Patents

Literature

87results about How to "Good self-emulsifying performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pharmaceutical compositions for lipophilic drugs

InactiveUS7070802B1Good self-emulsifying performanceShelf-stableCyclic peptide ingredientsCapsule deliveryMonoglycerideCyclosporins

Stable solutions of lipophilic drugs, such as cyclosporin, forming a polar lipid self-emulsifying drug delivery system. The solutions can include lipophilic drugs, such as cyclosporin, dissolved in a polar lipid, such as having a C6-C12 fatty acid monoglyceride content of at least about 50%, surfactants and triglycerides. The composition forms a fine emulsion on exposure to water. The encapsulated dosage form of this composition needs neither a hydrophilic component nor air-tight blister packaging, and is particularly suitable for oral administration.

Owner:WATSON LAB INC

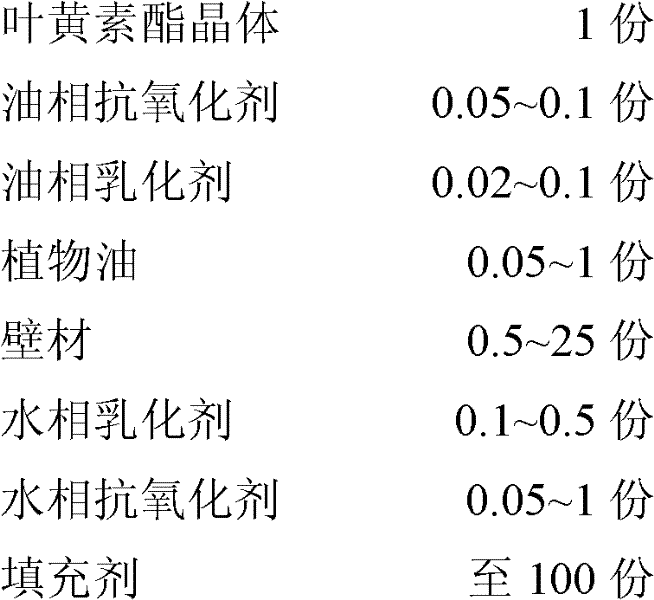

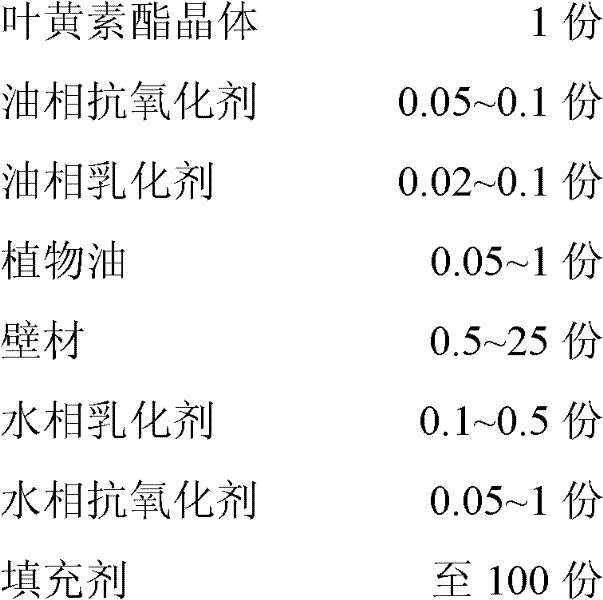

Lutein ester microcapsule powder and preparation method thereof

ActiveCN102389108AInstant highGood self-emulsifying performanceFood preparationAntioxidantFiller Excipient

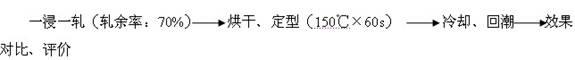

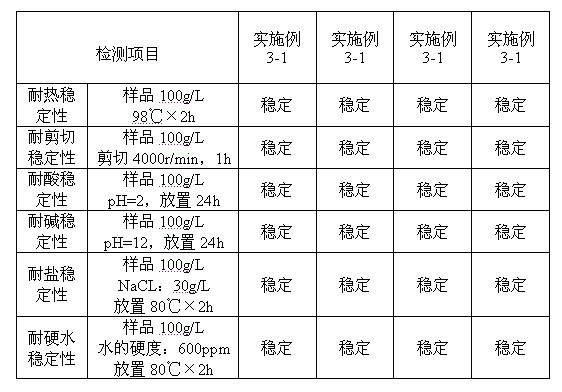

The invention discloses lutein ester microcapsule powder and a preparation method thereof. The preparation method comprises the following steps of: preparing an oil phase solution and a water phase solution respectively, and mixing and emulsifying the oil phase solution and the water phase solution; and non-water raw materials comprise the following components in part by weight: 1 part of lutein ester crystal, 0.05 to 0.1 part of oil phase antioxidant, 0.02 to 0.1 part of oil phase emulsifying agent, 0.05 to 1 part of plant oil, 0.5 to 25 parts of wall material, 0.1 to 0.5 part of water phaseemulsifying agent, 0.05 to 1 part of water phase antioxidant, and the balance of filler. In the preparation method for the lutein ester microcapsule powder, the oil-soluble lutein ester is fully dispersed in cold water in the form of sub nanometer particles, and the product can be self-emulsified in water, and is good in instant capacity and self-emulsification capacity, and high in stability, and has uniform and durable color; and the phenomena of oil floating, precipitation, adhesion to a bottle wall and the like are avoided during application. Organic solvents are not introduced in the powder, so solvent residues are avoided in the product. The production process is environment-friendly, simple and practicable, expensive equipment is not needed, and the microcapsule powder can be industrially produced easily and conveniently.

Owner:INNOBIO CORP LTD

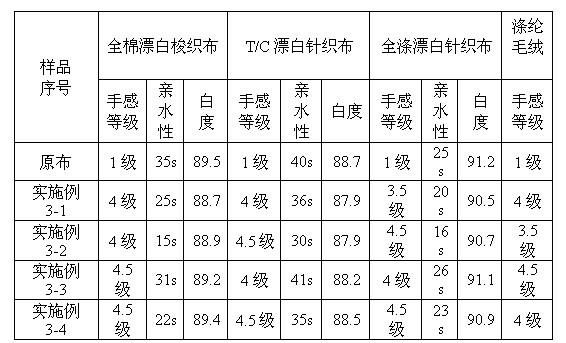

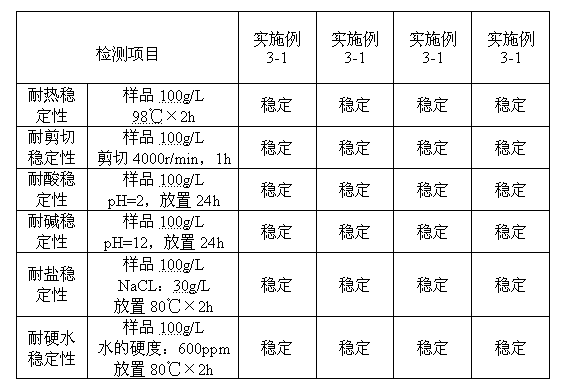

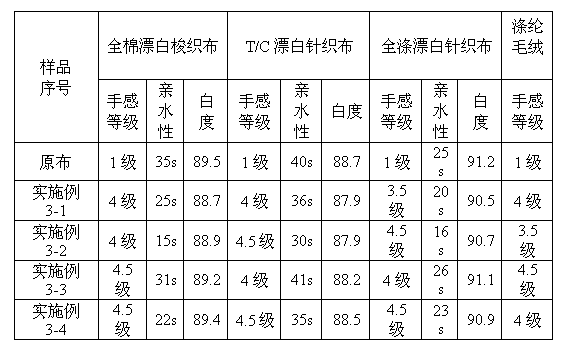

Supersoft hydrophilic block silicone oil compound and preparation method thereof

The invention relates to the field of textile finishing agent, in particular to supersoft hydrophilic block silicone oil compound and a preparation method thereof. The supersoft hydrophilic block silicone oil compound is composed of cations of the structural formula, wherein the n1 is the number of 5 to 10, the R is polyether group, and the degree of polymerization ranges from 3 to 50. The supersoft hydrophilic block silicone oil compound is applicable to handle finishing of fabric knitted by one or multiple fibers of cotton, dacron, chinlon and acrylic fibers and has softness, smoothness and looseness effects superior to those of amino-modified silicone oil, has excellent stability in acid and alkali resistance, electrolyte resistance, high temperature resistance, shearing resistance and the like and thoroughly solves the problems of easy demulsification, floating oil, roll banding, difficulty in refinishing and the like.

Owner:RUNHE ORGANICSILICONE NEW MATERIAL

Method for preparing super-smooth hydrophilic quaternary ammonium salt modified organic silicon copolymer

ActiveCN104072783AGood self-emulsifying performanceImprove hydrophilicityVegetal fibresAcetic acidOrganic solvent

The invention relates to the field of a textile finishing agent, and particularly relates to a method for preparing a super-smooth hydrophilic quaternary ammonium salt-modified organic silicon copolymer. The method comprises the following steps: synthesizing a cationic modified polyether amine intermediate by using aliphatic polyether diamine and an alkylating agent under the action of an acid catalyst; carrying out addition polymerization of amino and an epoxy group on the cationic modified polyether amine intermediate and terminated epoxy polyether silicone oil in the presence of an organic solvent, then adding a glacial acetic acid, and synthesizing ternary block silicon oil. The super-smooth hydrophilic quaternary ammonium salt modified organic silicon copolymer prepared by the method provides excellent hydrophilic performance to cotton fabric, and has an outstanding smooth effect, and the smoothness can achieve the level of common amino silicon oil, and is superior to that of most of ternary block silicon oil. The super-smooth hydrophilic quaternary ammonium salt modified organic silicon copolymer has certain antibacterial and antistatic functions by improvement of the cationization degree, meanwhile, the problem that amino is easy to yellow in a high-temperature condition can be effectively solved, and the processed fabric is small in yellowing, and applicable to finishing of white or light fabric.

Owner:GUANGDONG CHUANHUA FULIAN FINE CHEM CO LTD

Lubricating antistatic high-performance oil for drawing production of carbon fibre

InactiveCN101280475AAvoid defectsReduce frictionMonocomponent synthetic polymer artificial filamentSynthetic polymer filament chemical after-treatmentFiberEpoxy

The invention relates to the chemical materials of the new material field, in particular to a high-performance anti-static lubricating finish oil used in the carbon fiber wire-drawing production process. The composition of the raw materials is calculated with the weight percentage. The quaternary ammonium salt type cationic surfactant of 3 to 10, the polyoxyethylene-polyoxy-propylene-polyether of 1 to 3, the ammonia modified silicone oil of 2 to 8, epoxy-modified silicone oil of 2 to 8, polyether modified silicone oil of 2 to 8, the fluoride silicon oil of 10 to 20, lauric acid polyoxyethylene ester of 1 to 3, laurinol polyoxyethylene of 1 to 3, polyoxyethylene hydrogenerated castor oil of 4 to 20, and the rest of high-purity deionized water are stirred in a reaction kettle for 3 to 5 hours with the temperature controlled within the range of 56 to 60 DEG degree, thus the finish oil product can be produced. The invention is applied in the carbon fiber wiredrawing production process, in which the finish oil is in the formation of a membrane on the monofilament surface, not only the adhesion and merging between the monofilaments can be avoided, but also the friction and wear of the fiber surface and the roller during the production process can be prevented. Therefore, the finish oil has excellent smoothness, antistatic property, collection property and self-emulsifying property as well.

