Method for improving quality of cemandil sodium by using three-dimensional column plate to purify solvent

A technology of cefamandole sodium and three-dimensional trays is used in organic chemistry, pharmaceutical formulations, medical preparations containing active ingredients, etc., to achieve the effects of improving reaction quality and product quality, high product quality, and increasing solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

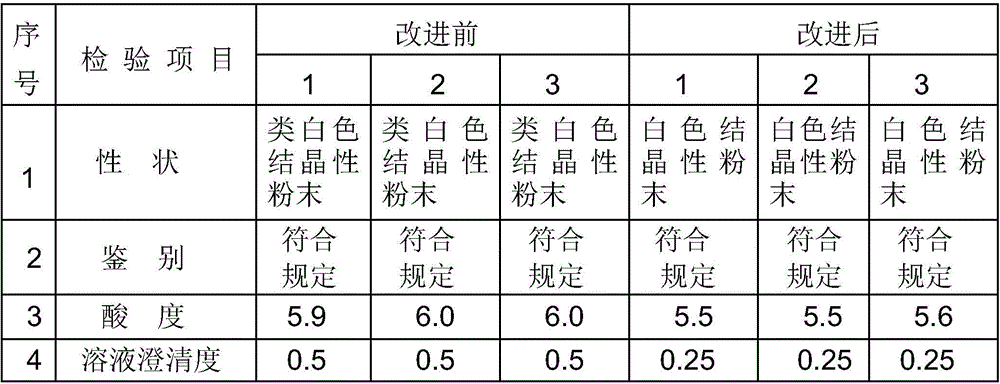

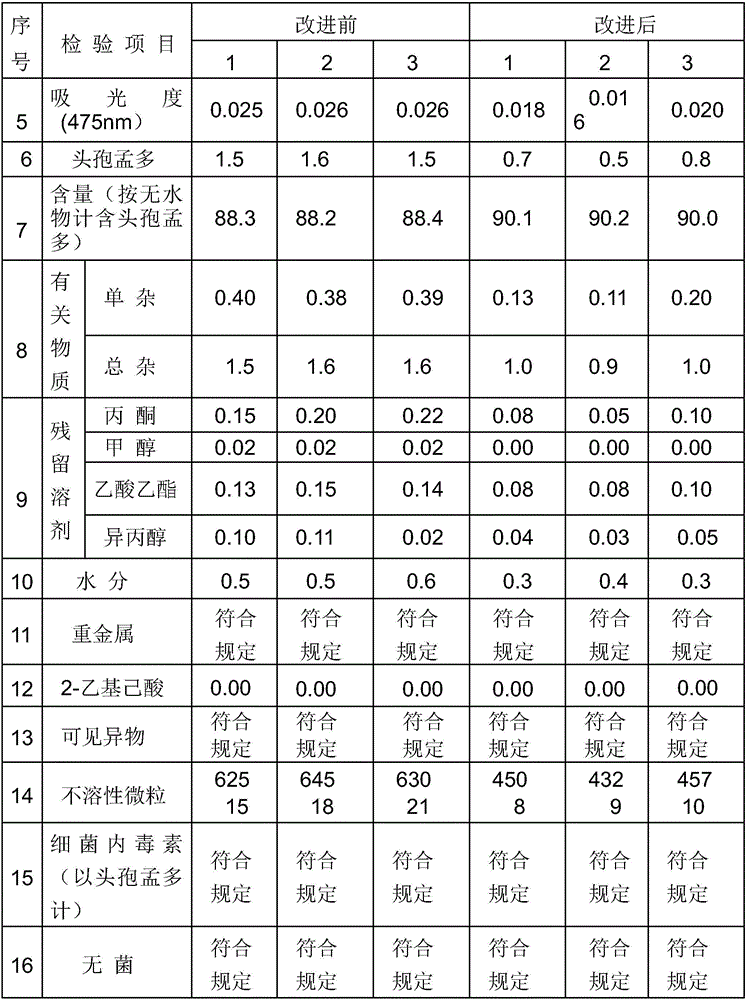

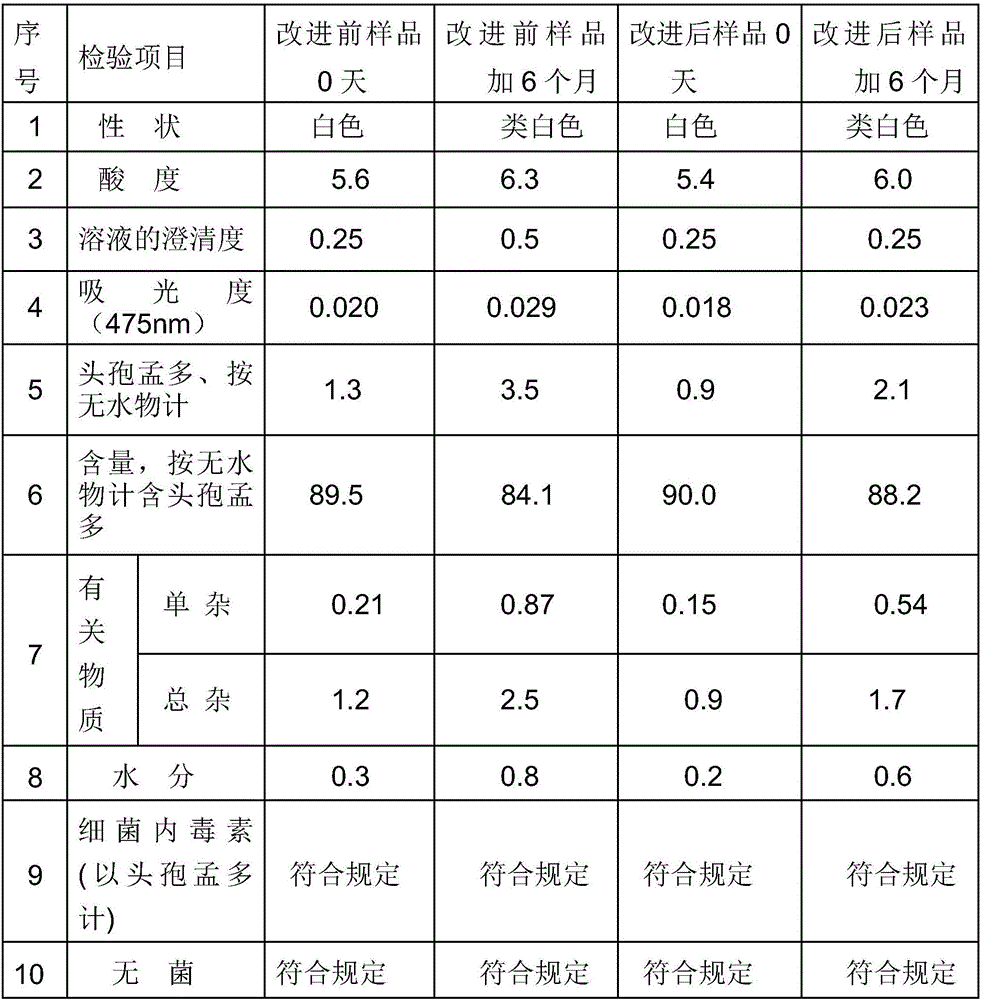

Examples

Embodiment 1

[0042] ①Purification of solvent: Purify the mixed organic solvent with three-dimensional tray mass transfer technology;

[0043] ②Silylation reaction: Add 30g of 7-TMCA to a 1000ml reaction bottle in sequence, add 340ml of purified dichloromethane-chloroform mixed solvent and 20ml of hexamethyldisilica in a mass ratio of 95:5 Amine, the temperature is 15°C, reflux reaction for 1.5h until the system is clear, and the temperature is lowered to -5°C to obtain the reaction solution 1;

[0044] 3. the synthesis of cefamandoleate: add 14mlN in the above-mentioned reaction solution, N-dimethylaniline, slowly add 18mlD-formyl mandelic acid chloride and 25ml, the dichloromethane-trichloromethane that mass ratio is 95:5 solution, the system was reacted at a constant temperature of -5°C for 4.5 hours to obtain reaction solution 2;

[0045] ④Extraction: When the residual amount of 7-TMCA is less than 1%, add 200ml of water at a temperature of 18-20°C, control the temperature at 13-15°C a...

Embodiment 2

[0049] ①Purification of solvents: Purify mixed organic solvents with high-throughput and high-efficiency three-dimensional mass transfer tray technology;

