Patents

Literature

95 results about "Sodium-p-toluenesulfinate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

P-cresol preparation method and equipment

InactiveCN105906481AShort processReduce in quantityOrganic compound preparationSulfonic acids salts preparationSlagSulfite salt

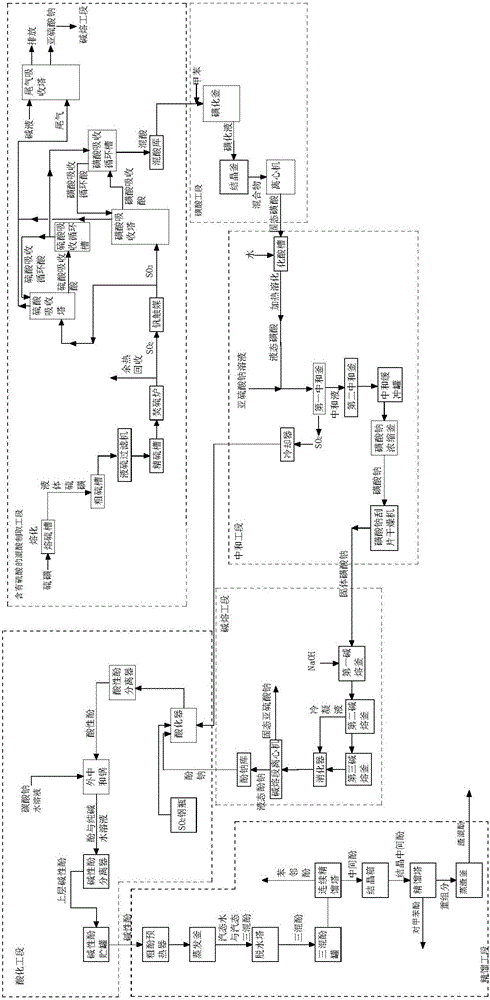

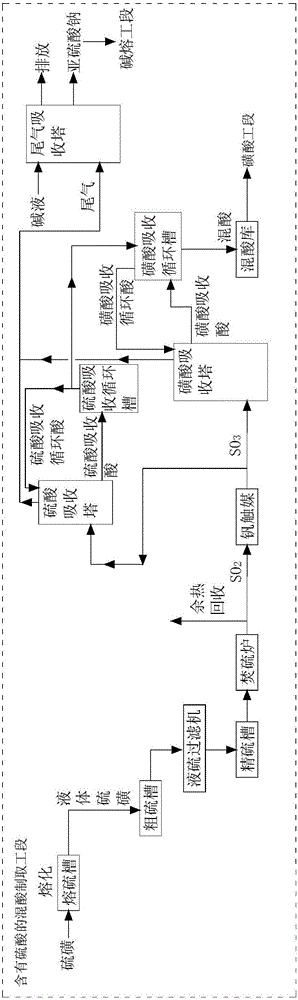

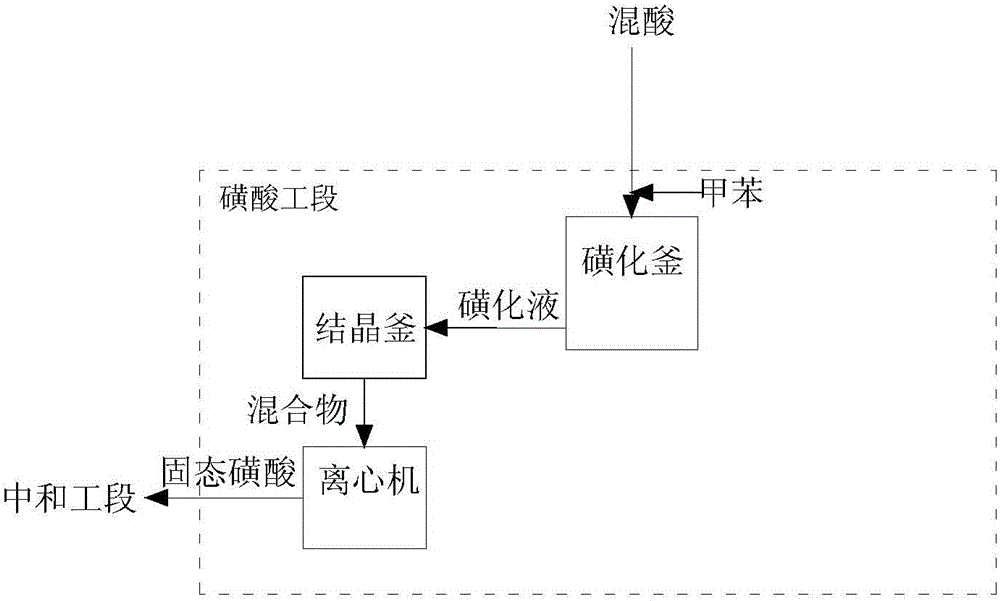

The invention provides a p-cresol preparation method and equipment. The method comprises the following steps that toluene and sulphuric acid take a reaction to obtain paratoluenesulfonic acid; the paratoluenesulfonic acid then takes a reaction with sodium sulfite to obtain sodium p-toluenesulfonate; the sodium p-toluenesulfonate generates sodium p-cresol under the alkaline condition; the p-cresol is generated by the sodium p-cresol under the alkaline condition. The method and the equipment can thoroughly solve the problem that in the current p-cresol production process, a great amount of waste water, waste gas and waste slag are generated; the automation level of the equipment is improved; most intermittent production is changed into continuous production; the work environment is improved.

Owner:JINNENG SCI & TECH

Lead-acid storage battery repairing liquid and method for repairing lead-acid storage battery by using same

ActiveCN103474707AImprove charge and discharge performanceImprove conductivitySecondary cells servicing/maintenanceFrequency wavePower flow

The invention discloses a lead-acid storage battery repairing liquid and a method for repairing the lead-acid storage battery by using the same, belongs to the field of the lead-acid storage battery, and solves the problems that a failure lead-acid storage battery caused by salinization is difficult to repair. The lead-acid storage battery repairing liquid comprises a catalytic complexing agent, a surfactant, a bulking agent, a sulfate additive and sodium p-toluenesulfonate. The method for repairing the lead-acid storage battery comprises the steps of (1) putting the storage battery in a container, injecting water to the container until a water level is flush with a middle cover of the storage battery, adjusting water temperature and charging the storage battery; (2) subjecting the storage battery to horizontal and vertical frequency wave vibration, taking out the storage battery and injecting the lead-acid storage battery repairing liquid; (3) connecting storage batteries with open circuit voltage differential voltage smaller than 0.3 V into a group in series; (4) charging for a plurality of times in different current, discharging at 2H rate and then charging for a plurality of times in different current; and (5) discharging redundant lead-acid storage battery repairing liquid. The horizontal and vertical frequency wave vibration allows lead sulfate to be smashed; the lead-acid storage battery repairing liquid allows the electrical conductivity of the storage battery to be enhanced and the internal resistance of the storage battery to be reduced; and the capacity of the lead-acid storage battery can be repaired to over 95% that of an original storage battery.

Owner:CHANGXING E CHUN NANO TECH +1

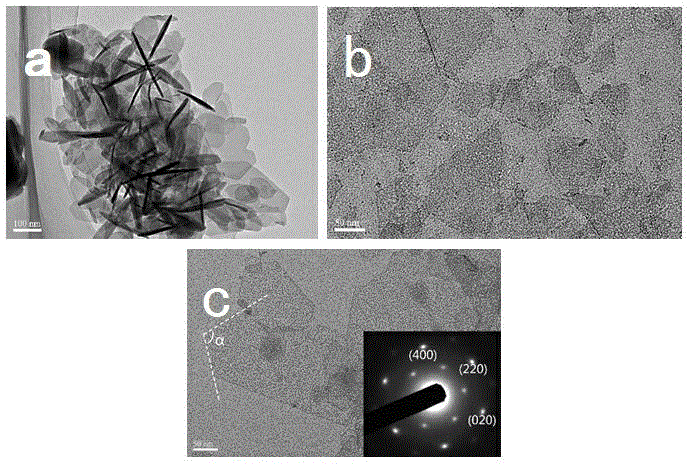

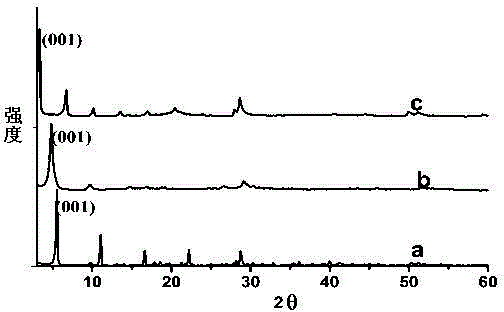

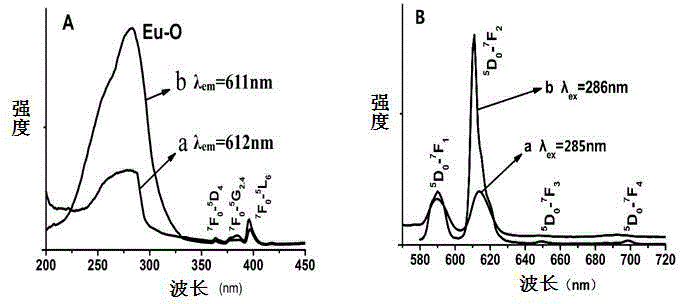

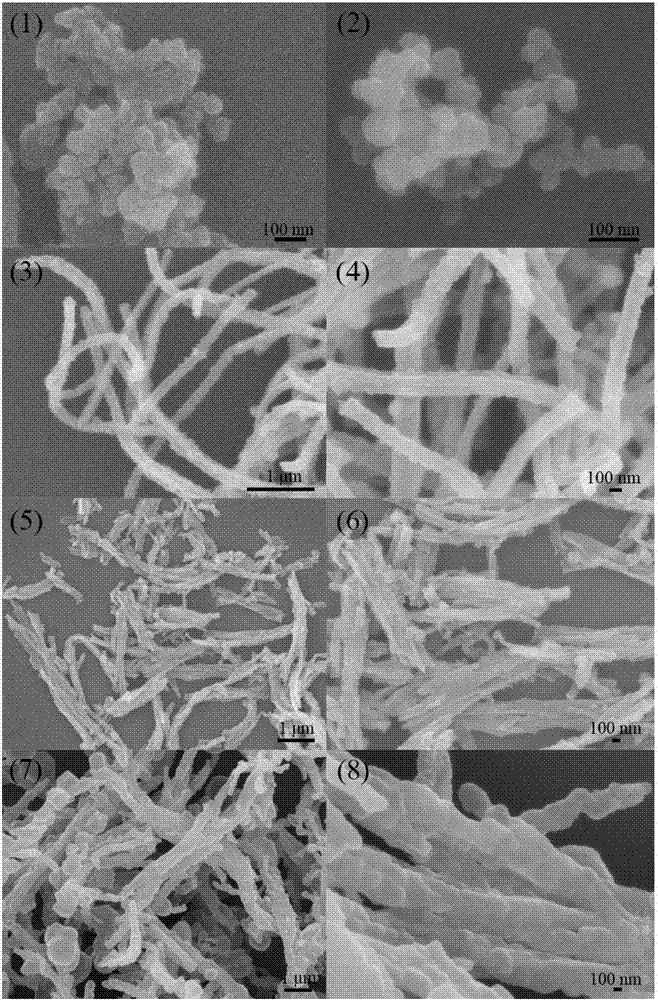

Preparation method of organic anion pillared rare earth hydroxide nanosheet sol

ActiveCN103979596AGood monochromaticityRich research significanceNanotechnologyRare earth metal compoundsBenzoic acidRare earth

The invention discloses a preparation method of an organic anion pillared rare earth hydroxide nanosheet sol, the composition of the nanosheet sol is {Y1.9Eu0.05(OH)5(+)}-A, wherein A is benzoic acid radical, p-toluenesulfonic acid radical or dodecyl sulfate radical, the method takes yttrium nitrate hexahydrate, europium nitrate hexahydrate and sodium benzoate, sodium P toluenesulfonate or sodium dodecyl sulfate as raw materials, a hydro-thermal synthetic method is used for synthesizing a layered material of Y1.9Eu0.1(OH)5[A].2H2O; the layered material is treated by ultrasound in a n-butyl alcohol solvent to obtain the nanosheet sol which is peeled to a flaky state. The preparation method is simple and is environment friendly.

