Processing method for chemical production wastewater

A technology for producing wastewater and treatment methods, applied in chemical instruments and methods, natural water treatment, heating water/sewage treatment, etc. The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

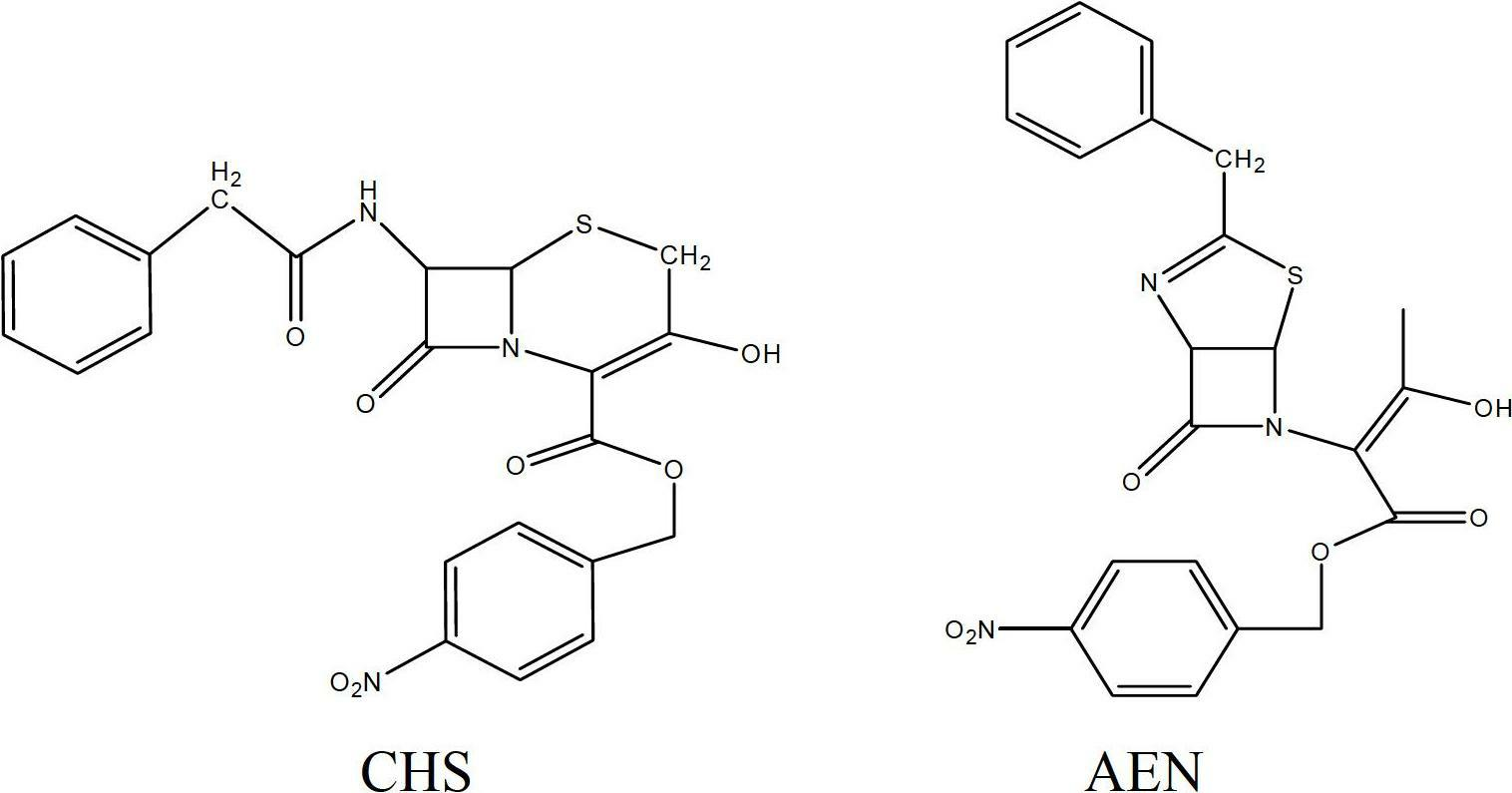

Image

Examples

Embodiment 1

[0027] (1) Add 350ml of dichloromethane, 22.0g of AEN, and 12.6g of p-toluenesulfonyl chloride in a four-neck flask. Add 20ml of 20% ammonia water dropwise at room temperature. After the addition is complete, keep the reaction for 2h. The phases were separated, the methylene chloride phase was subjected to the next reaction, and the water phase was distilled off to obtain 3.17 g of ammonium chloride with a recovery rate of 95.2%. The water recovery was used mechanically.

[0028] (2) After adding 60.0ml of morpholine aqueous solution into the dichloromethane phase, continue to add about 20ml of ammonia water within one hour, raise the temperature to room temperature for reaction, and maintain the reaction for 1 hour. After the reaction, separate the organic phase for the next step of reaction , the water phase was evaporated to remove the solvent to obtain 11.28 g of ammonium p-toluenesulfonate, the recovery rate was 95%, and the water recovery was used mechanically.

Embodiment 2

[0030] Sulfuric acid was added to the water phase in step (2) of Example 1 to acidify the water phase so that the pH of the water phase was 1, and an aqueous p-toluenesulfonic acid solution was obtained. Part of the water can be evaporated as needed to obtain the desired concentration of aqueous solution or crystallized product. All the other are with embodiment 1.

Embodiment 3

[0032] Add 3 times the amount of caustic soda to the water phase in step (2) of Example 1 for alkali fusion treatment, add 1.3 times the amount of alkali to acidify, and rectify p-cresol. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com