Anti-aging capacitor plastic shell and preparation method thereof

A capacitor and anti-aging technology, applied in the field of capacitors, can solve the problems affecting the use of capacitors, increasing the difficulty of processing, and easy water absorption, etc., to achieve the effects of ensuring stability and life, improving the degree of crosslinking, and enhancing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

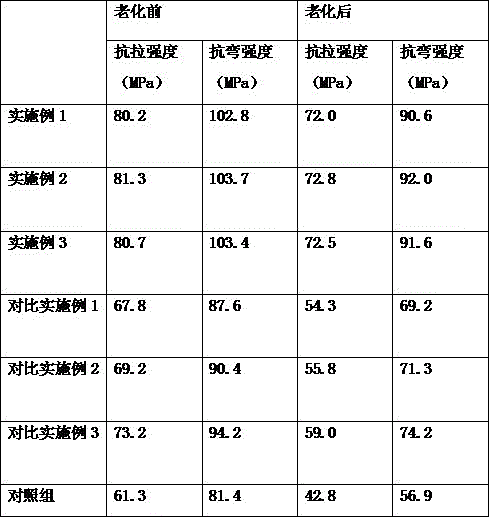

Examples

Embodiment 1

[0018] An aging-resistant capacitor molded case is made of the following substances in parts by weight:

[0019] 80 parts of polycarbonate, 20 parts of polyacrylate, 6 parts of polyvinyl chloride, 3 parts of polyimide, 6 parts of titanium dioxide, 5 parts of zinc oxide, 3 parts of kaolin, 1 part of defoamer, 2 parts of dispersant, 3 parts of isopropanol, 1 part of sodium hexametaphosphate, 0.5 parts of magnesium stearate, 0.5 parts of sodium p-toluenesulfinate, 0.5 parts of 2-undecyl imidazoline, 1 part of s-triazine, 2 parts of alkyl Phenol polyoxyethylene ether.

[0020] Further, the defoamer is polyoxyethylene polyoxypropylene pentaerythritol ether.

[0021] Further, the dispersant is triethylhexyl phosphoric acid.

[0022] A preparation method for an aging-resistant capacitor plastic case, comprising the steps of:

[0023] (1) First, ball mill the titanium dioxide until the particle size is 180-200 μm for later use; grind the zinc oxide until the particle size is 80-100...

Embodiment 2

[0029] An aging-resistant capacitor molded case is made of the following substances in parts by weight:

[0030] 85 parts of polycarbonate, 23 parts of polyacrylate, 8 parts of polyvinyl chloride, 4 parts of polyimide, 7 parts of titanium dioxide, 6 parts of zinc oxide, 4 parts of kaolin, 1.5 parts of defoamer, 2.5 parts of dispersant, 3.5 parts of isopropanol, 1.5 parts of sodium hexametaphosphate, 0.8 parts of magnesium stearate, 0.7 parts of sodium p-toluenesulfinate, 0.7 parts of 2-undecyl imidazoline, 1.5 parts of s-triazine, 2.5 parts of alkyl Phenol polyoxyethylene ether. All the other method steps are the same as in Example 1.

Embodiment 3

[0032] An aging-resistant capacitor molded case is made of the following substances in parts by weight:

[0033] 90 parts of polycarbonate, 25 parts of polyacrylate, 10 parts of polyvinyl chloride, 5 parts of polyimide, 8 parts of titanium dioxide, 7 parts of zinc oxide, 5 parts of kaolin, 2 parts of defoamer, 3 parts of dispersant, 4 parts of isopropanol, 2 parts of sodium hexametaphosphate, 1 part of magnesium stearate, 1 part of sodium p-toluenesulfinate, 1 part of 2-undecyl imidazoline, 2 parts of s-triazine, 3 parts of alkyl Phenol polyoxyethylene ether. All the other method steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com