Owner:李元杰

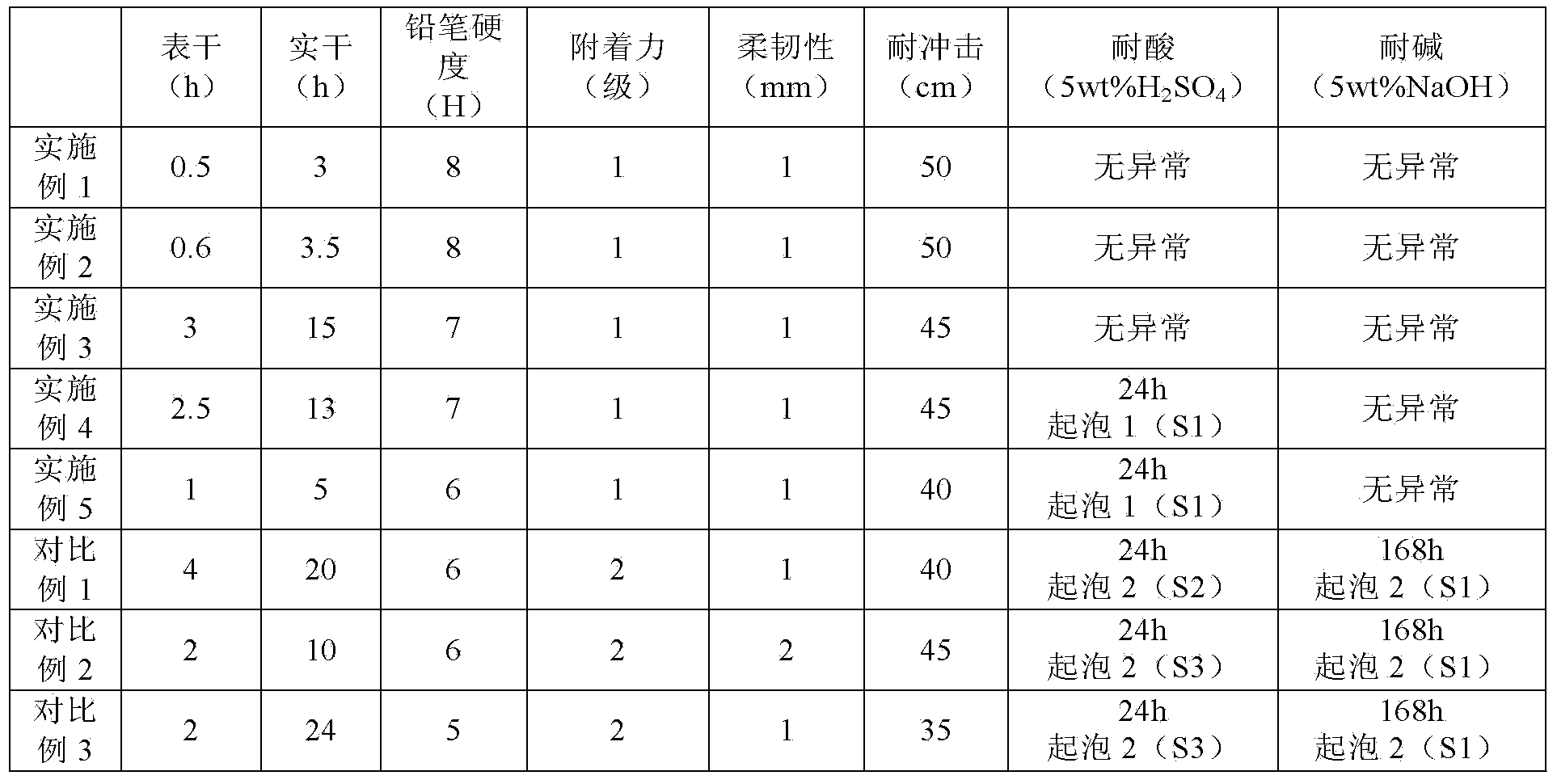

Self-emulsifying water-borne epoxy resin curing agent and preparation method thereof

The invention discloses a self-emulsifying water-borne epoxy resin curing agent and a preparation method thereof. The method comprises the following steps: S1, mixing and reacting single polyamine with epoxy resin according to the molar ratio of (1.8:2) to (2.1:1), so as to obtain an intermediate addition product; S2, blocking the intermediate addition product by adopting a single epoxy compound, so as to obtain the self-emulsifying water-borne epoxy resin curing agent; controlling the molar ratio of the single polyamine to the epoxy resin within a certain range; blocking the addition product by adopting the single epoxy compound, so as to obtain the curing agent which meets the water soluble requirements and has excellent application performance. The self-emulsifying water-borne epoxy resin curing agent has a good adaptive phase and coating property when being applied to a coating. The mode of neutralizing and blocking by adopting an organic acid when the self-emulsifying water-borne epoxy resin curing agent is prepared at present is abandoned, the process is simplified, and the problems that the cation water-soluble epoxy curing agent neutralized and prepared by adopting the organic acid is sensitive to pH value, and the unstability is generated when a basic dye and a filler are used together are solved.

Owner:BEIJING BSS CORROSION PROTECTION IND +1

Organic silicon acrylic acid modified waterborne epoxy emulsion and preparation method thereof

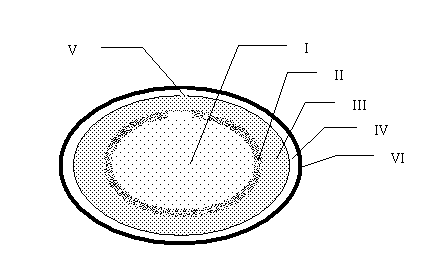

The invention provides an organic silicon acrylic acid modified waterborne epoxy emulsion and a preparation method thereof. The core layer consists of low-grade bisphenol A epoxy resin, reactive diluent, epoxy silane, a reactive emulsifier, an initiator, an assistant and an acrylic acid monomer; the shell consists of vinyl siliane, an acrylic acid monomer, a reactive emulsifier, an assistant, an initiator and de-ionized water. The obtained organic silicon acrylic acid modified waterborne epoxy emulsion is small and even in particle size and excellent in stability, is excellent in mechanical strength, environment-friendly and energy-saving after being formed to be films. The dry film matched with modified amine curing agent via the modified waterborne epoxy emulsion can reach the level of close to the film property of solvent-type epoxy resin.

