the sodium carbonate solution finished product in lithium carbonate production process for reaction with a lithium chloride solution. The method of the invention is characterized in that the deep purification of sodium carbonate solution is added before a traditional lithium carbonate production process, in order to reduce the content of Ca and Mg ions in the industrial grade sodium carbonate product, and can be used for the preparation of lithium carbonate with battery grade standard.

Owner:CINF ENG CO LTD +1

Preparation for cefbuperazone sodium

The invention discloses a preparation method of Cefbuprazone Sodium, aiming at providing a method for preparing Cefbuprazone Sodium, which can substitute for the method of freezing and drying so as to be suitable for preparing Cefbuprazone Sodium economically in large scale. Solution which contains Cefbuprazone Sodium is added into a solvent, then obtaining the Cefbuprazone Sodium product after separation.

Owner:FUXIN BROAD PHARMA

Method for decreasing content of sodium chloride impurities in recovered sodium formate

InactiveCN102746134ASodium chloride impurity content is reducedCarboxylic compound separation/purificationFiltrationRaffinate

The invention relates to a method for decreasing the content of sodium chloride impurities in recovered sodium formate, which is applicable for recovering the sodium formate from a rongalite mother solution. According to the method, sodium chloride is separated out in the concentrating working procedure of a rectified raffinate, and the method comprises the following steps of A. heating the concentrated rectified raffinate to the temperature of 105-110 DEG C under the vacuum degree of -0.08 to -0.09Mpa to separate out the sodium chloride from the raffinate; B. closing the vacuum, emptying, and continuously heating to the temperature of 130-135 DEG C to dissolve the sodium formate which is separated out through crystallization in the vacuum concentrating process of the raffinate; and C. after the temperature reaches to 130-135 DEG C, placing a material into a filter with a jacket, and carrying out vacuum filtration to separate the sodium chloride which is separated out of the material from a material solution; and placing the material solution which is obtained through the filtration into a crystallization kettle, and adding methanol with the volume accounting for about 1 / 4 of that of the material solution to obtain the recovered sodium formate with the low-content sodium chloride impurities through filter-pressing and drying processes after extraction and crystallization. The content of the sodium formate in a recovered sodium-formate product which is obtained by the method is higher than 88 percent, and the content of the sodium chloride impurities is lower than 5 percent.

Owner:湖南中成化工有限公司

Modified disodium pyrophosphate

Delayed reaction modified disodium dihydrogen diphosphate (SAPP), the preparation thereof and the use thereof as a leavening acid for the production of baked goods. The process for the preparation of the modified disodium dihydrogen diphosphate (SAPP), includes adding an aqueous solution containing at least one of sodium hydroxide and sodium carbonate to an aqueous phosphoric acid solution containing at least one compound of magnesium, calcium, potassium, aluminium the total amount of magnesium plus calcium plus potassium plus aluminium being at least 300 ppm, to obtain an aqueous solution product and dewatering the aqueous solution product at a temperature in the range of from 190 to 250° C. to obtain a modified disodium dihydrogen diphosphate product having an orthophosphate content, measured as P2O5, of <5.0 wt. %.

Owner:CHEM FAB BUDENHEIM AG

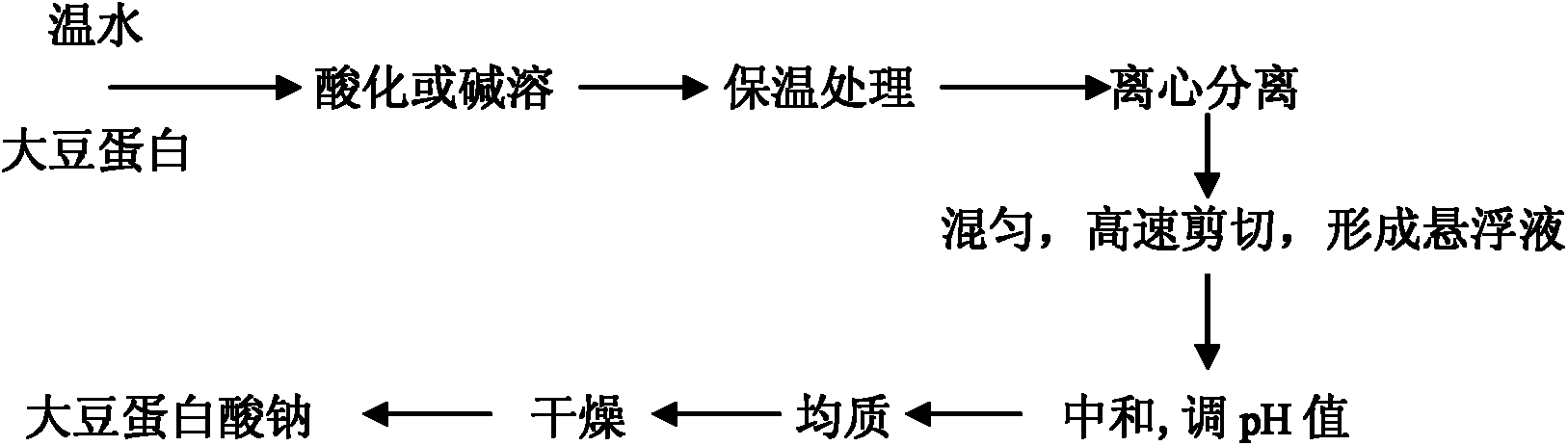

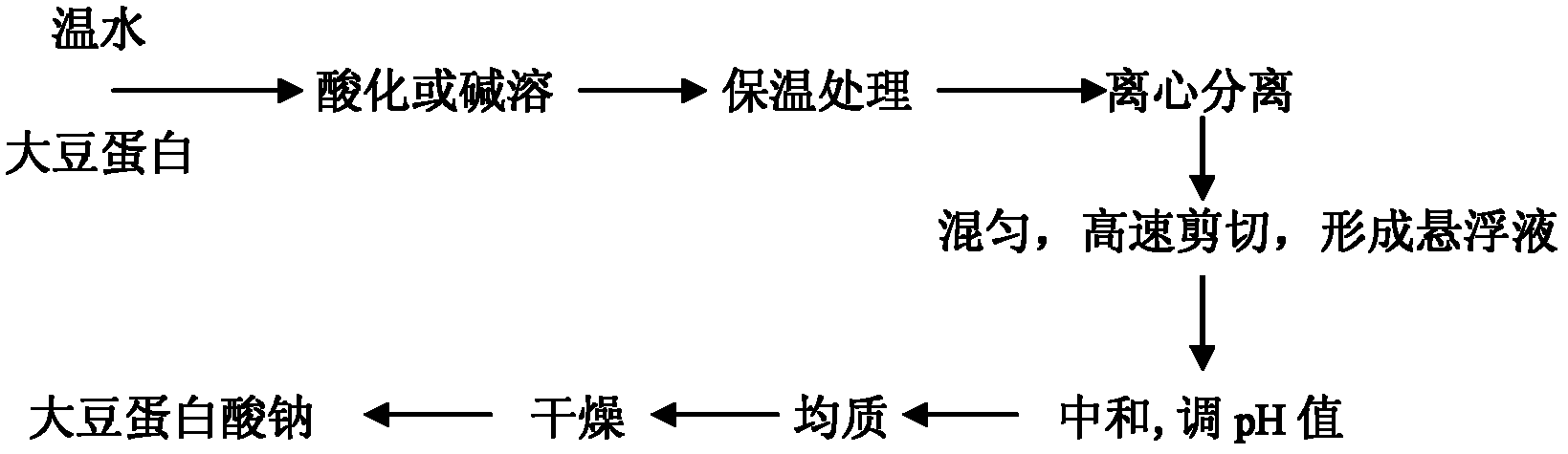

Preparation method of soybean protein acid sodium

InactiveCN102613386AIncrease the scope of applicationGood application effectVegetable proteins working-upSolubilityEmulsion

The invention relates to a preparation method of soybean protein acid sodium. The preparation method comprises the following steps: mixing soybean protein with warm water, acidifying or alkali-dissolving the mixture, thermally insulating the mixture for a period of time and then centrifuging the mixture, taking out the substances rich in protein and uniformly mixing the substances, carrying out high-velocity shearing to obtain a suspension, adjusting the pH value of the suspension to 7.0-8.0, and finally homogenizing and drying the suspension to obtain soybean protein acid sodium. According to the invention, the excellent solubility and emulsifying properties of the soybean protein are sufficiently utilized, the structure and property of the natural protein are changed by acid and alkali treatment and ionization treatment, furthermore, the hydrophilic / lipophilic balance value of the soybean protein is obviously changed, and the soybean protein acid sodium product with excellent foaming properties and emulsion properties is prepared, and moreover, the application range and effect of the soybean protein are expanded.