Owner:EAST CHINA NORMAL UNIV

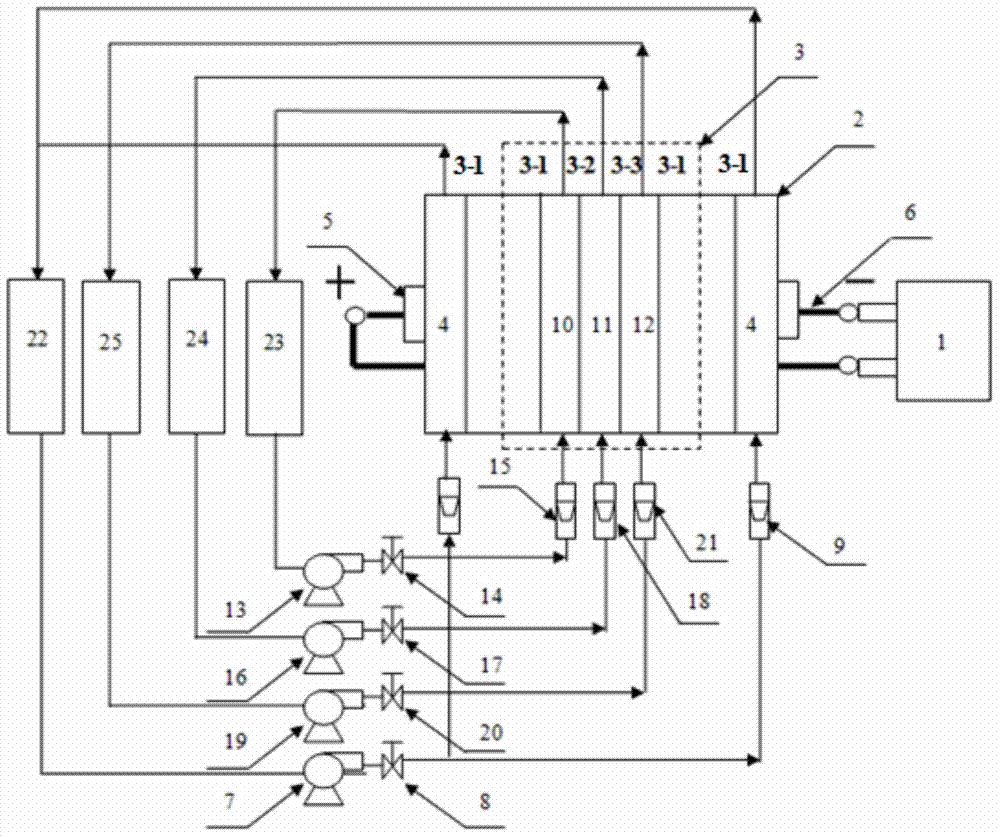

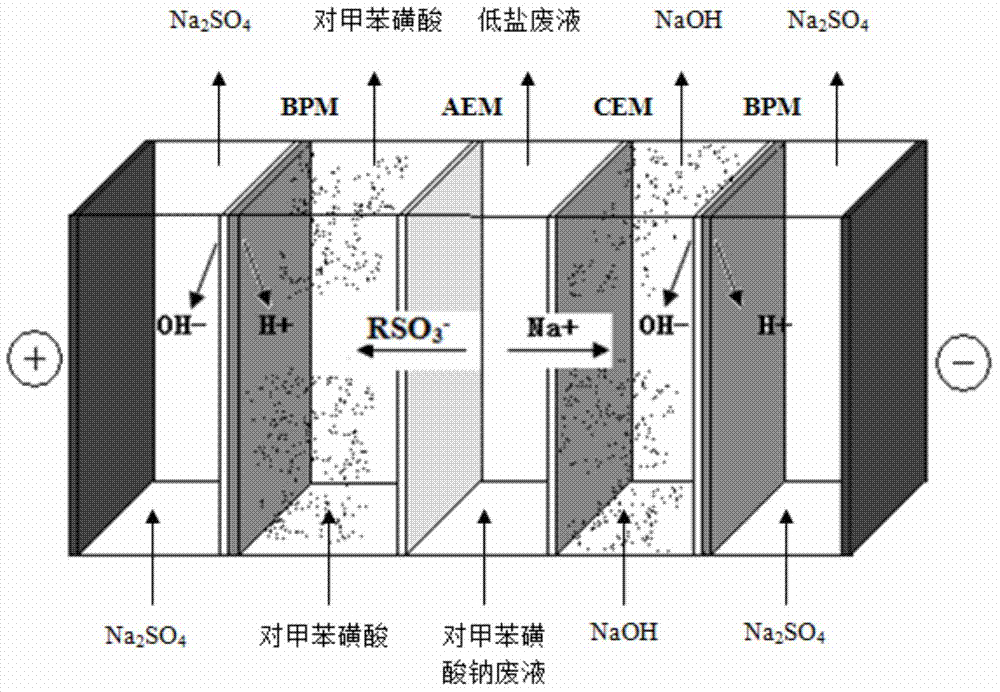

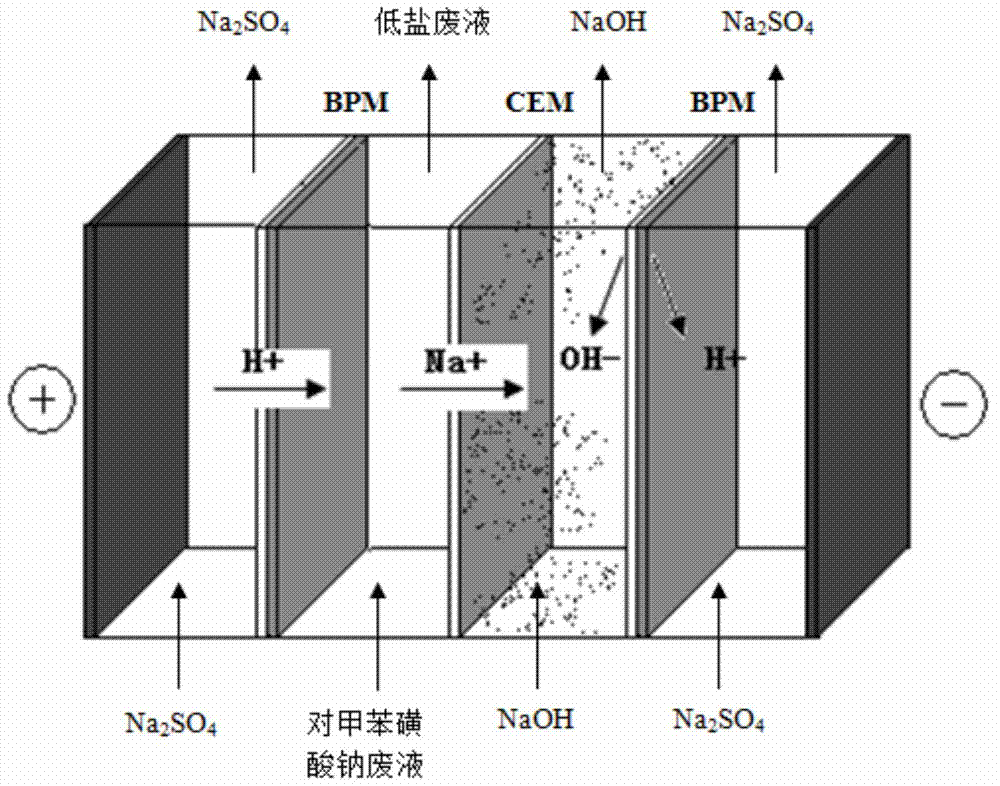

Device and method for processing sodium p-toluenesulfonate waste liquor

ActiveCN103787471ALower resistanceImprove conductivityWater contaminantsDispersed particle separationLiquid wasteHigh concentration

The invention relates to a device and method for processing sodium p-toluenesulfonate waste liquor. The device comprises a direct current power supply, a membrane stack, a clamping device, a carbon fiber felt electrode, an electrode liquor storage tank, an acid chamber storage tank, a waste liquor chamber storage tank, an alkali chamber storage tank, a liquor adjuster, an alkali chamber valve block, a waste liquor chamber valve block, an acid chamber valve block, an electrode chamber valve block, an acid chamber filled with a cation exchange resin, a salt chamber, an alkali chamber filled with an anion exchange resin, an anion exchange membrane, a cation exchange membrane and a bipolar membrane. A PAN (polyacrylonitrile)-based carbon fiber felt electrode used in the device and method has the characteristics of low resistance, good electric conductivity, oxidation resistance and corrosion resistance. The salt chamber is filled with a cation and anion mixed resin, and the acid chamber and the alkali chamber are respectively filled with the cation exchange resin and the anion exchange resin, so as to further improve the conductance of an electrodialysis cell, reduce the polarization and energy consumption, and lighten the membrane pollution. The device and method can be used for processing the production waste liquor of high-concentration hardly-degradable pentaerythritol triacrylate, so as to obtain acid and / or alkali and realize recycling of the waste liquor.