Owner:IANGSU JINLING SPECIAL PAINT CO LTD

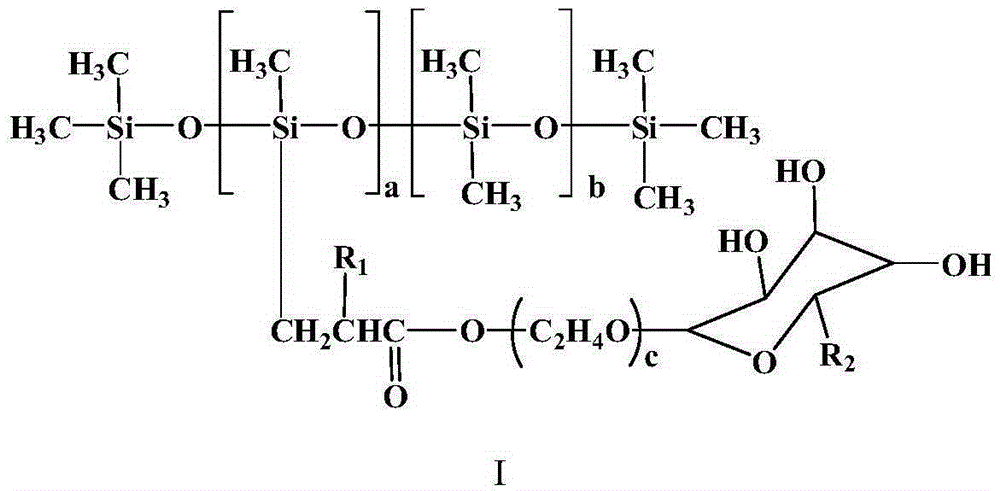

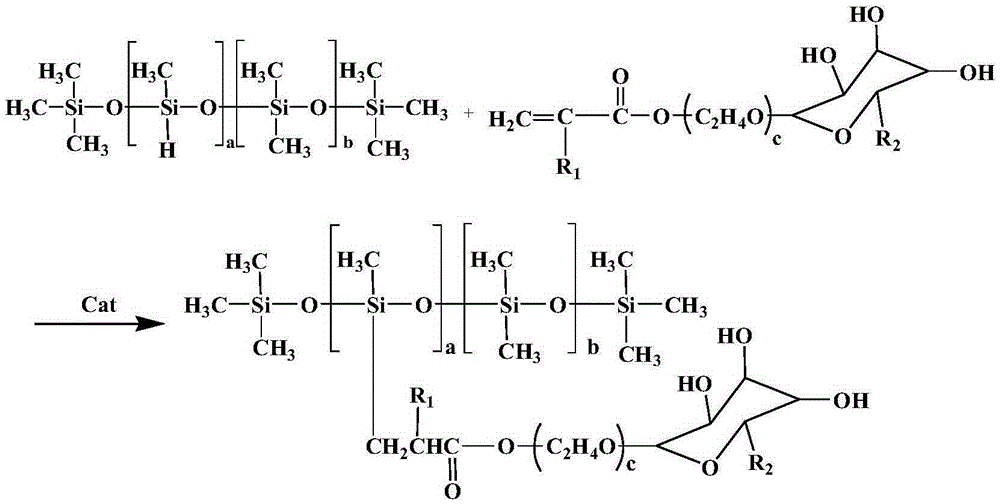

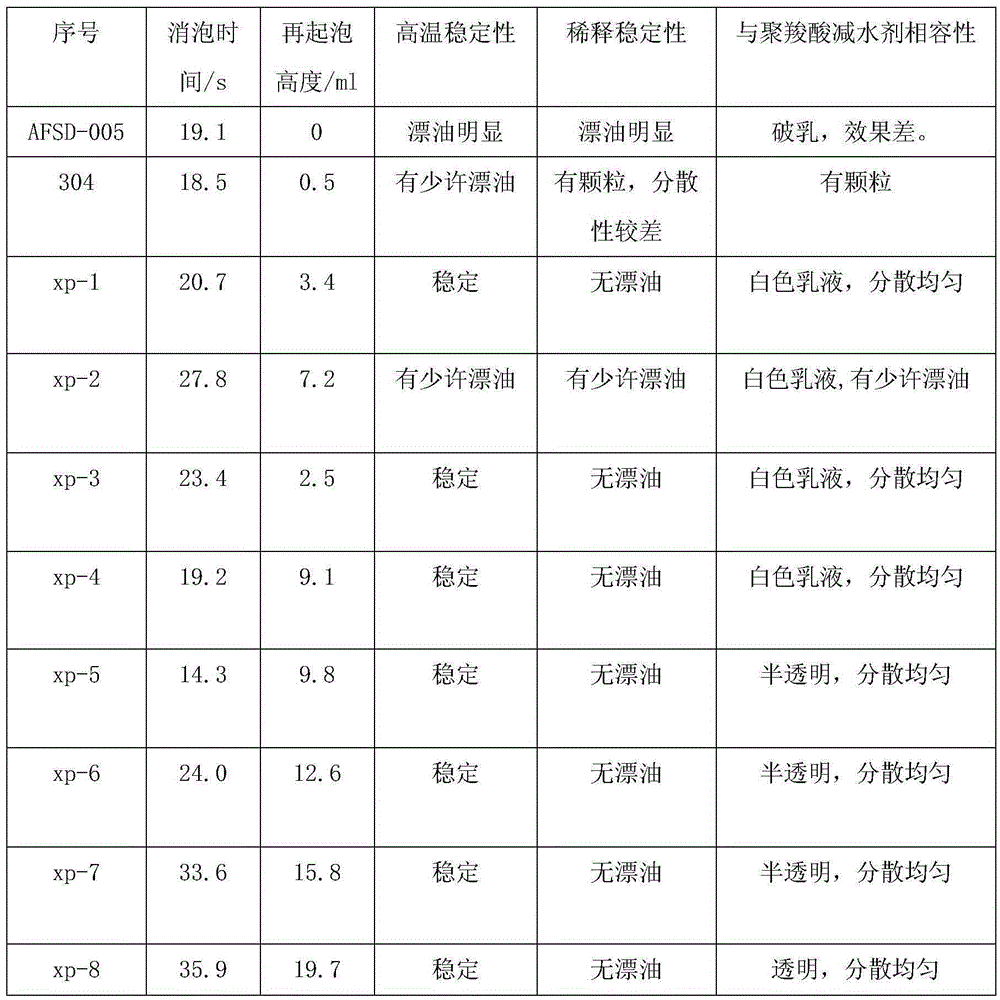

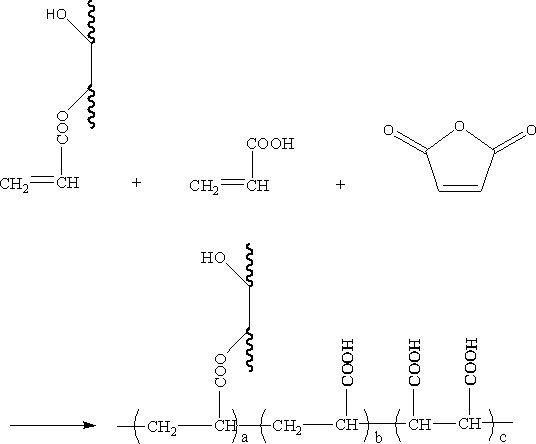

Self-emulsifying concrete defoamer and preparation method thereof

The invention belongs to the field of concrete admixtures and particularly relates to a self-emulsifying concrete defoamer and a preparation method thereof. The self-emulsifying concrete defoamer is prepared by addition reaction of siloxane or siloxane derivatives with low hydrogen content and glycosyl-containing acrylate compounds or derivatives thereof. The structural formula of the self-emulsifying concrete defoamer is shown in the formula I, wherein a is an integer of 8-20, b is an integer of 0-20, c is an integer of 1-15, R1 is -H or -CH3, and R2 is -H, -OH or -CH2OH. The self-emulsifying concrete defoamer provided by the invention has excellent self-emulsifying performance, good compatibility with other additives for concrete and strong acid and alkali resistant capabilities; when the self-emulsifying concrete defoamer is applied to concrete, large bubbles of which the diameter is greater than 50nm in the concrete can be eliminated; and meanwhile, micro-bubbles capable of obviously improving the concrete performance are introduced, so that the workability and anti-freeze durability of the concrete can be effectively improved.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD

Process for producing long-chain alkyl waterproof currying agent

InactiveCN1328392CGood self-emulsifying performanceImprove emulsion stabilityLeather impregnationLong chainMethacrylic acid

This method discloses a kind of producing method of long-chain alkyl water proof currying agent. Methyl acrylic acid long-chain unsaturated anhydride is used as product to synthesize methyl acrylic acid long-chain alkyl ester--- unsaturated anhydride copolymers. The amidation for the copolymer is made with amine, the long-chain alkyl water proof currying agent is obtained

Owner:ZHEJIANG UNIV

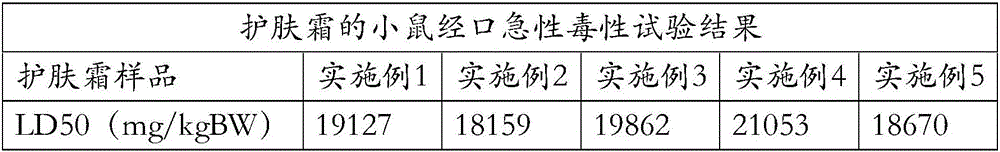

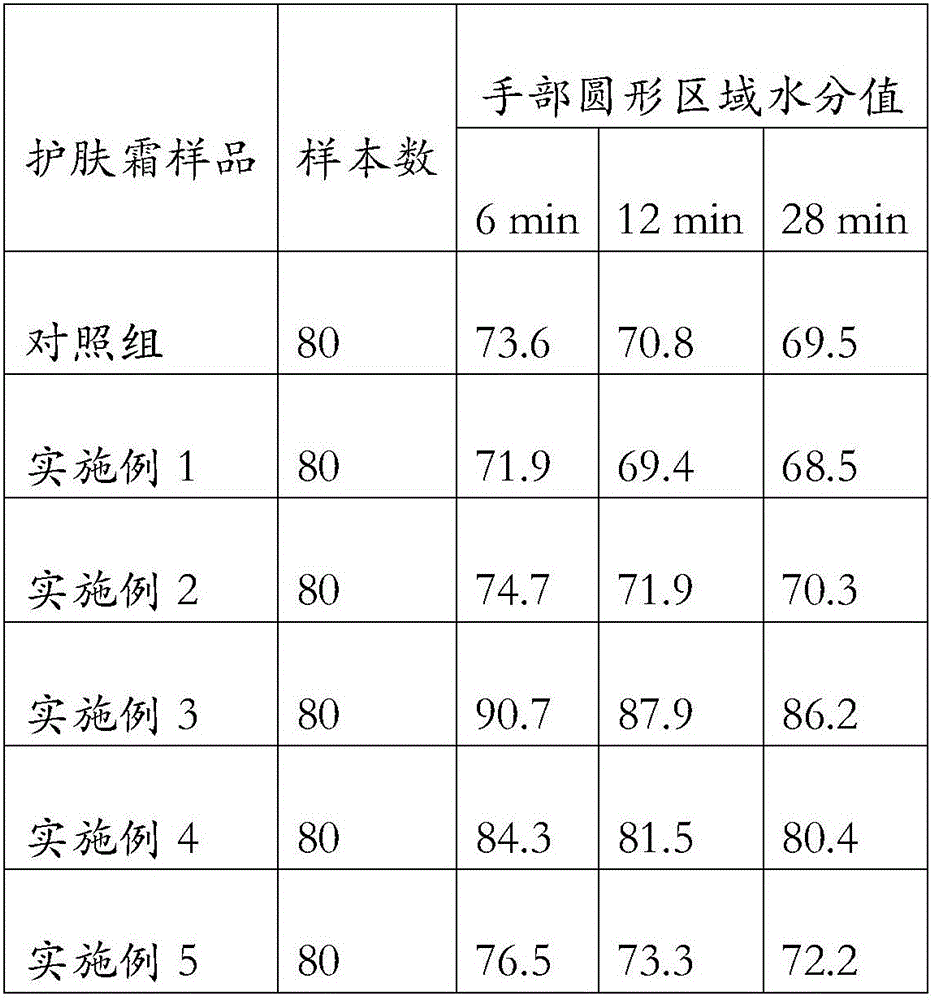

Baby skin moistening and protecting cream

InactiveCN106727020AGood self-emulsifying performanceStabilize protein active structureCosmetic preparationsToilet preparationsIrritationAnimal extract

The invention discloses baby skin moistening and protecting cream which comprises the following ingredients in percentage by weight: 2.15085-41.2% of plant extracts, 0.5-8% of at least one of caprylic triglyceride and capric triglyceride, 0.2-3% of sorbitan olivate, 0.5-10% of glycerinum, 0.2-3% of cetearyl olivate, 0.2-3% of glyceryl stearate, 0.1-5% of sorbitol, 0.05-0.3% of xanthan gum, 0.3-0.8% of tocopherol, 0.0001-0.5% of hyaluronic acid, 0.5-3% of erythritol and the balance of water, wherein the plant extracts include avocado butter, olea europaea fruit oil, rice chaff oil, wheat germ oil, oat germ oil, a paeonia suffruticosa root extract and rosmarinus officinalis leaf oil. The baby skin moistening and protecting cream is prepared from various plant extracts and animal extracts and chemicals with small skin irritation, so that the cream has a good effect of moistening and protecting baby skin and has no irritation and toxicity to the baby skin.

Owner:GUANGZHOU XIAOMIFENG BIOTECH CO LTD

Composition containing polyglycerol/medium-chain fatty acid ester

ActiveCN1889926AGood dispersionGood self-emulsifying performanceCosmetic preparationsMake-upPolymer scienceActive agent

The object of the present invention is to provide a composition containing polyglycerol medium-chain fatty acid ester and cosmetics containing the composition. The composition can form a water-in-oil microemulsion capable of solubilizing a large amount of water, and its dispersibility in water is It is also excellent in self-emulsification. The present invention relates to a composition containing polyglycerol medium-chain fatty acid ester and cosmetics containing the polyglycerol medium-chain fatty acid ester composition. The composition containing polyglycerol medium-chain fatty acid ester contains Polyglycerol medium-chain fatty acid ester and nonionic surfactant obtained by esterification of medium-chain fatty acid of 6-10 and polyglycerol with average polymerization degree greater than or equal to 3 but less than 100.

Owner:TAIYO KAGAKU CO LTD +1

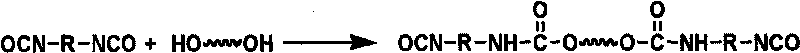

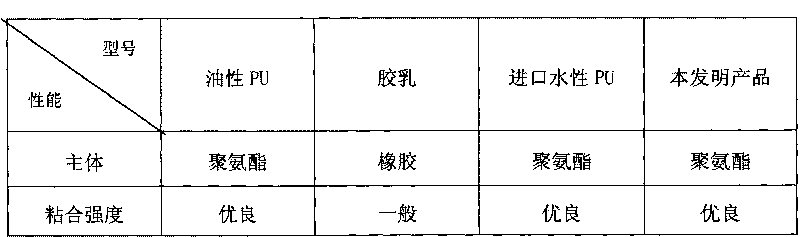

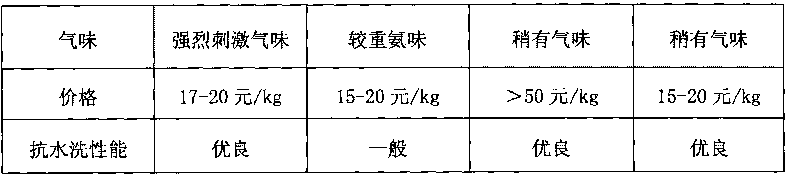

Method for preparing composite water-based polyurethane

The invention discloses a method for preparing composite water-based polyurethane. The method comprises the following steps of: adding polyether, epoxy resin, toluene diisocynate and rude MdI into a kettle, then adding a catalyst into the kettle, and preheating and prepolymerizing the mixture; measuring -NCO value, adding dimethylopropionic acid, after reacting the mixture, measuring -NCO value again; reducing the temperature, adding acetone, stirring the mixed solution, discharging the obtained product; placing the obtained product into a dispersion barrel, adding triethylamine into the dispersion barrel, stirring the mixture, adding water, and dispersing the mixed solution at a high speed; after dispersing the mixed solution uniformly, adding ethidene diamine, performing a chain extending reaction, and then stirring the obtained solution at a reduced speed; sealing and standing the obtained solution, then filtering the obtained solution and discharging the filter. The method overcomes the shortage of short-time use after the mixing of two components because the conventional oil polyurethane uses an irritant solvent, reduces waste and protects environment, has the advantages of non-toxicity and light smell by taking water as a solvent, and makes an adhesive achieve the adhesive strength by heating and activating the adhesive when clothes are bonded so as to achieve effect of good hand feeling after bonding and good water washing property.