Owner:LIUZHOU YANGSHENG TECH

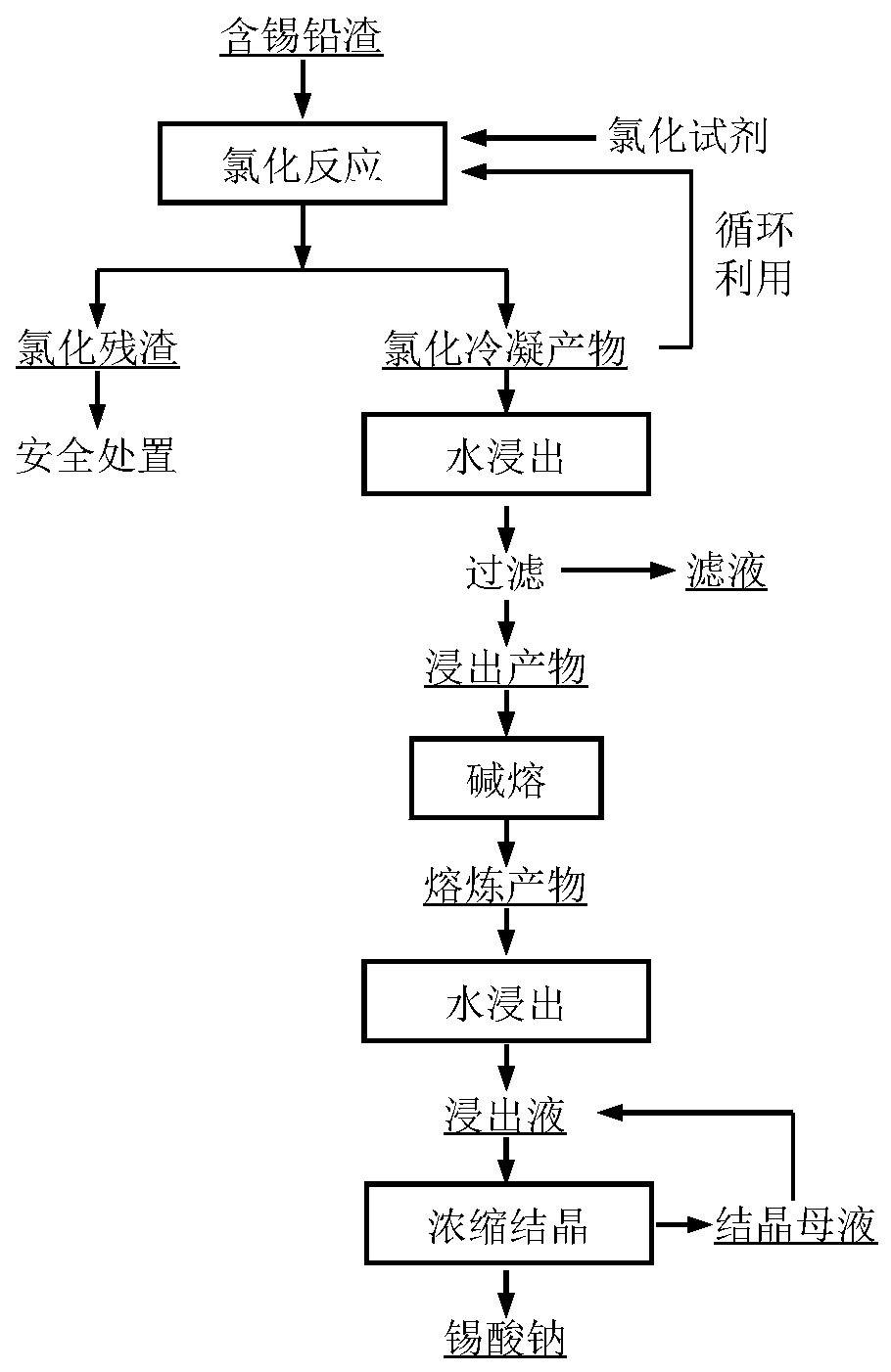

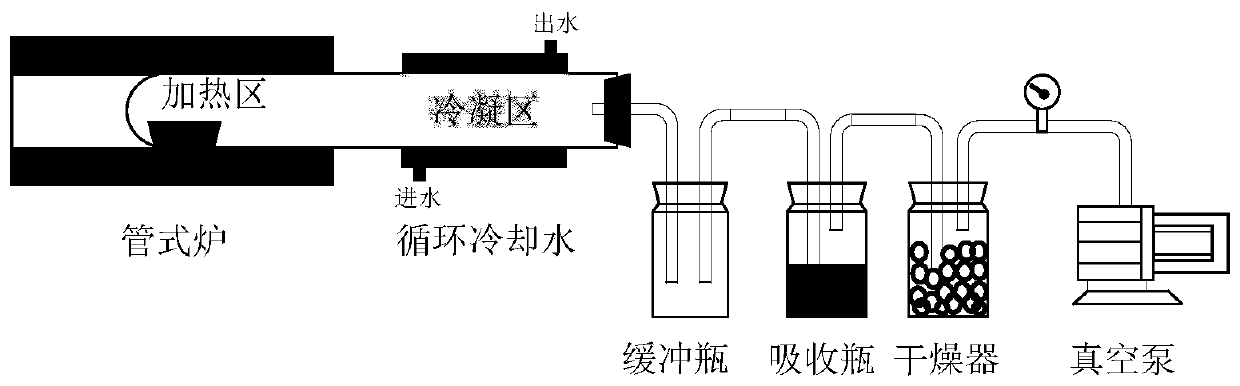

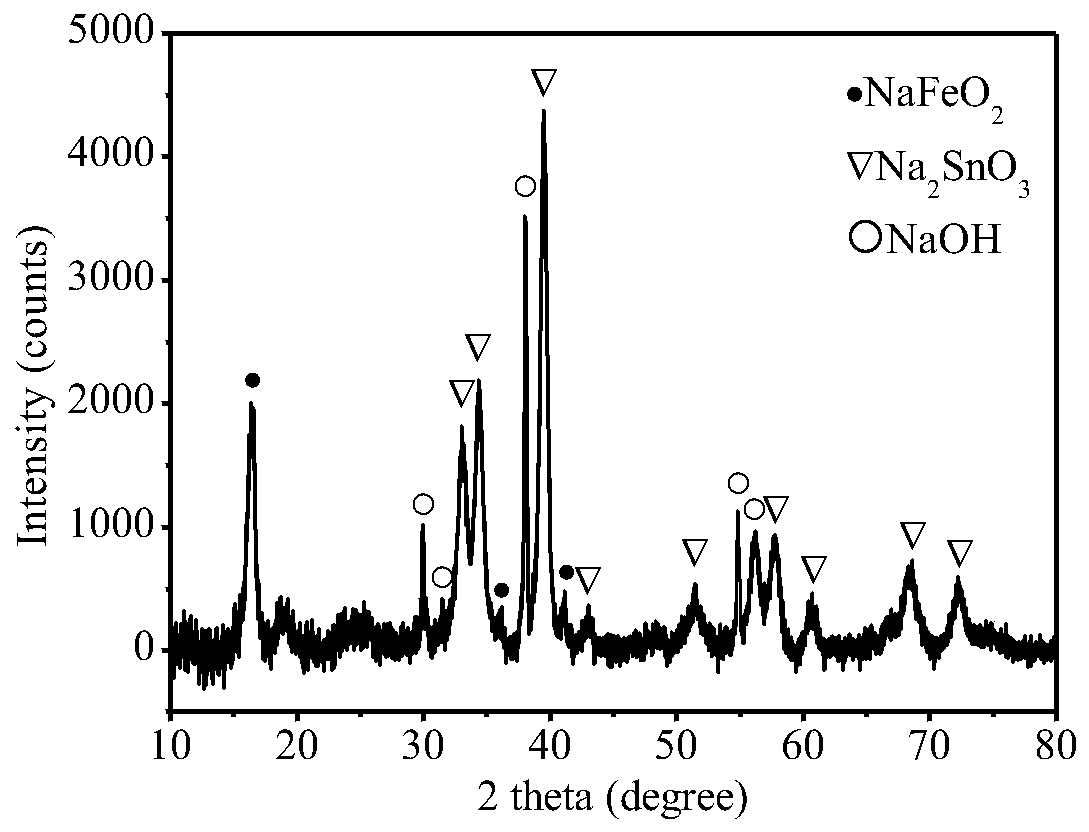

Method for recycling tin from tin-containing lead slag

ActiveCN110872649AThe process is simple and easy to controlProcess efficiency improvementSlagWater chlorination

The invention belongs to the field of solid waste recycling, and particularly relates to a method for recycling tin from tin-containing lead slag. According to the method for recycling tin from tin-containing lead slag, a sodium stannate product is prepared through a chlorination-water leaching-alkali fusion-water leaching-concentration crystallization process, the process is simple and controllable, low-grade tin elements in the tin-containing lead slag can be extracted, and the sodium stannate product is prepared. The prepared sodium stannate product meets the GB / T26040 first-level standard.The tin recycling rate in the process can reach 93.8wt%. The method provides a feasible path for recycling of low-grade tin slag.

Owner:HUAZHONG UNIV OF SCI & TECH

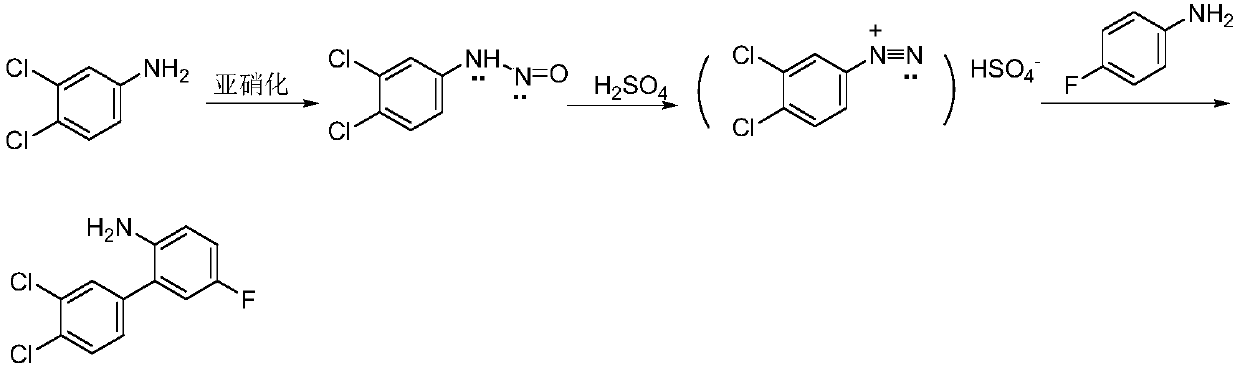

Method for synthesizing 3, 4-dichloro-2-amino-5-fluorobiphenyl

InactiveCN111072492AHigh selectivityAchieving processing powerAmino preparation from aminesAlkali metal sulfite/sulfate purificationNitrosylsulfuric acidNitroso

The invention discloses a method for synthesizing 3, 4-dichloro-2-amino-5-fluorobiphenyl. The method comprises the following steps: carrying out diazotization reaction on substrate 3, 4-dichloroaniline and nitroso sulfuric acid to prepare diazonium salt; carrying out a coupling reaction on the diazonium salt and 4-fluoroaniline to obtain the product 3, 4-dichloro-2-amino-5-fluorobiphenyl; sodium chloride needing landfill treatment is not generated in the reaction process, and the method has the characteristics of mild conditions, simple operation, high raw material conversion rate and productselectivity, low energy consumption and the like, and is suitable for industrial production; byproduct sodium sulfate generated by the reaction is a brownish yellow solid; a colorless sodium sulfate product is obtained after resin adsorption decoloration and thermal evaporation concentration crystallization combined process treatment, harmless treatment and resource utilization of sodium sulfate-containing waste salt slag are realized in the whole process, the produced sodium sulfate product reaches the industrial-grade anhydrous sodium sulfate product standard, the economic benefit is improved, and the environmental pollution is avoided.