Owner:UNIV OF SCI & TECH BEIJING

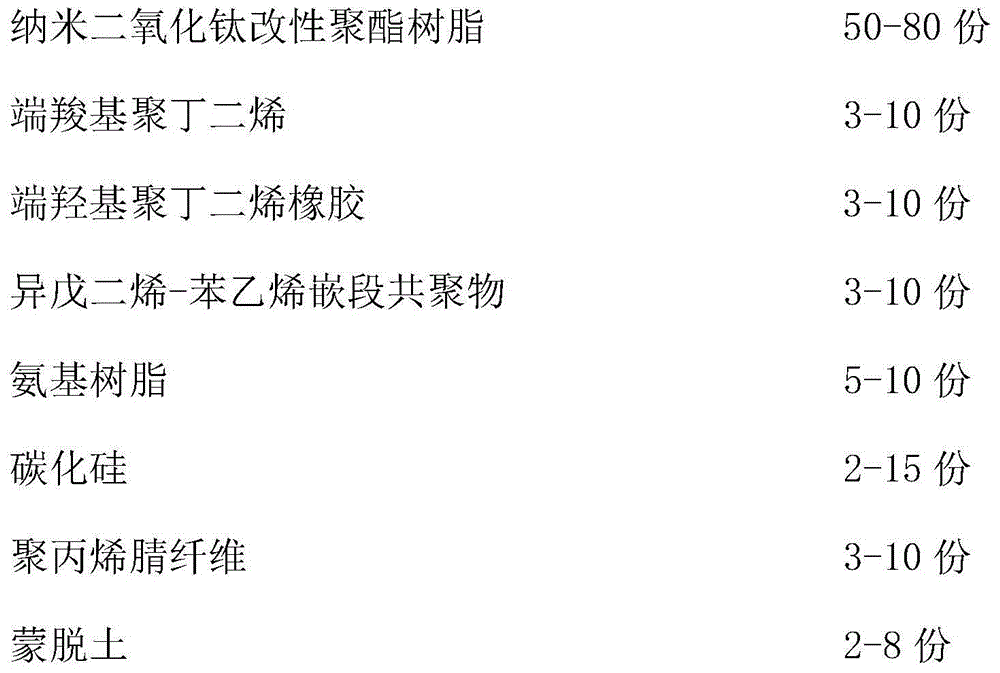

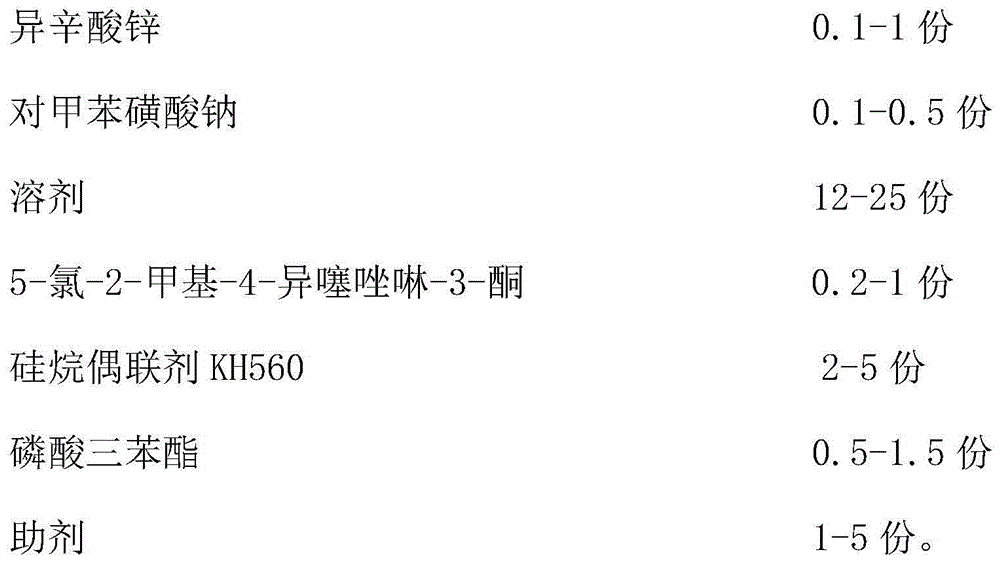

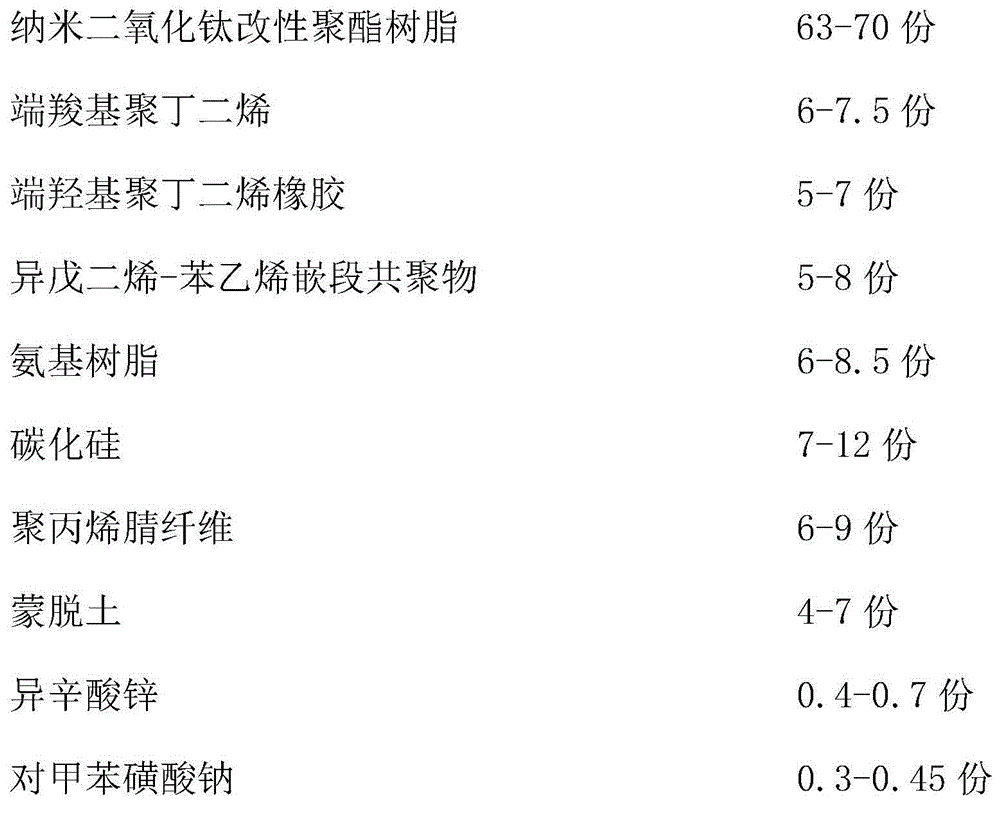

High strength modified polyester resin coating

The invention discloses a high strength modified polyester resin coating. The coating comprises, by weight, 50-80 parts of nanometer titanium dioxide modified polyester resin, 3-10 parts of carboxyl-terminated polybutadiene, 3-10 parts of hydroxyl-terminated polybutadiene rubber, 3-10 parts of isoprene-styrene block copolymer, 5-10 parts of amino resin, 2-15 parts of silicon carbide, 3-10 parts of polyacrylonitrile fiber, 2-8 parts of montmorillonite, 0.1-1 part of zinc isoocatanoate, 0.1-0.5 parts of sodium p-toluenesulfonate, 12-25 parts of a solvent, 0.2-1 part of 5-chloro-2-methyl-4-isothiazolin-3-one, 2-5 parts of a silane coupling agent KH560, 0.5-1.5 parts of triphenyl phosphate and 1-5 parts of an assistant. The high strength modified polyester resin coating has the advantages of high strength, good toughness, small shrinkage rate during curing, and excellent contamination resistance.

Owner:GUANGDE MEITUSHI CHEM

Method for extracting sodium p-toluenesulfonate from tiamulin synthesis wastewater

ActiveCN104262210AReduce CODRelieve stressOrganic chemistryOrganic compound preparationActivated carbonChemical oxygen demand

The invention relates to a method for extracting sodium p-toluenesulfonate from tiamulin synthesis wastewater, which comprises the following steps: regulating the pH value of tiamulin ammonification production wastewater to 7-8, and concentrating to 75-80% of the original volume under reduced pressure; cooling to 0-4 DEG C, stirring for 1-2 hours while keeping the temperature, and filtering; mixing the filter cake with purified water, adding activated carbon, heating to 80 DEG C, stirring for 30-60 minutes while keeping the temperature, and carrying out hot filtration; and cooling the mother solution to 2-4 DEG C to recrystallize, and filtering to obtain the sodium p-toluenesulfonate. A simple method is utilized to extract and recover the sodium p-toluenesulfonate, thereby changing wastes into valuable substances, increasing the available resources, lowering the wastewater COD (chemical oxygen demand), reducing the wastewater treatment pressure and lowering the wastewater treatment cost; and the method is green and environment-friendly, and has sustainable development meanings for production. The COD of the ammonification wastewater treated by the method is lowered by 50-60%, and the concentration of the sodium p-toluenesulfonate is 310 kg / m<3>.

Owner:宁夏泰瑞制药股份有限公司

Formulation technology of sterilization collar cleaning

InactiveCN1928043AWith sterilization functionAvoid spreadingNon-ionic surface-active compoundsDetergent compounding agentsSodium-p-toluenesulfinateChloride

The present invention is the technological process of compounding collar sterilizing detergent. The collar sterilizing detergent is produced with sodium hexadecyl benzene sulfonate, emulsifier NP, AEO-9, sodium paratoluene sulfate, liquid protease, sodium formate, ethanol, calcium chloride, monoethanolamine, dimethyl silicon oil, essence, water and high efficiency bactericide, and through one special technological process. It may be used to clean collar, kill virus and bacteria and avoid germ propagation.

Owner:TIANJIN WEALTH BIOENGINEERING SCI & TECH CO LTD

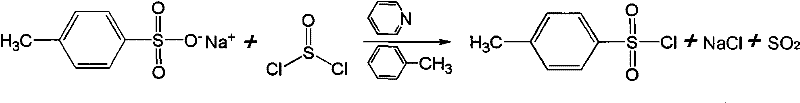

A New Process for the Preparation of p-Toluenesulfonyl Chloride

InactiveCN102295587AImprove securityQuick responseChemical recyclingSulfonic acid preparationSodium-p-toluenesulfinateReaction rate

The invention provides a new process for the preparation of p-toluenesulfonyl chloride. The process uses crude sodium p-toluenesulfonate extracted from industrial waste water as a raw material, and uses thionyl chloride in a toluene solvent with catalyst pyridine. As a chlorination agent, p-toluenesulfonyl chloride is prepared, which is characterized in that toluene is used as a solvent and pyridine as a catalyst. The process reduces the consumption of thionyl chloride, greatly improves the safety of the reaction operation, accelerates the reaction speed, and the product yield reaches more than 93%.

Owner:ANHUI FENGLE AGROCHEM

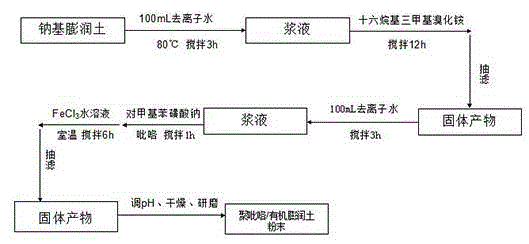

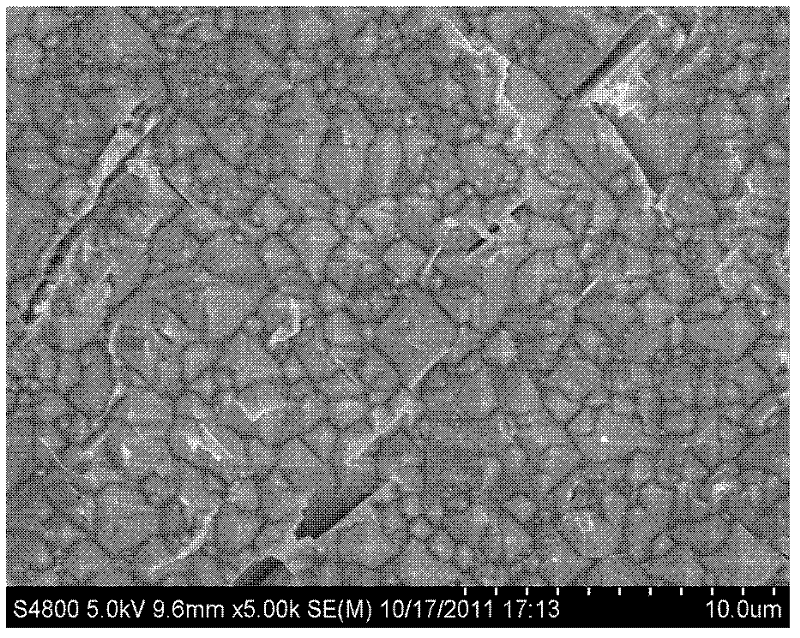

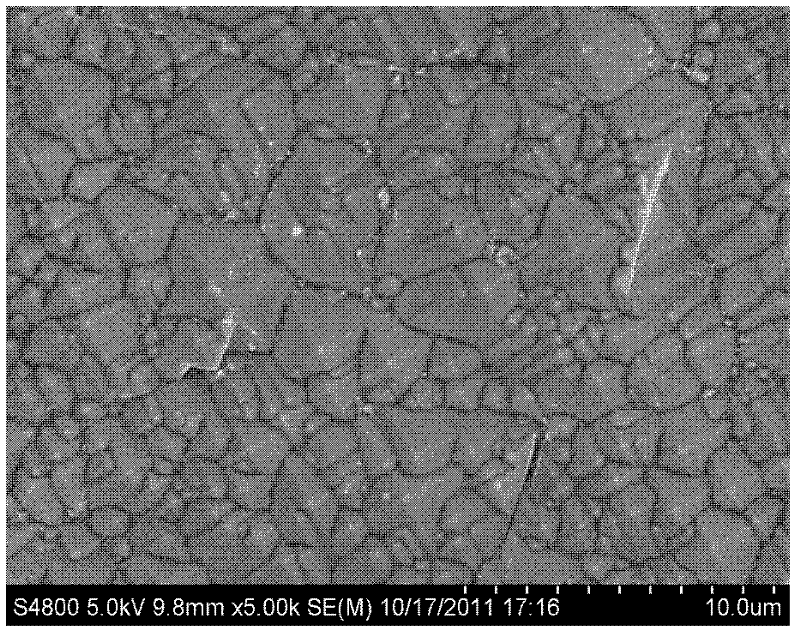

Novel macromolecule resistance-reducing agent and preparation method thereof

InactiveCN104966542AImprove the defect that it is easy to lose with rainwaterExtended service lifeOrganic conductorsOrganic fertilisersPolypyrroleConductive materials

