High-organic-matter sodium sulfate hazardous waste simple recycling process and system

A technology of organic matter and sodium sulfate, applied in the field of resources and environment, can solve the problems of complex components of hazardous waste, unutilized technology, consumption of social resources, etc., and achieve significant technical and economic effects, maximize the use of resources, and achieve huge social benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

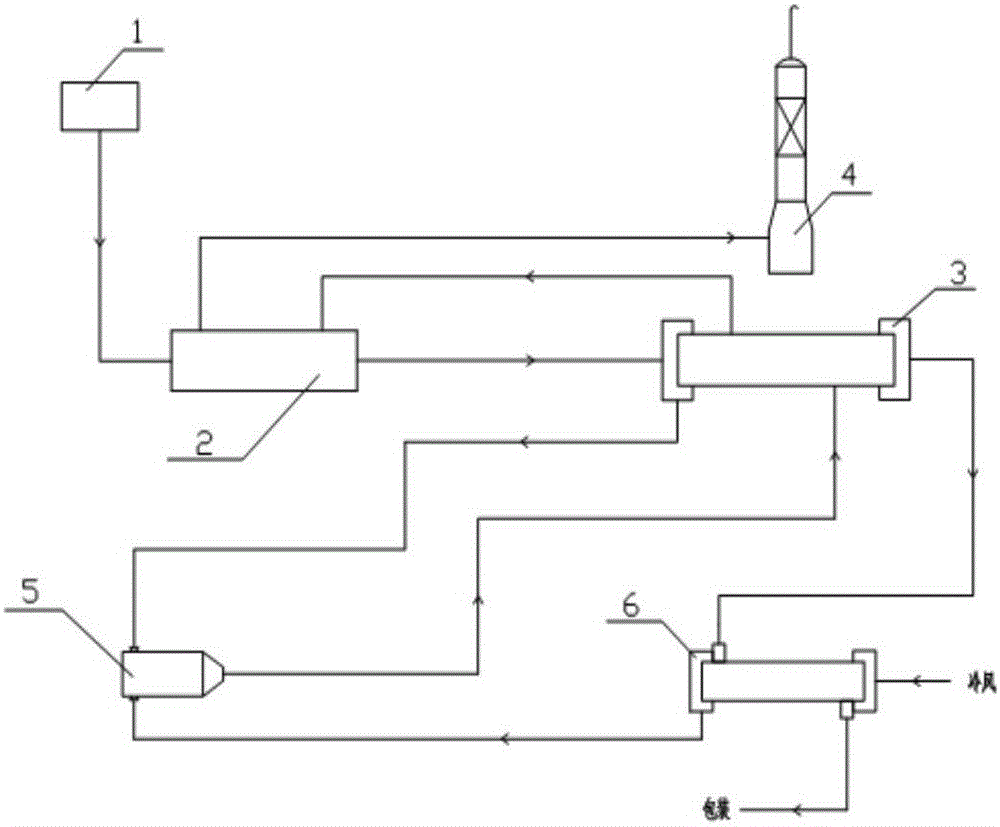

[0022] A kind of simple and convenient recycling process of high organic matter sodium sulfate concentrate, the steps are as follows:

[0023] 1) Ingredients drying system

[0024] The material that has been tested and calculated is mixed with anthracite coal powder according to the molar ratio S:C=1:2.2, mixed evenly and then sent to the drying system. At a temperature of 120°C, it is boiled and dried until the material moisture is 10%. After drying, Material enters step 2);

[0025] 2) Calcination reduction system

[0026] Materials with high organic matter from step 1) enter the high-temperature boiling oxidation furnace to decompose organic matter at 1000°C. After 40 minutes, the decomposition rate of organic matter reaches 99%, and the sodium sulfide content of the product reaches 90%. The material after decomposing organic matter is air-cooled After heat exchange, it enters the packaging; the hot air is used for the combustion of the burner, the tail gas is absorbed by...

Embodiment 2

[0028] A kind of simple and convenient recycling process of high organic matter sodium sulfate concentrate, the steps are as follows:

[0029] 1) Ingredients drying system

[0030] The material that has been tested and calculated is mixed with coke powder according to the molar ratio S:C=1:2.4, mixed evenly and sent to the drying system. At 130°C, boil and dry until the material moisture is 5%. After drying, Material enters step 2).

[0031] 2) Calcination reduction system

[0032] The material with high organic matter from step 1) enters the high-temperature boiling oxidation furnace and decomposes the organic matter at 1100 ° C. After 40 minutes, the decomposition rate of the organic matter reaches 99%, and the sodium sulfide content of the product reaches 96%; the material after the decomposition of the organic matter is air-cooled After heat exchange, it enters the packaging; the hot air is used for the combustion of the burner, the tail gas is absorbed by 10% sodium hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com