Owner:ZHEJIANG UNIV OF TECH

Faropenem sodium and tablet thereof

The invention provides faropenem sodium and a preparation method thereof. The preparation method comprises the steps of: (1) putting (R)-tetrahydrofuran-2-thionocarboxylic acid in a reaction bulb, adding 1 mol / L sodium hydroxide solution to regulate the pH to 9-10, dripping 4AA acetone solution at 0 DEG C, regulating the pH to about 8 through 1 mol / L sodium hydroxide after dripping the acetone solution, reacting at room temperature, and extracting to obtain a product 1; (2) mixing the product 1 with triethylamine and dichloromethane, dripping oxalyl chloride allyl ester at 0 DEG C, reacting at the same temperature after dripping the oxalyl chloride allyl ester, and extracting to obtain a light yellow oily product 2; (3) dissolving the product 2 in dimethylbenzene, adding hydroquinone and triethyl phosphate, heating and refluxing, and extracting to obtain a product 3; and (4) dissolving the product 3 in acetonitrile, adding 0.1 mol / L hydrochloric acid at room temperature, stirring to react, adding saturated sodium bicarbonate solution, distilling to remove the organic solvent, extracting and recrystallizing to obtain a pure faropenem sodium product. The invention further provides a tablet of faropenem sodium.

Owner:SUZHOU ERYE PHARMA CO LTD

Method for producing sodium fluoride and sodium silicate by utilizing fluorine-containing silicon slag

InactiveCN111392748ASolve the problem of solid waste treatmentNo pollutionAlkali metal silicatesAlkali metal fluoridesHexafluorosilicic acidSilicon dioxide

The invention discloses a method for producing sodium fluoride and sodium silicate from fluorine-containing silicon slag, which comprises the following steps: adding silicon slag containing silicon dioxide and fluosilicic acid into a sodium carbonate solution, and reacting to generate a mixture of sodium fluoride crystals and silicon dioxide; adding a caustic soda solution into filter cake obtained by solid-liquid separation, reacting to generate sodium fluoride crystal and sodium silicate mixed slurry, and carrying out solid-liquid separation to obtain crude sodium fluoride and liquid sodiumsilicate; subjecting the liquid sodium silicate to concentration and filtration again to remove precipitated sodium fluoride impurities so as to obtain a liquid sodium silicate product with the required modulus and concentration; washing and refining the crude sodium fluoride by using dilute caustic soda liquid, removing sodium silicate impurities, and neutralizing residual sodium hydroxide attached liquid on the sodium fluoride by using hydrofluoric acid to generate sodium fluoride; drying the refined wet sodium fluoride to obtain a sodium fluoride product of which the purity is greater than98%. The method is mature in technology, good in product quality, low in cost, free of waste water and waste residues and capable of thoroughly converting fluorine-containing silicon slag solid wasteinto sodium fluoride and sodium silicate products.

Owner:石家庄东昊化工研究院有限公司

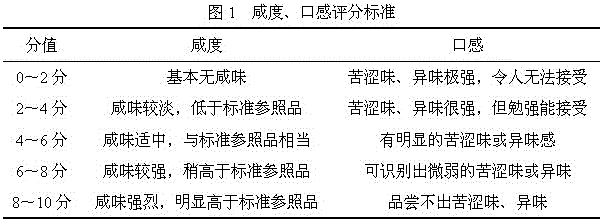

Preparation method of adult type organic and nutritious low-sodium salt

InactiveCN106418433AReduce intakeReduce sodiumFood ingredient functionsAdult typeAdditive ingredient

The present invention relates to a method of preparing adult type organic and nutritious low-sodium salt by using sodium gluconate. The present invention aims to reduce the harms caused to human body due to excessive ingestion of sodium elements in the edible salt. The organic and nutritious low-sodium salt is characterized by consisting of the following ingredients in weight percentages: 40%-50% of sodium chloride, 40%-50% of sodium gluconate, 4%-6% of resistant dextrin and 2%-5% of Shuke powder (a sweetener). The preparation method is as follows: the sodium chloride, sodium gluconate, resistant dextrin and Shuke powder are mixed according to the ratios, the mixture is dissolved in a deionized water, the dissolved mixture is stirred until the mixture is completely dissolved, and a spray-drying is conducted after the stirring for a certain time to obtain the organic and nutritious low-sodium salt products. When the low-sodium salt is used, the addition amount can refer to that of the edible salt.

Owner:温县兴发生物科技有限公司

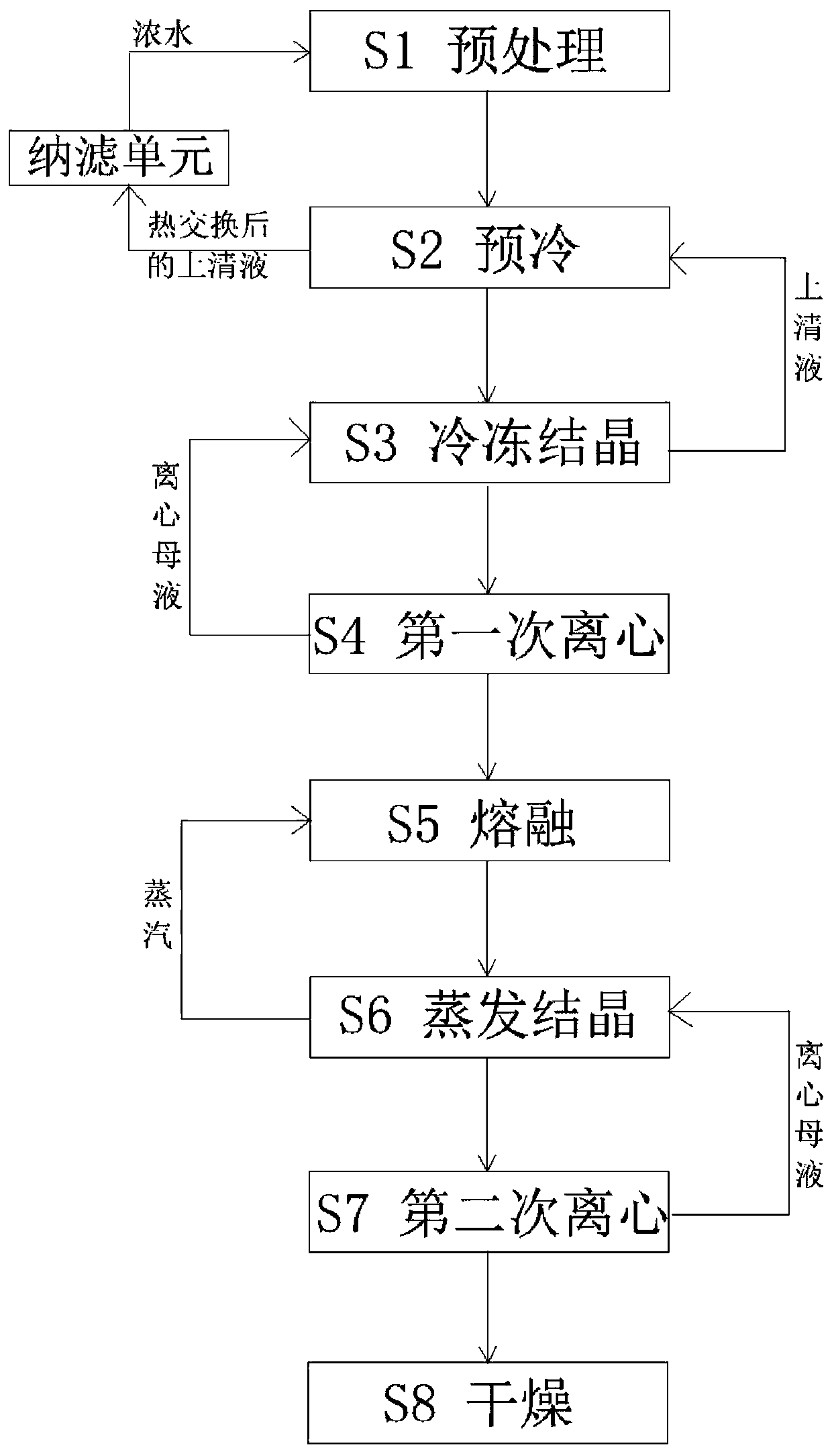

Process and system for recovering sodium sulfate from high-salt and high-COD wastewater in zero-discharge manner

InactiveCN111072205AGuaranteed uptimeHigh recovery rateWater/sewage treatment by centrifugal separationAlkali metal sulfite/sulfate purificationCentrifugationProcess engineering

The invention provides a process and a system for recovering sodium sulfate from high-salt and high-COD wastewater in a zero-discharge manner, and solves the problems that an existing system is unstable in operation and poor in zero-discharge reliability and sodium sulfate product salt cannot meet the requirements of class I first-class products. The process sequentially comprises the following steps: pretreatment, precooling, freezing crystallization, primary centrifugation, melting, evaporative crystallization, secondary centrifugation and drying. The system comprises a pretreatment unit, aprecooling heat exchanger, a circulating freezing crystallization unit, a first centrifugal machine, a hot melting kettle, a circulating sodium sulfate evaporation crystallization unit, a nanofiltration unit, an advanced oxidation pond, a second centrifugal machine and a drying packaging unit.

