Preparation method of polyethylene glycol (PEG)-modified vegetable oil emulsion mould release agent

A technology of modifying vegetable oil and mold release agent, which is applied in the petroleum industry, lubricating composition, etc., can solve the problems of surface contamination of steel bars and concrete, poor mold release effect, loss of mineral oil, etc., and achieves excellent mold release effect, Excellent peeling performance and small amount of sticky ash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

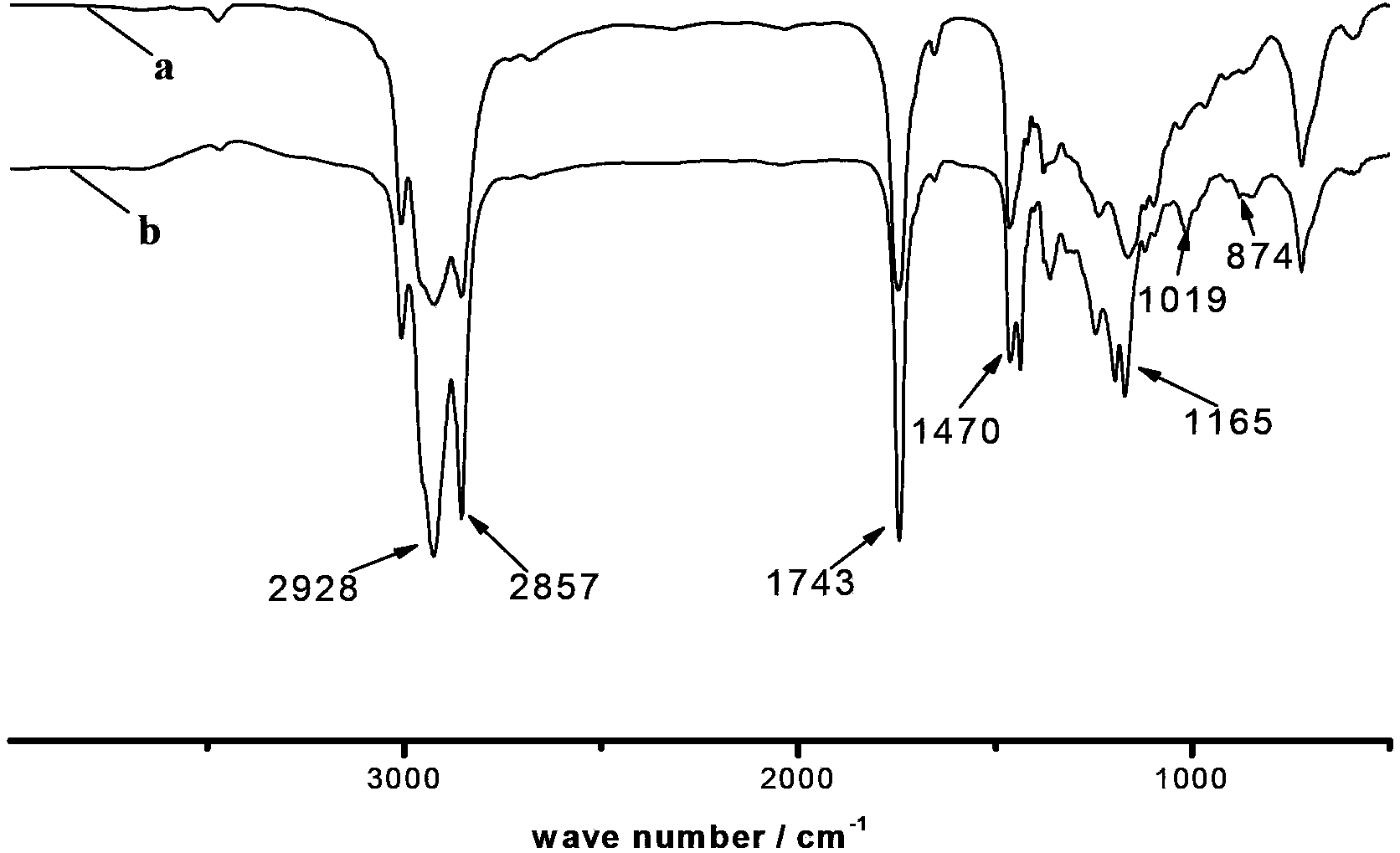

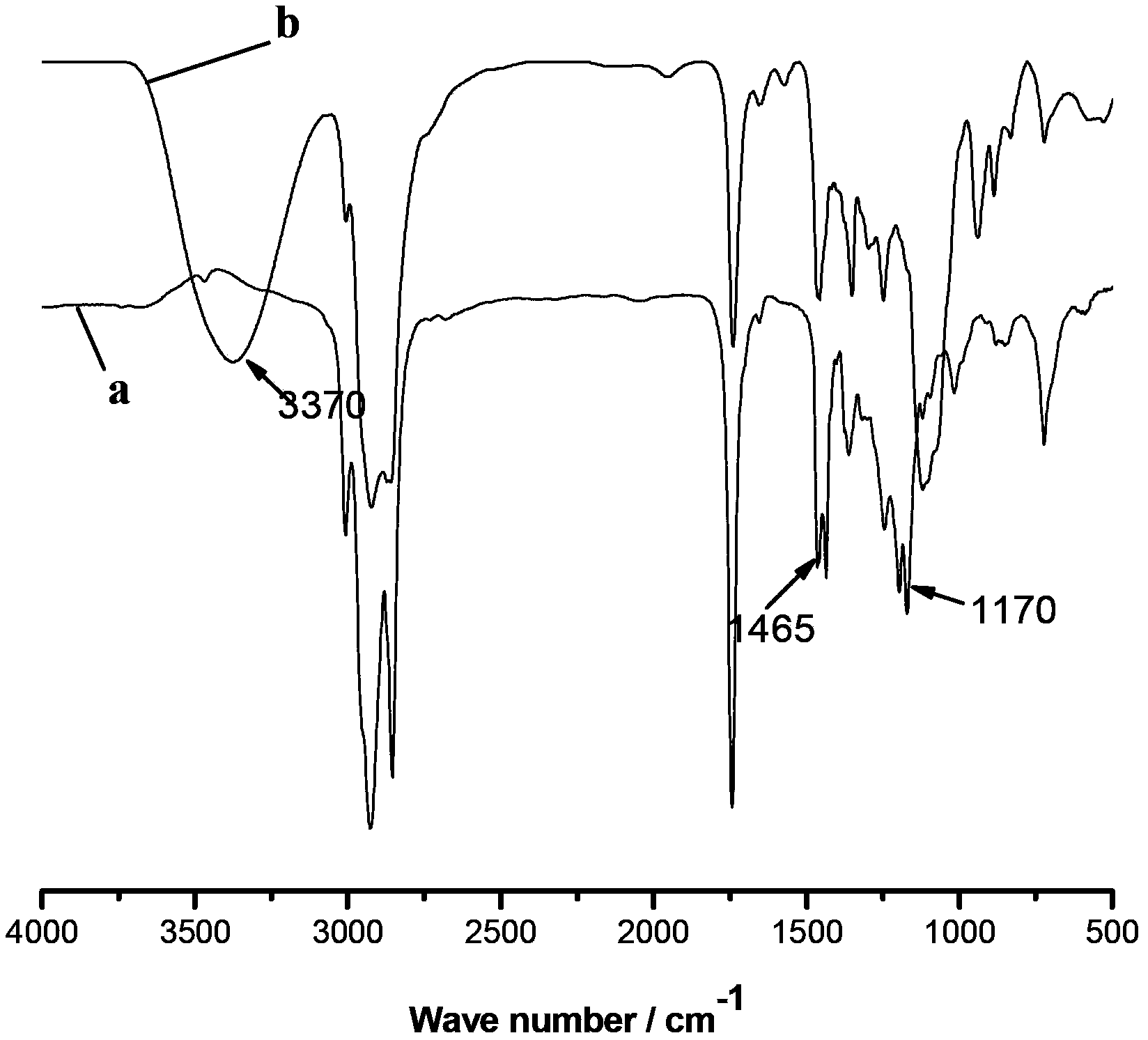

Method used

Image

Examples

Embodiment 1

[0021] 1. One transesterification

[0022] Put 20g of dried rapeseed oil in the reactor, add 5.2g of potassium hydroxide methanol solution with a mass concentration of 6-8% dropwise into the reactor, control the dropping time at about 20min, and keep warm at 60°C after dropping After reacting for 1h, the product was washed to neutrality after the reaction, and rapeseed oil methyl ester was obtained after removing the solvent;

[0023] 2. Secondary transesterification

[0024] Put 15g of rapeseed oil methyl ester and 0.6g of catalyst nano-magnesium oxide in the reactor, add 20g of PEG400 dropwise into the reactor, and keep the temperature at 200°C for 8h after dropping, filter after the reaction, and remove the solvent by rotary evaporation to obtain PEG-canola oil polymer;

[0025] 3. Emulsification

[0026] Add 5 g of PEG-rapeseed oil polymer into the reactor, and slowly add 76 g of deionized aqueous solution of emulsifier OP-10 with a mass concentration of 2% at 40°C (tha...