The invention discloses a novel macromolecule resistance-reducing agent and a preparation method thereof. The resistance-reducing agent comprises the following components in percentage by weight: 50% to 60% of leading agent, 5% to 10% of modifying agent, 20% to 30% of conducting material, and 5% to 10% of auxiliaries, the leading agent is sodium bentonite, the modifying agent is hexadecyl trimethyl ammonium bromide, the conducting material is polypyrrole, and the auxiliaries are sodium p-toluenesulfonate and a ferric chloride solution. The novel macromolecule resistance-reducing agent provided by the invention adopts a specific formula, through the combined effect of the leading agent and the conducting material, can overcome to a large extent the defect that the resistance-reducing agent is easily lost with rainwater, and has a longer service life; is small in corrosivity to a base metal, and basically has no corrosion to an iron-based metal; and has a good resistance-reducing effect, can reach electrical resistivity of 1.49[ohm]*m, is pollution-free to environment, and is non-toxic.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Pre-cleaning agent used before napping monocrystalline silicon piece and application method

InactiveCN102644084AReduce the chance of contaminationImprove yieldAfter-treatment detailsEutrophicationWater quality

The invention relates to a pre-cleaning agent used before napping a monocrystalline silicon piece and an application method. The existing main problem is that cleaning fluids in the market at present contain phosphorus substances, and the eutrophication of water quality can be caused if the phosphorus substances are discharged to the environment, and the phosphorus substances are not favorable of the development of efforts at environmental protection. The pre-cleaning agent is characterized by comprising the following components: alkylphenol ethoxylates, inorganic base and salt of the inorganic base, sodium citrate, paratoluenesulfonic acid sodium salt, cosolvent and the balance of water, wherein the deionized water is used as the water preferably. The pre-cleaning agent used before napping the monocrystalline silicon piece has the advantages that the occurrence probability of contaminations, such as fingerprints and spots on the surface of the silicon piece, can be reduced, a napping effect is obviously enhanced, the yield of the silicon piece is further increased, and the production efficiency of enterprises is increased. Moreover, a catalyst used by the pre-cleaning agent is nontoxic, non-corrosive and non-irritant, has no burning and explosion hazards and is not harmful to human bodies and the environment. Moreover, the catalyst is simple in preparation and application process, equipment is cheap and the repeatability is high.

Owner:ZHEJIANG TOPOINT PHOTOVOLTAIC

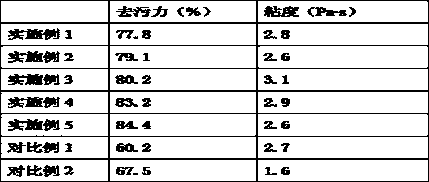

Dispersing agent capable of properly reducing viscosity of graphene oxide slurry and application thereof

InactiveCN110482537ALow viscosityGood dispersionCarbon compoundsTransportation and packagingSlurryHydrolysis

The invention belongs to the technical field of material preparation, and particularly relates to a dispersing agent capable of properly reducing viscosity of graphene oxide slurry and application ofthe dispersing agent. Molecules of the dispersing agent contain benzene rings, anions can be formed after hydrolysis, and the dispersing agent comprises but is not limited to one or more of sodium dodecylbenzene sulfonate, sodium p-toluenesulfonate, sodium benzenesulfonate and p-hydroxybenzoic acid. The pi bond of the benzene ring in the dispersing agent can promote self-assembling of the grapheneoxide micron sheets during film formation to form a high-orientation graphene oxide film, and the performance of the heat conduction film is improved; meanwhile, anions in the dispersing agent have the effect of a surfactant, the agglomeration phenomenon of the graphene oxide micron sheets can be hindered, the solid content of graphene oxide can be increased, and the dispersing agent used in themethod is environmentally friendly, non-toxic and harmless.

Owner:WUXI JONES TECH +1

Preparation method of composite biological liquid detergent containing sodium p-toluenesulfonate

InactiveCN108822976ANon-ionic surface-active compoundsOrganic detergent compounding agentsAdsorption effectP-toluenesulfonate

The invention provides a preparation method of a composite biological liquid detergent containing sodium p-toluenesulfonate. The method comprises the following steps: S1, preparing modified cellulosepowder; S2, preparing micro-porous starch; S3, weighing the modified cellulose powder, micro-porous starch, alkyl glycoside, sodium p-toluenesulfonate, sodium citrate, carboxymethyl cellulose, lipase,a perfume, ethanol and water according to corresponding weight parts; S4, heating the deionized water, and adding the micro-porous starch to obtain an aqueous micro-porous starch solution; S5, addingthe modified cellulose powder to ethanol to obtain an ethanol solution of the modified cellulose powder; and S6, adding the ethanol solution of the modified cellulose powder to the aqueous micro-porous starch solution, and performing mixing and uniform stirring to obtain the composite biological liquid detergent. The adsorption effect of the modified cellulose powder and the modified starch cooperates with the certain-strength mechanical stirring, temperature and rubbing effects in a washing process to accelerate the oil stain adsorption of starch and cellulose powder.

Owner:苏州华龙化工有限公司

Lead-acid storage battery repairing activating agent and preparation method thereof

InactiveCN108598602AShort repair timeImprove repair efficiencyFinal product manufactureElectrolyte/reactants regenerationPullulanMonopotassium phosphate

The invention discloses a lead-acid storage battery repairing activating agent. The lead-acid storage battery repairing activating agent is prepared from the following raw materials: acetylene carbonblack, zinc sulfate, sodium sulfate, sulfuric acid solution, nanometer silver, paratoluenesulfonic acid sodium salt, methoxypolyethylene glycols, potassium citrate, monopotassium phosphate, fumaric acid, ferrocene, titanium dioxide, glycerin, water glass, pullulan, sodium carbonate, carboxymethyl chitosan, vitamin E and deionized water. The lead-acid storage battery repairing activating agent hasthe advantages of relatively short repairing time, high repairing efficiency, relatively excellent repairing effect on a sulfurized storage battery, capable of effectively solving the problem of capacity failure caused by sulfation of the lead-acid storage battery, high in battery performance after repairing, and capable of prolonging the service life of the battery.

Owner:童振锴

Method for improving dispersity of photovoltaic panel electronic paste

InactiveCN112642316AEvenly dispersedGood dispersionMixing methodsTransportation and packagingSulfohydrazideSodium-p-toluenesulfinate

The invention relates to the technical field of electronic paste, and discloses a method for improving dispersity of photovoltaic panel electronic paste. The method comprises the following steps: preparing nano-copper powder from copper acetate and hydrazine hydrate under proper conditions, treating the nano-copper powder with toluenesulfonyl hydrazine, and aggregating toluenesulfonyl hydrazine on nano-copper tiny agglomerates; countless tiny bubbles are generated by decomposing in hot water, the bubbles burst and gas driving force generated by the bubbles promote tiny agglomerates formed by agglomeration of the nano-copper particles to be dispersed and fully infiltrated, and the sodium p-toluenesulfonate generated after the p-toluenesulfonylhydrazine is decomposed can promote effective infiltration of paste to the nano-copper particles. P-toluenesulfonyl hydrazide can hydrolyze on the surfaces of the nano-copper tiny agglomerates to generate countless small bubbles to crush the tiny agglomerates to be fully dispersed, and the generated sodium p-toluenesulfonate can also promote the slurry to fully infiltrate the nano-copper particles, so that the problem of agglomeration of the filler tiny agglomerates, which is difficult to solve by traditional mechanical stirring and ball milling, is effectively solved; therefore, uniform and stable dispersion of the conductive phase in the electronic paste is realized.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

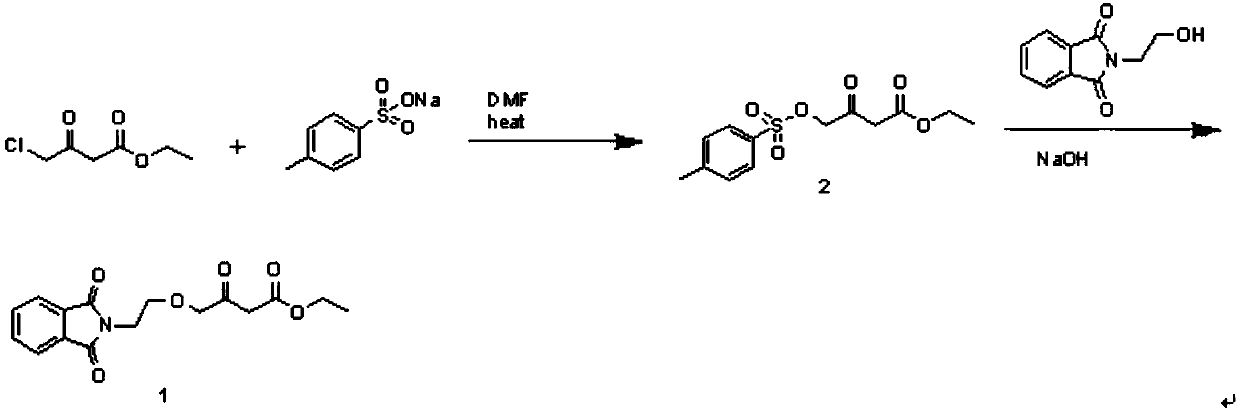

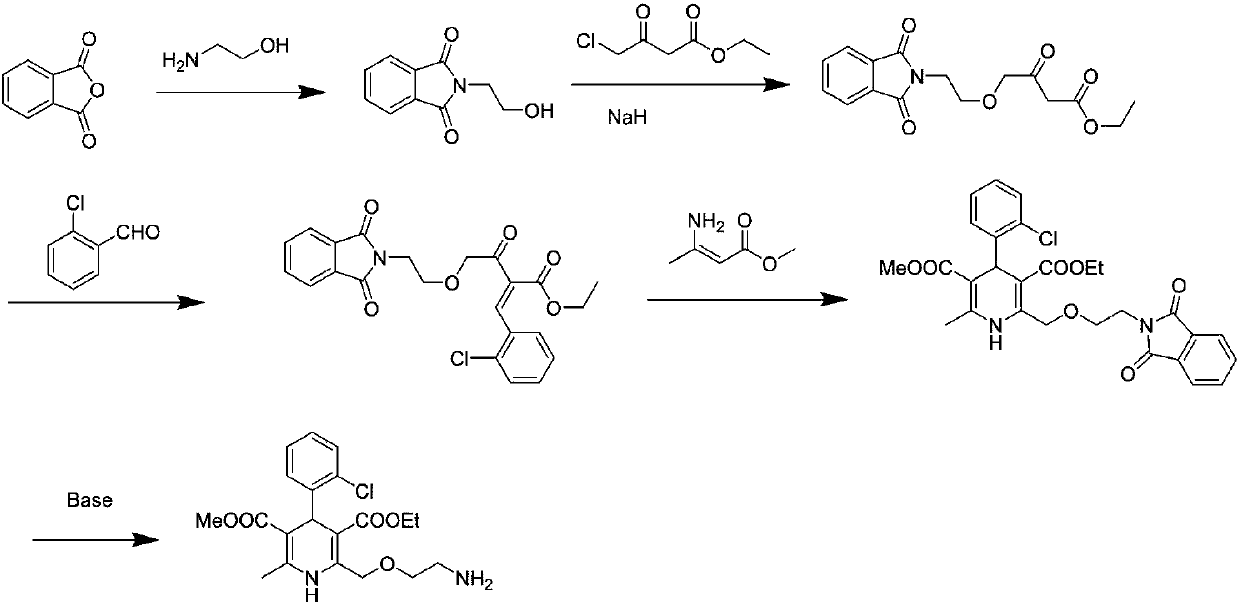

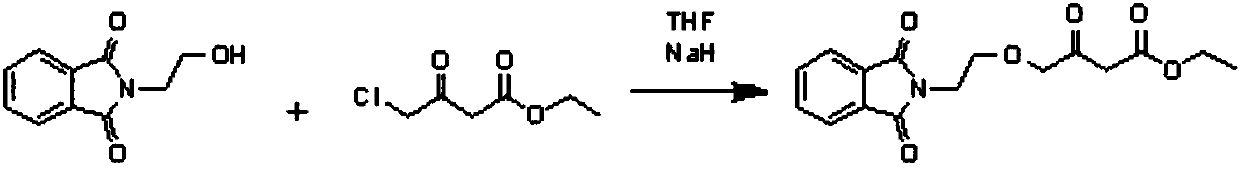

Preparation process of amlodipine intermediate

ActiveCN107935912AAvoid defectsReduce usageOrganic chemistryChemical recyclingAcetic acidSodium-p-toluenesulfinate

The invention relates to a method for preparing an amlodipine intermediate safely and efficiently (the formula is as shown in the description). The method particularly comprises the following steps: step 1, heating 4-chloroacetoacetic acid ethyl ester and para-toluenesulfonic acid sodium salt which serve as raw materials in a reaction solvent and performing reaction to obtain a compound 2; and step 2, adding an alkaline compound serving as a catalyst into the compound 2 and N-hydroxyethylphthalimide, adding a phase transfer catalyst simultaneously and heating to obtain a compound 1. The intermediate compound 2 adopts 4-chloroacetoacetic acid ethyl ester protected by para-toluenesulfonic acid, and p-toluenesulfonate is adopted, so the condition of an etherification step is greatly reduced,dangerous or expensive reagents are avoided and the production safety is greatly improved.