Owner:江苏光辉粘合科技有限公司

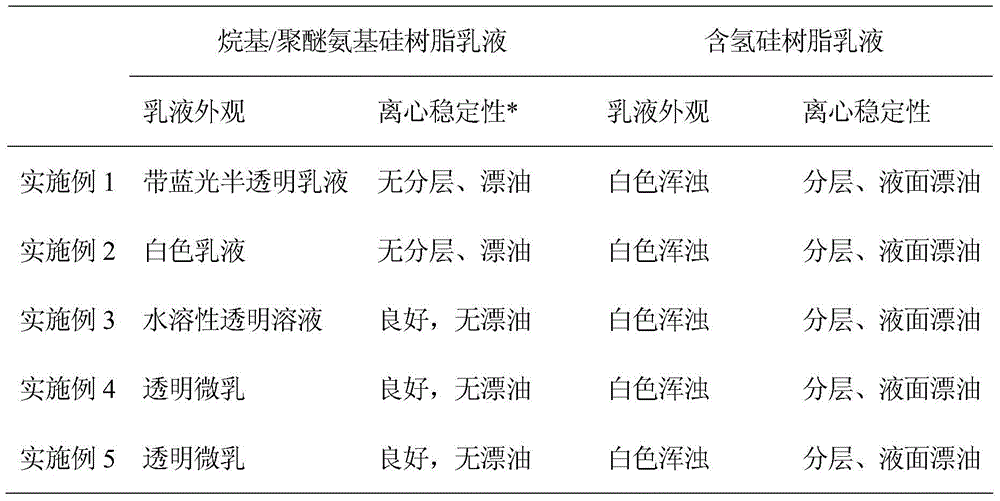

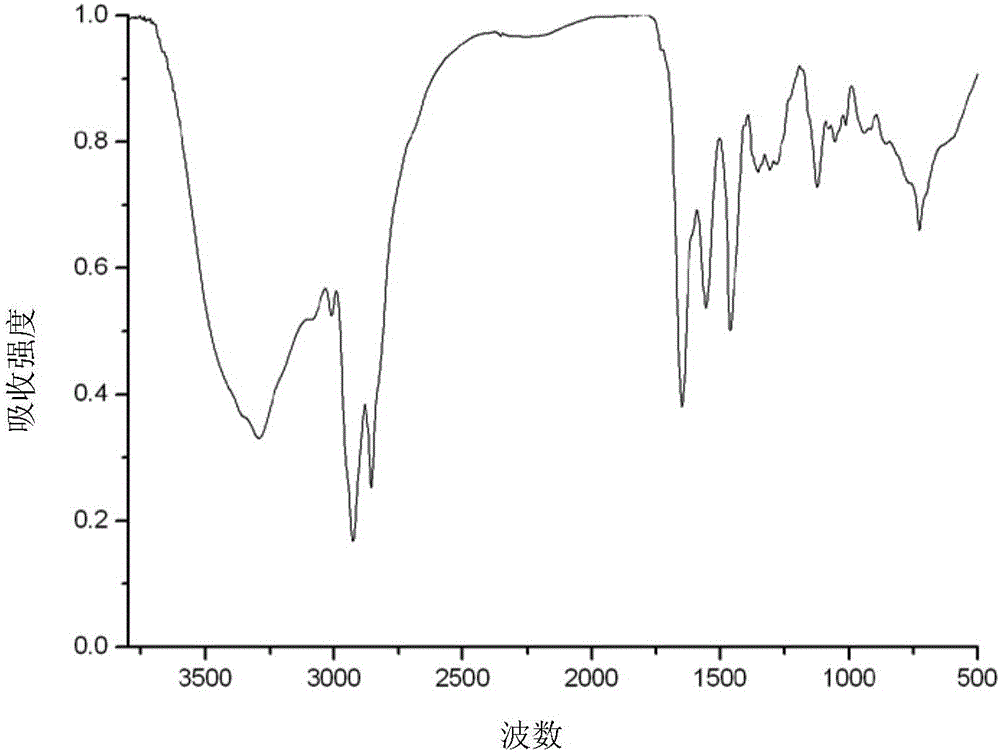

Preparation method of water dispersible alkyl/polyether amino silicone resin

The invention discloses a method for preparing a water-dispersible alkyl / polyether amino-silicon resin. The method comprises the following steps of firstly carrying out a hydrosilation addition reaction on hydrogen-containing silicone resin, small molecular alkenyl epoxy compound and alpha-olefin according to a molar ratio of Si-H bond to alkylene group C=C double bond of 1: (1.0-1.5), synthesizing an alkyl / epoxy silicone resin intermediate and then carrying out an ammonolysis ring-opening reaction on the intermediate and polyether at 45-120 DEG C to obtain the alkyl / polyether amino-silicon resin. The alkyl / polyether amino-silicon resin prepared according to the invention can be dissolved or dispersed in water to form a stable silicon emulsion or microemulsion after the alkyl / polyether amino-silicon resin is diluted with a solvent, and thus the silicon resin is expected to be used for the field of a water-based finishing agent or a coating material.

Owner:SHAANXI UNIV OF SCI & TECH

Epoxy resin water-permeable material curing agent and preparation method and application thereof

InactiveCN106046326AExcellent curabilityIncrease water permeability and breathabilityEpoxyRoom temperature

The invention belongs to the technical field of preparation of curing agents, and discloses an epoxy resin water-permeable material curing agent and a preparation method and application thereof. The curing agent is prepared from the following components in percentage by mass: 50-80 percent of ricinoleic acid and / or a polymer thereof, and 20-50 percent of fatty polyamine, alicyclic polyamine or polyoxypropylene polyamine containing a polypropylene oxide chain segment. The curing agent provided by the invention is a waterborne curing agent, has superior curing performance, and can be cured at the room temperature; a cured product has superior water permeability and air permeability, and can be applied to curing of an epoxy water-permeable material to prepare an epoxy ceramic forming mold or an epoxy water-permeable material. A fatty polyamine, polyoxypropylene polyamine or alicyclic polyamine curing agent is modified, so that the curing agent contains hydrophobic long-chain alkyl, hydrophilic hydroxyl, an amino group, acylamino and an ester group, has self-emulsifying performance, and can also be taken as a curing agent; a gap and a channel are formed between the epoxy resin and inorganic filler through a hydrophobic group, so that the obtained epoxy material has superior water permeability and air permeability.

Owner:NANXIONG MATERIAL PRODION BASE OF CHINESE ACADEMY OF SCI GUANGZHOU CHEM +1

Self-emulsifying lactescence and its preparation method

The invention provides a self-emulsifying lactescence and its preparation method. The self-emulsifying lactescence comprises a water phase and an oil phase; the water phase comprises colloidal silicasol and water; the oil phase comprises silane coupling agent and biodiesel; the volume ratio of the oil phase and the water phase is 1: 5-1: 25. The lactescence is prepared without massive external forces, the stable Pickering lactescence can be acquired under the condition of slight shake or swaying; the grain diameter of the lactescence prepared by the invention is relatively small, and the self-emulsifying lactescence has good stability and can effectively improve the harvesting rate of water displacing oil.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