Embodiment 2

[0031] The preparation method of step 1 and step 2 of this embodiment is the same as that of embodiment 1.

[0032] 3. Emulsification

[0033] Add 10g of PEG-rapeseed oil polymer into the reactor, and slowly add 72g of deionized aqueous solution of emulsifier OP-10 with a mass concentration of 2% at 40°C (that is, emulsified water) into the reactor under high-speed stirring until the emulsion Invert the phase, keep stirring for 30 minutes, continue to slowly add emulsified water, continue stirring for 20 minutes, then add 18 g of distilled water to the reactor, and discharge after stirring for 20 minutes to obtain a PEG modified vegetable oil emulsion release agent with a solid content of 10%.

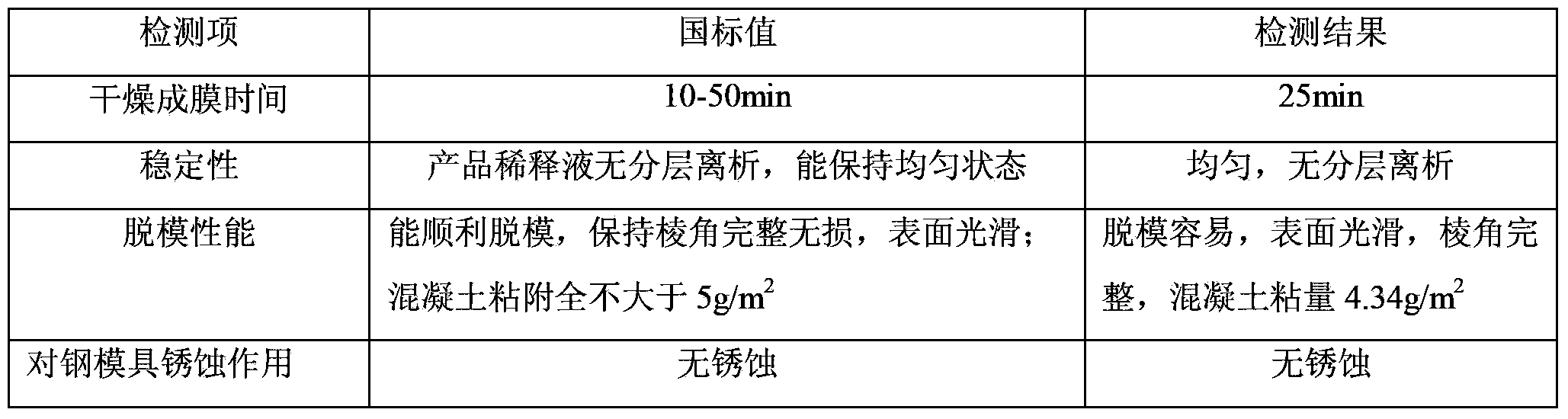

[0034] The PEG-modified vegetable oil emulsion release agent prepared in this example was subjected to a concrete release experiment according to the concrete industry standard JC / T949-2005, and the experimental results are shown in the table below.

[0035]

[0036] It can be seen...

Embodiment 3

[0038] The preparation method of step 1 and step 2 of this embodiment is the same as that of embodiment 1.

[0039] 3. Emulsification

[0040] Add 15g of PEG-rapeseed oil polymer into the reactor, and slowly add 68g of deionized aqueous solution of emulsifier OP-10 with a mass concentration of 2% at 40°C (that is, emulsified water) into the reactor under high-speed stirring until the emulsion Invert the phase, keep stirring for 30 minutes, continue to slowly add emulsified water, continue stirring for 20 minutes, then add 17 g of distilled water to the reactor, and discharge after stirring for 20 minutes to obtain a PEG modified vegetable oil emulsion release agent with a solid content of 15%.

[0041] The PEG-modified vegetable oil emulsion release agent prepared in this example was subjected to a concrete release experiment according to the concrete industry standard JC / T949-2005, and the experimental results are shown in the table below.

[0042]

[0043] It can be seen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com