Owner:SHAANXI AEROSPACE ELECTROMECHANICAL ENVIRONMENTAL ENG DESIGNING INST CO LTD

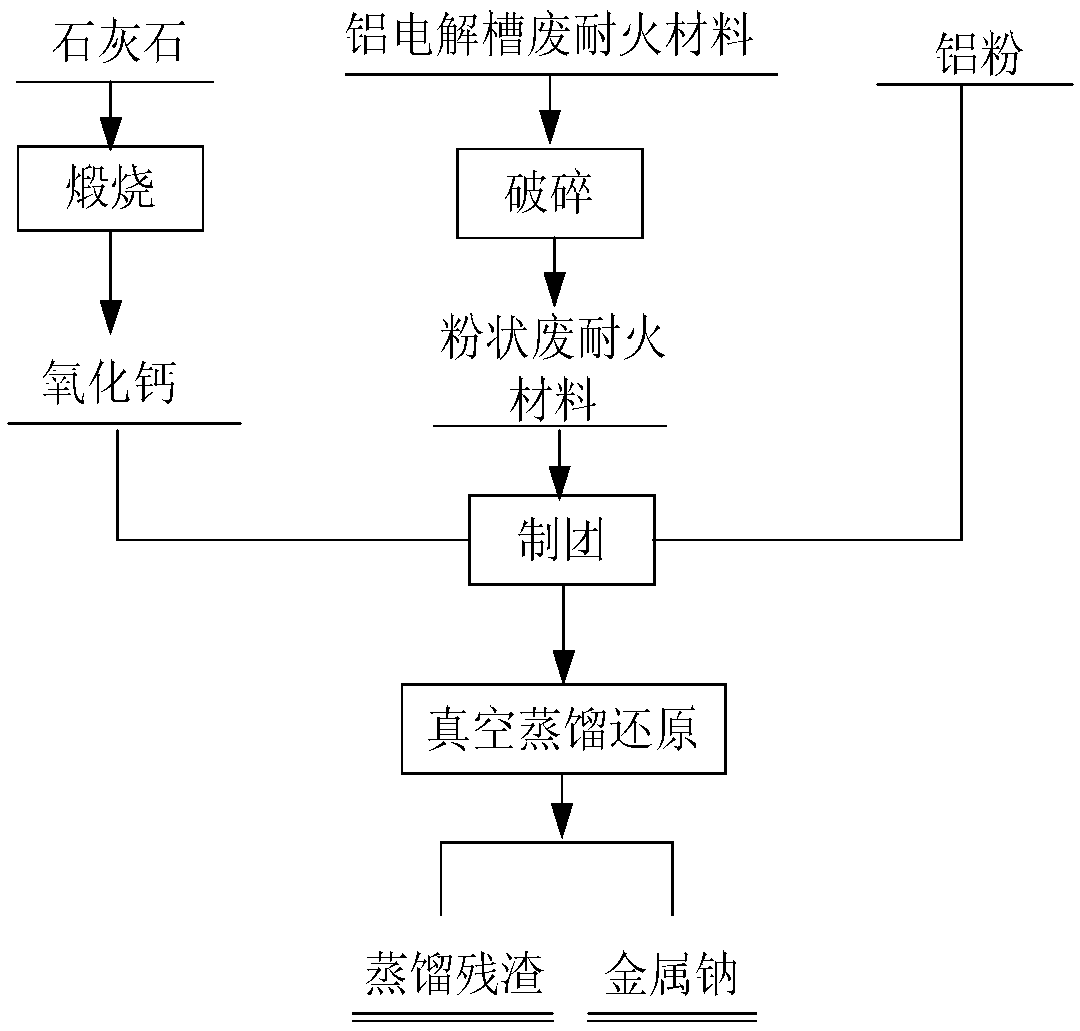

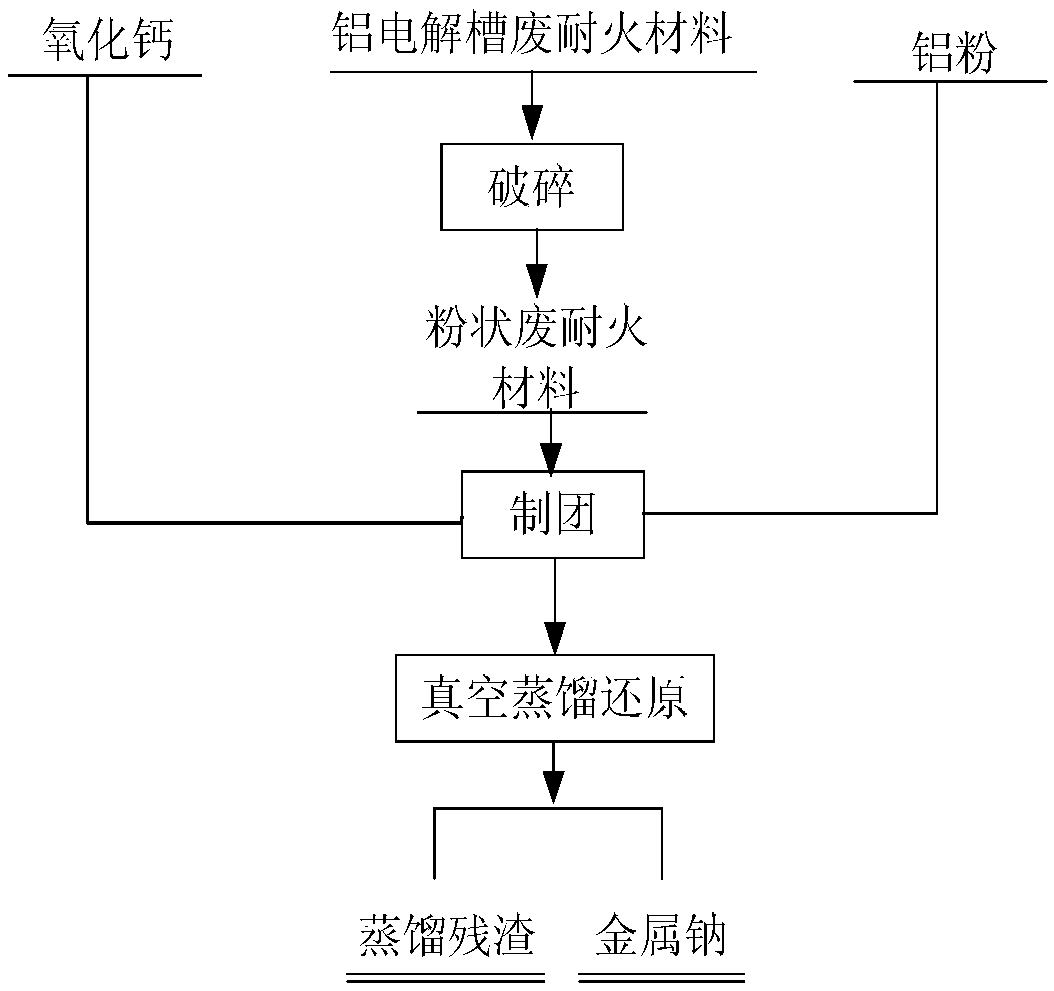

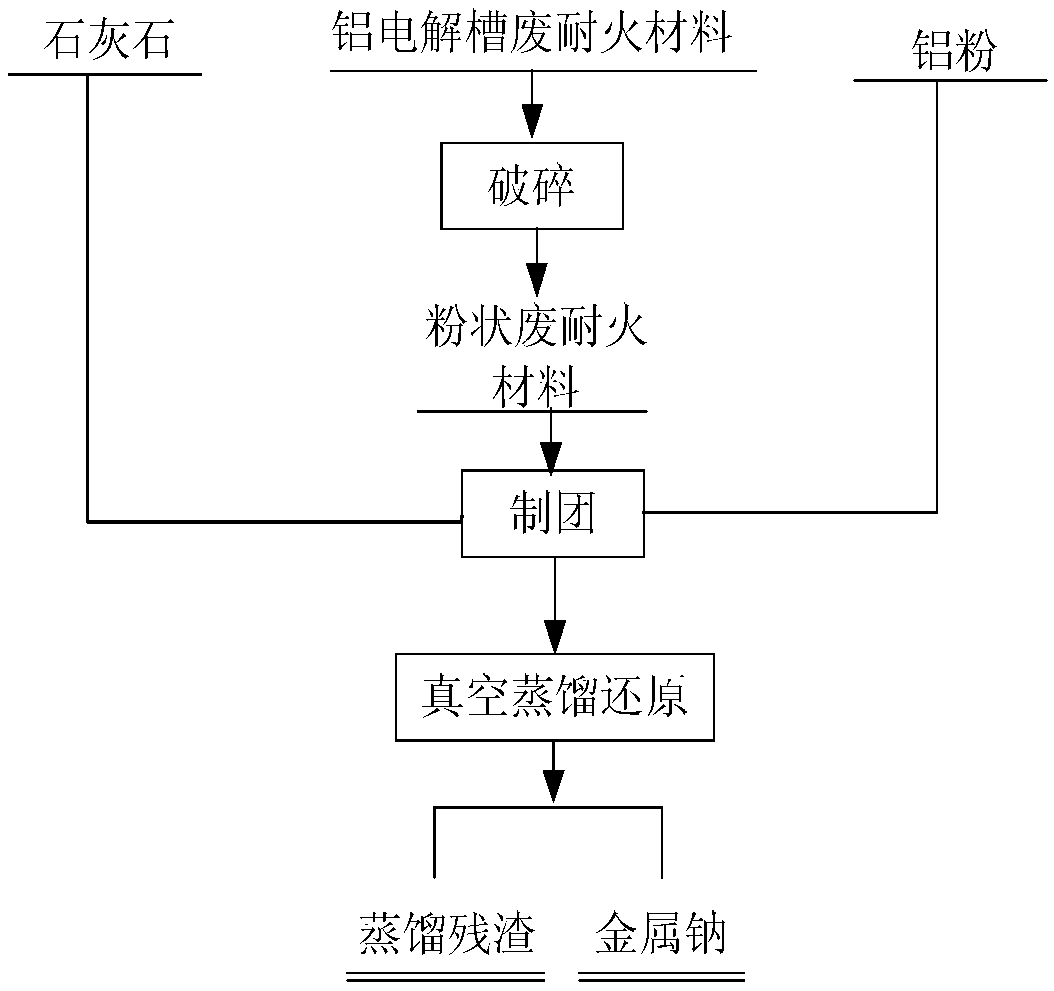

Treatment method of aluminum electrolysis cell waste fireproof material

ActiveCN109207738ARealize harmless treatmentSimple processCalcium/strontium/barium fluoridesProcess efficiency improvementRefractoryMixed materials