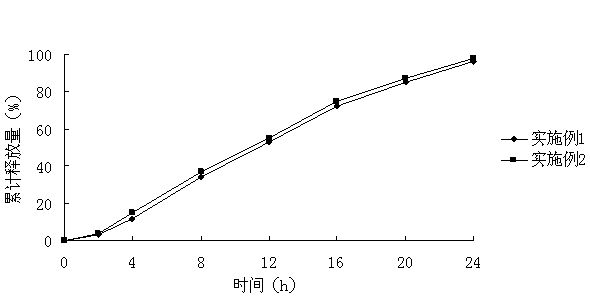

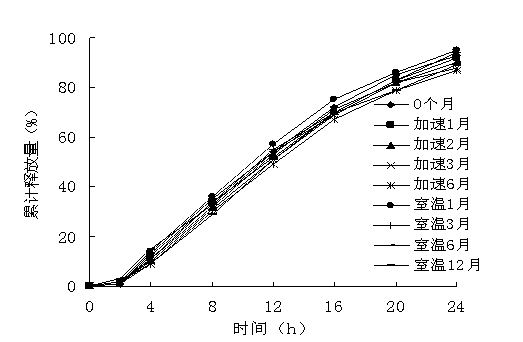

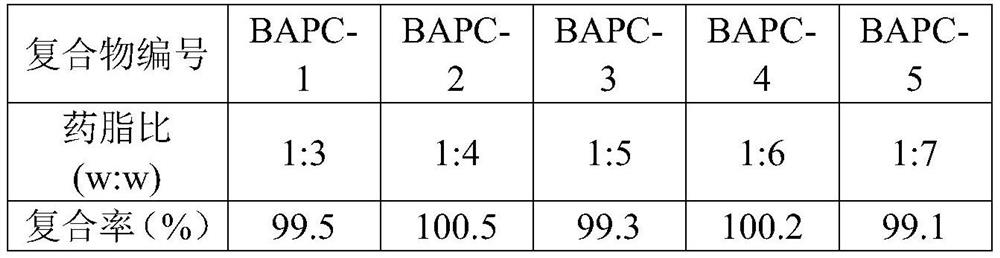

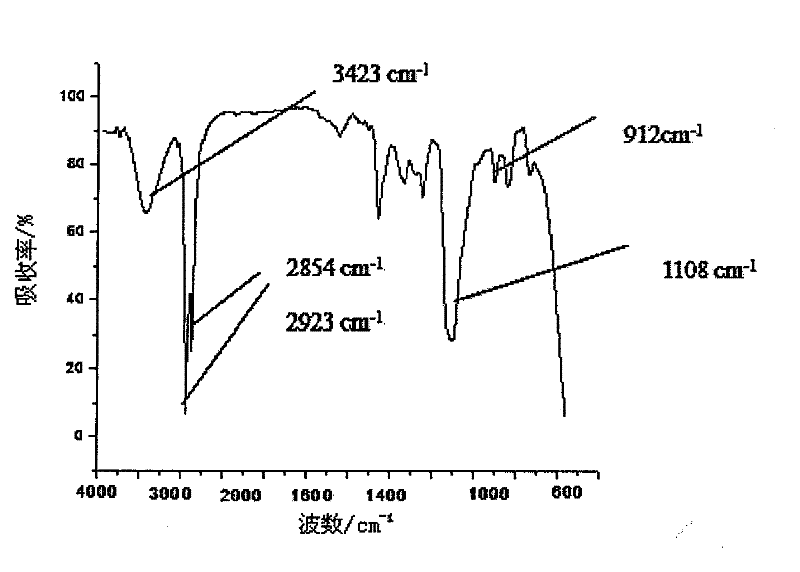

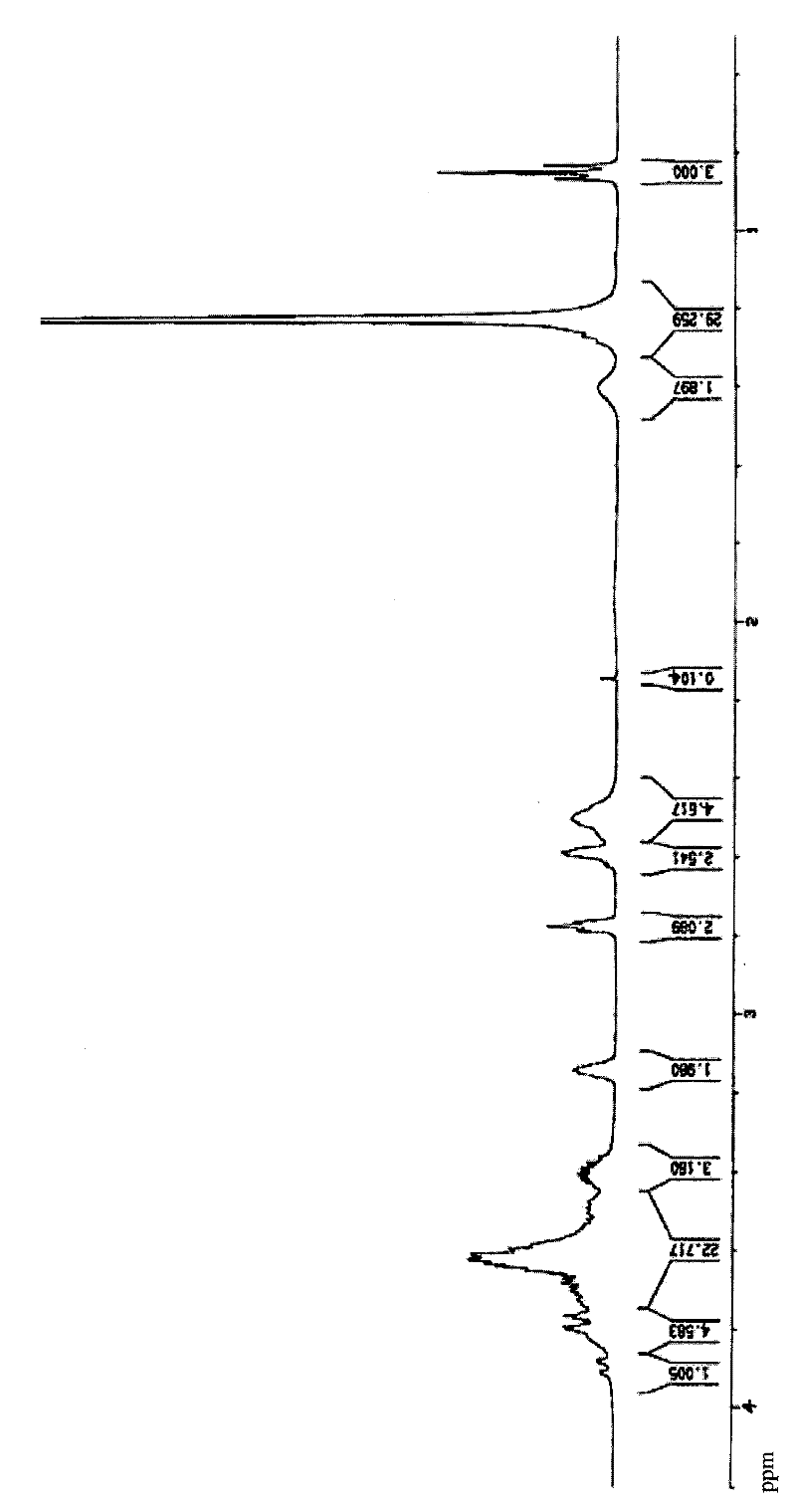

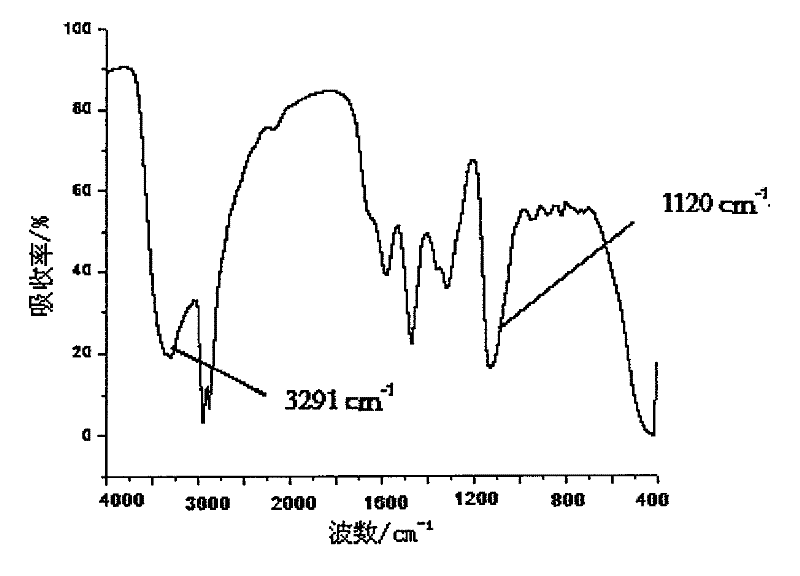

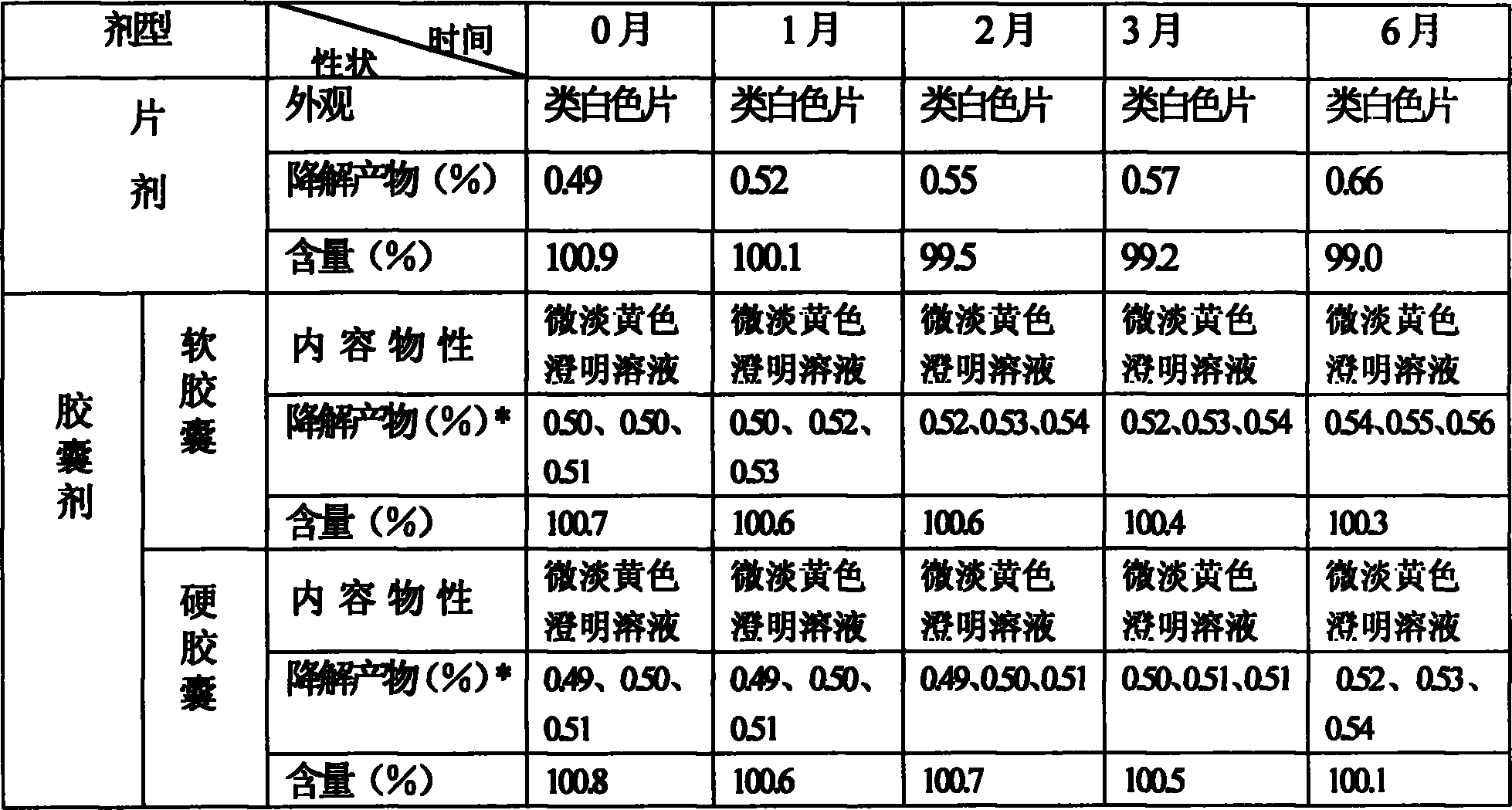

Butylphthalide controlled release preparation and preparation method thereof

ActiveCN103169685ASolve insolubleGood self-emulsifying performanceOrganic active ingredientsPharmaceutical delivery mechanismButylphthalidePharmaceutical Substances

The invention relates to a butylphthalide controlled release preparation and a preparation method thereof. Drugs can be uniformly released at a constant speed, and release of liquid drugs from the controlled release preparation in a liquid form is achieved.

Owner:CSPC ZHONGQI PHARM TECH (SHIJIAZHUANG) CO LTD +1

Biodegradable aqueous emulsion-type polylactic acid adhesive and its preparation method

The invention relates to a biodegradable aqueous emulsion-type polylactic acid adhesive and its preparation method. As a water dispersible emulsion, every 100 parts by weight of the adhesive at least contains 5-45 parts by weight of a polyethylene glycol grafted polylactic acid copolymer, 5-40 parts by weight of vinyl acetate grafted starch, and 0.5-30 parts by weight of an ethylene-vinyl acetatecopolymer. The aqueous emulsion-type polylactic acid adhesive provided in the invention is biodegradable, has high bonding fastness, adjustable filter rod hardness as well as good moulding performance, and simultaneously has filter rod adsorption enhancing and harm reduction performances.

Owner:长沙乐远化工科技有限公司

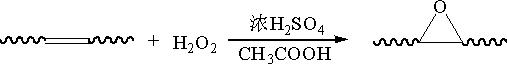

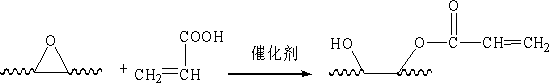

Jatropha carcass oil-based polymer fatting agent and preparation method thereof

ActiveCN107778420AIncrease productionGood self-emulsifying abilityTanning treatmentLeather impregnationMaleic anhydrideHydroquinone Compound

The invention relates to a preparation method of a jatropha carcass oil base polymer fatting agent. The preparation method comprises the following steps: a, performing epoxidation on jatropha carcassoil by using hydrogen peroxide, glacial acetic acid and concentrated sulfuric acid so as to obtain epoxy jatropha carcass oil; b, by taking sodium p-toluenesulfonate as a catalyst, hydroquinone as a polymerization inhibitor, and acrylic acid as a nucleophilic reagent, performing a ring-opening reaction on the epoxy jatropha carcass oil so as to obtain acrylic acid esterified jatropha carcass oil,and introducing an active vinyl part to a plant oil molecular chain; and c, by taking 2,2'-azobis(2-methylpropionitrile) as a catalyst, and acetanilide as an anti-gel agent, adding maleic anhydride, acrylic acid and acrylic acid esterified jatropha carcass oil, and performing copolymerization, thereby obtaining the jatropha carcass oil base polymer fatting agent. Based on natural plant oil which is cheap and easily available as a raw material, the prepared polymer fatting agent is relatively good in cold water emulsification property and good in hydrophilcity, and is an environment-friendly and degradable fatting material.

