Purification method of sodium carbonate solution in lithium carbonate production

A technology of sodium carbonate and lithium carbonate, applied in lithium carbonate;/acid carbonate, chemical instruments and methods, alkali metal carbonate, etc., can solve the problem that product upgrades are difficult to break through, impurity content is difficult to control, fluctuating bigger problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

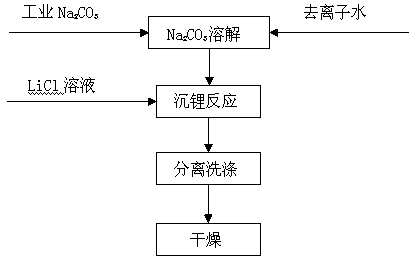

Image

Examples

Embodiment Construction

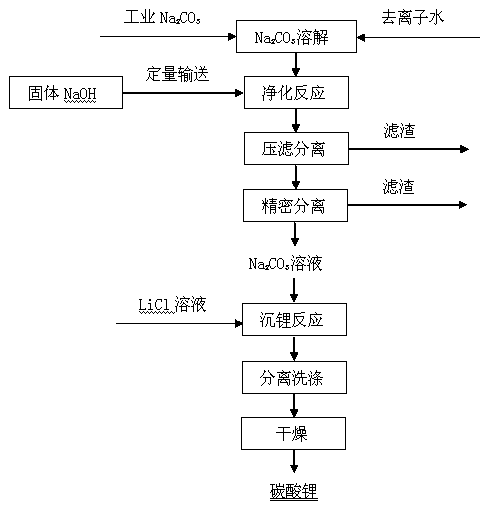

[0017] see figure 2 , the purification method of sodium carbonate solution in the production of lithium carbonate provided by the invention is as follows: adopt solid industrial sodium carbonate to add deionized water to prepare Na in the sodium carbonate solution preparation tank according to production requirements 2 CO 3 The mass percentage concentration is 25% sodium carbonate solution, the preparation process is carried out in order to better dissolve in order to dissolve, the initial Ca in the sodium carbonate solution, the Mg mass percentage concentration is respectively 0.005%, 0.02%; The quality index is the NaOH96 of mass percentage content %, Ca0.005%, Mg0.01% of solid sodium hydroxide, the solid sodium hydroxide is weighed according to the excess of 5% of the amount required for the reaction, and then transported to the sodium carbonate solution preparation tank, fully stirred, during the process NaOH and NaOH 2 C0 3 CaC0 in solution 3 , MgC0 3 Reaction occurs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com