The invention provides a treatment method of an aluminum electrolysis cell waste fireproof material, and belongs to the technical field of metallurgy and environment. The treatment method specificallycomprises the following steps that the waste fireproof material and aluminum powder are mixed with calcium oxide / calcium carbonate according to ratio to form a mixed material, the mixed material is produced to be blocks with the block diameter being 10-30mm, heating distillation is conducted, fluoride in the waste fireproof material reacts with calcium oxide to generate insoluble calcium fluoride, meanwhile sodium oxide in the waste fireproof material is reduced to be metal sodium by aluminum and distilled out under the vacuum condition, accordingly conversion of fluoride and separation of the sodium element in the waste fireproof material are achieved, the purpose of harmless treatment of the waste fireproof material is realized, the sodium product is obtained, the technology is simple,the cost is low, and the treatment method can save energy and is environmentally friendly.

Owner:NORTHEASTERN UNIV

Method and device for treating converted gas in production of sodium nitrate

ActiveCN103553084AHigh purityIncrease profitAlkali metal nitrate preparationNitric oxideDC - Direct currentVapor–liquid separator

The invention relates to a method and a device for treating converted gas in the production of sodium nitrate. The device comprises a conversion tower, a pre-conversion tower, an electric deentrainment tower, a gas-liquid separator, an acid-seal device and an absorption tower, wherein the electric deentrainment tower is provided with a constant-current high-pressure direct-current electric field for conversion. The gas outlet on the top of the conversion tower is connected with the converted gas inlet of the pre-conversion tower. The converted gas outlet of the pre-conversion tower is connected with the converted gas inlet, the converted gas outlet is connected with the absorption tower, and the separation liquid outlet is connected with the acid-seal device. Sodium nitrite mother solution and dilute nitric acid are subjected to conversion reaction in the conversion tower to produce sodium nitrate solution and converted gas, the sodium nitrate solution is sent to a nitrate work section to produce sodium nitrate product, and the converted gas enters into the pre-conversion tower to be subjected to pre-conversion reaction with the mother solution. The converted gas departing from the pre-conversion tower enters an alkali absorption system after the acid mist and liquid drops of nitric acid and fine foams of nitrate solution are removed by passing though the constant-current high-pressure direct-current electric field of the electric deentrainment tower. According to the method and the device for treating converted gas in the production of sodium nitrate, the high-voltage direct-current electric field is utilized to capture impurities in the converted gas so as to purify the converted gas, the use ratio of converted gas is increased, and the quality of sodium nitrite product and sodium nitrate product are improved.

Owner:SHIJIAZHUANG FENGSHAN CHEM

High-organic-matter sodium sulfate hazardous waste simple recycling process and system

ActiveCN105948079AShort processReasonable processEnergy inputAlkali metal sulfides/polysulfidesDecompositionSulfite salt

The invention discloses a high-organic-matter sodium sulfate concentrated solution simple recycling process and system. The method comprises the steps: determining according to hazardous waste total organic carbon, and adding a proper amount of a reducing agent into a material; and drying the mixture with system waste heat, allowing the mixture to enter a rotary reduction furnace, producing a sodium sulfide product, absorbing tail gas with an alkali, and producing anhydrous sodium sulfite. According to the process, wastewater COD oxygen consumption characteristics and the self heat value are creatively utilized, heat producing from organic matter decomposition is used, sodium sulfate is reduced to produce sodium sulfide while organic matters are degraded, high-cost treatment of sulfate hazardous waste is changed into benefit production, and the process is an ideal path for recycling the high-organic-matter sodium sulfate hazardous waste, and has huge economic value and social benefits.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY +2

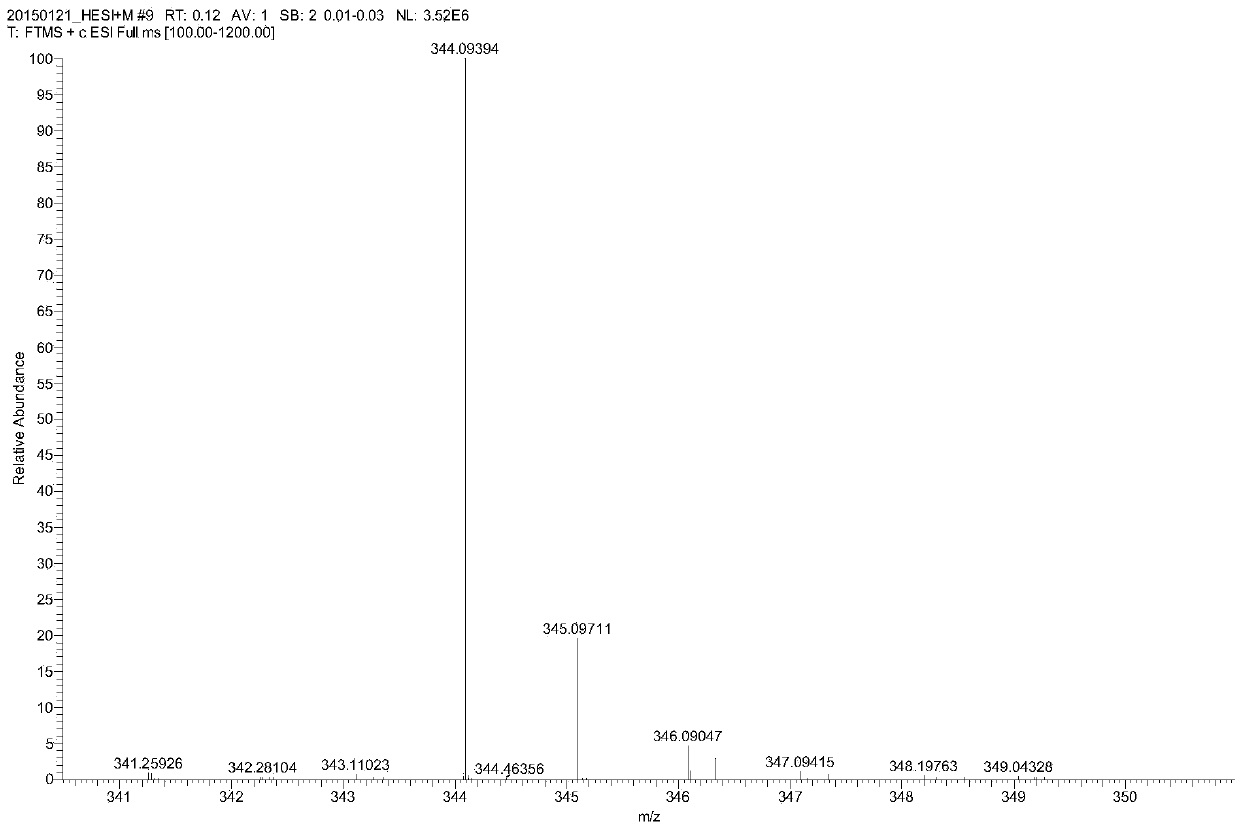

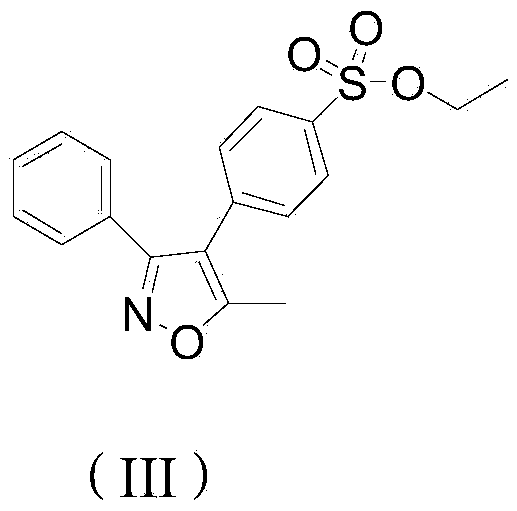

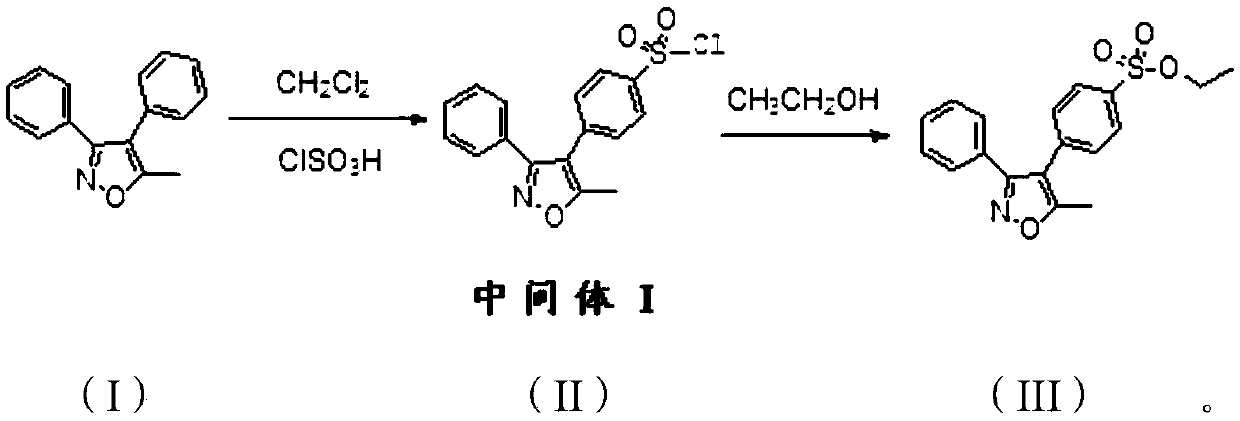

Preparation method of parecoxib sodium synthesis technology impurities

ActiveCN105367508AEffectively control the quality of finished productsEffective quality controlOrganic chemistryComponent separationParecoxib sodiumMass spectrometry