Owner:SHAANXI UNIV OF SCI & TECH

Process for producing long-chain alkyl waterproof currying agent

InactiveCN1740344AImprove elasticityImprove waterproof performanceLeather impregnationAcrylic acidLong chain

This method discloses a kind of producing method of long-chain alkyl water proof currying agent. Methyl acrylic acid long-chain unsaturated anhydride is used as product to synthesize methyl acrylic acid long-chain alkyl ester--- unsaturated anhydride copolymers. The amidation for the copolymer is made with amine, the long-chain alkyl water proof currying agent is obtained

Owner:ZHEJIANG UNIV

Self-emulsifying vitamin C preparation and method of preparing the same and application thereof

InactiveCN101278890AProduct quality is stableGood self-emulsifying performanceCosmetic preparationsToilet preparationsSolution compositionAntioxidant

The invention relates to a self-emulsified vitamin C preparation, a preparation method and application thereof, which pertains to the technical field of the latex and the latex preparation. The preparation consists of a lecithin in the weight percentage of 1 to 10%, a surfactant in the weight percentage of 20 to 50%, a cosurfactant in the weight percentage of 10 to 30%, a lipid material in the weight percentage of 10 to 30%, an antioxidant in the weight percentage of 0.1 to 2% and the vitamin C aqueous solution in the weight percentage of 10 to 30%. The materials are mixed evenly by stirring, so as to obtain the self-emulsified vitamin C preparation with a transparent or semitransparent appearance. The preparation can be self-emulsified in the water and form the latex with the grain diameter less than 300nm; the quality of the preparation is steady, thereby being applied to a cosmetic comprising the vitamin C.

Owner:TSINGHUA UNIV +1

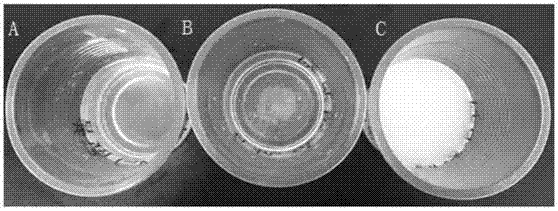

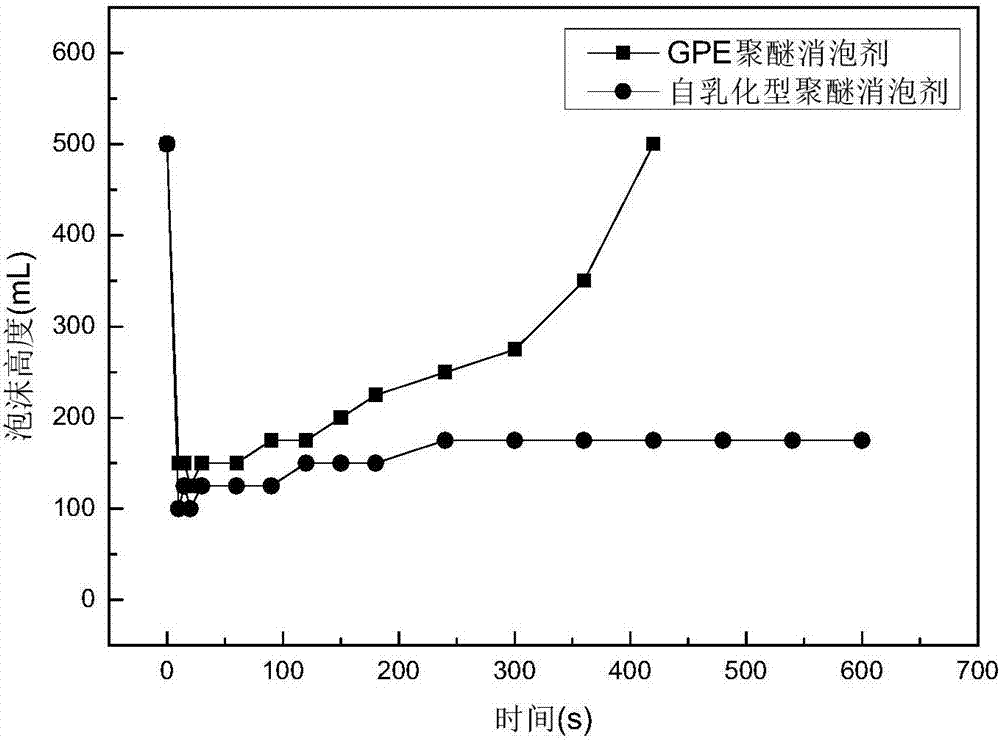

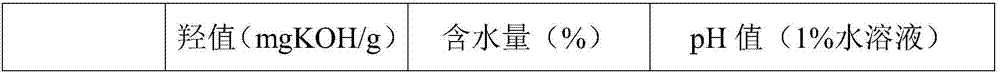

Self-emulsifying type antifoaming agent and preparation method thereof

ActiveCN107537185AGood self-emulsifying performanceImprove dispersion stabilityFoam dispersion/preventionAntifoam agentSelf emulsifying

The invention provides a self-emulsifying type antifoaming agent. The self-emulsifying type antifoaming agent comprises the following raw materials: C12-C18 alcohol, ethylene oxide and epoxypropane. The self-emulsifying type antifoaming agent has the advantages of good dispersion stability, good foam inhibiting capability, high defoaming efficiency, and lasting action time. The invention also provides a preparation method of the self-emulsifying type antifoaming agent, and the method comprises the following steps: C12-C18 alcohol and a catalyst are mixed under an anoxic environment, and ethylene oxide and epoxypropane are added; a polymerization is carried out for C12-C18 alcohol as well as ethylene oxide and epoxypropane, and the self-emulsifying type antifoaming agent is prepared. The preparation method of the self-emulsifying type antifoaming agent has simple operation and mild conditions, is suitable for large scale industrial production, and can be used for preparing the self-emulsifying type antifoaming agent with high defoaming and foam inhibiting performance.

