Method and device for treating converted gas in production of sodium nitrate

A technology for transforming gas and sodium nitrate, which is applied in the field of chemical production, can solve the problems of lack of separation effect, affect the absorption rate of nitrogen oxides, sodium nitrite concentration, and reduce the separation effect, so as to optimize production operations, increase concentration and conversion Gas absorption rate and effect of improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

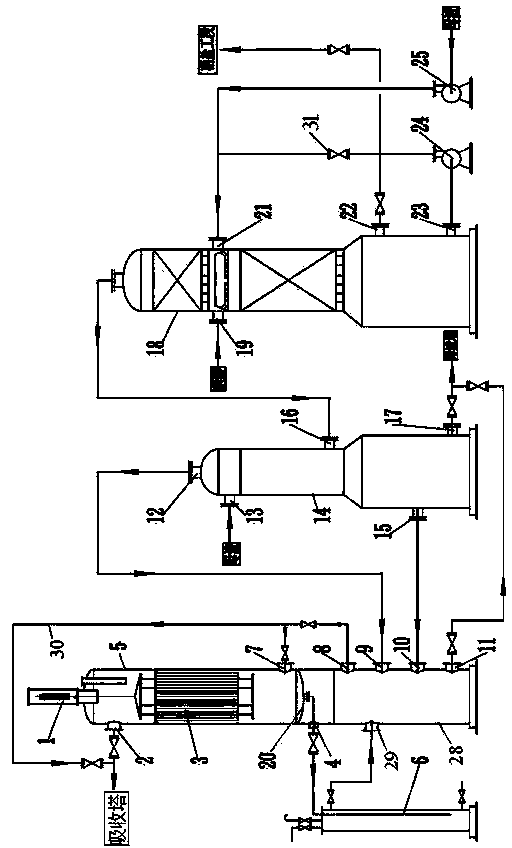

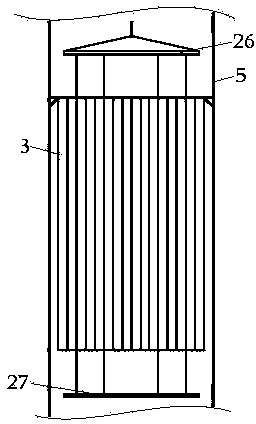

[0017] The device of conversion gas treatment in the production of sodium nitrate of the present invention is as figure 1 As shown, it includes a reforming tower 18, a pre-reforming tower 14, a mother liquid feed pump 25, an electric demister 5, a gas-liquid separator 28, an acid sealer 6 and an absorption tower. The conversion tower is provided with a mother liquid inlet 21, a conversion liquid outlet 22, a nitric acid inlet 19 and a tower top gas outlet, and the pre-reforming tower is provided with a pre-reforming tower reforming gas inlet 16, a pre-reforming tower mother liquor inlet 13, a pre-reforming tower reforming gas outlet 12 and The pre-transformation liquid communicates with port 15. The electrostatic defogging tower is equipped with a reforming gas outlet 2, a constant-current high-voltage DC electric field 3, a separation liquid outlet 4, and an electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com