The present invention provides a preparation method of parecoxib sodium synthesis technology impurities. The method comprises the step of using 5-methyl-3,4-diphenylisoxazole as a raw material to synthesize a target product 4-(5-methyl-3-phenyl-isoxazolyl) ethyl benzenesulphonate through sulfonation reaction and esterification reaction. The impurities are genotoxic impurities of parecoxib sodium, and the study of a synthesizing method of the impurities is beneficial to the study of an impurity profile of parecoxib sodium and quality control of a parecoxib sodium product. The structure of the impurities is as shown in a formula in the specification.

Owner:BENGBU BBCA MEDICINE SCI DEV

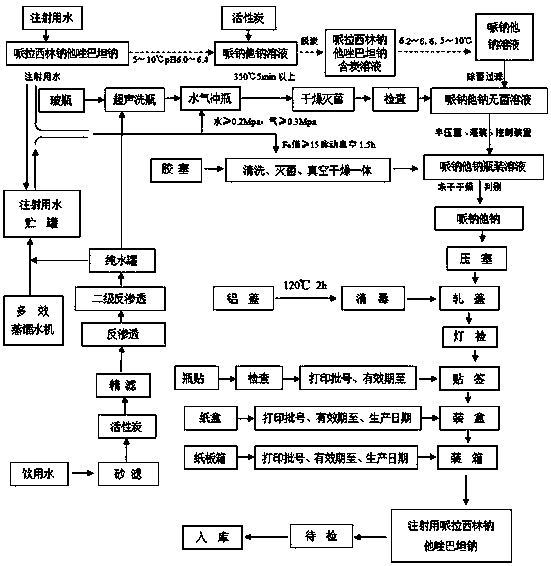

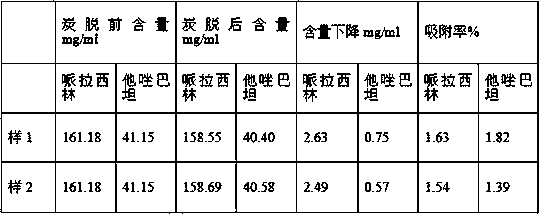

Prescription and technology of piperacillin sodium and tazobactam sodium for injection

InactiveCN108619154AQuality improvementSimple manufacturing process stepsAntibacterial agentsOrganic active ingredientsSodium bicarbonateActivated carbon

The invention discloses a prescription of piperacillin sodium and tazobactam sodium for injection, which comprises the following raw materials: 1000 parts of piperacillin sodium, 250 parts of tazobactam sodium, 25 parts of activated carbon, an appropriate amount of sodium hydrogen carbonate, and an appropriate amount of water for injection up to 6000 ml. The invention further discloses a technology of the piperacillin sodium and tazobactam sodium for injection, which comprises the following steps: selecting stainless steel utensils and performing dry heat sterilization treatment for later useafter washing clean; calculating the amount of the raw materials charged according to the ratio in the prescription, and preparing 1000 pieces of the piperacillin sodium and tazobactam sodium for injection, which comprise 1000 g of piperacillin sodium, 250 g of tazobactam sodium and 25 g of activated carbon respectively, according to the specification of 1.25g / piece; and preparing 1000 pieces of the piperacillin sodium and tazobactam sodium for injection, which comprise 2000 g of piperacillin sodium, 500 g of tazobactam sodium and 50 g of activated carbon respectively, according to the specification of 2.5g / piece. The prescription disclosed by the invention and the preparation technology using the prescription are simple in steps, and a higher quality piperacillin sodium tazobactam and sodium product for injection can be produced.

Owner:JIANGSU HAIHONG PHARMA

Method for removing sulfate radicals and hydrogen sulfate radicals when preparing sodium molybdate from molybdenum-containing waste catalyst through tertiary amine extraction method

InactiveCN110451563AGuaranteed uniform performanceTransportation and packagingSolid waste disposalKeroseneCompound (substance)

The invention relates to a method for removing sulfate radicals and hydrogen sulfate radicals when preparing sodium molybdate from a molybdenum-containing waste catalyst through a tertiary amine extraction method. The method comprises the following steps that alkalified oxidation roasting, water leaching filtration, phosphorous removal by a chemical precipitation method, tertiary amine and a kerosene solution are adopted to treat the molybdenum-containing waste catalyst under a faintly acid condition to extract a molybdenum-sodium hydroxide solution and re-extract and concentrate crystal sodium molybdate product. According to the method, a dilute sodium hydroxide solution is used for eluting a molybdenum-loaded organic phase, which can reduce the sulfate radicals of the molybdenum-loaded organic phase to 1.96 g / L from 10.82 g / L before elution with the elution rate of 81.88%. After the molybdenum-loaded organic phase is diluted through a dilute alkali liquor, an alkali liquor is used for reextraction to obtain a high-concentration sodium molybdate solution with Mo / SO4<2-> larger than 100 and SO4<2-> content less than 2g / L, and the crystal is concentrated to obtain the sodium molybdate product with the SO4<2-> less than or equal to 0.05%, which meets the requirements of industrial first-class products.

Owner:河北欣芮再生资源利用有限公司

Environment-friendly production method for preparing paratoluenesulfonic acid sodium salt from waste sulfuric acid

InactiveCN106748900ASimple process equipmentLow heating temperatureOrganic compound preparationSulfonic acids salts preparationTosylic acidSodium-p-toluenesulfinate

The invention discloses an environment-friendly production method for preparing paratoluenesulfonic acid sodium salt from waste sulfuric acid. The environment-friendly production method comprises the following steps: (1) concentrating the waste sulfuric acid until weight percentage concentration of the sulfuric acid is greater than 70%, and adding methylbenzene into the sulfuric acid in a weight ratio of (1.2 to 2.0) : 1, and heating to 100-160 DEG C to react, thereby obtaining p-toluenesulfonic acid; (2) enabling a solution containing the p-toluenesulfonic acid to perform neutral reaction with a sodium hydroxide aqueous solution, thereby obtaining paratoluenesulfonic acid sodium; and (3) discoloring the solution containing paratoluenesulfonic acid sodium through active carbon, performing crystal separation, and drying to obtain a paratoluenesulfonic acid sodium product. The environment-friendly production method is used to solve the problem that the waste sulfuric acid is difficult to treat and provide a new idea for a paratoluenesulfonic acid sodium preparation process, and has great innovativeness and common applicability for a preparation process for the paratoluenesulfonic acid sodium salt.

Owner:四川省中明环境治理有限公司

Method for improving quality of cemandil sodium by using three-dimensional column plate to purify solvent

ActiveCN106565749AImprove product qualityInhibitionAntibacterial agentsPowder deliveryAlkyl transferOrganic solvent

The present invention discloses a method for improving the quality of cemandil sodium by using a three-dimensional column plate to purify a solvent. The method comprises: solvent purification, alkylation reaction, cefamandole ester synthesis, extraction, cemandil sodium synthesis, and sterile sub-packaging. According to the present invention, during the cemandil sodium preparation process, the reaction system solvent is purified by using the high-throughput efficient three-dimensional mass transfer column tray technology so as to finally improve the quality of the cemandil sodium product and ensure the quality of the cemandil sodium powder-needle preparation for injection. The invention provides the method for improving the quality of the cemandil sodium powder-needle preparation for injection by using the three-dimensional column tray mass transfer technology to purify the organic solvent.

Owner:NORTH CHINA PHARMA HEBEI HUAMIN PHARMA

Method for preparing energy-saving and environment-friendly triazole sodium

The invention discloses a method for preparing energy-saving and environment-friendly triazole sodium. The method comprises the followings steps of reacting formamide with hydrazine hydrate at the temperature of between 150 and 180 DEG C for 12 to 15 hours; after reaction, reducing the temperature to 60 to 80 DEG C, adding a mixed solvent prepared from butanediol and methanol, adding a 30 to 60 percent sodium hydroxide solution dropwise, and keeping the temperature of the mixture at 60 to 80 DEG C for 3 to 4 hours; and cooling and crystallizing, centrifuging and distilling, recycling centrifugal mother liquid, and drying crystals to obtain the triazole sodium product. The method has the advantages of eliminating a pilot process, separating by-products and intermediates by using the mixed solvent, realizing the production of triazole sodium in one step, shortening the process flow, lowering labor intensity, improving the purity of triazole sodium, recycling the intermediates, really saving energy and realizing environment-friendly and pollution-free production.