Owner:CHANGZHOU RUIMING PHARMA

Preparation method of syn-p-menthyl-3,8-diol

InactiveCN106380377AEasy to makeHigh purityOrganic compound preparationHydroxy compound preparationSodium-p-toluenesulfinateDiol

The invention discloses a preparation method of syn-p-menthyl-3,8-diol. The preparation method comprises the following steps of adopting citronellal as a raw material, carrying out cyclization reaction in a water solution with the temperature of 20 to 50 DEG C and pH of 2 to 4 under the action of para-toluenesulfonic acid sodium salt and benzyl triethyl ammonium chloride, and obtaining the syn-p-menthyl-3,8-diol as a product after complete reaction, wherein the feeding quality of the para-toluenesulfonic acid sodium salt is 1 percent to 1.5 percent of the feeding quality of the citronellal, and the feeding quality of the benzyl triethyl ammonium chloride is 1 percent to 2 percent of the feeding quality of the citronellal. The preparation process is simple and environmental-friendly, the prepared product has good purity which can achieve not less than 99 percent, and the conversion rate is high.

Owner:ZHANG JIA GANG VINSCE BIO PHARM

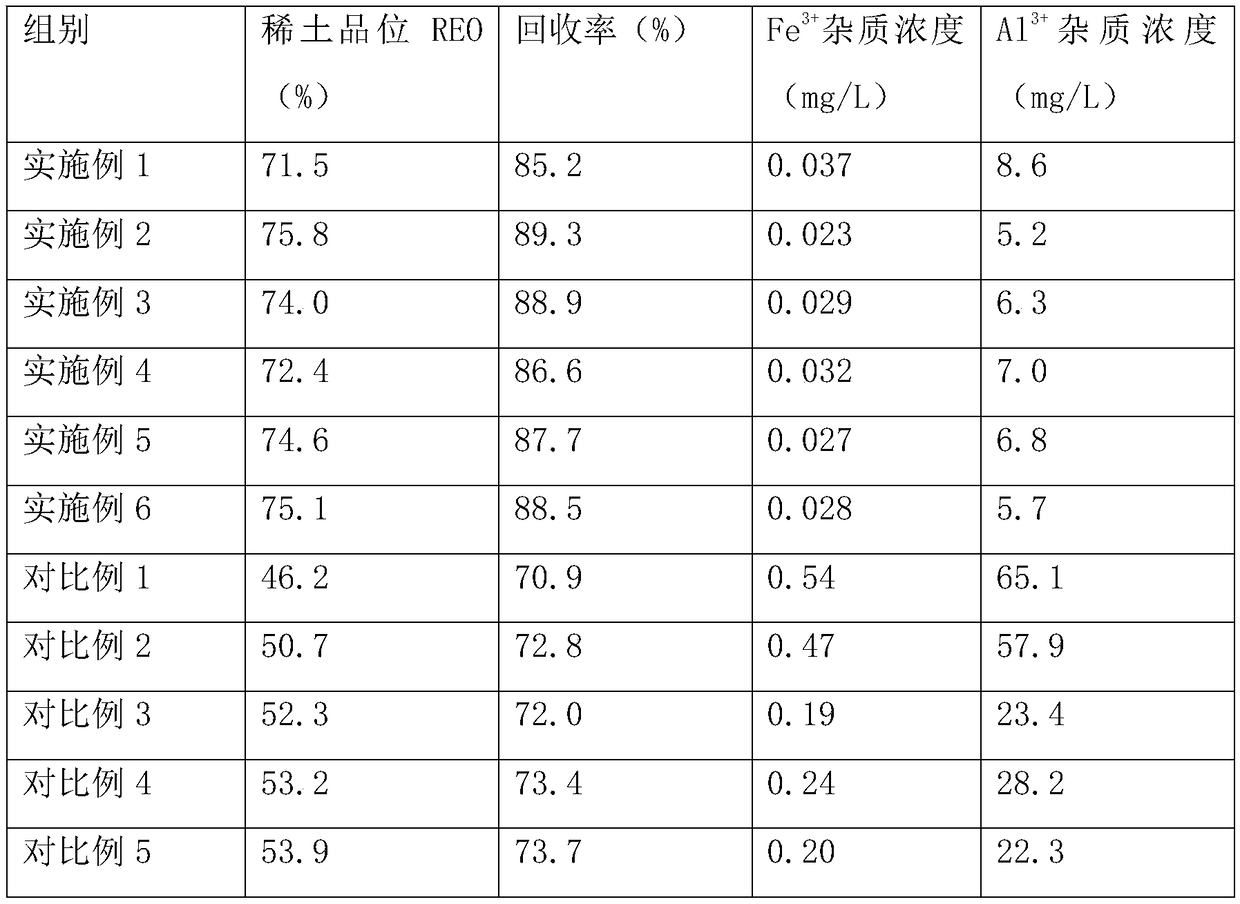

Rare-earth ore beneficiation method

ActiveCN109395887AGuarantee the effect of fine flotationHigh purityFlotationSodium-p-toluenesulfinateRare earth

The invention belongs to the technical field of rare-earth ore production, and provides a rare-earth ore beneficiation method. Three times rough flotation and three times fine flotation are adopted, NaOH, water glass and alkyl hydroximic acid used as a first collecting agent are added in the first rough flotation, on the basis of sodium hydroxide, a surfactant of sodium potassium tartrate, sodiump-toluenesulfonate and a sodium cocoyl methyl taurate mixture are added into a fifth collecting agent, on the basis of the sodium hydroxide, a non-ionic surfactant of dodecyl glucoside and a sodium dodecyl sulfate mixture are further added into a sixth collecting agent. By adopting the rare-earth ore beneficiation method, final concentrate of the rare-earth ore grade (REO) obtained is 70% or above, the recovery rate is 85% or above, the impurities are low, and the rare earth ore grade, the recovery rate and the purity are all high; and in addition, the method does not need complex equipment, and the feasibility is higher.

Owner:崔源发

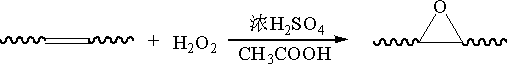

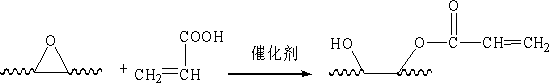

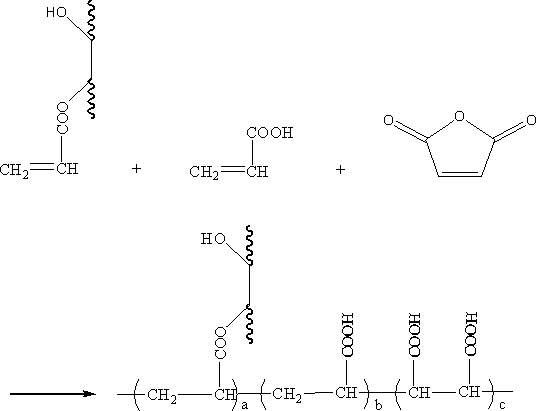

Jatropha curcas oil acrylate polymer fatliquor prepared based on miniemulsion polymerization method and method for preparing jatropha curcas oil acrylate polymer fatliquor

InactiveCN108623760AHigh polymerization activityGood self-emulsifying performanceLeather impregnationVegetable oilOil phase

The invention relates to a jatropha curcas oil acrylate polymer fatliquor prepared based on a miniemulsion polymerization method and a method for preparing the jatropha curcas oil acrylate polymer fatliquor. The method comprises the following steps: epoxidizing jatropha curcas oil by using hydrogen peroxide, glacial acetic acid and concentrated sulfuric acid to obtain epoxy jatropha curcas oil; taking sodium p-toluenesulfonate as a catalyst, hydroquinone as a polymerization inhibitor and acrylic acid as a nucleophilic reagent to carry out ring-opening reaction on the epoxy jatropha curcas oilto obtain jatropha curcas oil acrylate and introducing an active vinyl part into a vegetable oil molecular chain; dissolving sodium dodecyl sulfate and n-butyl alcohol into deionized water, carrying out ultrasonic uniformity to form an aqueous phase, mixing the aqueous phase with an oil phase, carrying out shearing emulsification and ultrasonic operation to obtain faint yellow stable miniemulsion;adding maleic anhydride, a catalyst, acetanilide and acrylic acid into the miniemulsion for carrying out polymerization reaction to obtain the jatropha curcas oil acrylate polymer fatliquor. The fatliquor has better cold water emulsibility and hydrophilicity, and is a green environmental and biodegradable fatliquoring material.

Owner:SHAANXI UNIV OF SCI & TECH

Environment-friendly production method for preparing paratoluenesulfonic acid sodium salt from waste sulfuric acid

InactiveCN106748900ASimple process equipmentLow heating temperatureOrganic compound preparationSulfonic acids salts preparationTosylic acidSodium-p-toluenesulfinate

The invention discloses an environment-friendly production method for preparing paratoluenesulfonic acid sodium salt from waste sulfuric acid. The environment-friendly production method comprises the following steps: (1) concentrating the waste sulfuric acid until weight percentage concentration of the sulfuric acid is greater than 70%, and adding methylbenzene into the sulfuric acid in a weight ratio of (1.2 to 2.0) : 1, and heating to 100-160 DEG C to react, thereby obtaining p-toluenesulfonic acid; (2) enabling a solution containing the p-toluenesulfonic acid to perform neutral reaction with a sodium hydroxide aqueous solution, thereby obtaining paratoluenesulfonic acid sodium; and (3) discoloring the solution containing paratoluenesulfonic acid sodium through active carbon, performing crystal separation, and drying to obtain a paratoluenesulfonic acid sodium product. The environment-friendly production method is used to solve the problem that the waste sulfuric acid is difficult to treat and provide a new idea for a paratoluenesulfonic acid sodium preparation process, and has great innovativeness and common applicability for a preparation process for the paratoluenesulfonic acid sodium salt.

