Jatropha curcas oil acrylate polymer fatliquor prepared based on miniemulsion polymerization method and method for preparing jatropha curcas oil acrylate polymer fatliquor

A technology of miniemulsion polymerization and jatropha oil, which is applied in animal husbandry, small raw hide/large raw hide/leather skin/fur chemical treatment, application, etc., and can solve the problems of low polymerization activity, low grafting rate, and fatliquor performance Poor problems, to achieve the effect of large output, good self-emulsification ability, and reduced atomization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The following are parts by mass

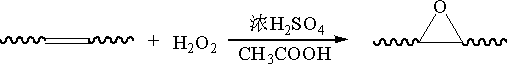

[0053] Step 1: Preparation of epoxy jatropha oil

[0054] Add 50 parts of jatropha oil, 10 parts of glacial acetic acid, and 0.75 parts of concentrated sulfuric acid into a 250ml three-necked flask and mix evenly, raise the temperature to 30°C, drop 40 parts of hydrogen peroxide into the three-necked flask, add dropwise for 1 hour, and heat up to React at 60°C for 6 hours. After the reaction, cool to room temperature to remove water, wash with water until neutral, and obtain epoxy jatropha oil.

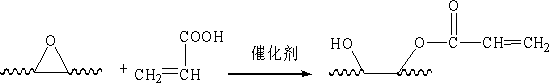

[0055] Step 2: Preparation of jatropha oil acrylate

[0056] Add the epoxy jatropha oil, the reaction product of step 1, into a 250ml three-necked flask, add 0.5 parts of p-toluenesulfonic acid as a catalyst, add 0.1 parts of hydroquinone as a polymerization inhibitor, and slowly drop 15 parts of acrylic acid Into a three-necked flask, add dropwise for 0.5h, and react at 100°C for 3h to obtain jatropha oil acrylate.

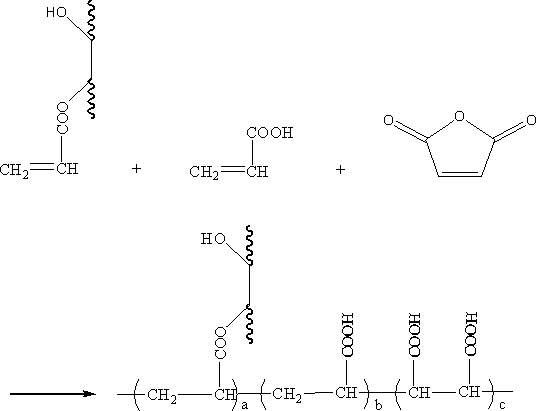

[0057] Step 3: Preparat...

Embodiment 2

[0062] The following are parts by mass

[0063] Step 1: Preparation of epoxy jatropha oil

[0064] Add 48 parts of Jatropha curcas oil, 10.5 parts of glacial acetic acid, and 0.8 parts of concentrated sulfuric acid into a 250ml three-necked flask and mix evenly, raise the temperature to 30°C, drop 42 parts of hydrogen peroxide into the three-necked flask, add dropwise for 1 hour, and heat up to React at 60°C for 6.5 hours. After the reaction, cool to room temperature to remove water in layers, wash with water until neutral, and obtain epoxy jatropha oil.

[0065] Step 2: Preparation of Acrylated Jatropha Oil

[0066] Add the epoxy jatropha oil, the reaction product of step 1, into a 250ml three-necked flask, add 0.4 parts of p-toluenesulfonic acid as a catalyst, add 0.2 parts of hydroquinone as a polymerization inhibitor, and slowly drop 15 parts of acrylic acid To a three-necked flask, add dropwise for 0.5h, and react at 100°C for 3h to obtain acrylated jatropha oil.

[00...

Embodiment 3

[0072] The following are parts by mass

[0073] Step 1: Preparation of epoxy jatropha oil

[0074] Add 45 parts of jatropha oil, 11 parts of glacial acetic acid, and 0.85 parts of concentrated sulfuric acid into a 250ml three-necked flask and mix evenly, heat up to 30°C, drop 45 parts of hydrogen peroxide into the three-necked flask, add dropwise for 1 hour, and heat up to React at 60°C for 6 hours. After the reaction, cool to room temperature to remove water, wash with water until neutral, and obtain epoxy jatropha oil.

[0075] Step 2: Preparation of jatropha oil acrylate

[0076] Add the epoxy jatropha oil, the reaction product of step 1, into a 250ml three-necked flask, add 0.45 parts of p-toluenesulfonic acid as a catalyst, add 0.3 parts of hydroquinone as a polymerization inhibitor, and slowly drop 15 parts of acrylic acid To a three-necked flask, add dropwise for 0.5h, and react at 100°C for 3h to obtain acrylated jatropha oil.

[0077] Step 3: Fine emulsification of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com