Owner:CHANGSHA XINBEN CHEM

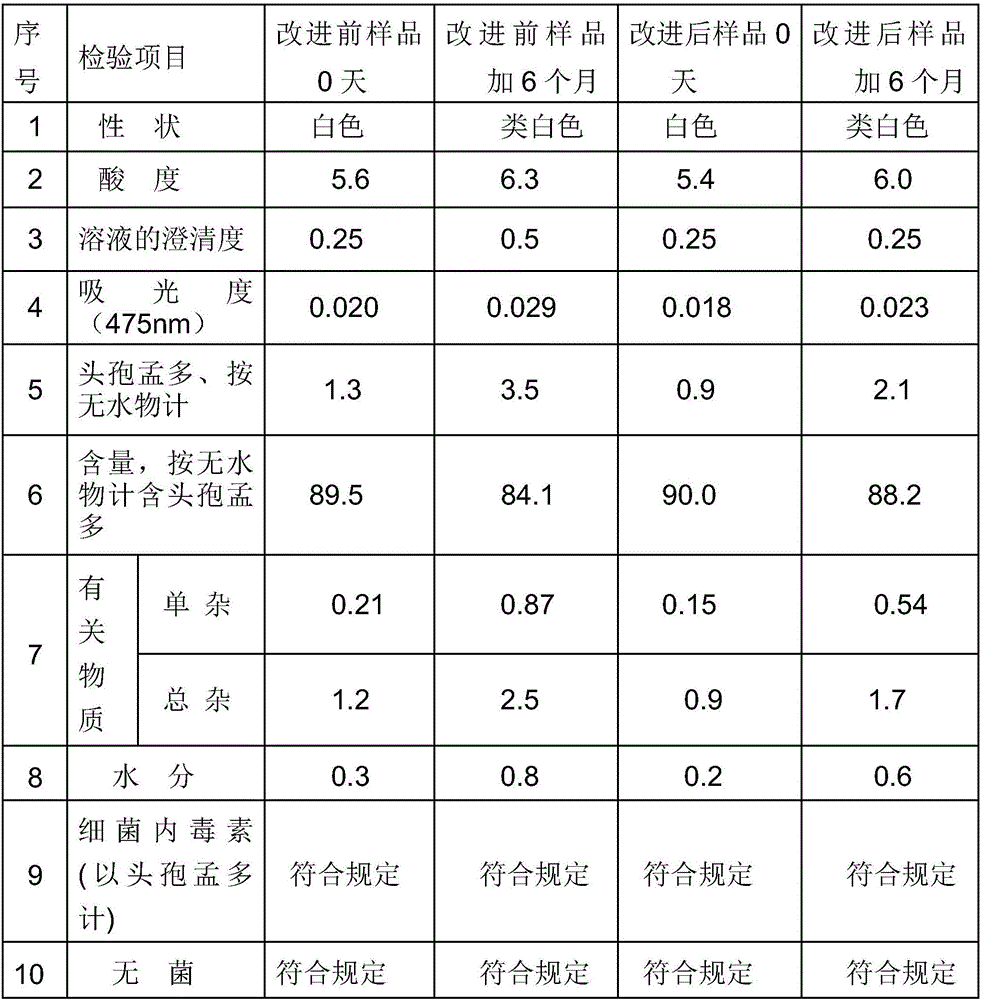

Method for preparing sodium sulfate from baking soda desulfurized fly ash by wet process

PendingCN114195174AWill not introduceHigh puritySulfate/bisulfate preparationHydration reactionResource recovery

The invention relates to a method for preparing sodium sulfate from baking soda desulfurized fly ash by a wet process, which comprises the following steps: firstly detecting the content of each component in the baking soda desulfurized fly ash, mixing with water to prepare turbid liquid after the content is qualified, then sequentially adding an oxidizing agent and an acid reagent for reaction, and finally evaporating, crystallizing and separating to obtain a target product Na2SO4. 10H2O. By means of the method, the steel mill solid waste baking soda desulfurization ash can be thoroughly converted into a high-purity and high-economic-value sodium sulfate hydrate product, the product is widely applied to multiple industries such as chemical engineering, food and pharmacy, and good economic benefits can be generated. Compared with existing other desulfurization ash solid waste resource recycling and reusing methods, the method has the advantages of being large in treatment capacity, thorough in conversion, high in product purity, little in waste water, free of limitation of other conditions and the like, and construction of green steel mills is promoted.

Owner:武汉钢铁有限公司

Preparation process of high-purity fluoxefom sodium

The invention discloses a preparation technology of high-purity flomoxef sodium. The preparation technology includes following steps: on the basis of a flomoxef intermediate, performing an acidifying reaction to obtain a reaction liquid; performing a water washing process, an extraction process, an aseptic filtration process and the like to the reaction liquid; and performing a solventing-out crystallization step through a one-step crystallization process to obtain a flomoxef sodium product with a purity being higher than 99.90%, wherein key points in the solventing-out crystallization step are selection and proportion of a solventing agent and dropwise addition of a salifying agent and the solventing agent at the same time with crystal growing. The preparation technology overcomes problems which are difficult to control during the solventing-out crystallization step of the flomoxef sodium. The flomoxef sodium is prepared in one step with the flomoxef intermediate as a raw material and the purity of the product of the flomoxef sodium reaches higher than 99.90% just through one crystallization step, which is cannot be achieved through a freeze-drying method or a common solventing-out crystallization process in the prior art. Quality of the product is in conformity with or even exceeds a standard in japanese pharmacopoeia JP16. The preparation technology has a more wide application prospect.

Owner:NORTH CHINA PHARMA HEBEI HUAMIN PHARMA

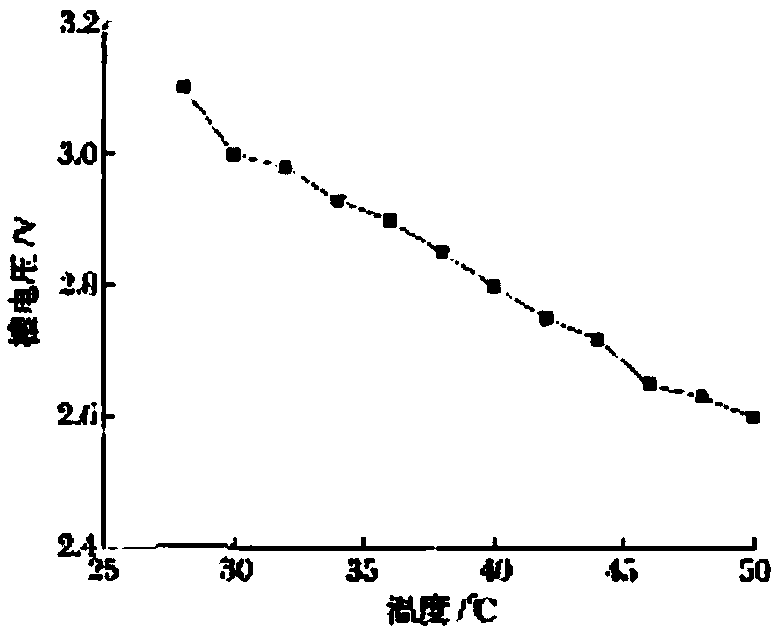

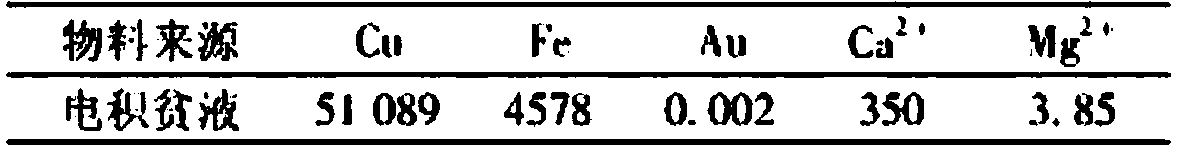

Method for producing sodium sulfide crystal by using electrowinning lean solution

InactiveCN108298564AReduce dosagePurify impuritiesPhotography auxillary processesAlkali metal sulfides/polysulfidesSulfationRoom temperature

The invention discloses a method for producing a sodium sulfide crystal by using an electrowinning lean solution. The method comprises the following steps: 1, evaporating and crystallizing the lean solution: evaporating the electrowinning lean solution in 100 DEG C hot water, cooling and crystallizing the evaporated solution at room temperature, filtering the crystallized solution, and performingnatural drying and weighing, wherein a product obtained after the crystallization is sodium sulfide, and can be applied as a leaching agent to a leaching system adopting sodium sulfide self-produced after sulfation and crystallization during antimony leaching; 2, adding the crystallized sodium sulfide obtained in step 1 in a dissolving liquid to form a sodium sulfate solution; 3, neutralizing andpurifying the sodium sulfate solution; and 4, performing reduction to prepare a sodium chloride product. The electrowinning lean solution is evaporated and crystallized to produce the sodium sulfide crystal, and the sodium sulfide crystal returns to a leaching workshop section and is afresh used in production, so the use amount of the sodium sulfide agent is reduced, impurities are removed from anelectrolyte, and the electrowinning process is optimized.

Owner:GANSU ZHAOJIN PRECIOUS METALS SMELTING

Method for reducing content of chloride ions in sodium stannate by using ultrasonic waves

The invention relates to a method for reducing the content of chloride ions in sodium stannate by using ultrasonic waves. The method comprises the following steps: (1) solution preparation: preparing a solution from a high-chlorine sodium stannate product and absolute ethyl alcohol according to a certain solid-liquid ratio; (2) heating: a step of heating the solution to 50 to 60 DEG C; (3) ultrasonic washing: placing the solution in an ultrasonic washing tank for ultrasonic concussion for 30 to 40 min; and (4) standing and filtering: after standing of the solution, carrying out filtering and drying so as to obtain a sodium stannate product with low chlorine content. The method provides a novel approach for removing chloride ions in the high-chlorine sodium stannate product; after treatment with the method, the high-purity sodium stannate product with chloride ion content of less than 0.01% can be obtained, so product quality is improved and influence of chloride ions on application of the sodium stannate product is reduced; and the method is simple and effective and provides a novel approach for preparation of the high-purity sodium stannate product.