Owner:四川省中明环境治理有限公司

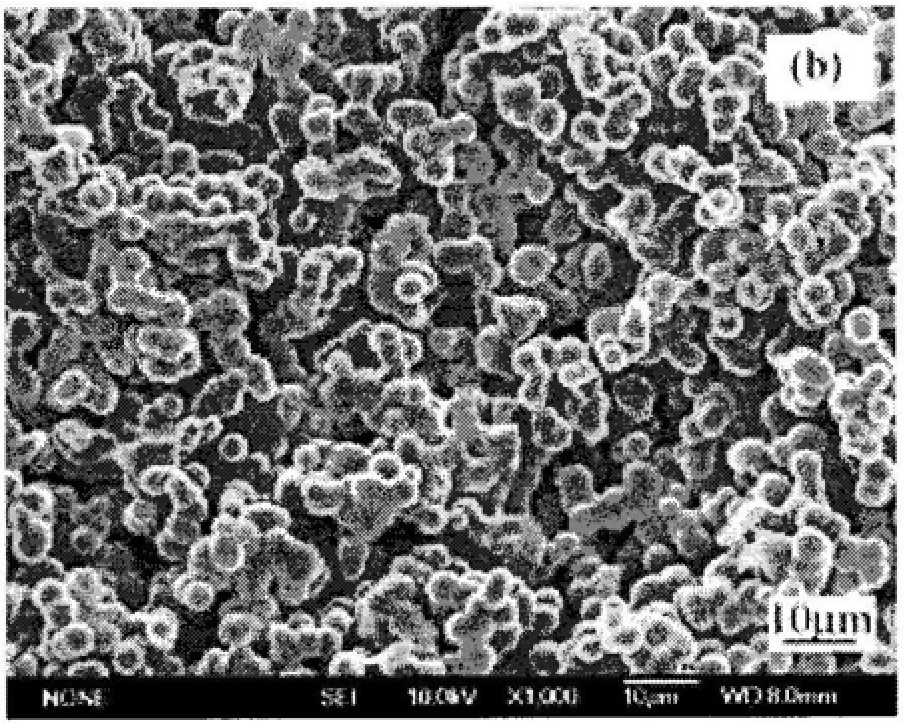

Reaction sintering lightweight silicon carbide mirror blank and preparation method thereof

The invention relates to a reaction sintered lightweight silicon carbide reflective mirror blank and a preparation method thereof, belonging to the field of optical materials. The invention adopts the method of porous carburizing silicon carbide to prepare reaction sintered silicon carbide material, and further prepares light-weight silicon carbide mirror blank. The present invention is characterized in that furfuryl alcohol and / or furfuryl alcohol resin is used as carbon source, alcohols such as diethylene glycol are used as solvent and pore-forming agent, p-toluenesulfonic acid or sodium p-toluenesulfonate is used as catalyst, and polymerization phase separation technology is adopted The green body of pure porous carbon with controllable pore size was prepared, and the reaction sintered silicon carbide was prepared by liquid phase or vapor siliconizing. The silicon carbide mirror blank provided by the present invention does not contain the original added coarse silicon carbide particles in the blank, and all the silicon carbide in the product is formed in the reaction process, so the prepared silicon carbide material is different from the traditional reaction sintered silicon carbide Compared with the material, the material has the advantages of uniform microstructure, fine crystal grains, low silicon content, excellent performance, etc.; at the same time, the preparation method of the mirror blank provided by the invention is simple in process and easy to implement, and the prepared mirror blank has high reliability and stable quality.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Hole-sealing agent and preparation method thereof

InactiveCN104451822AReduce pollutionExtended temperature rangeSurface reaction electrolytic coatingActive agentPhosphoric acid

The invention discloses a hole-sealing agent. The hole-sealing agent comprises an accelerator, a surfactant and a stabilizer, wherein the accelerator comprises citric acid and trisodium phosphate, the surfactant comprises sodium p-toluenesulfonate and ammonium lignosulfonate and the stabilizer comprises sodium heptonate, sodium carbonate and boric acid. The hole-sealing agent disclosed by the invention has the beneficial effects that the operable temperature range of the product is 50-100 DEG C, the temperature applicable range of a device is effectively increased, the energy consumption is saved, the device is convenient to operate, the service life is long, the level of the environmental pollution is decreased, the market scope of application is broad and the hole-sealing agent is conducive to the promotion and application of the market.

Owner:DONGGUAN RIYE CHEM TECH

Extraction method of methyl isobutyl ketone and sodium p-toluenesulfonate

ActiveCN110922320ALow costHigh purityOrganic compound preparationCarbonyl compound separation/purificationDistillationTosylphenylalanyl Chloromethyl Ketone

The invention relates to an extraction method of methyl isobutyl ketone and sodium p-toluenesulfonate. The extraction method comprises the following steps: carrying out atmospheric distillation on high-concentration tiamulin wastewater to distill out a mixed solution of an organic phase and water; cooling, carrying out liquid separation on the mixed solution, removing the water layer to obtain anorganic phase, adding calcium oxide into the organic phase, removing water and carrying out reduced pressure distillation to obtain high-purity methyl isobutyl ketone; carrying out vacuum concentration, cooling, separating out crystals and filtering on the residual wastewater mother liquor after distilling and separating out the organic phase and water mixed liquor; adding a solvent into the filter cake, heating and carrying out reflux water diversion; and after water separation, cooling, filtering and drying the filter cake to obtain high-purity sodium p-toluenesulfonate. The extraction method is simple, the extracted methyl isobutyl ketone and sodium p-toluenesulfonate are high in purity and the COD value of wastewater is greatly reduced.

Owner:河北威远药业有限公司

Processing method for chemical production wastewater

ActiveCN102659195AAvoid mixingReduce manufacturing costOrganic compound preparationMultistage water/sewage treatmentEnamineOil phase

The invention discloses a processing method for chemical production wastewater. The processing method comprises the following steps of: carrying out split-phase on thiazoline enol ester after carrying out sulfonylation on methylbenzene, carrying out enamine on an oil phase, evaporating water in a water phase to dryness to obtain ammonium chloride in the water phase, recycling the evaporated water, thereby reducing the production cost and preventing the ammonium chloride from mixing with water in a product in the next step; carrying out split-phase on the oil phase again after carrying out enamine on the oil phase, carrying out next reaction on the oil phase obtained through secondary split-phase, adding enough caustic soda to the water phase, carrying out alkali fusion treatment, then carrying out acidification, rectifying to obtain p-cresol or directly evaporating water to obtain paratoluenesulfonic acid sodium salt or paratoluenesulfonic acid ammonia or adjusting acidity-basicity toobtain paratoluenesulfonic acid. According to the processing method, paratoluensulfonyl chloride is used and generates salt in an aqueous solution so that multiple industrial raw materials with low cost can be obtained through derivation processing of the salt, thereby changing waste into valuable.

Owner:JIANGSU JIUJIUJIU TECH

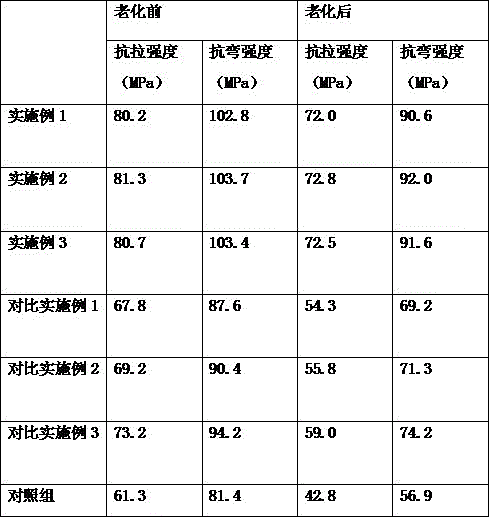

Anti-aging capacitor plastic shell and preparation method thereof

The invention discloses an anti-aging capacitor plastic shell, and belongs to the technical field of capacitors. The plastic shell is prepared from the following materials: polycarbonate, polyacrylic ester, polyvinyl chloride, polyimide, titanium dioxide, zinc oxide, kaolin, a defoaming agent, dispersant, isopropanol, sodium hexametaphosphate, magnesium stearate, sodium p-toluenesulfinate, 2-undecylimidazoline, s-triazine and alkylphenol polyoxyethylene. The plastic shell has the advantages of high overall strength, high dielectric strength, excellent temperature resistance and strong aging resistance, ensures stability and service life of capacitors, and has a good popularization value.

Owner:宁国市大荣电器有限公司

Natural whitening laundry detergent and preparation method thereof

InactiveCN110846141ANo pollutionImprove decontamination abilityInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsBiotechnologyActive agent

The invention discloses a natural whitening laundry detergent. The natural whitening laundry detergent is composed of the following components, by weight, 10-20 parts of glycerol, 5-8 parts of olive leaf extract, 5-8 parts of aloe extract, 6-10 parts of camellia oil, 6-10 parts of coconut oil, 5-7 parts of an antibacterial agent, 3-5 parts of sodium percarbonate, 3-5 parts of sodium p-toluenesulfonate, 3-5 parts of alkaline protease, 5-10 parts of a thickener, 3-6 parts of a surfactant and 60-80 parts of deionized water. The invention further discloses a preparation method of the natural whitening laundry detergent. The natural whitening laundry detergent disclosed by the invention can effectively whitening, and meanwhile, the components are natural and safe.

Owner:高万东

Method for treating waste liquid from production of 2,6-di-t-butyl-p-cresol

ActiveCN106854026ASolve the real problemLow costWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesLiquid wasteThermal energy

The invention relates to a method for treating waste liquid from production of 2,6-di-t-butyl-p-cresol. The method comprises the following steps: (1) pretreatment of waste liquid; (2) concentration and neutralization of the waste liquid: preheating the waste liquid to 70 to 80 DEG C, then cooling and separating the waste liquid, delivering the separated waste liquid to a third-effect evaporation chamber and a third-effect heating chamber for heating, then introducing a heated mixture to a second-effect evaporation chamber and a second-effect heating chamber for heating, and then introducing a mixture to a first-effect evaporation chamber and a first-effect heater for heating; and (3) recovery of sodium p-toluenesulfonate: subjecting the mixture obtained in the previous step to filtering and separating, allowing a separated mixture to successively pass through an aggregate vortex chamber and a cyclone separator for separating and dedusting, and then carrying out discharging. According to the invention, heat produced in treatment of the waste liquid can be used as heat energy for production; condensed water can be repeatedly used; treatment cost for the waste liquid is effectively lowered; sodium p-toluenesulfonate can be recycled as a product for reuse; and conventional waste water problems are overcome, and green production is realized.