Owner:JIAHUA CHEM MAOMING

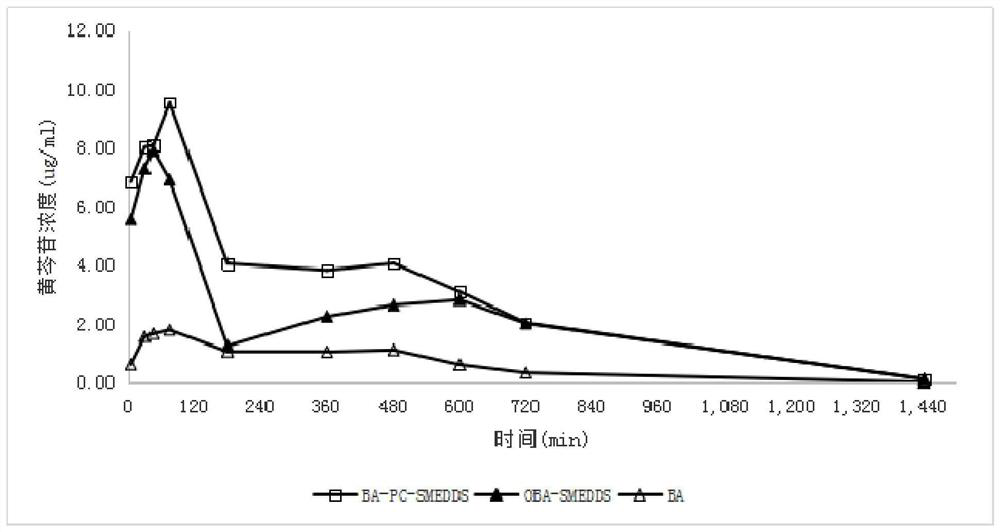

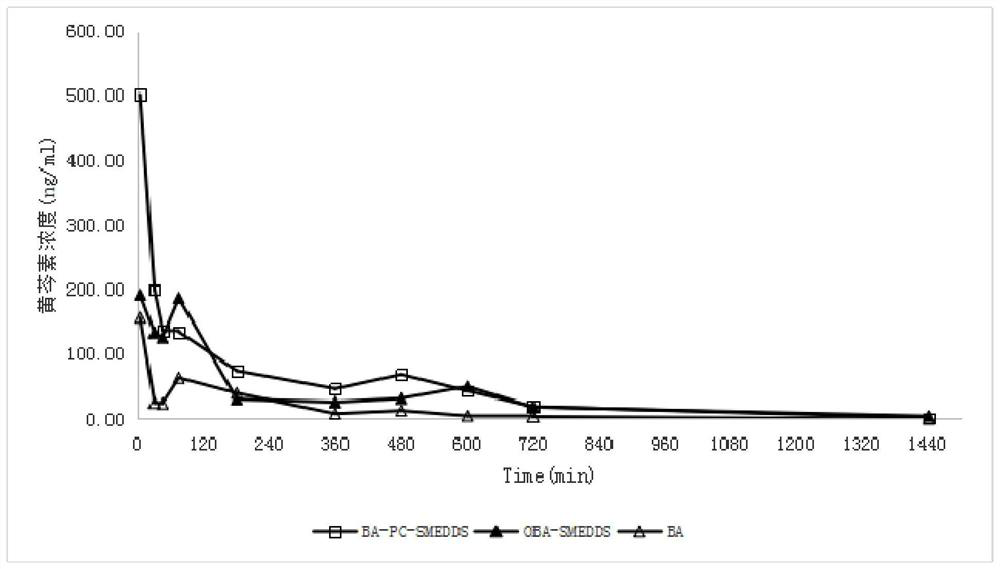

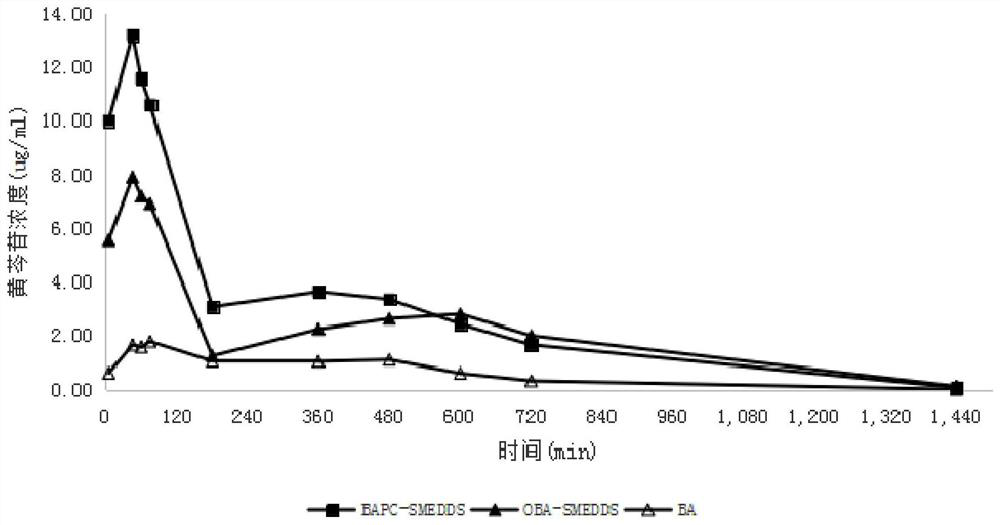

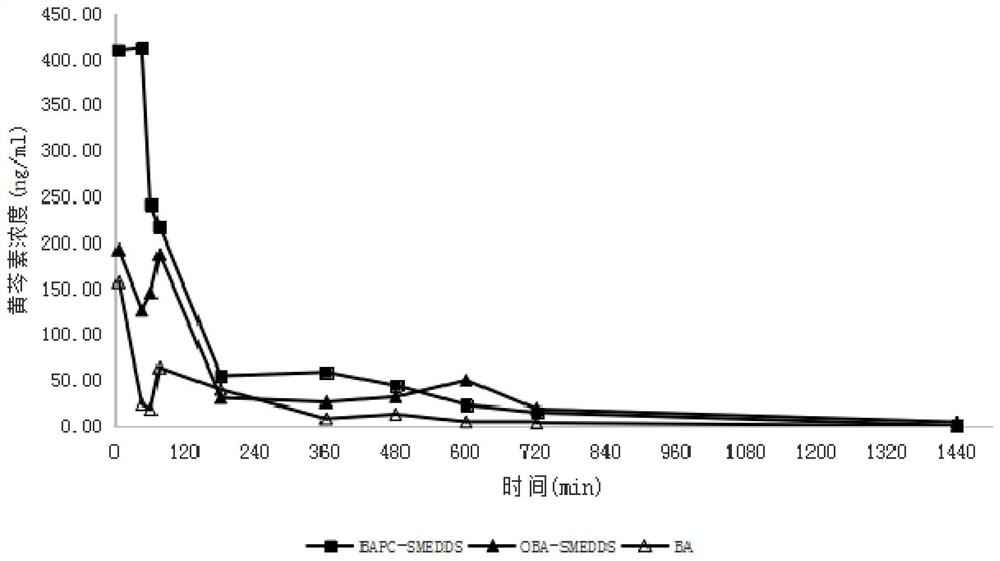

Flavonoid polyphenol drug self-emulsifying composition, preparation method thereof, pharmaceutical composition and application of pharmaceutical composition

PendingCN111789815AImprove stabilityHigh drug loadingNervous disorderHydroxy compound active ingredientsPhospholipidOil phase

The invention discloses a phospholipid-containing flavonoid polyphenol drug self-emulsifying composition. The composition comprises a flavonoid polyphenol drug, free phospholipid, an oil phase, an emulsifier and a co-emulsifier, and the flavonoid polyphenol drug comprises one or more materials selected from baicalein, procyanidine, quercetin, curcumin and resveratrol. The composition has the beneficial effects of good stability, high drug loading capacity, higher bioavailability and the like.

Owner:BEIJING WEHAND BIO PHARMA CO LTD +1

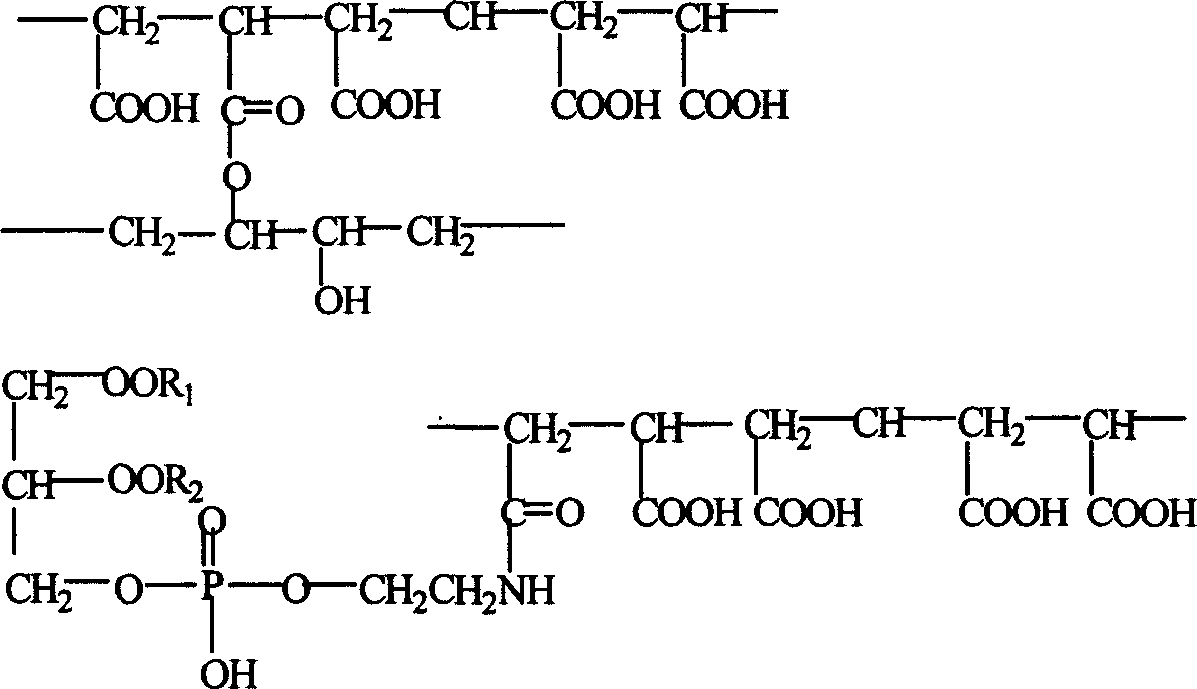

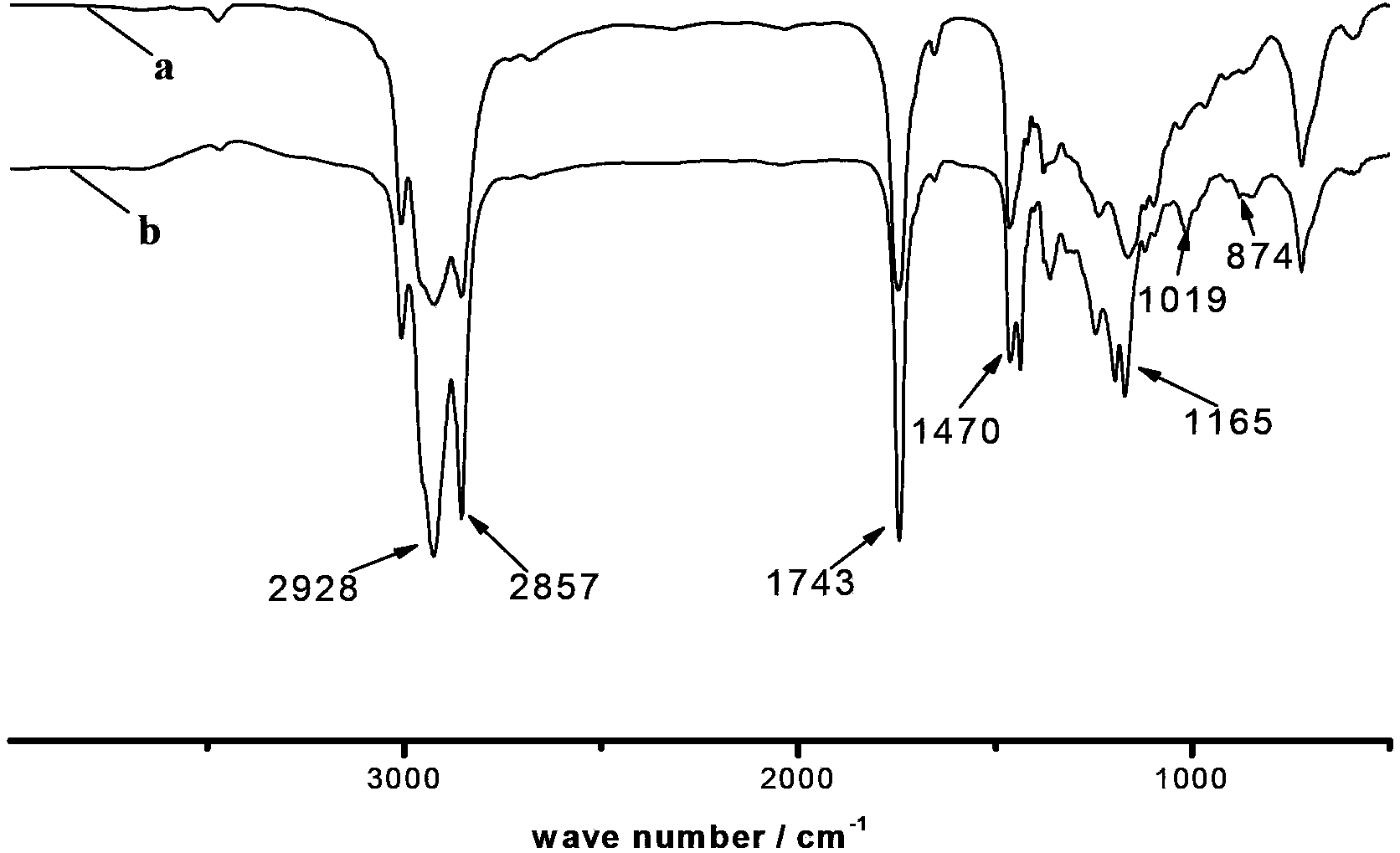

Method for preparing lecithoid retanning agent with lipide being added

A preparation method for phosphatide oiling retaining agent takes maleic anhydride and acrylic acid as the raw materials to synthesize an acrylic-maleic anhydride low polymer, acetic acid peroxide is used to oxidize and concentrate bean phosphatide to prepare phosphatide hydroxide, then the acrylic acid-maleic anhydride polymer is condensated with the phosphatide hydroxide to prepare the phosphatide oiling retanning agent.

Owner:SHAANXI UNIV OF SCI & TECH

Composition containing polyglycerol/medium-chain fatty acid ester

InactiveUS20070116663A1Good dispersionImprove bath effectCosmetic preparationsMake-upGlycerolDegree of polymerization

An object of the present invention is to provide a polyglycerol medium-chain fatty acid ester-containing composition capable of forming a water-in-oil microemulsion, the microemulsion being capable of solubilizing a large amount of water, and the composition having excellent dispersibility and self-emulsifiability in water, and cosmetics comprising the composition. The present invention relates to a polyglycerol medium-chain fatty acid ester-containing composition comprising a polyglycerol medium-chain fatty acid ester formed by esterification of a medium-chain fatty acid having 6 to 10 carbon atoms and a polyglycerol having an average degree of polymerization of 3 or more and less than 100, and a nonionic surfactant; and cosmetics comprising the polyglycerol medium-chain fatty acid ester-containing composition as defined above.