Owner:LIUZHOU BAIRENTE ADVANCED MATERIALS

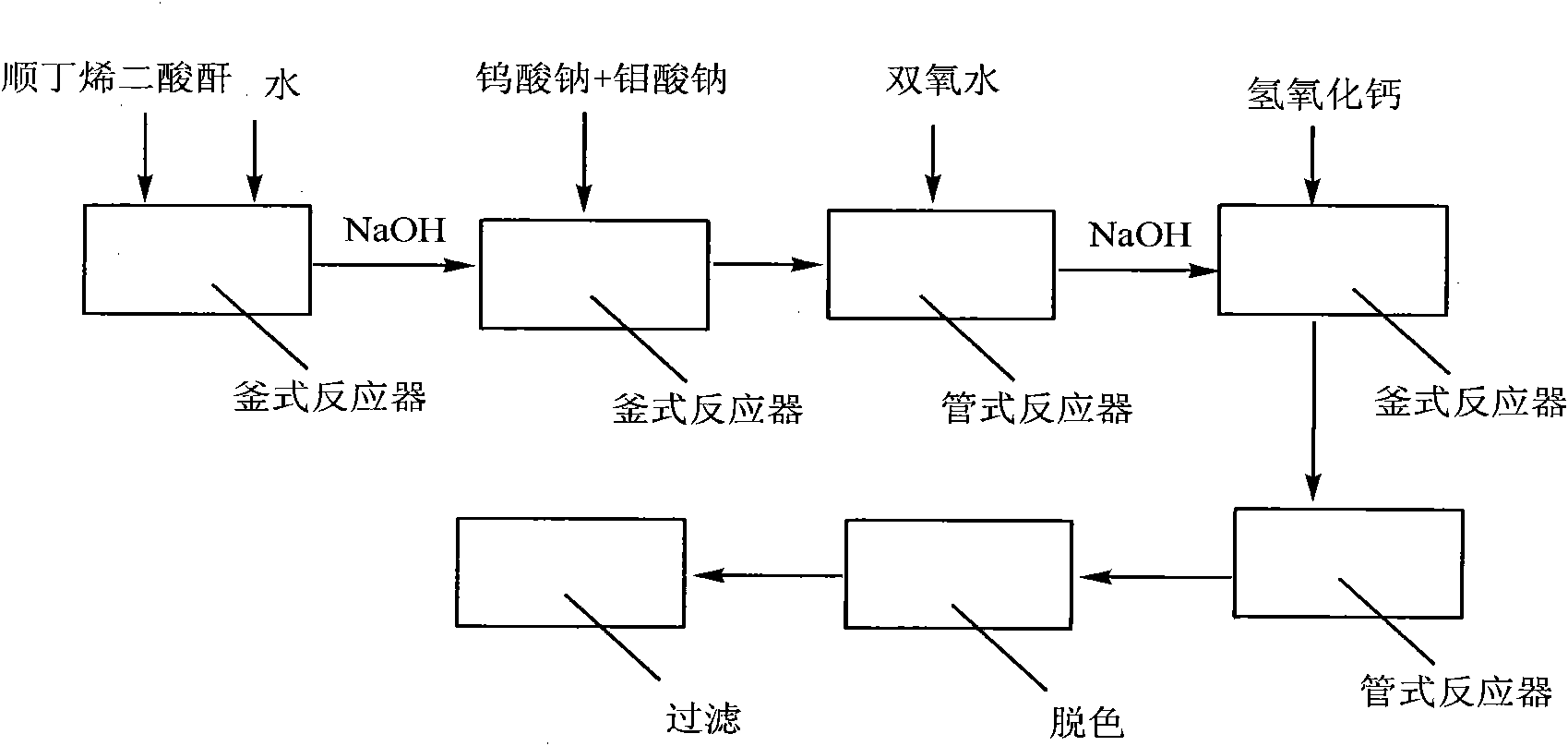

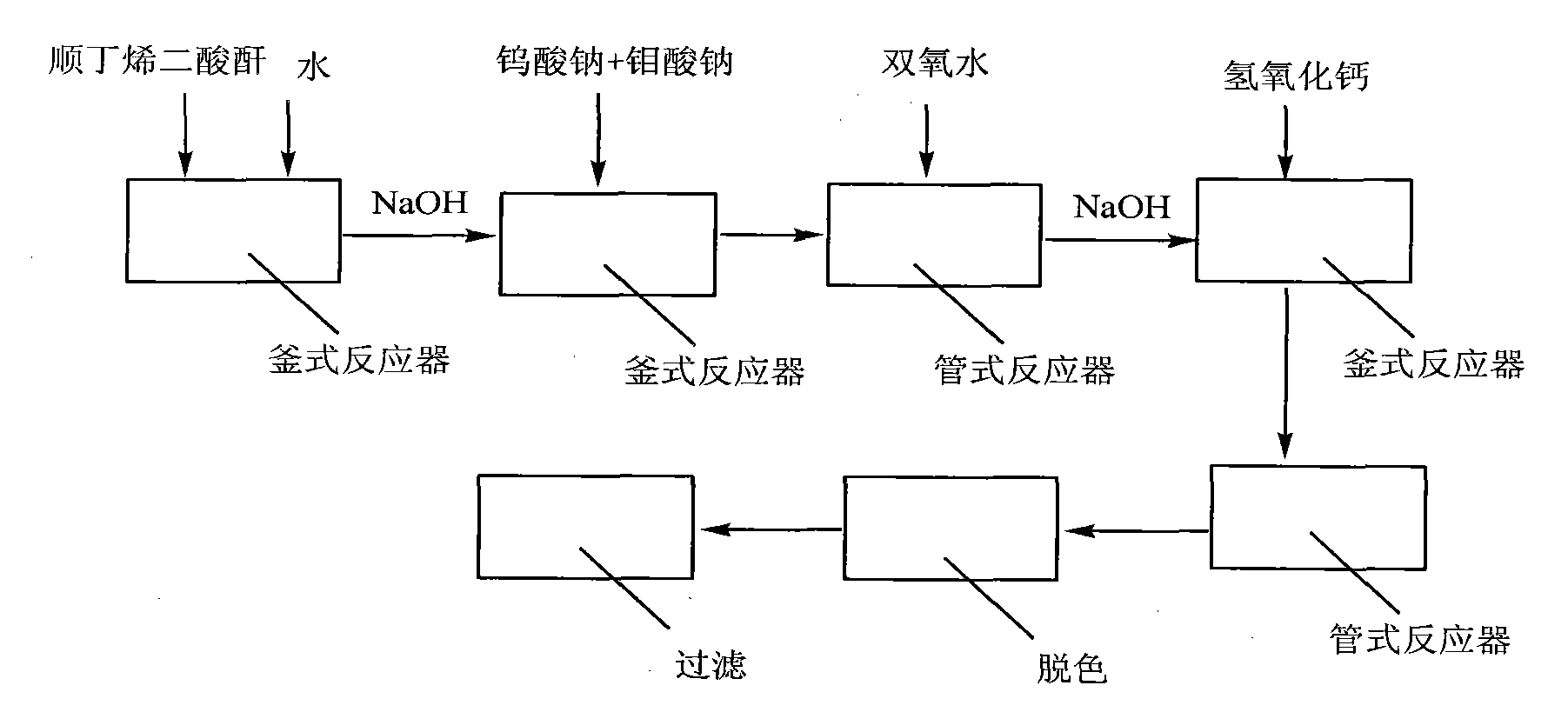

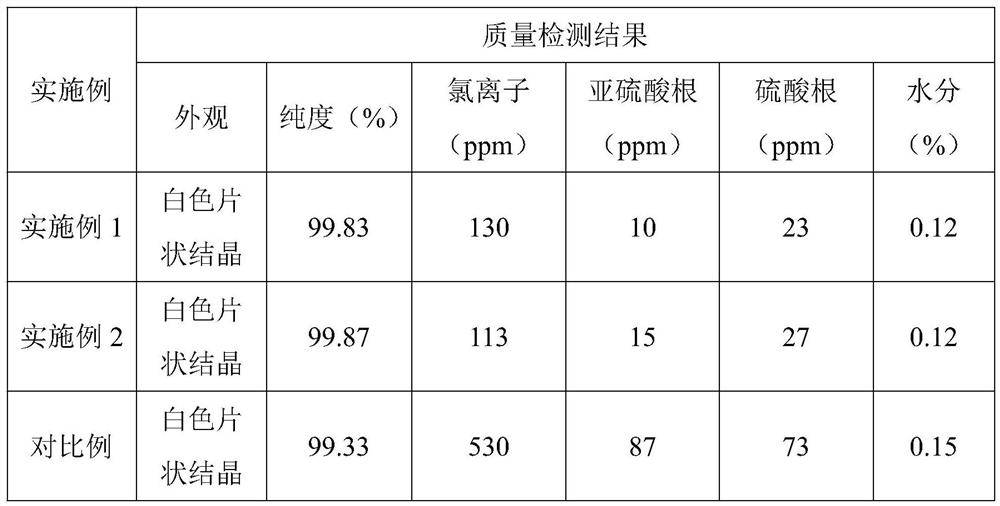

Preparation method for polyepoxy sodium succinate for water treatment

ActiveCN101602852BAvoid it happening againInhibit peroxidationScale removal and water softeningEpoxySuccinic acid

The invention relates to a preparation method for polyepoxy sodium succinate for water treatment. Maleic anhydride is hydrolyzed in water and alkaline environment; then one or two of sodium tungstate and sodium molybdate and hydrogen peroxide react in a tube-type reactor to generate epoxy sodium succinate; calcium hydroxide is added to react with the epoxy sodium succinate in the tube-type reactor at the temperature of 80-100 DEG C for 2-72 hours. The diameter of the tube-type reactor is phi 50-80 cm, and the length thereof is 30-200m. The obtained polyepoxy sodium succinate has stable product quality.

Owner:SHANDONG TAIHE WATER TREATMENT TECH CO LTD

A kind of synthetic and refining method of sodium methacrylate

ActiveCN112851555BIncrease concentrationIncrease productivityOrganic compound preparationOrganic chemistry methodsSulfite saltSodium sulfate

Owner:ZHEJIANG HUANGMA TECH +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com