Owner:江苏迈达新材料股份有限公司

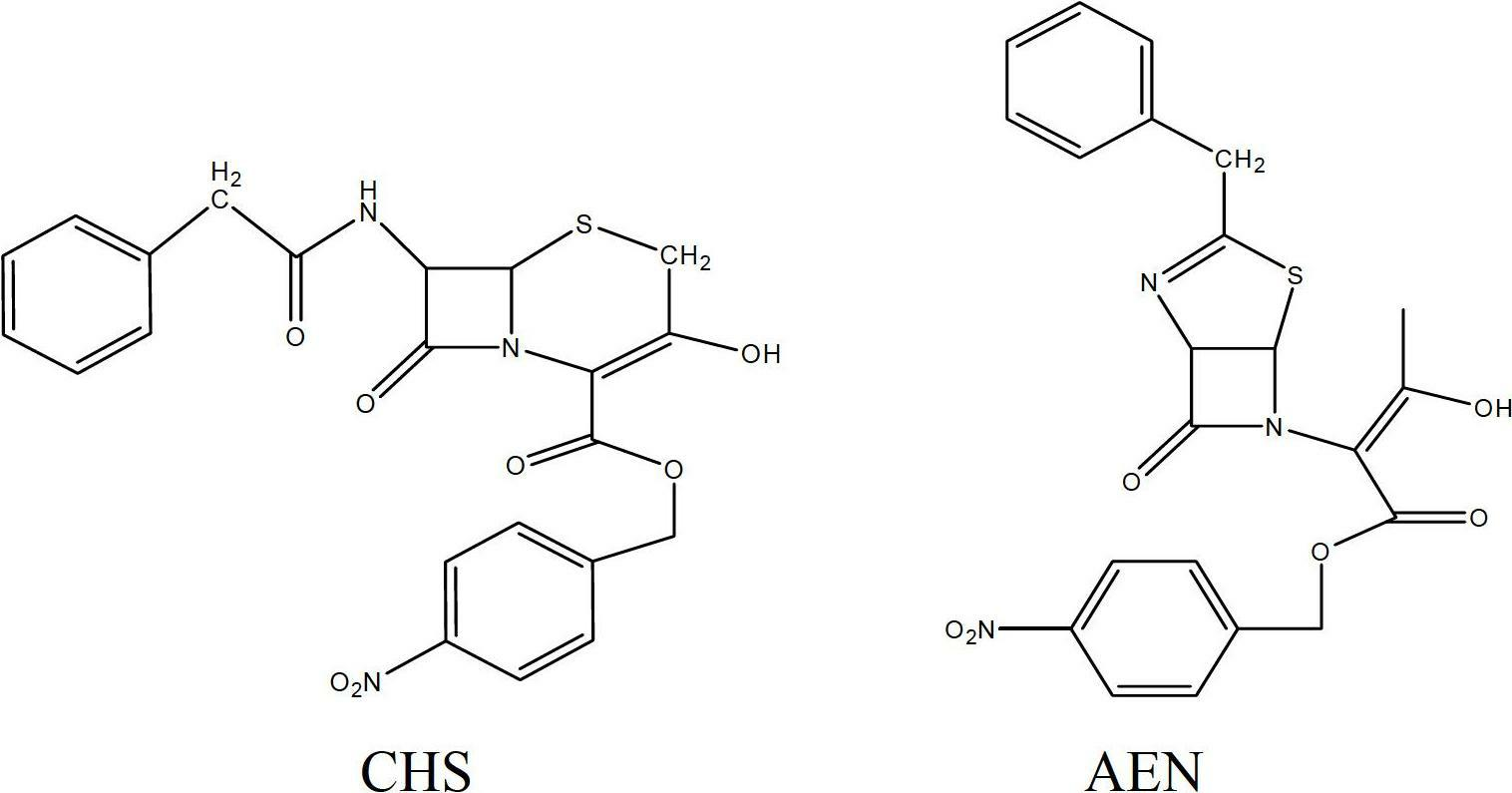

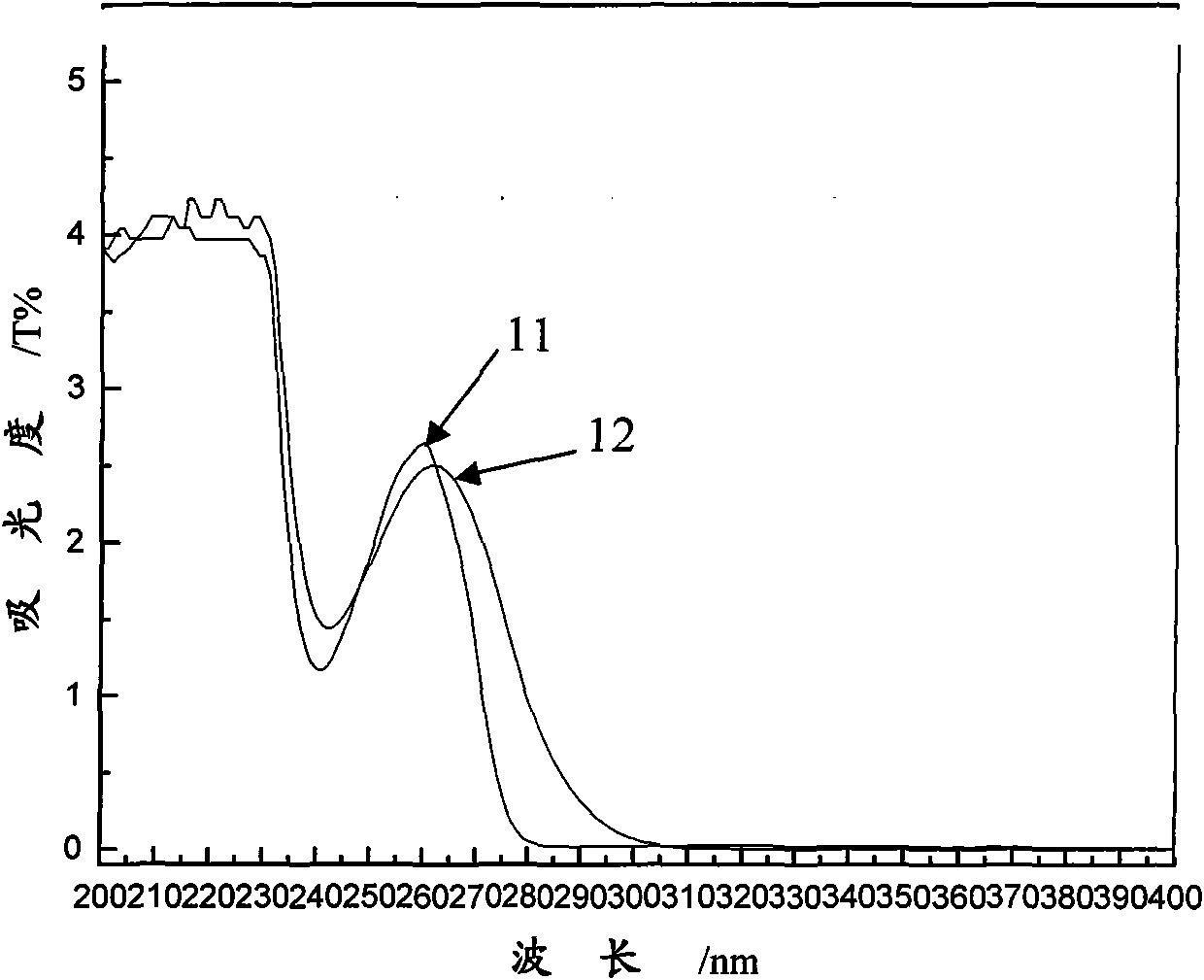

Method for determining content of sodium p-toluenesulfinate in reduction process of p-toluenesulfonyl chloride