Owner:TAIYO KAGAKU CO LTD +1

Preparation method of polyethylene glycol (PEG)-modified vegetable oil emulsion mould release agent

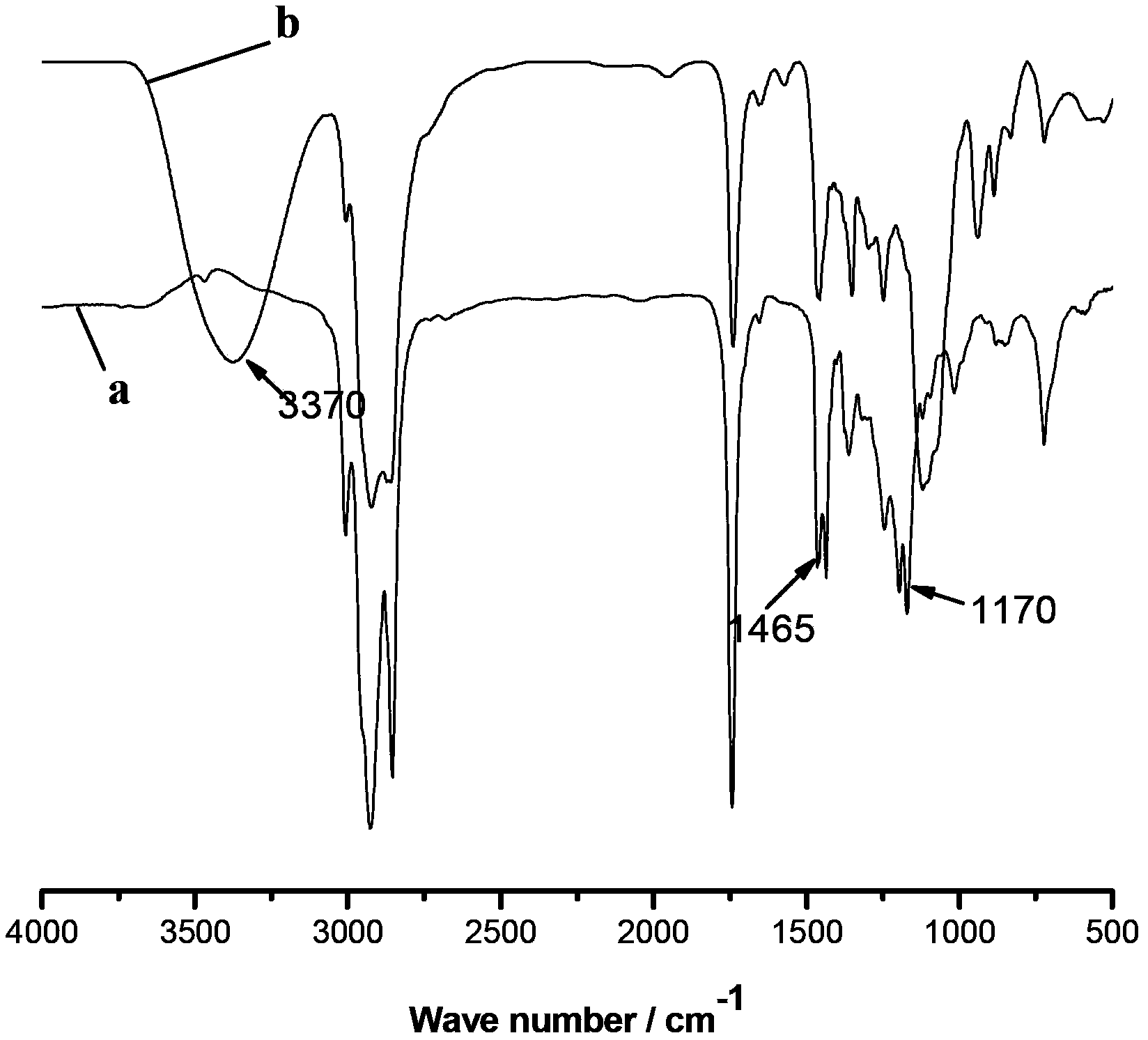

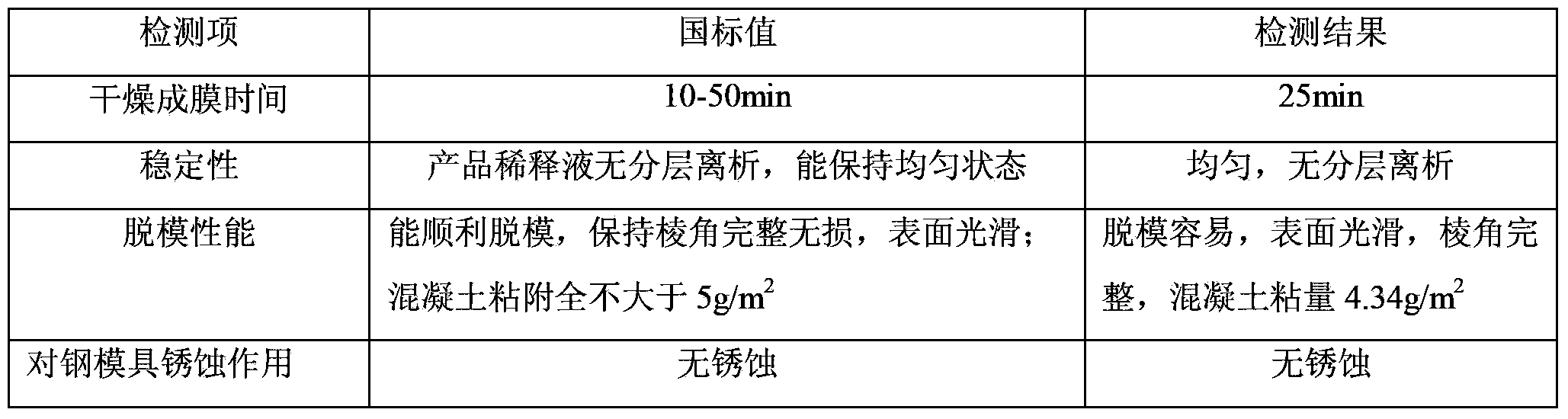

InactiveCN103305329BGood self-emulsifying performanceExcellent peelabilityLubricant compositionVegetable oilEmulsion

The invention discloses a preparation method of a polyethylene glycol (PEG)-modified vegetable oil emulsion mould release agent. The preparation method comprises the following steps: first, performing interesterification between vegetable oil serving as a raw material and methanol; then, performing interesterification between the vegetable oil and PEG to obtain a PEG-vegetable oil polymer; and finally, emulsifying the PEG-vegetable oil polymer to obtain the mould release agent. The PEG-modified vegetable oil mould release agent has high stripping performance; the surface of the stripped concrete is smooth and complete, has no defects and low amount of adhered concrete (namely the weight of the concrete adhered to per square mould), does not rust a mould and does not pollute the environment, and is a real environment-friendly mould release agent.

Owner:HEFEI UNIV OF TECH

Flavone polyphenol drug self-emulsifying composition, preparation method of flavonoid polyphenol drug self-emulsifying composition, drug composition and application

ActiveCN111803632AImprove stabilityHigh drug loadingAntibacterial agentsPowder deliveryMolecular biologyOil phase

The invention discloses a flavone polyphenol drug self-emulsifying composition based on a flavone polyphenol drug-phospholipid complex as an intermediate. The self-emulsifying composition comprises the flavone polyphenol drug-phospholipid complex, an oil phase, an emulsifier and a co-emulsifier. Flavone polyphenol drugs include one or more selected from baicalein, procyanidine, quercetin, curcuminand resveratrol. The self-emulsifying composition has the beneficial effects of good stability, high drug loading capacity, high bioavailability and the like.

Owner:BEIJING WEHAND BIO PHARMA CO LTD +1

Nonionic self-emulsifying water-based epoxy curing agent and its preparation method and application

InactiveCN101624385BLow viscosityImprove hydrophilicityOrganic compound preparationEpoxy resin adhesivesPolymer scienceActive agent

The invention relates to an epoxy curing agent, and specifically provides a non-ionic self-emulsifying water-based epoxy curing agent. The curing agent is first reacted with a hydrophobic alkylamine and a low molecular weight hydrophilic bisglycidyl ether to prepare a A kind of diepoxy compound with epoxy groups at both ends and a long hydrophobic alkyl side chain connected to the middle nitrogen atom, and then reacted with fatty amines or both ends are blocked with fatty amines and hydrophilic amines respectively, An amino-terminated nonionic self-emulsifying water-based epoxy curing agent with a structure similar to that of a surfactant is prepared. The curing agent can be further mixed with deionized water to prepare a light yellow water-based epoxy resin curing agent with a solid content of 50% to 60%. The curing agent prepared by the invention has good self-emulsification effect, good compatibility with epoxy resin, high stability, good flexibility and surface activity. It can be widely used in water-based epoxy resin coatings, epoxy resin adhesives and water-based epoxy grouting materials.

Owner:GUANGZHOU CHEM GROUTING CO LTD CAS

A super soft silicone oil finishing agent

The invention relates to the textile finishing agent field, in particular to a super-soft finishing agent of silicone oil. The super soft finishing agent of the silicone oil comprises a silicone oil compound with the following cation structural formula as followed. The silicone oil compound occupies a weight percentage of 2%-60% in the finishing agent, the n1 is 5-10, the R is a polyether group, and a polymerization degree is 3-50. The super soft finishing agent of the silicone oil is suitable for feel finishing of one or more fiber constituted fabric such as cotton, Dacron, chinlon and acrylic fibers, and provided with better soft, smooth and fluffy effects than amino-modified silicone oil and excellent stability in resistance to acid and alkali, electrolyte, high temperature, shearing and the like; and problems of easy demulsification, floating oil, roll banding, difficult rework and the like in the existing amino-modified silicone oil are completely solved.

Owner:NINGBO RUNHE HIGH TECH MATERIAL CO LTD

Aldoforwe ester self-emulsifying capsule preparation and its making method

InactiveCN101073576AImprove stabilityImprove liquidityOrganic active ingredientsDigestive systemHard CapsuleInstability

The invention is concerned with a kind of Adefovir Dipivoxil self-emulsification capsule preparation and its produce method. Adefovir Dipivoxil is anti-hepatitis B virus agent with instability and the biology utilization ratio of existing preparation is low with complicated process and big harmless of dust. Mix the middle solution with Adefovir Dipivoxil in the amount of prescription and oil, dispose the middle solvent by extrusion method after rotating-film evaporating technique, add emulsifying agent, heat in water with constant temperature or ultrasonographic to get even and transparent liquid and produce into soft capsule or hard capsule. The production has nice stability, high biology utilization ratio and easy for using.

Owner:TASLY HLDG GRP CO LTD

Synthetic sperm oil complex greasing agent and preparation method thereof

ActiveCN103667548AImprove hydrophilic abilityGood self-emulsifying performanceLeather impregnationSolubilitySperm oil

The invention provides a synthetic sperm oil complex greasing agent and a preparation method thereof. The method specifically comprises the following steps: (1) adding oleic acid and catalyst, warming to 90 DEG C, adding polyethylene glycol within 1 hour, wherein the mol ratio of the oleic acid to the polyethylene glycol is 1:1.05, and the dosage of the catalyst is 0.1-0.5% of the total mass of the material; (2) then warming to 150-200 DEG C, vacuumizing and hydrating, reacting for 2-5 hours, examining the acid value per hour until the acid level is unchanged, and detecting water solubility, cooling to 40 DEG C and less when up to standard, filtering catalyst and emptying to obtain red brown transparent oily liquid synthetic sperm oil; (3) adding oxazolidine which is 10-15% of the mass of the synthetic sperm oil, 2-5% of polyether modified silicone oil and 5-10% of sulfitation, compounding, and then adding deionized water to regulate the solid content to 50% to obtain red brown transparent synthetic sperm oil complex greasing agent.

Owner:QI HE LI HOU CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com