[0050] ②Silylation reaction: Add 30g of 7-TMCA to a 1000ml reaction bottle in turn, add 330ml of purified dichloromethane-chloroform mixed solvent and 20ml of hexamethyldisilica in a mass ratio of 95:5 Amine, the temperature is 17°C, reflux reaction for 1h until the system is clear, and the temperature is lowered to -5°C to obtain the reaction solution 1;

[0051] 3. the synthesis of cefamandoleate: add 14mlN in the above-mentioned reaction solution, N-dimethylaniline, slowly add 18mlD-formyl mandelic acid chloride and 25ml, the dichloromethane-trichloromethane that mass ratio is 95:5 solution, the system was reacted at a constant temperature of -2°C for 4.5 hours to obtain a reaction solution 2;

[0052] ④Extraction: When the residual 7-TMCA is less than 1%, add 200ml of water at a temperature of 13-15°C, control the temp...

Embodiment 3

[0056] ①Purification of solvents: Purify mixed organic solvents with high-throughput and high-efficiency three-dimensional mass transfer tray technology;

[0057] ②Silylation reaction: Add 30g of 7-TMCA to a 1000ml reaction bottle in turn, add 300ml of dichloromethane-trichloromethane mixed solvent and 20ml of hexamethyl dichloromethane at a mass ratio of 95:5 Silicon amine, the temperature is 20°C, reflux reaction for 1.5h until the system is clear, and the temperature is lowered to -5°C to obtain the reaction solution 1.

[0058] 3. The synthesis of cefamandoleate: add 14mlN, N-dimethylaniline, slowly add 18mlD-formylmandelic acid chloride and 25ml, the solution of dichloromethane-trichloromethane that mass ratio is 95:5, system constant temperature React at -2°C for 5 hours to obtain reaction solution 2;

[0059] ④Extraction: When the residual amount of 7-TMCA is less than 1%, add 200ml of water at a temperature of 13-15°C, control the temperature at 13-15°C and stir for 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com