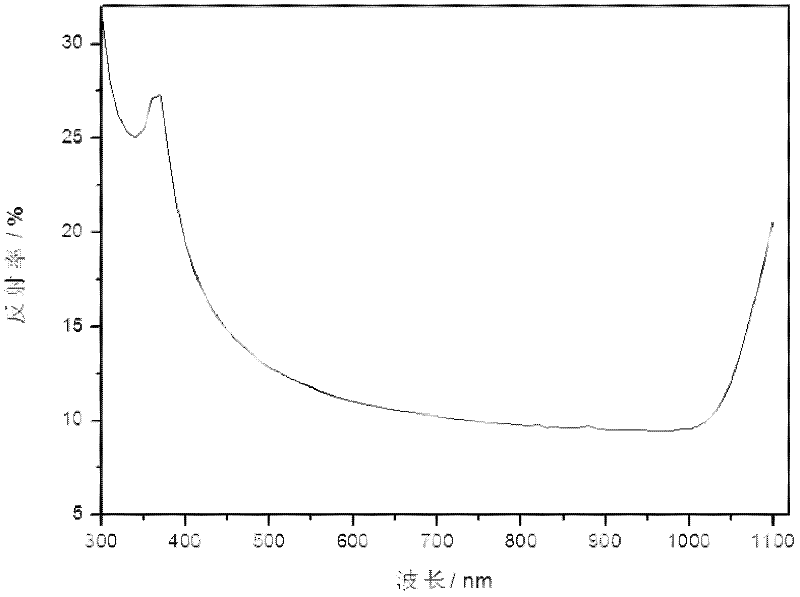

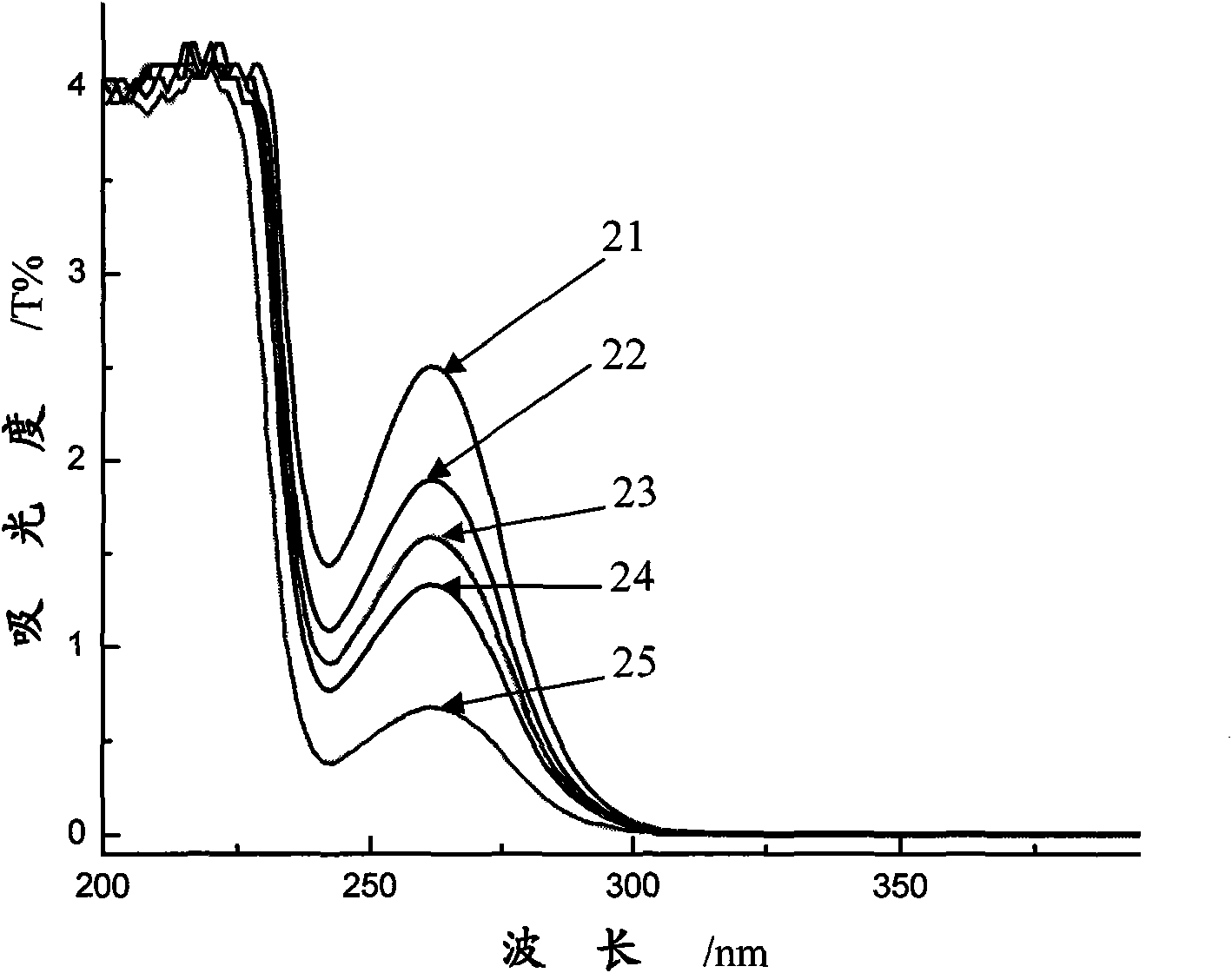

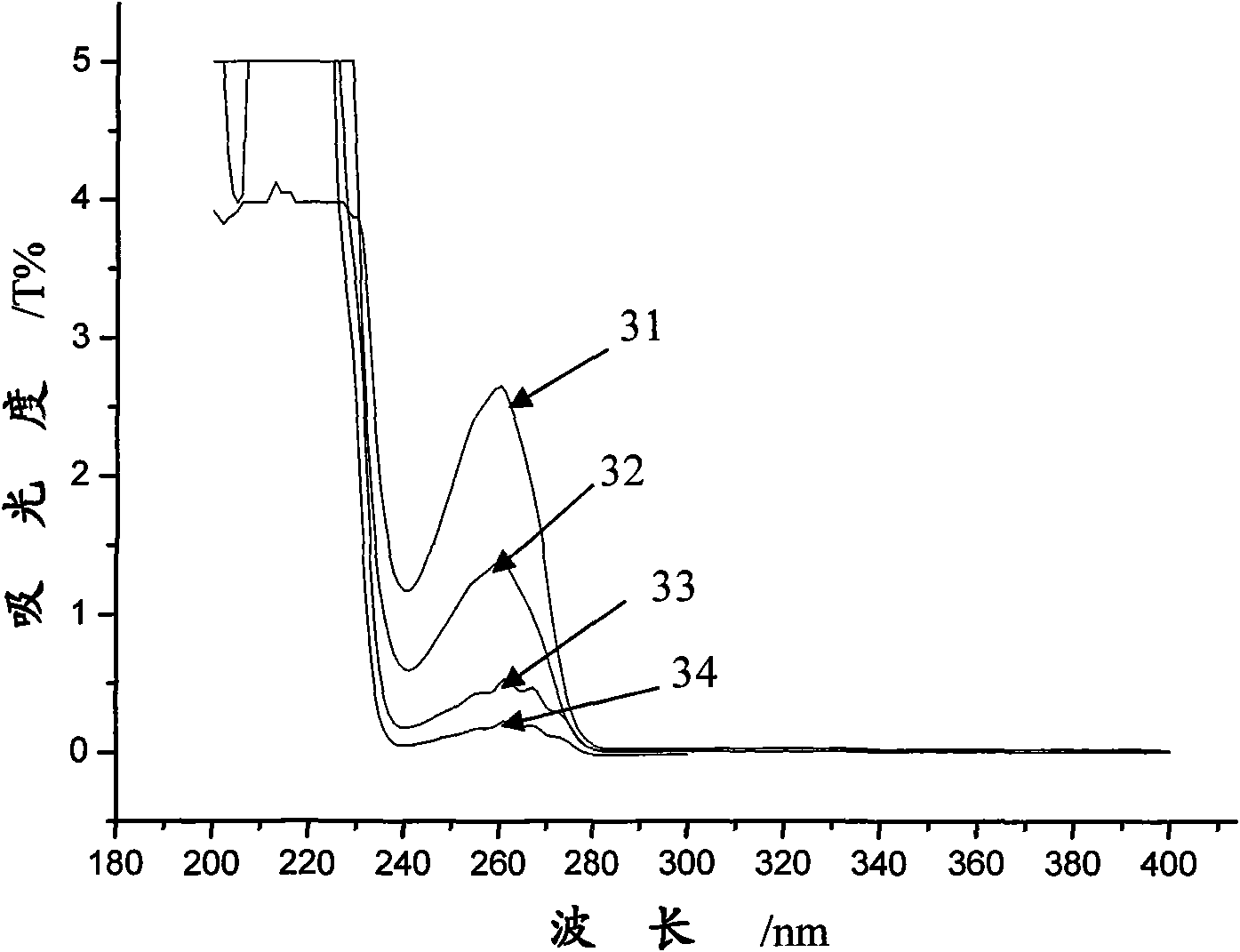

InactiveCN101650304ARealize quantitative detectionDetermination of contentColor/spectral properties measurementsSodium-p-toluenesulfinateQuantitative determination

The invention relates to a method for determining the content of sodium p-toluenesulfinate in a reduction process of p-toluenesulfonyl chloride. A wavelength of 282 nm, which does not absorb sodium 4-toluenesulfonate and absorbs a great amount of sodium p-toluenesulfinate, is obtained by respectively scanning ultraviolet-spectrum full wavelengths of standard solutions of the sodium 4-toluenesulfonate and the sodium p-toluenesulfinate, not only can favorably determine the content of the sodium p-toluenesulfinate, but also can satisfy the needs on detection sensitivity. Under the wavelength, the method not only can differentiate the sodium 4-toluenesulfonate from the sodium p-toluenesulfinate which are contained in the solution, but also can simultaneously achieve the quantitative determination of the sodium p-toluenesulfinate.

Owner:JIAXING UNIV

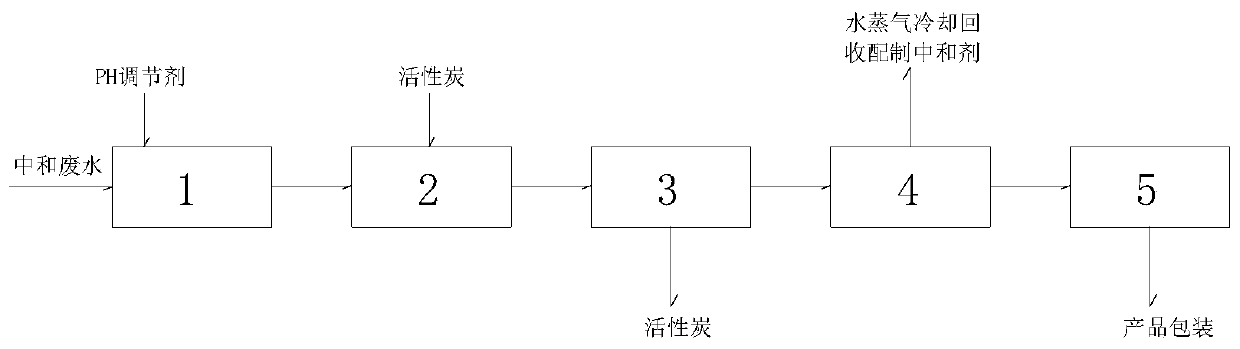

Method using neutralizing wastewater in BHT (butylated hydroxytoluene) production to produce sodium p-toluenesulfonate

InactiveCN110294695AEliminate the separation and purification processSimple processOrganic chemistryOrganic compound preparationHydrogenSodium-p-toluenesulfinate

The invention belongs to the technical field of chemical engineering, and particularly relates to a method using neutralizing wastewater in BHT (butylated hydroxytoluene) production to produce sodiump-toluenesulfonate. The neutralizing wastewater comprises sodium p-toluenesulfonate and an alkaline neutralizing agent. The method comprises the following steps of step 1, adjusting the pH (potentialof hydrogen) value of the produced neutralizing wastewater in BHT production process to 6 to 7; step 2, discoloring the neutralizing wastewater with adjusted pH value by an adsorbent; step 3, filtering the discolored neutralizing wastewater, evaporating and concentrating, cooling, and crystallizing, so as to obtain a crude product of the sodium p-toluenesulfonate. The method has the advantages that the wastewater of the BHT technology can be eliminated, the difficult problem of environment protection is solved, the wastewater can be recycled as resource, the production cost of the sodium p-toluenesulfonate is reduced, and the economic benefit is increased.

Owner:江苏迈达新材料股份有限公司

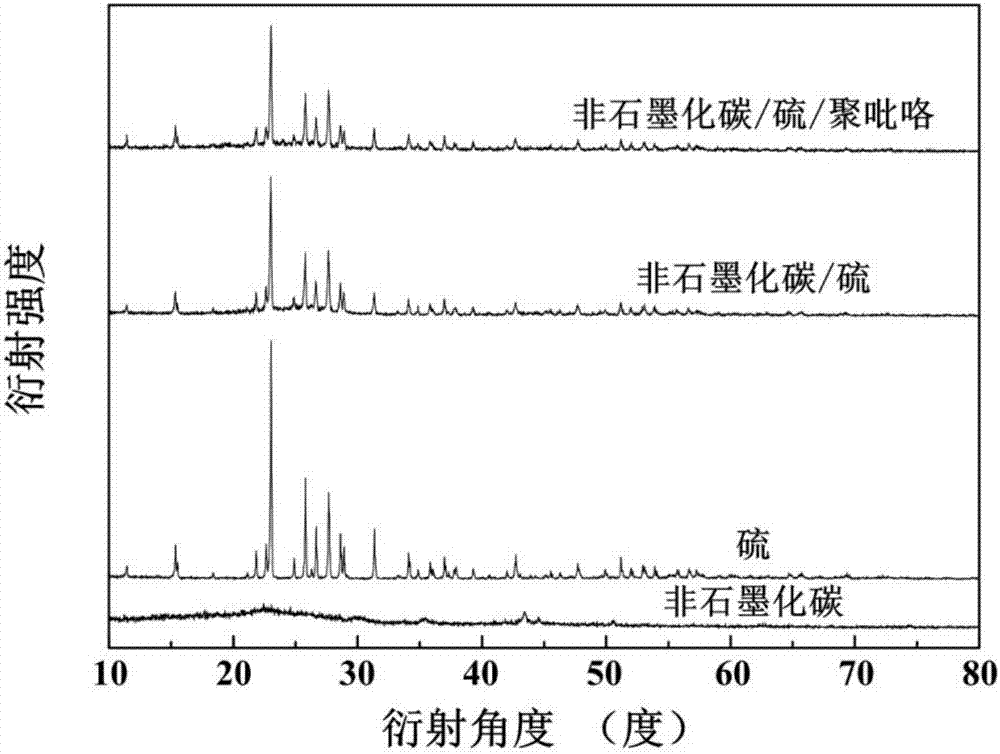

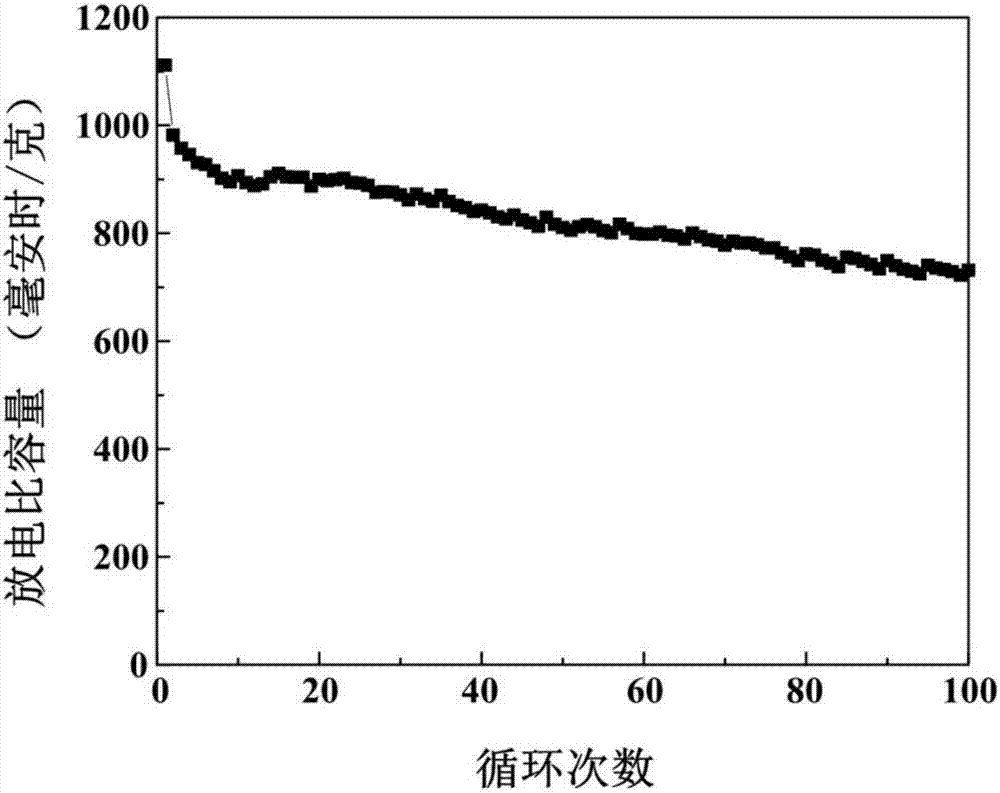

Method for preparing ungraphitised carbon and polypyrrole collaboratively coated sulfur

InactiveCN106876677AImprove electrochemical performanceEasy to spreadCell electrodesPolypyrroleAdvanced composite materials

The invention discloses a method for preparing ungraphitised carbon and polypyrrole collaboratively coated sulfur, and belongs to the technical field of preparation processes of advanced composite materials. An ungraphitised carbon / sulfur / polypyrrole composite material utilizes ungraphitised carbon as a conductive modified phase and utilizes polypyrrole as a coating phase so as to enhance the charging and discharging cycle performance of the composite material. The ungraphitised carbon / sulfur / polypyrrole composite material is prepared from sodium pentahydrate, concentrated hydrochloric acid, pyrrole monomers, methyl orange, hexahydrate ferric chloride, sodium p-toluenesulfonate and deionized water by carrying out an in-situ precipitation reaction, an in-situ chemical oxidation reaction, drying and heat treatment. The method is simple in production process and low in cost, and the prepared ungraphitised carbon / sulfur / polypyrrole composite material has excellent electrochemical performance.

Owner:JILIN UNIV

Preparation method for organic ironferric fertilizer with water retention function

InactiveCN109020738AImprove water holding capacityRaw materials are easy to getOrganic fertilisersUrea compound fertilisersSodium-p-toluenesulfinateAdditive ingredient

The invention provides a preparation method for organic iron fertilizer with a water retention function. The organic iron fertilizer is prepared by effectively blending substances of which the raw material ingredients have water retention, substances containing organic iron elements, attapulgite powder, paratoluenesulfonic acid sodium salt, vermiculite and perlite under a certain condition. The organic iron fertilizer has an obvious effect on enhancing soil water holding capacity, preventing and treatingcuring physiological diseases caused by iron deficiency of crops and accelerating crops togrow and develop.

Owner:艾生豪

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com